Professional Documents

Culture Documents

96dpi MTM Produktblatt FT8

Uploaded by

blahblah8888Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

96dpi MTM Produktblatt FT8

Uploaded by

blahblah8888Copyright:

Available Formats

Technical data

Mechanical Drive Shaft power Thermal efficiency Heat rate kW HP % kJ/kWh Btu/HPh Generator Drive Power at generator terminals Electrical efficiency Heat rate kWe % kJ/kWh Btu/kWh Exhaust Gas Data Exhaust gas temperature Exhaust gas mass flow C F kg/s lb/s Gas Generator (LP/HP) Speed Compressor stages Turbine stages Weight approx. (DLN) Power Turbine Speed Stages Weight approx. kg rpm kg rpm

FT8 PowerPac -

FT8 TwinPac -

FT8 MechPac 25,870 34,690 38.6 9,330 6,594

25,570 38.1 9,440 8,950

51,140 38.1 9,440 8,950

458 856 85.1 188

458 856 170.2 376

457 855 85.9 189

FT8 Gas Turbine

7,100/11,520 8/7 2/1 3,000 (3,950)

7,100/11,520 8/7 2/1 3,000 (3,950)

7,100/11,520 8/7 2/1 3,000 (3,950)

3,000* 4 6,000

3,000* 4 6,000

2,500 - 5,500 3 5,100 MAN Turbo AG

Above specifications valid under the following conditions: 15C (59F), sea level, no inlet/outlet losses, RH = 60%, natural gas, * 3,600 rpm available on request gen. = 98%

Steinbrinkstrasse 1 46145 Oberhausen/Germany Phone +49. 208. 6 92-01 Fax +49. 208. 6 92-20 19 www.manturbo.com MAN Turbo a member of the MAN Group

In the interest of technical progress, subject to change without notice. Printed in Germany. December 2008 Turbo 1001 e 1208 2.5 ba

Engineering the Future since 1758.

MAN Turbo

FT8 Gas Turbine Aeroderivative gas turbine for industrial applications

The FT8 gas turbine is based on the proven technology of the JT8D aircraft engine from Pratt & Whitney, which was adapted for industrial applications. The FT8 stands out through its compact and modular design. Time-tested in a variety of industrial applications, the FT8 has proven itself to be an exceptionally reliable, high-availability product.

MechPac The MechPac includes the skid-mounted gas turbine directly coupled to the equipment it drives (compressor) mounted on a separate baseframe including all ancillary equipment required to form a complete package for outdoor/indoor installation. Combustion systems

Power turbine for mechanical drive applications Speed of 5,500 rpm, variable from 2,500 5,750 rpm, counterclockwise (in flow direction) Robust DLN combustion system Package concept The package concept for the FT8 offers high flexibility, as the FT8 arrives not completely preassembled at the site. It is therefore ideal for sites with space and access restrictions. The FT8 gas turbine comes to the site without an enclosure, premounted and prewired on a base frame including the fuel plate and junction boxes. After the gas turbine has been placed onto the foundation, the enclosure consisting of prefabricated compact modules is quickly and easily assembled. Miscellaneous power turbine designs available Fast start-up and loading capability Features Flexible package concept Benefits Ideally suited for indoor installations with restricted access No need for adjusting the control system in case of changing operating/ambient conditions especially for mechanical drive applications Ideally suited for daily start and stop operation and/or peaking applications such as peak shaving and emergency power plants For both power generation and mechanical drive applications, the driven equipment can be directly connected to the gas turbine no load gear is required Applications The FT8 is used in:

Power versus temperature (PowerPac) n = 5,500 rpm Diffuser GG8-Gas generator n = 3,600 rpm Generator drive applications Collector box n = 3,000 rpm PT8-30/36-Power turbine

Modular FT8 concept for generator drive and mechanical drive applications

Diffuser

Configurations With the PowerPac and TwinPac, two versions for power generation purposes are available. The MechPac was developed for mechanical drive applications, such as driving compressors. MAN Turbo specifically designed the 5,500 rpm power turbine for this package. PowerPac The FT8 PowerPac includes the skidmounted gas turbine directly coupled to the synchronous generator mounted on a separate baseframe as well as all ancillary equipment required to form a complete package for outdoor/indoor installation. TwinPac The FT8 TwinPac is comprised of two FT8 gas turbines. Each gas turbine is directly connected to a centrally located double-end synchronous generator. Together with the ancillary equipment, a completely self-contained package is formed, either for outdoor or indoor installation.

Depending on the application, the FT8 gas turbine can be equipped with two different combustion systems. Standard combustion system The basic version permits the use of gaseous and liquid fuels of various specifications and mixes, thereby offering high fuel flexibility. DryLowNOx combustion system A DLN (DryLowNOx) combustion system for gaseous fuel operation is available as an option. The extremely robust DLN system allows quick load changes and is insensitive to changing gas compositions and ambient conditions.

