Professional Documents

Culture Documents

Model No:: Optical Alignment Gauge

Uploaded by

Uchenna AkintayoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Model No:: Optical Alignment Gauge

Uploaded by

Uchenna AkintayoCopyright:

Available Formats

INSTRUCTIONS FOR:

OPTICAL ALIGNMENT GAUGE

Thank you for purchasing a Sealey product. Manufactured to a high standard this product will, if used according to these instructions and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

Model No:

GA40

1.1

F ! ! ! F ! % % % F

GENERAL SAFETY WARNING! Ensure Health & Safety, local authority, and general workshop practice regulations are adhered to when using this equipment. Maintain the gauge in good condition (use an authorised service agent). Replace or repair damaged parts. Use genuine parts only. Unathorised parts may be dangerous and will invalidate the warranty. Locate gauge in a suitable working area, keep area clean and tidy and free from unrelated materials. WARNING! Use gauge on level and solid ground. Keep the gauge clean to ensure accurate performance. DO NOT use outside in damp or wet weather conditions. DO NOT allow untrained persons to operate the gauge. DO NOT leave the gauge unattended. WARNING! When setting front end alignment on commercial vehicles never make adjustments to drop arms or interconnecting links. Doing so could result in serious tyre, wheel and steering problems. ! Any alignment changes deemed necessary as a result of using this equipment must be made strictly in accordance with the vehicle manufacturers recommendations.

1.

SAFETY INSTRUCTIONS

Steel and cast aluminium construction. Measures toe-in and toe-out by contact with wheel rims and using optical sight to align markers. Works on practically all cars and light commercial vehicles with rim diameters between 200mm and 600mm.

2.

INTRODUCTION & SPECIFICATION

Fig. 1.

Fig. 2.

3.

3.1.

ASSEMBLY & CALIBRATION

ASSEMBLY. Your gauge has been supplied in flat pack form for quick and easy assembly.

3.1.1 Take each ready assembled side frame in turn and slide on the balance leg (fig.1.8). Slide the balance leg back onto the alignment peg and tighten the thumbscrew. 3.1.3 Place the periscope unit onto the tube and slide it to the left until it stops against the end of the tube. Tighten the two thumb screws on the back of the unit to secure it to the main bar. Attach the target plate (fig. 1.4.) to the periscope using the screws supplied. 3.1.4 Slip the mirror unit (fig. 1.2.) onto the main bar of the other frame and tighten the thumb screw to secure it. 3.1.5 Attach a contact bar (fig. 1.1.) to each of the upright arms. Firstly loosen the thumb screw on the contact bar holder and place through the upright arm. Slide the square portion of a contact bar through the holder, tighten the thumbscrew to secure. 3.1.6 Each contact bar may be fitted either to the left or the right of its respective support arm. This is to allow the gauge to handle all tyres on 8 to 24 diameter rims and to allow close contact when required e.g. when in use on a vehicle lift. 3.2.

3.1.2 Place the two frames opposite each other with each extended bar portion positioned to the right hand side. The frame nearest to you is the one to which the periscope (fig. 1.3.) unit should be attached.

CALIBRATION. The gauge will be calibrated each time it is used as part of the process of checking wheel alignment. Calibration will be done with the two halves of the gauge facing each other with the contact bars touching.

GA40 - 1 - 080304

3.2.1 3.2.2 3.2.3. 3.2.4.

Stand the complete gauge on a level, clean floor with contact bars touching as in fig. 1.

Sighting through the periscope move the pointer (fig. 1.5.) until the image reflects the hair line in the centre of the triangle between the vertical lines as in (fig. 2.). The pointer should now be at zero on the graduated scale (fig. 1.6.). If not slacken the two wing nuts holding the scale, adjust the scale to zero and tighten the wing nuts. The gauge is now ready for use.

Adjust the mirror and periscope until the reflection of the target plate (fig. 1.4.) is visible through the periscope.

4.

NOTE: 4.1. 4.2.

OPERATING THE GAUGE - CARS & VANS

Ensure that the vehicle is on a smooth level surface with the wheels pointing straight ahead. Do not back the vehicle into position. CARS & VANS. Prior to use check vehicle manufacturers recommendations relating to loading. Check that tyre pressures are correct.

4.3. 4.4. 4.5. 4.6. 4.7.

