Professional Documents

Culture Documents

Data Acquisition System For Gas Monitoring in Landfills

Uploaded by

Abhijeet PrajapatiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Data Acquisition System For Gas Monitoring in Landfills

Uploaded by

Abhijeet PrajapatiCopyright:

Available Formats

ICCBT2008

Data Acquisition System for Gas Monitoring in Landfills

F. N. M. Fauzi, Universiti Tenaga Nasional, MALAYSIA

N.A. Abu Bakar, Universiti Tenaga Nasional, MALAYSIA

T. Syed Jalal, Universiti Tenaga Nasional, MALAYSIA

N. Md. Din*, Universiti Tenaga Nasional, MALAYSIA

ABSTRACT

Landfill energy extractions comprise of a large number of gas wells used to yield the gas

methane for electricity generation. These wells are dispersed over a large land area. To

manage the gas wells manually would require visiting each one of the wells to inspect the

conditions of the wells. This paper describes an effort to develop a data acquisition

framework for a centralized gas monitoring system in landfills for a location in Malaysia. It

describes the options of utilizing sensors, signal conditioners, communication links and

centralized consoles. Initial development of the data acquisition system and signal

conditioning circuit using LABVIEW are presented.

Keywords: Landfill, Data acquisition system, Gas monitoring, Sensors, Signal conditioning.

*Correspondence Authr: Assoc. Prof. Dr. Norashidah Md Din, Universiti Tenaga Nasional, Malaysia. Tel:

+60389212395, Fax: +60389212116. E-mail: norashidah@uniten.edu.my

ICCBT 2008 - D - (34) – pp363-372

Data Acquisition System for Gas Monitoring in Landfills

1. INTRODUCTION

Worldwide, mankind produces an abundant amount of wastes where the handlings become

increasingly difficult with time as the world’s population grow and land becomes limited and

more expensive. Improper waste treatments also pose hazardous impacts to the ecology,

environment and health. With these effects in mind, the concept of waste to wealth is on the

rise where waste can be made into useful materials and energy sources to promote good waste

management. The next figure shows the massive supply of waste available in Malaysia to be

tapped for energy.

Table 1. The annual amount of waste in Malaysia [1]

Year Population Estimated amount

of waste

(Tonnes/Year)

1991 17,567,000 4,488,369

1994 18,917,739 5,048,804

2015 31,773,889 7,772,402

2020 35,949,239 9,092,611

Landfill is a common solution for Municipal Solid Waste (MSW) management in Malaysia.

In landfills, methane is naturally produced through anaerobic process in the MSW

decomposition. Besides methane, landfill gas is composed of a mixture of hundreds of

different gases. By volume, landfill gas typically contains 45% to 60% methane and 40% to

60% carbon dioxide. Landfill gas also includes small amounts of nitrogen, oxygen, ammonia,

sulfides, hydrogen, carbon monoxide, and nonmethane organic compounds (NMOCs) such as

trichloroethylene, benzene, and vinyl chloride. Since the MSW degradation process is a

natural and spontaneous process, the amount of methane varies from time to time, depending

on the external factors that influence the chemical process.

A centralized monitoring system for gas wells monitoring and gas composition monitoring is

proposed in order to ease the operations in collecting the methane at landfills. The methane

levels in wells are to be monitored using appropriate sensors. The wells are to be clustered to

a data acquisition box and a Wirelass Local Area Network (WLAN) access point. WLAN

communications will then be made between access point and centralized monitoring station

located at the main office. The centralized monitoring station will be the focal point for

database management and escalation process. The escalation process includes sending short

message service (SMS) messages to the person-in-charge.

2. DATA ACQUISITION SYSTEM

Data acquisition is the process of gathering or generating information in an automated fashion

from analog and digital measurement sources such as sensors and devices under test. Data

acquisition uses a combination of PC-based measurement hardware and software to provide a

364 ICCBT 2008 - D - (34) – pp363-372

F. N. M. Fauzi et. al.

flexible, user-defined measurement system [2]. The hardware part is made of sensors, cables,

signal conditioning, data acquisition card. The software part is made of the data acquisition

logic and the analysis software and some other utilities that can be used to configure the logic

or to move data from data acquisition memory to the central console.

In this work, a data acquisition system [3] for gas monitoring was designed using LABVIEW

software. Several monitoring specifications have been identified in order to design the

monitoring system. The specifications include methane classification and factors that affect

the landfill methane gas production rate. Methane classification is shown in Table 2 below.

