Professional Documents

Culture Documents

AC001 Carrier 30HWC035 Chiller Wiring-30HWA

Uploaded by

Celso OtalOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AC001 Carrier 30HWC035 Chiller Wiring-30HWA

Uploaded by

Celso OtalCopyright:

Available Formats

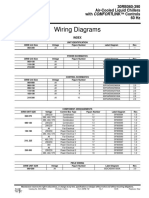

30HK040-060 30HL050, 060, 30HW018-040 Packaged Hermetic Reciprocating Liquid Chillers 50/60 Hz

Wiring Diagrams

DIAGRAM INDEX

UNIT 30 HK, HL HK, HL HK, HL HK, HL HW HW HW HW VOLTAGE ALL ALL ALL ALL ALL ALL ALL ALL DIAGRAM TYPE Component Arrangement Power Schematic Control Schematic Field Wiring Diagram Component Arrangement Power Schematic Control Schematic Field Wiring Diagram FIGURE NO. 1 2 3 4 5 6 7 8 LABEL DIAGRAM NO. 30HK510003 30HK510003 30HK510002 30HK510064 30HW500231 30HW500221 30HW500221 30HW500168 SERIAL NO. EFFECTIVE 3398F 3398F 3398F 3398F 2896F 2896F 2896F 2896F

SAFETY CONSIDERATIONS

Installing, starting up, and servicing this equipment can be hazardous due to system pressures, electrical components, and equipment location. Only trained, qualified installers and service mechanics should install, start up, and service this equipment. Untrained personnel can perform basic maintenance functions such as cleaning coils. All other operations should be performed by trained personnel. When working on the equipment, observe precautions in the literature and on tags, stickers, and labels attached to the equipment. Follow all safety codes. Wear safety glasses and work gloves. Use care in handling, rigging, and setting bulky equipment. ELECTRIC SHOCK HAZARD Open all remote disconnects before servicing this equipment. Use only designated overload protection.

SEQUENCE OF OPERATION

The 30H units have a multiple-step temperature controller, factory set to maintain capacity control through leaving chilled fluid temperature. The controller has 4 capacity steps. All 30HK, HL units have 4 capacity steps as standard. The 30HW018 and 028-040 units have 3 steps as standard, with a fourth step available as a factory-installed option. The 30HW025 units have 2 steps of capacity as standard with a third step available as a factory-installed option. All units have electric solenoid unloaders. At initial start-up, assume that all safety devices are satisfied and there is a call for cooling. 30HK, HL Units Close the compressor circuit breaker and turn the ON-OFF switch to ON position. In approximately 5 minutes, the lead compressor starts and the unloaders are energized (compressor unloads when compressor unloader solenoid is energized). On 30HL units, the liquid line solenoid valve will remain closed for the first 10 seconds of compressor operation. The low-pressure and oil pressure switches are bypassed for 2 minutes. At the end of the 2-minute bypass period, the low-pressure and oil pressure switches are active in the control circuit. Approximately 30 seconds (high setting) or 3 minutes (low setting) later, depending on the sample rate setting, the lag compressor starts and the unloaders are energized (compressor unloads when compressor unloader solenoid is energized). On 30HL units, the liquid line solenoid valve will remain closed for the first 10 seconds of compressor operation. The lowpressure and oil-pressure switches are bypassed for 2 minutes. At the end of the 2-minute bypass period, the low-pressure and oil-pressure switches are active in the control circuit. Approximately 30 seconds (high setting) or 3 minutes (low setting later, depending on the sample rate setting, the lead compressor is loaded (unloader solenoids deenergized).

SAFETY FEATURES

1. On resumption of power after a power failure, the unit will recycle automatically, bringing on the compressor after a period of 6 seconds to 5 minutes has elapsed. 2. To reset the compressor overtemperature protection, high-pressure switch circuit, low-pressure switch circuit, and oil pressure switch (if equipped), turn the ON-OFF switch to OFF, then back to ON position. IMPORTANT: If a compressor shuts down because the overtemperature protector opens, check for refrigerant leaks, proper unit voltage, and sufficient fluid flow before resetting. 3. The specially calibrated circuit breakers are designed and selected for hermetic refrigeration-duty compressor motors.