Position the periscope unit against the offside front wheel ( see fig. 3 ) and adjust the height of the contact bars by fixing them in which ever of the five preset positions is closest to a horizontal line through the centre of the wheel. At the same time adjust the side to side positioning of the contact bars so that they touch the sidewall of the tyre either side of the rim. Position the tips of the contact bars to touch the centre of the sidewalls at the greatest point of curvature. Avoid any ribs or raised lettering on the tyre side wall. The contact bars of the mirror unit should now be set up to the same height and width as Fig. 3. the periscope unit. To do this remove the periscope unit from its position on the tyre and place it in front of the mirror unit to make the necessary adjustments. When the contact bar arrangements on both units match, proceed to calibrate the gauge. ( See calibration set - up 3.2.1 to 3.2.4. ) Set up both units as in (fig. 4.). Looking through the periscope adjust the pointer until the hair line bisects the triangle between the two vertical lines.(fig. 2.) The amount of toe-in or toe-out can now be read from the scale (fig. 6.) in degrees and minutes. Fig. 4.

To allow for any possible lateral run out of the wheels and tyres the vehicle should be moved forward until the wheels have rotated half a revolution (1800) and the operation repeated. If a different reading is obtained the two results should be averaged.

4.8.

The calculator (fig. 1.7.) allows conversion of the angle obtained to a linear measurement in millimetres or fractions of an inch (Linear toe in or toe out). Set the large arrow on the top dial to the specified width on the bottom dial. The specified width may either be the nominal wheel diameter or a dimension equivalent to a diameter to the tyre sidewall e.g. mid sidewall (or in accordance with the measuring position figures in the appropriate workshop manual or handbook). Read the linear toe reading from the bottom dial, opposite the angular toe reading from the top dial. Any alignment necessary must be made strictly in accordance with the vehicle manufacturers recommendations.

5.

OPERATING THE GAUGE - COMMERCIAL VEHICLES

NOTE:

5.1

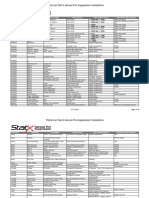

When setting front end alignment, never make adjustments to drop arms or interconnecting links. Doing so could result in serious tyre, wheel and steering problems. Single Steering Axle : Procedure is the same as for cars and vans. Twin Steering Axles : When checking wheel alignment on twin steering vehicles you will also need to use the optional equipment package comprising larger mirror and frame. Order Item: GA43

COMMERCIAL VEHICLES. The gauge is also designed to check wheel alignment on two, three or four axle vehicles. Before using the gauge, the vehicle manufacturers recommendations in respect of loading, tyre pressures etc must be complied with. In the absence of definite instructions, it is normal practice to check commercial vehicles when fully laden and with all wheels parallel.

5.2

Fig. 5.

GA40 - 1 - 080304

5.2.1 Check alignment of the two pairs of front axle wheels ( A & B in fig.5 ) in the same way as you would for cars including the calibration procedure. Adjust if required to the manufacturers recommendations or set to parallel.

5.2.2 Replace normal mirror unit with the larger mirror unit. Place this unit against the last axle ( Y in fig.5 ) with the mirror orientated towards the front of the vehicle. 5.2.3 Stand the periscope unit on a level floor approximately 1metre ahead of the front bumper with the target plate facing the mirror. This is the set up shown in fig.5. With the pointer at zero, move the periscope unit until the hair line bisects the triangle as in fig. 2. 5.2.4 Without moving the periscope unit, transfer the mirror unit to the next axle ( X in fig.5 ) and check the reading. This should be identical to axle Y. If not then the rear axles are not parallel and will require adjustment. 5.2.5 Position mirror unit at axle A and check reading. If the original setting was parallel, the hair line should be central on the target plate. For a toe in setting, move the pointer until it shows half the amount of the recommended toe-in ( e.g. a 20 movement for a 40 toe-in ). The hair line should now be in the central position on the target plate. If not, gently turn the steering wheel, keeping the contact bars positioned on the rim or the tyre sidewall until the hair line is central. Axle A is now correctly aligned with the rear axles.

5.2.6 Move the mirror unit to axle B and note the reading in comparison to axle A.

5.2.7 If the reading is different the inter-axle adjuster will need adjustment, recheck from step 5.2.2 onwards.

5.2.8 To compensate for run-out in tyres and/or wheels roll the vehicle forward until the wheels have rotated half a revolution (1800). Repeat steps 5.2.2 to 5.2.6. Should the results vary, average the figures obtained. Adjust the connecting rods as necessary until the hair line appears central.