Mechanical drive applications Driving compressors

33 Mechanical drive applications Sea level, rel. humidity = 60% Natural gas No inlet/outlet losses Standard combustion system Generator efficiency: 98% PT8-55-Power turbine

Generator drive applications Power turbine Power turbines for driving generators Speed of 3,000 rpm, no gear unit, coupled directly to a generator for 50 Hz Speed of 3,600 rpm, no gear unit, coupled directly to a generator for 60 Hz Both power turbines are available for clockwise and counterclockwise rotation Power stations Combined heat and power stations (CHP)

Power at generator terminals (MW)

30

27

24

21

18 -30 -15 0 15 30 45 Inlet temperature (C)

You might also like

- FT 8 PDFDocument33 pagesFT 8 PDFvcharles100% (1)

- Gas Turbines: A Handbook of Air, Land and Sea ApplicationsFrom EverandGas Turbines: A Handbook of Air, Land and Sea ApplicationsRating: 4 out of 5 stars4/5 (9)

- Brochure SGT6 5000F TG 8Document25 pagesBrochure SGT6 5000F TG 8RUBEN DARIO AQUIZE PALACIOSNo ratings yet

- Flashback Mechanisms in Lean Premixed Gas Turbine CombustionFrom EverandFlashback Mechanisms in Lean Premixed Gas Turbine CombustionNo ratings yet

- Solar 5.2MVADocument15 pagesSolar 5.2MVAsohaila7No ratings yet

- Thermal Peaking PDFDocument26 pagesThermal Peaking PDFkhozaqiNo ratings yet

- MHPS Large Frame F Series Gas Turbine PDFDocument8 pagesMHPS Large Frame F Series Gas Turbine PDFI Wayan Arimbawa100% (1)

- Thermal Cycles of Heat Recovery Power PlantsFrom EverandThermal Cycles of Heat Recovery Power PlantsRating: 5 out of 5 stars5/5 (2)

- 9FA Enhancement Brochure - GEA17570Document8 pages9FA Enhancement Brochure - GEA17570Peter_Phee_341No ratings yet

- Kawasaki Gas Turbine PDFDocument45 pagesKawasaki Gas Turbine PDF13421301508100% (1)

- GE LM6000 1275-GryDocument1 pageGE LM6000 1275-GryuzairmughalNo ratings yet

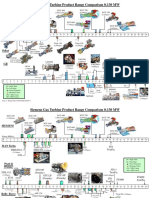

- GTs World Comparison Picture - 1-130 MW - 2015 01 PDFDocument2 pagesGTs World Comparison Picture - 1-130 MW - 2015 01 PDFdvcher78No ratings yet

- General Electric Power Business Unit: Strategic Analysis Tools and Techniques - Coursework 2Document13 pagesGeneral Electric Power Business Unit: Strategic Analysis Tools and Techniques - Coursework 2Ibilola IbisankaleNo ratings yet

- Ge Industrial Aeroderivative Gas TurbinesDocument2 pagesGe Industrial Aeroderivative Gas TurbinesJHONNATTAN RODRIGUEZ0% (1)

- Gas Turbine Lm5000 Operations ManualDocument4 pagesGas Turbine Lm5000 Operations ManualMuhammad Ilham RiyadiNo ratings yet

- Siemens GTDocument8 pagesSiemens GThbalu007No ratings yet

- Eco 100 Wind Turbine PlatformDocument4 pagesEco 100 Wind Turbine PlatformSofiane HalimiNo ratings yet

- SGT Torque Converter Governor: Supplement To Manual 04048Document24 pagesSGT Torque Converter Governor: Supplement To Manual 04048pcatruongNo ratings yet

- Pivot Arm Turning GearDocument24 pagesPivot Arm Turning Gearoom_tgw100% (1)

- LM6000 PC O&M - GEK 105059 CHG 06Document1,988 pagesLM6000 PC O&M - GEK 105059 CHG 06Alejandro J. Vigo50% (2)

- Course Catalog: SectionsDocument54 pagesCourse Catalog: SectionsJlkm BnjlkmNo ratings yet

- GT Gas Fuel and Air FlowDocument38 pagesGT Gas Fuel and Air FlowhinaNo ratings yet

- Basic GT EngineDocument22 pagesBasic GT EngineabuhurairamunirNo ratings yet

- Aerosila NPP JSC: Gas Turbine Power PlantsDocument30 pagesAerosila NPP JSC: Gas Turbine Power PlantsSatish Babu Garikapati100% (2)

- GTX100 - ABB's New 43-MW Advanced Gas Turbine: The ABB Review Web SiteDocument1 pageGTX100 - ABB's New 43-MW Advanced Gas Turbine: The ABB Review Web SiteMohammad BahreiniNo ratings yet

