Professional Documents

Culture Documents

A Numerical Study of Natural Gas Combustion in A Lean Burn Engine

Uploaded by

Chin Yuan GohOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Numerical Study of Natural Gas Combustion in A Lean Burn Engine

Uploaded by

Chin Yuan GohCopyright:

Available Formats

Fuel Vol. 77, No. 12, pp.

1339-1347, 1998

0 1998 Elsevier Science Ltd. All rights reserved

Printed in Great Britain

PII: SOOl6-2361(98)0@048-9 0016-2361/98 $19.00+0.00

on in a lean

Dehong Zhang and Steven Ii. Frankel*

Thermal Science and Propulsion Center, School of Mechanical Engineering, Purdue University,

West Lafayette, IN 47907-7003, USA

(Received 15 July 1997; revised 22 January 19981

Results from multidimensional numerical simulations and cycle simulations are presented in an effort to optimize

the performance of a fuel-lean-burn, homogeneous charge, natural gas spark-ignition internal combustion (IC)

engine. The multidimensional numerical simulations are performed using modified versions of the KIVA-2 and

IUVA-3 computer codes. The engine cycle simulations are performed using the WAVE code. The IUVA codes

are enhanced with a turbulent combustion submodel which employs a two-step, natural gas/air chemical kinetics

scheme with a temperature-dependent activation energy, together with a modified eddy dissipation model to treat

the effects of turbulence on the burning rate. The output from the multidimensional calculations is used, in a novel

way, as input to the WAVE cycle simulation code to predict overall engine performance. The Caterpillar G3400

and G3.500 fuel-lean-bum natural gas engines are the specific engines under study. The predictions for brake

specific fuel consumption (BSFC) are within 1% of the measured values for all cases where engine data are

available. The effects of swirl, combustion chamber geometry, and spark location on burning rate and BSFC are

investigated. Specifically, the results show that: (1) the numerical predictions are in good qualitative and

quantitative agreement with engine data; (2) there is an optimum initial swirl ratio for the central bowl, central

spark plug geometry; (3) an offset bowl results in a lower BSFC than a central bowl for the same initial swirl ratio

and spark plug location; and (4) an offset spark plug results in a lower BSFC than a central plug for the same initial

swirl ratio. 0 1998 Elsevier Science Ltd. All rights reserved

(Keywords: natural gas engines; turbulent combustion; numerical modeling)

INTRODUCTION modeling. Because of the nature of the models used and

the sensitivity of the results to grid resolution, it is important

The widespread use of natural gas as an alternative to

gasoline and diesel fuel in internal combustion (IC) engines to have engine data available for model calibration. This

is motivated by dwindling fuel oil reserves and desires for combined numerical/experimental testing can reduce the

reduced pollutant emissions. Previous experimental studies cost and time of the design process considerably. The

objective of this paper is to investigate the effects of swirl,

have reported that natural gas bums slower than conven-

tional fuels, such as gasoline and diesellS2. Therefore, in combustion chamber geometry, and spark plug location on

the burning rate and overall engine performance in the

order to achieve fuel-lean-burn natural gas combustion, and

still maintain competitive performance levels, manu- Caterpillar G3400 and G3500 series fuel-lean-bum, homo-

facturers of natural gas IC engines need to make design geneous charge, natural gas, spark-ignited engines. The

modifications to achieve a faster bum while optimizing approach combines multidimensional KIVA simulations to

engine performance3. These design modifications should predict the in-cylinder combustion process with the WAVE

consider the effects of in-cylinder flow motion, e.g. swirl cycle simulation code to predict the overall engine

and tumble, combustion chamber geometry, e.g. for a bowl- performance. The rest of the paper is organized as follows.

in-piston chamber, circular versus non-circular bowl, The next section discusses the numerical models employed

centered versus offset bowl, open versus deep bowl, etc., in the study, including details on the governing equations,

and spark plug location (an extensive review has been the turbulent combustion model, the initial and boundary

published elsewhere4). In order to examine all possible conditions, numerical methods and grid-refinement effects.

combinations of the aforementioned design modifications in This is followed by a summary of the specific engine

the test cell, expensive and time-consuming engine testing details. Results are presented and discussed, folIowed by

would be required. With recent improvements in the conclusions.