Optional equipment consisting of a larger size mirror and a target plate enlargement frame. Order Item: GA43

NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice. IMPORTANT: No liability is accepted for incorrect use of this product. WARRANTY: Guarantee is 12 months from purchase date, proof of which will be required for any claim. INFORMATION: For a copy of our latest catalogue and promotions call us on 01284 757525 and leave your full name and address, including postcode.

Sole UK Distributor, Sealey Group, Bury St. Edmunds, Suffolk.

01284 757500

01284 703534

sales@sealey.co.uk

9A>

www.sealey.co.uk

GA40 - 1 - 080304

You might also like

- VW Transporter T4 ( Diesel - 2000-2004) Workshop Manual: Owners Edition (Owners' Workshop Manuals)From EverandVW Transporter T4 ( Diesel - 2000-2004) Workshop Manual: Owners Edition (Owners' Workshop Manuals)Rating: 1 out of 5 stars1/5 (3)

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreFrom EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreRating: 4.5 out of 5 stars4.5/5 (11)

- Chevy Differentials: How to Rebuild the 10- and 12-BoltFrom EverandChevy Differentials: How to Rebuild the 10- and 12-BoltRating: 5 out of 5 stars5/5 (8)

- John Bean Mod. 8.6-8.7Document36 pagesJohn Bean Mod. 8.6-8.7dionisio emilio reyes jimenezNo ratings yet

- Wheel Alignment Theory Operation PDFDocument5 pagesWheel Alignment Theory Operation PDFOskars ŠtālsNo ratings yet

- Vemco 612 User's ManualDocument25 pagesVemco 612 User's ManualRobert Cannavino100% (1)

- 978 Easy Rider Bike RackDocument3 pages978 Easy Rider Bike RackDaniel CampbellNo ratings yet

- Tracked Vehicles Steering MechanismDocument3 pagesTracked Vehicles Steering MechanismSiva ShankerNo ratings yet

- 1st Central Claim FormDocument1 page1st Central Claim FormJim NascoNo ratings yet

- ECE R100 Lithium Battery TestingDocument2 pagesECE R100 Lithium Battery TestingDetectives en Madrid Grupo ArgaNo ratings yet

- TT Bearing Insp Proc v3Document7 pagesTT Bearing Insp Proc v3Rino AdityaNo ratings yet

- Shaft Alignment - Rim and Face MethodDocument6 pagesShaft Alignment - Rim and Face MethodWajdi MansourNo ratings yet

- Alignment of TwoDocument15 pagesAlignment of TwoquintanacalzadillasjaimeNo ratings yet

- Tms700e13 SM Ctrl512-01 SpanishDocument390 pagesTms700e13 SM Ctrl512-01 Spanishjose veraNo ratings yet

- Centrifugal Comp. Alignment-PDocument7 pagesCentrifugal Comp. Alignment-PvinothenergyNo ratings yet

- Engine Alignment DetailsDocument13 pagesEngine Alignment DetailsNaufal HilmiNo ratings yet

- Tms700e13 SM Ctrl512 01 Spanish With Alignment SuppDocument390 pagesTms700e13 SM Ctrl512 01 Spanish With Alignment SuppVictor VegaNo ratings yet

- TMS9000 2 SM CTRL649 01 SPANISH With Alignment Supp Light PDFDocument414 pagesTMS9000 2 SM CTRL649 01 SPANISH With Alignment Supp Light PDFJhonnatan Alexis roaNo ratings yet

- Shaft Alignment: Your Photo HereDocument75 pagesShaft Alignment: Your Photo HereMahmoud Elghandour0% (1)

- Spiral Bevel AssyDocument3 pagesSpiral Bevel AssyvijaykumarnNo ratings yet

- Ford V8 4C 1932Document89 pagesFord V8 4C 1932rukford1No ratings yet

- Manual: STD: Is-5120: Series: VCPDocument21 pagesManual: STD: Is-5120: Series: VCPKaushik ChakrabortyNo ratings yet

- Factors Influencing Alignment ProcedureDocument23 pagesFactors Influencing Alignment ProcedureClint Garcia100% (1)

- Wheel Alignment - Theory and OperationDocument4 pagesWheel Alignment - Theory and OperationKai Chieh HsuNo ratings yet

- Anti-Roll Bar Installation Part # XSB005, XSB011Document2 pagesAnti-Roll Bar Installation Part # XSB005, XSB011Jose Francisco GuzmánNo ratings yet