Table 2. Methane Classification

0% - 5% 5% - 15% 15% - 60%

Failure Need Checking OK

st

(both lights (1 light turns

turn red) red)

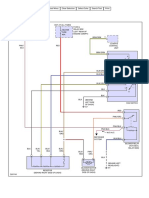

Figure 1. Block Diagram of the Monitoring System

Figure 1 illustrates the block diagram layout of the monitoring system. This program utilized

the g-programming language by LABVIEW. This monitoring system is designed by

considering one of the factors that affect the methane production rate in the landfill which is

temperature.

Methane production rate is directly proportional to the change of temperature. As the

temperature decreases, the methane percentage also decreases. Based on figure 1, it can be

seen that the block diagram consists of two simulated signal components which generate

signals for the thermometer and the methane percentage meter. In this program, the knob is

ICCBT 2008 - D - (34) – pp363-372 365

Data Acquisition System for Gas Monitoring in Landfills

used to represent the input and to adjust the increment and decrement in temperature. The

knob represents the gas sensor. It is connected to the first simulated signal component to

increase or decrease the temperature which is in the range of 20ºC to 80ºC. At landfill the

temperature is approximately 40ºC to 60ºC, but in this design, average value is used as the

initial temperature which is 50ºC. The temperature is then displayed on the temperature graph

as well as the thermometer to improve the readability.

The second simulation signal component represents the methane percentage. The value of the

methane is displayed using the meter and also the value is displayed numerically. In the

graphical programming, comparison Boolean is used to ensure that the light will turn red at

certain condition according to methane classification. At the same time, when the value of the

methane is within 5% to 15 %, the first light will turn red indicating that the system needs

checking. When the methane percentage goes below 5% then both light will turn red

indicating the system failure. The typical value of methane at landfill is within 54% to 60%.

Figure 2. During normal Condition

Figure 3. Failure Condition

366 ICCBT 2008 - D - (34) – pp363-372

F. N. M. Fauzi et. al.

Figure 4. Need Checking Condition

3. OPTICAL GAS SENSOR

Optical measurements are the most accurate and reliable method for gas analysis. Optical gas

sensors [4] depend on measuring the transmission of light at different wavelength for each

gas. The particular wavelength identifies the gas and the amount of light absorbed by the gas

determines the gas concentration.

Figure 5. A Basic Fiber Optic Sensor System

Figure 6. Absorption of Common Gases

The concentration of methane in landfill gas can be monitored by using an optical gas

detection system. The methane will be absorbed by a gas absorption cell. A light source at a

ICCBT 2008 - D - (34) – pp363-372 367

Data Acquisition System for Gas Monitoring in Landfills

specific wavelength is passed through the cell and interacts with the absorbed gas. The

returned light is then examined to determine the amount of power absorbed by the gas cell.

This is then translated into the concentration of methane gas.

A multiplexed system can be used to monitor multiple wells simultaneously. One single

source can possibly be used to power up all gas absorption cells. An intelligent data

acquisition can collect data and send it to a central processing computer for data storage and

analysis. The connection from the source to the each individual well is made using a normal

fiber optic cable.

There are several methods of methane gas detection over optical fiber paths that can be used

[5]. One of them is by using a broadband white light source and a rotating-

chopper/interference-filter arrangement to sequentially interrogate the transmission of the

sample cell, over the desired fiber optic cable link. Semiconductor LED sources can also be

used in conjunction with a fiber-remoted methanometer. The useful power that can be

extracted from a broadband incandescent or LED source can be increased by using Fabry-

Perot cavity having the wavelength spacing equal to that between each of the rotational

absorption lines of methane gas.

Figure 7. Absorption Spectrum of Methane

4. OPTICAL SENSOR IMPLEMENTATIONS

Basically, there three are types of optical sensor implementations as shown in Figure 8 [6, 7].

They are:

1. Point sensor.

The measurement is carried out at a single point in space, but it is possible to use

multiple channels to address multiple points.

368 ICCBT 2008 - D - (34) – pp363-372

F. N. M. Fauzi et. al.

2. Distributed sensor.

The parameter of interest is measured with a certain spatial resolution at any point

along a single optical cable.

3. Quasi-distributed sensor.

The measurand is determined at a number of fixed, discrete points along a single

fiber optical cable.

Figure 8: Optical Sensor Implementation [6, 7]

5. FIBER OPTIC METHANE SENSOR

Figure 9 shows the components of fiber optic methane sensors [8]. White light and optical

filters are used to measure methane concentration using differential absorption techniques.