accuracy of multidimensional numerical engine modeling

codes and the increase in speed of computational perfor-

mance of desktop workstations, it has become feasible to NUMERICAL MODEL

conduct engine optimization studies using numerical KIVA multidimensional model

The multidimensional numerical models used to simulate

*Corresponding author the in-cylinder combustion process are the KIVA-2 and

Fuel 1998 Volume 77 Number 12 1339

A numerical study of natural gas combustion: D. Zhang and S. H. Frankel

KIVA-3 computer program?‘. The main difference predictions of engine heat release and pressure can often

between the two codes is related to grid generation. For be achieved with a simpler chemical scheme. Therefore. a

the rest of this paper, we will simply refer to KIVA global, two-step chemical kinetics scheme’s with a

simulations in general. The KIVA code integrates the temperature-dependent activation energy is used in con-

transient, conservation of mass, momentum, energy and junction with a modified eddy dissipation model”. The

species equations governing the ensemble averaged temperature-dependent activation energy was found to be

behavior of chemically reacting turbulent flows. The necessary in order to predict the entire combustion process,

standard two-equation K--E turbulence model, with some from ignition through to the power stroke. In order to

added terms to account for compressibility effects, is used to address the closure problem, the KIVA code was modified

characterize the eddy viscosity. The mathematical form of to include a turbulent combustion submodel in order to

the governing equations is provided in detail in the KIVA account for the effects of turbulence on the mean reaction

users manual and is not repeated here5. In the original code, rate. The model was developed by Zhangi” and was initially

combustion is modeled using either finite-rate laminar calibrated against data from swirling premixed natural gas/

chemistry or chemical equilibrium. In the version used in air, constant volume combustion experiments16. In the

the present study, the combustion model has been modified present study, the model treats natural gas as methane. The

to account for the important effects of turbulence on the chemical kinetics scheme and the eddy dissipation model

mean reaction rate. The details of this model are described are used to compute characteristic chemistry and turbulent

in the next section. KIVA integrates finite-difference mixing time scales. The turbulent combustion rate is

approximations to the governing equations. Temporal and predicted based on the limiting process.

spatial differencing is achieved using a semi-implicit, quasi- The two-step chemistry scheme involves methane oxida-

second-order up-winding approach together with the tion to form carbon monoxide and water via an initial step:

arbitrary Lagrangian Eulerian (ALE) technique to treat

CH4 + ;02 - CO + 2H20 (1)

grid movement associated with the piston motion. More

details can be found in the marma?. which is followed by carbon monoxide oxidation to form

In-cylinder calculations are performed after intake valve carbon dioxide:

closing and therefore initial conditions are required for all

flow variables at all points within the cylinder and on the co + 40, - co* (2)

walls. In addition, boundary conditions must be enforced to The consumption rate of methane is given by”:

obtain a unique solution. The initial in-cylinder velocity

field is chosen in order to mimic any swirl which would k, KI-U”[~,lb (3)

have been generated during the intake process. In KIVA,

and the consumption rate of carbon monoxide is given by17:

this is achieved by specifying a non-zero initial swirl

number which is defined as the ratio of the swirling air speed W~lcP,ldkb~l’ (4)

to the crankshaft speed, together with a Bessel function

where k, and k2 are the reaction rate coefficients for the first

velocity profile. More details can be found in the manuals.

Turbulent law-of-the-wall velocity conditions with fixed and second chemistry steps, respectively, and a, b, c, d, and

e are empirical coefficients and are specified in Table 1. The

temperature walls are employed. Both two-dimensional,

reaction rate coefficient for the ith step has the following

axisymmetric and three-dimensional configurations are

simulated. In configurations where symmetry planes exist, Arrhenius form:

the computational domain is restricted to a pie-shaped

sector of the physical domain, with periodic boundary

conditions enforced at the azimuthal ends of the domain.

where Ai, Ei, R,, and T are the pre-exponential factor, the

Turbulent combustion model activation energy, the universal gas constant, and the tem-

Two major obstacles to including hydrocarbon finite-rate perature, respectively. The values for Ai are specified in

chemistry into multidimensional engine simulations are: (a) Table 2. The activation energy is a constant for elemental

uncertainties and the large computational expense asso- chemical reactions, but in global empirical chemistry

ciated with implementing detailed reaction mechanisms in modeling treating the activation energy as a constant can

turbulent flame simulations; and (b) closure of the filtered lead to problems, especially in transient situations where

chemical production term in the averaged thermochemical ignition phenomena are importa@. In IC engine simu-

conservation equations. Detailed7 and reduced8 chemical lations our numerical tests have shown that it is not possible

kinetics models for methane exist, but the application of to predict both the early burning and main burning rates

these mechanisms to turbulent reacting flows is still in its with a constant activation energy. Therefore, in this study

early stages’. The computational expense associated with

finite-rate chemistry is related to integration of additional Table 1 Concentration coefficients in chemical kinetics scheme

species transport equations, which increase storage and

CPU time considerably”. Due to the wide range of time a b c d e

scales associated with chemical kinetics, systems of stiff - 0.3 1.3 1.o 0.65 0.5

differential equations also result. Recent work in developing

computationally efficient techniques for implementing

combustion chemistry in turbulent flame analyses appear

promising, but have not yet been tested in multidimensional Table 2 Combustion model parameters

engine simulations ’’. In engine simulations, interest in Reaction step AI EiO ni *, B,

predicting kinetically-controlled phenomenon such as igni-

1 2.51 X IO5 1.82 X lo4 7.26 0.95 0.53

tion, knock or pollutant emissionsrfenerally requires a fairly 2 6.40 X lo9 1.07 X 10’ 1.55 0.95 0.015

sophisticated chemistry model . Reasonably accurate __ ._

1340 Fuel 1998 Volume 77 Number 12

A numerical study of natural gas combustion: D. Zhang and S. H. Frankel

a temperature-dependent activation energy for each reaction Table 3 Engine details

is formulated in the form: Engine Bore Stroke Speed (r/s) Compression

ratio

Ei = Eio + niTm’ (6)