- Alignment: Diagnosis, ServiceDocument33 pagesAlignment: Diagnosis, Service2791957No ratings yet

- Helical Inline Geared Motors Manual PDFDocument24 pagesHelical Inline Geared Motors Manual PDFHEMANTKHERA0% (2)

- 8013 Instruction Manual For Camflex and VarimaxDocument10 pages8013 Instruction Manual For Camflex and Varimaxtoche33No ratings yet

- Para-Flex Couplings Dodge: Installation Instructions Manual ForDocument4 pagesPara-Flex Couplings Dodge: Installation Instructions Manual ForAdrian CantaragiuNo ratings yet

- Dial Indicator Alignment BasicsDocument24 pagesDial Indicator Alignment Basicskiki270977100% (2)

- RevTek Lift KitDocument5 pagesRevTek Lift KitJim EberhartNo ratings yet

- FT2300K Instruction SheetDocument5 pagesFT2300K Instruction Sheetjesi_dNo ratings yet

- Wheel Alignment Theory/Operation Article TextDocument4 pagesWheel Alignment Theory/Operation Article TextGatis IvbulisNo ratings yet

- Mounting The Dial Indicator FixturesDocument10 pagesMounting The Dial Indicator Fixturesmohamed elejmiNo ratings yet

- Effect of Heat On AlignmentDocument11 pagesEffect of Heat On Alignmentvinothenergy100% (1)

- Dodge DGF Gear Couplings: Instruction ManualDocument2 pagesDodge DGF Gear Couplings: Instruction ManualTony_Black99No ratings yet

- Warning: Complete Gearbox With MotorDocument35 pagesWarning: Complete Gearbox With MotorSinaNo ratings yet

- Wheel Alignment Theory OperationDocument5 pagesWheel Alignment Theory OperationToua YajNo ratings yet

- Imi Steering 2Document3 pagesImi Steering 2Rob RoddosNo ratings yet

- Manual El Dyn1440g 2017Document51 pagesManual El Dyn1440g 2017ppalomino171No ratings yet

- Torque Screwdriver RepairDocument16 pagesTorque Screwdriver RepairFrancisco Ros AlvaradoNo ratings yet

- Rim & Face Alignment MethodDocument9 pagesRim & Face Alignment Methoddg_cd7340No ratings yet

- TMH-6 - ST9Document14 pagesTMH-6 - ST9ATHOLSCHWARZNo ratings yet

- Field Application Note: Reverse Dial Indicator Alignment RdiaDocument7 pagesField Application Note: Reverse Dial Indicator Alignment RdiaYasir BhattiNo ratings yet

- Rim and Face AlignmentDocument8 pagesRim and Face Alignmentnazir305No ratings yet

- Lab 4 Wheel Alignment REV BDocument7 pagesLab 4 Wheel Alignment REV BsyahfendyNo ratings yet

- C12 Kingpin-Camber-Caster InstructionDocument3 pagesC12 Kingpin-Camber-Caster InstructionIbrahim PagbelemNo ratings yet

- Rough Country Kit Lift 633XN2Document8 pagesRough Country Kit Lift 633XN2veabreuNo ratings yet

- Erection Procedure SCRDocument23 pagesErection Procedure SCRvskreddy90% (10)

- Calibre Valvulas MP8 s34-5116Document20 pagesCalibre Valvulas MP8 s34-5116Jose AGNo ratings yet

- P+S SKATER Mini ManualDocument17 pagesP+S SKATER Mini ManualElectra/Off TraxNo ratings yet

- (OTO-HUI - Com) Rack and Pinion in The Freightliner CascadiasDocument13 pages(OTO-HUI - Com) Rack and Pinion in The Freightliner Cascadiaseng_ebrahim_2000No ratings yet

- Pumps Processes 0302Document3 pagesPumps Processes 0302Guru Raja Ragavendran Nagarajan100% (1)

- SPANCO PFseries Gantry Instparts Manual 103 0003Document12 pagesSPANCO PFseries Gantry Instparts Manual 103 0003raulcont786No ratings yet

- Spicer Automatic Slack Adjuster PDFDocument16 pagesSpicer Automatic Slack Adjuster PDFJorge Castillo HdzNo ratings yet

- Thomas Thomas Thomas Thomas: Type Cmr/AmrDocument4 pagesThomas Thomas Thomas Thomas: Type Cmr/AmrGustavo Espinosa MartinezNo ratings yet