The gas concentration is determined by the amount of light absorbed by the gas. Detectors

that are located behind each of the filters convert the light into electrical signals that are

processed to calculate the concentration of methane present in the gas cell.

Figure 9. Fiber Optic Methane Sensor

ICCBT 2008 - D - (34) – pp363-372 369

Data Acquisition System for Gas Monitoring in Landfills

6. ADVANTAGES OF OPTICAL SENSORS

Optical sensors have significant advantages compared to conventional sensor types, in terms

of their properties. Following are the advantages of optical sensors [9-11]:

• Immune to electromagnetic interference (EMI), cross talk and space radiation.

• Completely passive

• Small size, light weight, low cost, low power.

• High sensitivity, large dynamic range and resolution

• Remote operation over several miles length without any lead sensitivity

• Can measure a large number of points along a single optical cable.

• Can monitor a wide range of physical and chemical parameters.

• High temperatures resistance.

7. SIGNAL CONDITIONING

Usually the output of a sensor is only in the range of milivolts. The signal is not strong enough

to pass through to the data acquisition system. Therefore, signal conditioning is needed to

amplify the output sensor so that the data acquisition can process the data.

Figure 10 shows the schematic of signal conditioning circuit that had been designed for the

centralized gas monitoring system. Meanwhile, Table 3 shows the results obtained from the

circuit simulation. From the results, we can see that this signal conditioning amplify the

output sensor with a gain of 10 [12].

Figure 10. Signal Conditioning

370 ICCBT 2008 - D - (34) – pp363-372

F. N. M. Fauzi et. al.

Table 3. Sensor Outputs after Amplification

Input (mV) Output (V)

480.5 4.805

532.2 5.322

633.8 6.338

710.6 7.106

789.2 7.892

822.6 8.226

8. CONCLUSION

By developing a data acquisition system for centralized gas monitoring in landfills, the

manpower can be reduced. Besides that, accurate results can be obtained with reduced human

errors.

Taking advantage of the capacity of optical fibers to send and receive optical signals over long

distances, it shows that using optical sensor for gas monitoring is a viable solution for the

centralized monitoring system. By using optical sensors, it is not necessary to convert between

electronics and photonics separately at each sensing site, and thereby reduces costs and

increases flexibility.

REFERENCES

[1]. Mazlinda Hashim, "Present Status and Problems of Biomass Energy Utilization in

Malaysia", APECATC-Workshop on Biomass Utilization, 19-21 January 2005 in

Tokyo and Tsukuba, Pusat Tenaga Malaysia

[2]. Data Acquisition (DAQ), National Instruments, 2008

[3]. Nurul Akmar Abu Bakar, "Data Acquisition Software for Centralized Landfill Wells

Monitoring", Final Year Thesis, Universiti Tenaga Nasional, 2008.

[4]. Mary Jane Perry, "Optical Sensors", School of Marine Sciences and Ira C. Darling

Marine Center, University of Maine, 2003, white paper.

[5]. Dr. J P Darkin, "Optical Fiber Gas Sensors" Review Paper, Optoelectronics Research

Centre, University of Southampton, SO17 1BJ UK, SPIE 102, paper 27.

[6]. Dr. Rudiger Paschotta, "Fiber Optic Sensors", Encyclopedia of Laser Physics and

Technology, RP Photonic Consulting GmbH, 2008.

[7]. Paul E. Sanders, "Optical Sensors in the Oil & Gas Industry", Wheatherfold

International, Slide Presentation, 2004.

ICCBT 2008 - D - (34) – pp363-372 371

Data Acquisition System for Gas Monitoring in Landfills

[8]. Thomas H. Dubaniewicz, Joseph E. Chilton, and Harry Dobroski, Jr., "Fiber Optic for

Atmospheric Mine Monitoring", IEEE Transactions on Industry Applications, Vol. 29,

No. 4, July/August 1993.

[9]. A. Selvarajan, Fiber Optic Sensors and Their Applications, Department of Electrical

Communication Engineering Indian Institute of Science, Bangalore, 2000.

[10]. Nina Morgan, "Let There Be Light", Frontiera, April 2002.

[11]. Dr. Colin Fitzpatrick, “Optical Fiber Sensor…The Other Optical Revolution!!”

Elements, Issue 6, May 2006.

[12]. Fara Nadiah Mohd Fauzi, "Monitoring System for Landfill Gas (LFG) Power

Generation in Malaysia: Gas Monitoring System"; Final Year Thesis, Universiti Tenaga

Nasional, 2008.