3400 137 152 25 -12.5:1

where Eio is the constant part of the activation energy, 3500 170 190 25 12:l

which makes up about three-quarters of the total activation

energy, and ni and mi are two constants, for each reaction

step. The values for these quantities are also specified in

fuel and combustion products are also accounted for in the

Table 2.

model. The energy equation involves the first law of

The effect of turbulence on the mean reaction rate is

thermodynamics and accounts for internal energy changes

accounted for by using a modified version of the eddy

of the in-cylinder gases due to enthalpy fluxes, heat transfer

dissipation modeli4. In this model, premixed turbulent

and piston work. More details can be found in the manua119.

combustion is treated as a mixture of unburned and burned

The WAVE code is used here to predict the engine brake

gas turbulent eddies with chemical reaction presumed to

specific fuel consumption (BSFC). As input to the model,

occur at the interface between these eddies. The chemical

the cumulative heat release and wall heat flux are input as a

production rate per unit volume is assumed to depend upon

function of crank angle from results obtained from the

either a chemical kinetics rate or the turbulent mixing rate of

multidimensional KIVA simulations.

these eddies. The rate of turbulent mixing of these eddies is

assumed to be proportional to the rate of decay of the

turbulent kinetic energy. ENGINE AND COMPUTATIONAL DETAILS

The implementation of this model involves the calcula-

The two engines under investigation in this study are the

tion of two characteristic time scales. The first is based on

Caterpillar G3400 and G3500 series fuel-lean-burn natural

the chemical kinetics and the second is based on turbulent

gas engines. The main difference between the two engines is

mixing. They are computed based on the following

their size. The G3400 engine is smaller than the G3500

expressions:

engine as indicated by the geometric details for each engine

summarized in Table 3.

Data are available from these engines for different aspects

of the numerical study in the form of combustion chamber

pressure and cumulative heat release versus crank angle.

for the chemical time scale, and The cumulative heat release is defined as the ratio of the

amount of heat released from the actual combustion process

k

7ti = Bi - at the present crank angle to that after complete combustion.

E Heat release data are collected by measuring time resolved

for the turbulent time scale, where Bi is a constant which, cylinder pressure. A crank angle encoder and cylinder

along with the other parameters in the model, is calibrated to pickup are used to collect cylinder pressure data. Proprietary

match experimental data. Values for Bi used in this study are software (heat transfer model) is used by Caterpillar to

summarized in Table 2. These two time scales are compared determine rate of heat release and cumulative heat release

in order to determine which is larger. The chemical produc- curves for methane-based fuels. Caterpillar has been using

tion rate is determined based upon which process, finite-rate heat release rates and cumulative heat release information to

chemistry or turbulent mixing, is slower or limiting. In order monitor combustion improvements for the past decade”.

to provide a smooth transition between the chemical Fuel consumption is measured with a positive displacement

kinetics-limited regime and the turbulent mixing-limited meter where the time required for usage of a specified

regime, a buffer regime is incorporated into the formula- volume of fuel is measured and corrected for gas

tion18. Thus, the combustion process is divided into three temperature, pressure and lower heating value. The fuel

regimes: (1) a chemical kinetics limited regime when lower heating value is constantly monitored with an on-line

T,i/7ti > 10, and the chemical production rate is computed gas chromatograph. Fuel is supplied by the local gas utility.

from ki = l/rci; (2) a turbulent mixing-limited regime when Calculations are started just after intake valve closing

r,Jrti < 0.1, and the chemical production rate is computed with initial conditions specified as discussed above, and

from ki = l/rti; and (3) a combined chemical kinetics and estimated from engine measurements. The fuel-to-air

turbulent mixing regime when 10 > 7,i/7ti > 0.1, and the equivalence ratio is fixed at 0.7 in all cases. The mixture

chemical production rate is computed from is ignited along the cylinder axis, unless otherwise

ki = ll[Dr,i + (1 - D)rJ, where D = 7cil(7ci + Eli). The Cut- indicated, close to the cylinder head by internal energy

offs at 10 and 0.1 are arbitrarily chosen, but are found to be deposition as described in the KIVA manual. The

sufficient. computational grid size for each case is specified below,

but the average grid spacing is 1.9 mm and the typical

WAVE engine code average flame thickness is 10 mm, based on the average

The WAVE cycle simulation program is a code which is temperature profile15. All results have been checked for grid

often used by engine manufactures for design calcula- and time step sensitivity and the trends are observed to be

tions”. This package is used here in a novel way by consistent in all cases.