- Gas Turbine Engines Characteristics and Performance Combustion ChamberDocument2 pagesGas Turbine Engines Characteristics and Performance Combustion ChamberNicolas Guatibonza LNo ratings yet

- 2017 Gps Product CatalogDocument60 pages2017 Gps Product CatalogAzhar1109100% (1)

- LM6000 PC Time Limited ComponentsDocument7 pagesLM6000 PC Time Limited ComponentsmstaszelNo ratings yet

- Gas Turbines Siemens InteractiveDocument22 pagesGas Turbines Siemens InteractiveBony DiazgNo ratings yet

- Gas Turbine CombustionDocument9 pagesGas Turbine Combustionvarun kumarNo ratings yet

- List of Illustrations: Lm6000 PD Gek 105061 Ge Industrial Aeroderivative Gas TurbinesDocument4 pagesList of Illustrations: Lm6000 PD Gek 105061 Ge Industrial Aeroderivative Gas TurbinesJHONNATTAN RODRIGUEZNo ratings yet

- Ge Mid Idm 6000 1.Lm6000 PerformanceDocument10 pagesGe Mid Idm 6000 1.Lm6000 PerformanceChristopher HamptonNo ratings yet

- APA DOC No. 2014 PDFDocument67 pagesAPA DOC No. 2014 PDFThanapaet RittirutNo ratings yet

- Ger 3658d Speedtronic Mark V Gas Turbine Control System PDFDocument19 pagesGer 3658d Speedtronic Mark V Gas Turbine Control System PDFyos100% (1)

- RussiaPower 2012 Moscow SGT5-4000F Low Ambient Temperature Conditions Siemens Slad.Document11 pagesRussiaPower 2012 Moscow SGT5-4000F Low Ambient Temperature Conditions Siemens Slad.Uhrin ImreNo ratings yet

- Lm2500 DescripDocument2 pagesLm2500 DescripDenis Jimenez100% (1)

- Fact Sheet Variable Inlet Guide Vane PDFDocument1 pageFact Sheet Variable Inlet Guide Vane PDFemadNo ratings yet

- Applicability Guide PDFDocument2 pagesApplicability Guide PDFtriplbingaziNo ratings yet

- SGT800 Verification ReportDocument58 pagesSGT800 Verification ReportThanapaet RittirutNo ratings yet

- MANDocument6 pagesMANMadhana GopalNo ratings yet

- F646 CompleteSampleDocument36 pagesF646 CompleteSampleraj4523No ratings yet

- PB Thermal PowerDocument62 pagesPB Thermal PowerrakeshNo ratings yet

- Fulltext01 PDFDocument99 pagesFulltext01 PDFKelly FosterNo ratings yet

- Advantages of Aeroderivatives IAGT 206 - Final - PaperDocument15 pagesAdvantages of Aeroderivatives IAGT 206 - Final - PapermvanzijpNo ratings yet

- CPM - Ap - Lm6000-Ind-024 (1) 2009Document64 pagesCPM - Ap - Lm6000-Ind-024 (1) 2009Victor Nahun ReyesNo ratings yet

- Gas Turbine SpecificationDocument94 pagesGas Turbine SpecificationAbRoxNo ratings yet

- Siemens 1 GTX 100 TurbineDocument16 pagesSiemens 1 GTX 100 TurbinejparmarNo ratings yet

- Overview of SCF6 ExchangeDocument2 pagesOverview of SCF6 Exchangechdi100% (1)

- WTUI NewUserPrestentation PDFDocument35 pagesWTUI NewUserPrestentation PDFsppramNo ratings yet

- WTUI - NewUserPrestentation TM2500 GEDocument35 pagesWTUI - NewUserPrestentation TM2500 GEjoravicaNo ratings yet

- Gas Transport-Mallnow-Natural-Gas-Compressor-Station PDFDocument8 pagesGas Transport-Mallnow-Natural-Gas-Compressor-Station PDFJaswindersingh BhatiaNo ratings yet

- 3 - Gas Turbine Overview 8.09Document25 pages3 - Gas Turbine Overview 8.09Sujeet Kumar100% (1)

- Psib 20150212Document10 pagesPsib 20150212Léandre Ettekri NdriNo ratings yet

- Siemens' Medium Size Gas TurbineDocument25 pagesSiemens' Medium Size Gas Turbinenasirfahim100% (2)

- GTG 1636FPC PWFT4 50HzDocument24 pagesGTG 1636FPC PWFT4 50HzEmanuel CondeNo ratings yet

- TB Maintenance Concept PDFDocument16 pagesTB Maintenance Concept PDFhamedia83No ratings yet