372 ICCBT 2008 - D - (34) – pp363-372

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Calefaccion Mazda 3 2006 - 2010Document2 pagesCalefaccion Mazda 3 2006 - 2010Jhon ConnorNo ratings yet

- Laborator Chimie DIYDocument11 pagesLaborator Chimie DIYotonel100% (1)

- Introduction To WeldingDocument28 pagesIntroduction To WeldingMohammed Suleman0% (1)

- Omnicomm LLS 4 Fuel Level Sensors: User Manual 18.12.2018Document20 pagesOmnicomm LLS 4 Fuel Level Sensors: User Manual 18.12.2018Giovanni QuinteroNo ratings yet

- Additive Manufacturing STR 2 2018Document20 pagesAdditive Manufacturing STR 2 2018Denis StancuNo ratings yet

- Elements Periodic TableDocument168 pagesElements Periodic TablejackzhangNo ratings yet

- Ernest Rutherford 1Document8 pagesErnest Rutherford 1api-400268497No ratings yet

- Milling Machine - W200 BrochureDocument56 pagesMilling Machine - W200 BrochureMohammad YounesNo ratings yet

- 1559038005845442000Document171 pages1559038005845442000Patel IbrahimNo ratings yet

- Rencana Power Energize 11 Feb 21 Rev.2Document11 pagesRencana Power Energize 11 Feb 21 Rev.2Ari Puji HidayatullahNo ratings yet

- Samsung LPC 247sm-06sDocument2 pagesSamsung LPC 247sm-06saboalghadbNo ratings yet

- Our Technology Background Framo Cargo Pumping SystemDocument199 pagesOur Technology Background Framo Cargo Pumping SystemSorescu Radu VasileNo ratings yet

- Technical Specification For 20 MVA Transformer PDFDocument21 pagesTechnical Specification For 20 MVA Transformer PDFamulya00428100% (10)

- Whirlpool Awm 4120Document16 pagesWhirlpool Awm 4120Zoran ProkicNo ratings yet

- Vdocuments - MX - Tac 404 Electronic Control Family Specifications PDFDocument111 pagesVdocuments - MX - Tac 404 Electronic Control Family Specifications PDFTeho IVTNo ratings yet

- Lecture 2Document17 pagesLecture 2Physicist91No ratings yet

- Mvot Fso Orkid Close-Out Report Ex Database - SignedDocument170 pagesMvot Fso Orkid Close-Out Report Ex Database - Signedhai dang maiNo ratings yet

- Emailing Net Chemical Sciences Paper Dec. 2018Document24 pagesEmailing Net Chemical Sciences Paper Dec. 2018Baban BaidyaNo ratings yet

- Impact of Hot and Cold Aisle Containment On Data Center Temperature and Efficiency PDFDocument14 pagesImpact of Hot and Cold Aisle Containment On Data Center Temperature and Efficiency PDFdexiNo ratings yet

- Jaypee Water Pre Treatment Plant: A Project ReportDocument15 pagesJaypee Water Pre Treatment Plant: A Project ReportRachit KhandelwalNo ratings yet

- Fuel Cells and Its Applications (Che 694)Document15 pagesFuel Cells and Its Applications (Che 694)kolade olayodeNo ratings yet

- Bca SyllabusDocument55 pagesBca Syllabusapi-349492533No ratings yet

- Pastite For Pipe Connection System Bul 4300 PTPDocument6 pagesPastite For Pipe Connection System Bul 4300 PTPanoop9079No ratings yet

- INSEKTOMORDocument12 pagesINSEKTOMORRamoNo ratings yet

- Sizing Phase-Change Energy Storage Units For Air-Based Solar Heating SystemsDocument5 pagesSizing Phase-Change Energy Storage Units For Air-Based Solar Heating Systemsfabio1199No ratings yet

- ERM Malaysia Brochures - Clients (18th Nov 2013) - ClientsDocument33 pagesERM Malaysia Brochures - Clients (18th Nov 2013) - ClientsthirumalaiNo ratings yet

- Quantitative Determination OF AND: Vitamin A Vitamin EDocument20 pagesQuantitative Determination OF AND: Vitamin A Vitamin EAras RafiqNo ratings yet

- Sugar Industry PrimerDocument38 pagesSugar Industry PrimerDody IrawanNo ratings yet

- 12 Physics Exemplar Chapter 14Document11 pages12 Physics Exemplar Chapter 14Haarish KrishnamurthyNo ratings yet

- Part Manual 4BT DGBB-BC-CA-CB 960-0291DDocument91 pagesPart Manual 4BT DGBB-BC-CA-CB 960-0291DJunior EspinalNo ratings yet