providing input from the multidimensional KIVA simula-

tions. WAVE involves a time-dependent simulation of the

RESULTS AND DISCUSSION

in-cylinder processes using the equations of mass and

energy conservation. The mass equation accounts for In the next three subsections, results, in the form of

changes in in-cylinder mass due to flow through valves combustion chamber pressure, cumulative heat release, wall

and due to fuel injection. Fluxes of air, vaporized fuel, liquid heat flux, and turbulence kinetic energy versus crank angle,

Fuel 1998 Volume 77 Number 12 1341

A numerical study of natural gas combustion: D. Zhang and S. H. Frankel

are presented. Comparisons are made to engine data where

available. Contour plots of temperature are also presented to

examine mean flame shapes. Cumulative heat release and

wall heat flux information are then provided as input to the

WAVE engine cycle simulation code in order to predict

overall BSFC. These results will be presented and compared

for different cases in the last section.

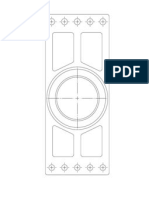

Figure 1 Computational grid for axisymmetric computations of

Effect of swirl

G3500 central bowl-in-piston combustion chamber

In order to confidently examine the effect of swirl on the

burning rate, it is important to first calibrate the model

against available engine data. The computational grid for

the calculations presented in this section is shown at TDC

(4 (top dead center) in Figure I for the G3500 central bowl-in-

A Qhp ~-0

piston geometry. There are 23 grid points in the axial

direction, i.e. along the cylinder axis, and 44 grid points in

100 the radial direction. In Figure 2, plots of cumulative heat

release versus crank angle are presented comparing KIVA

90 numerical predictions to engine data for initial swirl ratios

T

@ of (a) 0.0 and (b) 2.0. Reasonable agreement between the

80

numerical predictions and the engine data can be observed.

% The model predicts a slower initial bum rate in comparison

(II 70

P to the engine data which may be due to lower initial in-

$! 60 cylinder turbulence levels, the lack of an ignition model, or

t the effect of cycle-to-cycle variations not captured in the

aI 50

c simulations. With the parameters in the combustion model

g 40 tuned to this data set, the initial swirl level is now further

._ varied, while keeping all model parameters fixed, to

3 30 examine its effect on the overall burning rate.

Figure 3 shows cumulative heat release plotted versus

i 20

crank angle for four different initial swirl ratios 0.0, 1 S, 2.0,

and 3.3. The results show that as the initial swirl ratio is

increased from 0.0 to 2.0 the burn rate increases

continuously. When the initial swirl ratio is set at 3.3, the

numerical model predicts a slower burning rate than even

the case with zero initial swirl. There is no engine data at

(b) / A P/exp -21 j_/__()_-- 1.5

-2 -----3.31

100

/,/*

100

90

1 90

T

b

- a0

f 70

Q,

z 60

.E

tii 50

$ 40

._

z 30

3

E 20

_T

Figure 2 Cumulative heat release versus crankangle for G3500

central bowl with initial swirl ratio of (a) 0 and (b) 2.0 Figure 3 Cumulative heat release versus crankangle for G3500

(experimental data as symbols, numerical predictions as lines) central bowl for initial swirl ratios of 0, 1.5, 2.0, and 3

1342 Fuel 1998 Volume 77 Number 12

A numerical study of natural gas combustion: D. Zhang and S. H. Frankel

I-*_- 0 --- 1.5 -2 ______3.31

sr = 0

x = 14.4

(a)

O”~ .-._.--

..-

_-.-.._ .- . .

*-.. ._..._. .’

_*

.I-*. :

‘*

sr = 2.0

x= I$.4

@I

ol

CA [ATDC]

Figure 5 Total turbulent kinetic energy versus crankangle for

G3500 central bowl for initial swirl ratios of 0, 1.5, 2.0 and 3

sr = 3.3

x = 13.0 _._- 0 --- 1.5 -2 _____.3.3/

(Cl

Figure 4 Temperature contour plots for G3500 central bowl at 10

ATDC for three different initial swirl ratios (indicated by sr value)

along with corresponding cumulative heat release value (indicated

by x value (%))

this high initial swirl ratio. Contour plots of mean

temperature are compared for initial swirl ratios of 0.0,

2.0, and 3.3 at 10” ATDC (after TDC) in Figure 4, in order

to examine the effect of swirl on the flame shape and explain

the adverse effect of high swirl on the burning rate as

predicted by the simulations. The corresponding cumulative

heat release value is also shown for reference. The zero

swirl case shows a hemispherical flame shape, the

intermediate swirl case shows a conical flame shape, and

the high swirl case reveals a barrel flame shape. It appears

that the effect of swirl is to suppress flame propagation in

the radial direction, allowing the flame to propagate faster in

the axial direction. This so called ‘flame pencilling effect’

can be attributed to the centrifugal force that is created by

the swirling motion and the density difference between the

burned and unburned gases. Similar behavior has been Figure 6 Wall heat flux versus crankangle for G3500 central

bowl with initial swirl ratios of 0, 1.5, 2.0 and 3.3

observed experimentally in swirling, premixed natural gas/

air constant volume bomb combustion’6, lending some

credence to the numerical predictions. Figure 5 shows the

total turbulence kinetic energy versus crank angle for the turbulence levels lead to higher wall heat fluxes as can be

different swirl cases. Increasing the initial swirl ratio seen in Figure 6, which shows wall heat flux versus crank

increases the turbulence levels in the cylinder. angle for the different initial swirl ratios considered. This