- Alignment HandoutDocument34 pagesAlignment HandoutAbdul ShanawasNo ratings yet

- Reverse Dial Indicator MethodDocument14 pagesReverse Dial Indicator MethodvinothenergyNo ratings yet

- SB G13-005 TT Bearing Movement PDFDocument7 pagesSB G13-005 TT Bearing Movement PDFDeepak MishraNo ratings yet

- Click Wrench RepairDocument31 pagesClick Wrench RepairTu PhamNo ratings yet

- 6-1 Explanation of Cold AlignmentDocument18 pages6-1 Explanation of Cold AlignmentTuhoyoTarahao50% (2)

- VW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004From EverandVW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004Rating: 3 out of 5 stars3/5 (1)

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationFrom EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo ratings yet

- 2014 Kia Sorento 37088Document508 pages2014 Kia Sorento 37088Anderson CruzNo ratings yet

- Engines Deutz TCD 2013 4v IntroductionDocument22 pagesEngines Deutz TCD 2013 4v Introductionctorres_50574650% (6)

- 10 Ch7 DepotDocument17 pages10 Ch7 DepotSOMU_61No ratings yet

- People vs. LagatDocument17 pagesPeople vs. LagatYhelene Marie Avenido-AbiasNo ratings yet

- Operation Manual: User's GuideDocument161 pagesOperation Manual: User's GuideKomen KimtaiNo ratings yet

- AV Policy Guidance PDFDocument116 pagesAV Policy Guidance PDFTechCrunch100% (1)

- Truck FC4J ServiceDocument646 pagesTruck FC4J ServiceAndres JuarezNo ratings yet

- Vehicle Gen27 PDFDocument46 pagesVehicle Gen27 PDFMOHAN KUMARNo ratings yet

- TM 9-816 AUTOCAR U 7144Document280 pagesTM 9-816 AUTOCAR U 7144Advocate100% (1)

- Continental CorporateDocument25 pagesContinental Corporatepranjalbaruah8No ratings yet

- Toyota 8FDF 18 20 25 8FGF18Document382 pagesToyota 8FDF 18 20 25 8FGF18SARAMQR100% (4)

- Champion Bus Owner's ManualDocument54 pagesChampion Bus Owner's ManualStealNo ratings yet

- IntouroDocument16 pagesIntouroPhilippine Bus Enthusiasts Society100% (1)

- Construction Safety Manual PDFDocument68 pagesConstruction Safety Manual PDFMonica AstridNo ratings yet

- Vehicle Inspection ManualDocument50 pagesVehicle Inspection ManualA.t. BelagamaNo ratings yet

- Mercedes Bus - EcitaroDocument16 pagesMercedes Bus - EcitaroVasile ContiuNo ratings yet

- OM - Sport - BSIV - Rev 03 - SBT PDFDocument67 pagesOM - Sport - BSIV - Rev 03 - SBT PDFHasen BashaNo ratings yet

- MOW 312 - Semester Test 2 (2020) MemoDocument5 pagesMOW 312 - Semester Test 2 (2020) MemoWillem van der WaltNo ratings yet

- Electric VehiclesDocument135 pagesElectric Vehiclessaty16100% (2)

- Introduction & Classification of Automobile EngineeringDocument52 pagesIntroduction & Classification of Automobile Engineeringravi100% (1)

- Uploads DLM Uploads 2019 04 Stat-X-Installation-References-2020Document18 pagesUploads DLM Uploads 2019 04 Stat-X-Installation-References-2020Sher SinghNo ratings yet

- Case Study of ToyotaDocument22 pagesCase Study of ToyotaRohit Shirude100% (2)

- Tata Xenon ManualDocument132 pagesTata Xenon Manualxtemp100% (10)

- Dev of TL-5 Concrete BarrierDocument368 pagesDev of TL-5 Concrete Barrierofmedina100% (1)

- Fuel Pump General Installation Instructions and PrecautionsDocument1 pageFuel Pump General Installation Instructions and PrecautionsDavid HickeyNo ratings yet

- Component Codes Component TitlesDocument6 pagesComponent Codes Component TitlesMelinte Lucian GeorgeNo ratings yet

![VW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004](https://imgv2-2-f.scribdassets.com/img/word_document/282876773/149x198/5fb74bd6e1/1675169638?v=1)