- Thermal Tests of The 45MW SGT-800 Gas Turbine EquipmentDocument7 pagesThermal Tests of The 45MW SGT-800 Gas Turbine Equipmentbagusu_6No ratings yet

- Torques 3406 CaterpillarDocument3 pagesTorques 3406 CaterpillarJuan Dolla Jjau90% (48)

- Mach Oil BrochureDocument44 pagesMach Oil BrochureIntan DavidNo ratings yet

- Software: Measurlink Is An Easy-To-Use, Windows-Based Family of Quality Data Management Software ApplicationsDocument8 pagesSoftware: Measurlink Is An Easy-To-Use, Windows-Based Family of Quality Data Management Software ApplicationsBrandi DaleNo ratings yet

- Fenelon - Dialogues With The DeadDocument279 pagesFenelon - Dialogues With The DeadjuanojedamenaNo ratings yet

- Transport ModellingDocument37 pagesTransport ModellingRiza Atiq Abdullah Rahmat100% (6)

- Feedwater Heating SystemsDocument82 pagesFeedwater Heating SystemsJitendra ChaudhariNo ratings yet

- Lab No 8Document5 pagesLab No 8LO Ver JG100% (1)

- Tool PresettingDocument22 pagesTool PresettingAtulMaurya100% (1)

- Optimized Design of A Bagasse Dryer System For The Sugar IndustryDocument6 pagesOptimized Design of A Bagasse Dryer System For The Sugar IndustryTJ BolorNo ratings yet

- Notes On Foam From SFPE HandbookDocument10 pagesNotes On Foam From SFPE HandbookkdsessionsNo ratings yet

- CE5604 Term PaperDocument6 pagesCE5604 Term PaperCemre CaglarNo ratings yet

- Factors Affecting Beam StrengthDocument2 pagesFactors Affecting Beam StrengthkalpanaadhiNo ratings yet

- DTC 5618Document20 pagesDTC 5618Gajaram SutharNo ratings yet

- Negative Skin Friction Aaron Budge Minnesota State UniversityDocument46 pagesNegative Skin Friction Aaron Budge Minnesota State UniversityNguyễn Thành NhânNo ratings yet

- Patrick Bernard Resume 2018 ExecutiveDocument3 pagesPatrick Bernard Resume 2018 ExecutivePatrick BernardNo ratings yet

- Flowable-Fill Final 03-2006Document22 pagesFlowable-Fill Final 03-2006Hector Alberto Garcia LopezNo ratings yet

- Cabezas de Rotulas-RotulasDocument64 pagesCabezas de Rotulas-RotulasFRANCISCO100% (1)

- Changing Out The Injector Seals On A 2007 PJ Ford Ranger 3.0 TDCiDocument3 pagesChanging Out The Injector Seals On A 2007 PJ Ford Ranger 3.0 TDCiAgustinus D100% (3)

- Catalog07 PDFDocument13 pagesCatalog07 PDFdeig15050% (2)

- Datasheet Fuji F5018 F5020Document6 pagesDatasheet Fuji F5018 F5020StaryzgredNo ratings yet

- Reduced Vertical Separation Minimum - RVSM: IVAO HQ Training DepartmentDocument4 pagesReduced Vertical Separation Minimum - RVSM: IVAO HQ Training DepartmentjesusNo ratings yet

- Ford Fiesta Specifications: Exterior DimensionsDocument2 pagesFord Fiesta Specifications: Exterior DimensionsBuhuntuUhuNo ratings yet

- 1762 Um002 - en PDocument144 pages1762 Um002 - en PDavid LucioNo ratings yet

- HILTI Typical Plumbing ApplicationsDocument140 pagesHILTI Typical Plumbing ApplicationskuraimundNo ratings yet

- Drawings Phase IIDocument12 pagesDrawings Phase IIY Go GltdNo ratings yet

- Hydraulic Vehicle Lift ST List of Parts and Appendices Stertil B.V BDocument24 pagesHydraulic Vehicle Lift ST List of Parts and Appendices Stertil B.V BOvidiu PopaNo ratings yet

- Heidegger Midterm DissDocument72 pagesHeidegger Midterm Dissrhoda mae a. paquinolNo ratings yet

- Company Profile Metro GoldrichDocument29 pagesCompany Profile Metro GoldrichBids and Awards CommitteeNo ratings yet

- Novel PWM Inverter Strategy For A Inverter Open End Winding Induction MotorDocument7 pagesNovel PWM Inverter Strategy For A Inverter Open End Winding Induction MotorGanesh ChallaNo ratings yet

- Duty Engineer: Grand Mercure & Ibis Yogyakarta Adi SuciptoDocument1 pageDuty Engineer: Grand Mercure & Ibis Yogyakarta Adi Suciptoali maulana yuthiaNo ratings yet