The main result from this part of the study is that for a increase in wall heat flux with increase in swirl levels will, in

central bowl-in-piston geometry, with central spark ignition, general, affect the overall engine BSFC. This issue will be

there exists an optimum swirl ratio for fast burning. Higher investigated in the section on overall engine performance.

swirl does generate more turbulence, which, in general,

should increase the burning rate. However, the flow pattern Effect of combustion chamber geometry

which is generating the turbulence, in this configuration, is In order to overcome the flame pencilling effect observed

not conducive to rapid flame propagation. Also, higher at high swirl levels with the central bowl in the previous

Fuel 1998 Volume 77 Number 12 1343

A numerical study of natural gas combustion: D. Zhang and S. H. Frankel

..

Figure 7 Computational grid for three-dimensional computa-

tions of G3500 offset bowl-in-piston combustion chamber

2 60.

/-_-- 1.5 -2 - - - - 3.3 A 2lexp

100

90

5

T 80

3g 70

CA [ATDC]

g 60

Figure 9 Cumulative heat release versus crankangle for G3400

z offset bowl with initial swirl ratio of 1.8 (experimental data as

a 50

c symbols, numerical predictions as lines)

$ 40

‘G

2 30

Further validation of the abilities of the combustion

zz 20 model to predict the effect of the offset bowl are shown in

Figure 9 which compares predictions of cumulative heat

10 release versus crank angle to engine data for the G3400

offset bowl configuration for an initial swirl ratio of 1.8.

Good agreement with the engine data is observed lending

v ”

7

cl

z LFi 8 s further credence to the results obtained in the G3500 study

CA [ATDC] discussed above.

In order to examine the effect of swirl and bowl offset on

Figure 8 Cumulative heat release versus crankangle for G3500 the combustion process, temperature contour plots at 10”

offset bowl with initial swirl ratios of 1.5, 2.0, and 3.3

ATDC are shown for three different swirl ratios in Figure 10

(experimental data as symbols, numerical predictions as lines)

for the G3500 engine. In addition, the corresponding

cumulative heat release value (represented by the x value)

is included on the figure. For the zero initial swirl case, the

subsection, the bowl is offset by 8 mm in an attempt to flame shape is similar to the centered bowl case. For the

disturb the alignment between the flame center and the swirl intermediate swirl case, the flame shape becomes distorted

center. The offset bowl will also generate a stronger squish by the swirl and offset bowl effects. For the high swirl case,

jet and hence more turbulence, which should help overcome the flame has already propagated to the piston crown with a

the swirl-induced pencilling effect. The three-dimensional significant increase in the cumulative heat release value as

computational mesh for the offset bowl, shown in Figure 7, compared to the other two cases. Also comparing the offset

shows 44 X 18 X 23 grid points at TDC in the radial, bowl case to the central bowl case for the intermediate swirl

azimuthal and axial directions, respectively. The effect of level there is a significant increase in the burning rate and

bowl offset on the in-cylinder combustion process is hence the cumulative heat release for the offset case.

represented by a plot of the cumulative heat release versus Figures 11 and 12 show plots of turbulent kinetic energy

crank angle for several different initial swirl ratios shown in and wall heat flux versus crank angle, respectively, for the

Figure 8. Data is available for the case with initial swirl offset bowl cases. The results show that higher turbulence

ratio of 2.0 and reasonable agreement with the numerical and wall heat flux levels accompany the faster bum

prediction is observed. An increase in the initial swirl ratio, associated with the offset bowl and high swirl. The net

in the offset bowl combustion chamber, results in a effect of these changes on the overall engine performance

continuous increase in the burn rate. This is in contrast to will be examined in a later section.

the central bowl case where there was a decrease in the bum

rate at high swirl. The reason the offset bowl is able to Effect of spark plug location

overcome the flame pencilling effect is due to higher In this section, the effect of spark plug location on

turbulence levels from the stronger squish jet and the fact burning rate in the G3400 engine is examined. Three plug

that the flame center is slightly offset from the swirl center. locations are studied for the central circular bowl with an

Thus, in addition to a diffusive burn, a swirl-induced initial swirl ratio of 1.8: (1) at the center, (2) at r/2, and (3) at

convective bum is becoming important. r, where r is the bowl radius. Figure 13 shows the grid and

1344 Fuel 1998 Volume 77 Number 12

A numerical study of natural gas combustion: D. Zhang and S. H. Frankel

I--- 1.5 -2 - - - - 3.3

sr = 0

x = 15.0

(4 .

-I

7

0 0

z :: z 3

CA [ATDC]

Figure 11 Total turbulent kinetic energy versus crankangle for

G?500 offset bowl with initial swirl rat& of 0, 2.0, and 3.3

sr = 2.0

x = 26.0

(b)

sr = 3.3

x = 46.5

Figure 10 Temperature contour plots for G3500 offset bowl at

10 ATDC for three different initial swirl ratios (indicated by sr

value) along with corresponding cumulative heat release value

(indicated by n value (%))

01

Table 4 Brake specific fuel consumption (BSFC) (kJ/kWh) X 8 z 0

51 8 8

104. CC, central circular bowl; GC, offset circular bowl; CR, com-

CA [ATDC]

pression ratio; swirl ratio is 1.8

G34OO/CC/CR= 12.5 G34OOKMYCR

= 12.0 Figure 12 Wall heat flux versus crankangle for G3.500 offset

bowl with initial swirl ratios of 0, 2.0, and 3.3

Experimental 0.928 0.937

Numerical 0.937 0.941

mixture. This is consistent with previous experiments

the ignition locations. Figure 14 compares cumulative heat examining the effect of spark location on combustion in a

release plots for the three different cases. The fastest burn variable swirl engine*‘. The turbulence levels are not

occurs when the spark plug is located at r. The burning in significantly effected by the spark location, as shown in

this case begins in the high swirl region towards the outside Figure 15, but the wall heat flux is found to be higher in the

of the bowl and the flame is convectively swept around the offset plug cases, as shown in Figure 16. The overall effect

periphery of the bowl by the swirling flow while propagat- of spark plug location on engine performance will be

ing towards the center of the bowl to consume the unburned determined in the next section.

Fuel 1998 Volume 77 Number 12 1345

A numerical study of natural gas combustion: D. Zhang and S. H. Frankel

I~--- 1.8-c - - - - - - 1 .&r/2 - 1.8-r

__ j

Figure 13 Computational grid for offset ignition computations of

G3400 central bowl-in-piston combustion chamber

-_-. 1.8-c ------1.8-r/2 - 1.8-r 1

CA [ATDC]

Figure 15 Total turbulent kinetic energy versus crankangle for

G3400 central bowl with intial swirl ratio of 1.8 and ignition offset

at 0, r/2, and r

mm-

1.8-c - - - - - - 1.8-r/2 - 1.8-r

0 0 0

7 Ei

CA [ATDC]

Figure 14 Cumulative heat release versus crankangle for

G3400 central bowl with swirl ratio of 1.8 and ignition offset at

0, r/2, and r

Table 5 Brake specific fuel consumption (BSFC) (kJ/kWh) X

104. CC, central circular bowl; OC, offset circular bowl; CR, com-

pression ratio; swirl ratio is 1.8

G35OO/CC/SR = 0 35OOlCCISR= 2.0 G35OOIOClSR= 3.3

1.011 0.978 0.924 CA [ATDC]

Figure 16 Cumulative heat release versus crankangle for G3400

central bowl with intial swirl ratio of 1.8 and ignition offset at 0, rl

2, and r

Overall engine petformance

In this section, predictions from the WAVE code for

BSFC for several different engine configurations are

presented with comparison to engine test data where higher swirl case, the faster burning, which results from the

available. In Table 4, WAVE predictions are compared to offset bowl, leads to better overall performance.

experimental data for two G3400 configurations. In both

cases, the predictions are within 1% of the test data. In

CONCLUSIONS

Table 5, the offset circular bowl with high swirl results in

the lowest BSFC for the three G3500 configurations. Thus, Results from multidimensional numerical modeling and

in spite of the higher wall heat flux associated with the thermodynamic cycle simulations have been used to

1346 Fuel 1998 Volume 77 Number 12

A numerical study of natural gas combustion: D. Zhang and S. H. Frankel

optimize the performance of two Caterpillar fuel-lean-bum, 3 Bruch, K. I., Caterpillar G3500 high efficiency engine

spark-ignited, homogeneous charge, natural gas engines by development. Number ICE-25-3, ASME, 1995.

examining the effects of swirl, combustion chamber 4 Hill, P. G. and Zhang, D., Eflects of swirl and tumble on

geometry and spark plug location. The KlVA computer combustion in spark-ignition engines. Prog. Energy Com-

bust. Sci., 1994, 20, 373-429.

code, modified to include a turbulent combustion submodel,

5 Amsden, A. A., O’Rourke, P. J. and Butler, T. D., KIVA-II:

is used in the multidimensional simulations of the in- A Computer Program for Chemically Reactive Flows with

cylinder combustion process, and the WAVE code is used in Sprays, Los Alamos, NM, 1989.

the thermodynamic cycle simulations to determine the 6 Amsden, A. A., O’Rourke, P. J. and Butler, T. D., KIVA-3: A

engine BSFC. The key results from this study are as follows: KIVA Program with Block Structured Mesh for Complex

Geometries, Los Alamos, NM, 1993.

(1) The KIVA predictions of the in-cylinder combustion

7 Zhou, G. and Karim, G. A., A comprehensive kinetic model

process and the hybrid KlVA/WAVE predictions of for the oxidation of methane. ASME Emerging Energy Tech-

BSFC are in reasonable agreement with engine data nol., 1994, PD57, 49-57.

for several swirl ratios and combustion chamber 8 Peters, N. and Rogg, B. (eds), Reduced Kinetic Mechanisms

geometries. for Application to Combustion Systems, Vol. 15 of Lecture

(2) There exists an optimum swirl ratio for fast burning in a Notes in Physics. Springer-Verlag, Berlin, Heidelberg,

central bowl-in-piston configuration with central 1993.

ignition. This is primarily due to centrifugal forces, gen- 9 Seshardi, K. and Williams, F. A., Reduced chemical systems

erated by the swirling fuel/air motion and the combus- and their application in turbulent combustion. In Turbulent

Reacting Flows, ed. P. A. Libby and F. A. Williams. Com-

tion-induced density differences, which impede radial

bustion Treatise, Academic Press, San Diego, CA, 1994.

flame propagation resulting in a flame pencilling effect.

10 Westbrook, C. K. and Dryer, F. L., Chemical kinetic model-

(3) The offset bowl results in higher turbulence levels and a ing of hydrocarbon combustion. Prog. Energy Combust.

partial misalignment between the flame center and the Sci., 1984, 10,l-57.

swirl center, both of which help to overcome the flame 11 Yang, B. and Pope, S. B., Treating chemistry in combustion

pencilling effect and achieve faster burning and higher with detailed mechanisms-in situ adaptive tabulation in

wall heat flux than the central bowl at the same swirl principal directions-premixed combustion. Combust.

ratio. Flame, 1997, 112, 85-121.

12 Maly, R. R., State of the art and future needs in SI engine

(4) The offset ignition site, with a central bowl, results in

the fastest burning. This is achieved by taking advan- combustion. In Proc. 25th Symposium (bit.) on Combustion.

Combustion Institute, Pittsburg, PA, 1994, pp. 111-124.

tage of the swirl-induced convective bum and burning

13 Westbrook, C. and Dryer, F., Simplijed reaction mechan-

from the outside in. High wall heat fluxes are observed

isms for the oxidation of hydrocarbon fuels in $ames. Com-

in this case as well. bust. Sci. Technol., 1981, 27, 3 l-43.

(5) The optimum overall BSFC, as predicted by the hybrid 14 Magnussen, B. F. and Hjertager, B. H., On mathematical

KlVA/WAVE approach, is achieved for the high swirl, modeling of turbulent combustion with special emphasis

offset bowl G3500 engine and for the intermediate on soot formation and combustion. In Proc. 16th Symp.

swirl, central bowl, offset ignition G3400 engine. (Znt.) on Combustion. Combustion Institute, Pittsburgh,

PA, 1976, pp. 719-729.

15 Zhang, D., Turbulent swirling combustion of premixed

natural gas and air. Ph.D. thesis, University of British

ACKNOWLEDGEMENTS

Columbia, Vancouver, Canada, 1995.

The authors would like to acknowledge Caterpillar Inc., 16 Zhang, D. and Hill, P., Effect of swirl on combustion in a

Lafayette, IN, specifically Kevin Bruch and Min Wu, for short cylindrical chamber. Combust. Flame, 1996, 106(3),

financial support of this project, and for providing the 318-332.

engine test data and many useful discussions. The WAVE 17 Yetter, R. A., Dolyer, F. L. and Rabitz, C., Complication of

one-step kinetics for moist CO oxidation. In Proc. 21st

simulations were performed by Min Wu.

Symp. (lnt.) on Combustion. Combustion Institute,

Pittsburgh, PA, 1986, pp. 749-760.

18 Ahmadi-Befrui, B., Gosman, A. D., Lockwood, F. C. and

REFERENCES Watkins, A. P., Multidimensional calculation of combustion

in an idealized homogeneous charge engine. Progress

1 Andrews, A. E. and Bradley, D., The burning velocity of Report, No. 810151, SAE, 1981.

methane air mixtures. Combust. Flame, 1975,24,275-288. 19 WAVE Engine Manual, Technical Report, Ricardo Soft-

2 Metghalchi, M. and Keck, J. C., Burning velocities of ware, Burr Ridge, IL, 1996.

mixtures of air with methanol, isooctane, and indolene at 20 Bruch, K., Private communication, 1977.

high pressure and temperature. Combust. Flame, 1982,48, 21 Witze, P. O., The effect of spark location on combustion in a

191-210. variable swirl engine. No. 820044, SAE, 1982.

Fuel 1998 Volume 77 Number 12 1347

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Paper ChristianLaemmle DessauJuni05Document15 pagesPaper ChristianLaemmle DessauJuni05Chin Yuan GohNo ratings yet

- Mock Up HubDocument1 pageMock Up HubChin Yuan GohNo ratings yet

- Tolerance ChartDocument1 pageTolerance ChartChin Yuan GohNo ratings yet

- Design of The Impact Attenuator For A Formula Student Racing CarDocument14 pagesDesign of The Impact Attenuator For A Formula Student Racing CarChin Yuan GohNo ratings yet

- Design of The Impact Attenuator For A Formula Student Racing CarDocument14 pagesDesign of The Impact Attenuator For A Formula Student Racing CarChin Yuan GohNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- National Institute of Technology Durgapur: Department of Chemical EngineeringDocument2 pagesNational Institute of Technology Durgapur: Department of Chemical Engineeringpiyush dwivediNo ratings yet

- Ma8491 ModelDocument2 pagesMa8491 ModelANNo ratings yet

- Thermal Oil Boiler Vega PDFDocument2 pagesThermal Oil Boiler Vega PDFrafiradityaNo ratings yet

- Visible Emission of Hydrogen FlamesDocument8 pagesVisible Emission of Hydrogen FlamesgajodharlauduNo ratings yet

- p1k Pde2577tcuk 052009 PDFDocument20 pagesp1k Pde2577tcuk 052009 PDFwalid8311No ratings yet

- Data SheetDocument14 pagesData SheetMelchiNo ratings yet

- SilverThin Slewing Rings and Pinions CatalogDocument16 pagesSilverThin Slewing Rings and Pinions CatalogGanesh LohakareNo ratings yet

- Flint-2 5Document671 pagesFlint-2 5GNZLNo ratings yet

- Hardness Test BlocksDocument2 pagesHardness Test BlocksAvijit DebnathNo ratings yet

- SETTLING VELOCITY 2.1 - Calculations of Sedimentation Velocity and Hindered Settling Rate of ParticlesDocument74 pagesSETTLING VELOCITY 2.1 - Calculations of Sedimentation Velocity and Hindered Settling Rate of ParticlesSonu Singh100% (4)

- Paper - Fatigue Lifetime of Welded Joints Under Random Loading - Colombini P., Dolinski K. - 2001Document11 pagesPaper - Fatigue Lifetime of Welded Joints Under Random Loading - Colombini P., Dolinski K. - 2001Claudio RodriguesNo ratings yet

- Advanced Organic Test Questionnaire Practice KeyDocument8 pagesAdvanced Organic Test Questionnaire Practice KeyJuitchiboy Nunez DumaoNo ratings yet

- Rockwell Round Correction ChartsDocument2 pagesRockwell Round Correction Chartsdarwin_huaNo ratings yet

- Sko0061283 R2Document52 pagesSko0061283 R2ciwidop390No ratings yet

- Several Problems of The Polish Physics Olympiad: Waldemar GorzkowskiDocument4 pagesSeveral Problems of The Polish Physics Olympiad: Waldemar GorzkowskiVikram SaurabhNo ratings yet

- Gear BoxDocument135 pagesGear BoxSubhendu Jana50% (2)

- A Comparison of IEC 479-1 and IEEE STD 80 On Grounding Safety CriteriaDocument10 pagesA Comparison of IEC 479-1 and IEEE STD 80 On Grounding Safety Criteriaperijoy100% (1)

- Discrete Element Modelling of Rockfill Railway EmbankmentsDocument15 pagesDiscrete Element Modelling of Rockfill Railway EmbankmentsHerdin AsyidiqNo ratings yet

- AnimationDocument9 pagesAnimationAruna AruchamiNo ratings yet

- Lec 1 PrintDocument13 pagesLec 1 PrintPolito PogbaNo ratings yet

- Critical Analysis of Properties of Ready Mix Concrete With Site Mix Concrete of Smart Road ProjectDocument6 pagesCritical Analysis of Properties of Ready Mix Concrete With Site Mix Concrete of Smart Road ProjectGolam Shahriar SakibNo ratings yet

- At N.p.c.i.l., RawatbhataDocument30 pagesAt N.p.c.i.l., RawatbhataDevendra SharmaNo ratings yet

- Trial Mix Design Report PDFDocument38 pagesTrial Mix Design Report PDFTimothy HughesNo ratings yet

- TemperatureDocument4 pagesTemperatureDr.AhmedNo ratings yet

- Stainless Steels For Springs and Other Demanding Applications (S 3411 ENG - Sept.2002)Document14 pagesStainless Steels For Springs and Other Demanding Applications (S 3411 ENG - Sept.2002)DanielNo ratings yet

- Hot and Dry Climate SolarPassiveHostelDocument4 pagesHot and Dry Climate SolarPassiveHostelMohammed BakhlahNo ratings yet

- 1.1 Expansive SoilDocument9 pages1.1 Expansive SoilYatin JethiNo ratings yet

- RodinDocument27 pagesRodinThe Dead Alewives WatchtowerNo ratings yet

- Micro Servo RobotDocument40 pagesMicro Servo Robotlokesh mahor0% (1)

- Energy TestDocument19 pagesEnergy TestDataNo ratings yet