Book 2 Tab 5c

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations. PC 903 Catalog No. 533-015 Printed in U.S.A. Form 30H-2W Pg 1 7-99 Replaces:30H-1W

When the load is satisfied and the leaving fluid temperature falls below the set point, the last stage activated is dropped immediately. If the leaving fluid temperature still remains below the set point, then the control drops an additional stage every 30 (high setting) or 180 (low setting) seconds, depending on the sample rate setting. Once the compressor is shut-off, the control system prevents the compressor from restarting within 5 minutes of when it was last shut down. Once this period has elapsed and the leaving fluid temperature rises above the set point, the compressor will start within 5 seconds. If the unit is equipped with field-installed hot gas bypass, the hot gas bypass valve opens only when stage 1 is active. If the unit trips out on high pressure, low pressure, ground current (accessory), or low oil pressure, the control module locks the unit off and must be manually reset (turn the ONOFF switch to OFF and then back to ON position). If the unit trips out on low fluid temperature, chilled fluid flow switch or chilled fluid pump switch, it restarts automatically when the condition is corrected. 30HW Units Close the compressor circuit breaker and move ON-OFF switch to ON position. The switch should light up. In approximately 3 seconds, the compressor starts unloaded. For 2 minutes the low-pressure switch is bypassed and the unloaders are energized (compressor unloads when compressor

unloader solenoid is energized). At end of 2-minute bypass period, the low-pressure switch activates in the control circuit and the temperature controller regulates the capacity steps based on leaving cooler fluid temperature, and set point and deadband settings on the temperature controller. If system load drops to the point where unit is fully unloaded and the fluid temperature is below the lower deadband limit, the compressor shuts off and is not able to restart until the 5minute anti-short cycle has expired. If during normal operation, the fluid temperature rises above the upper deadband limit, the temperature controller adds a step of capacity (assuming a step is left to be added). On condenserless units (30HWA), or on fluid-cooled units (30HWB, C, and S) equipped with the accessory oil safety switch, the control module provides a 2-minute bypass of the oil safety switch. If the unit is equipped with the hot gas bypass option, the hot gas bypass valve closes before unloaders are deactivated If the unit trips out on high or low pressure, ground current (accessory), or low oil pressure, the control module locks the unit off and must be manually reset (by turning the ON-OFF switch to OFF, then back to ON position). If the unit trips out on low fluid temperature, chilled fluid flow switch, or chilled fluid pump switch, it restarts automatically when the condition is corrected.

LEGEND

A C CB CH CM COM COMP COTP CR CMR CWFS CWP D DLS EQUIP GCS GND HGB HGS HPS ILC J L LLSV LPS N Alarm Contactor, Compressor Circuit Breaker Crankcase Heater Control Module Common Compressor Compressor Overtemperature Protection Control Relay Control Module Relay Chilled Water (Fluid) Flow Switch Chilled Water (Fluid) Pump Interlock Discharge Demand Limit Switch Equipment Ground Current Sensor Ground Hot Gas Bypass Hot Gas Solenoid High Pressure Switch Condenser Interlock Jumper Light Liquid Line Solenoid Valve Low-Pressure Switch Neutral NC Normally Closed NEUT Neutral Wire Lug NO Normally Open OPS Oil-Pressure Switch PL Plug R Relay SEC Seconds SW Switch T Thermistor TB Terminal Block TC Temperature Control TDR Time Delay Relay THERM Thermistor TOR Toroid TRAN Transformer TSW Thermistor Switch U Unloader Terminal Block Terminal (unmarked) Terminal (marked) Splice Factory Wiring Field Wiring Accessory or Option Wiring To indicate Common Potential Only, Not to Represent Wiring

NOTES

1. Factory wiring is in accordance with the National Electrical Code (U.S.A.). Any field modifications or additions must be in compliance with all applicable codes. 2. Field-installed power wires must be rated 75 C minimum. 3. All circuit breaker must-trip amps are equal to or less than 156% rated load amps. 4. Schematic (Fig. 3 and 7 shows controller in fully loaded position. Compressor unloads when compressor unloader solenoid is energized. 5. Oil pressure safety switch is standard on 30HL and 30HWA and 30HW brine duty units only. 6. All field interlock contacts must have a minimum rating of 2 amps at 24 vac sealed. See field interlock wiring. 7. Compressors are thermally protected. Three-phase motors are protected against primary single-phasing conditions. 8. On 30HW units, connect yellow wire to (H2) for 208, 346, and 575 v; to (H3) for 230, 380, and 400 v; to (H4) for 460 v. 9. When installing GSCs CWPS, CWP, DLS or remote ON/OFF switch factory jumpers must be removed, refer to unit label diagram for more detail.

Fig. 1 Component Arrangement; 30HK,HL Units

4 Fig. 2 Power Schematic; 30HK,HL

Fig. 3 Control Schematic; 30HK,HL Units

COOLER LEAVING WATER

Fig. 3 Control Schematic; 30HK,HL Units (cont)

FIELD POWER WIRING, 50 Hz UNITS w/ACCESSORY TRANSFORMER

FIELD CONTROL WIRING, 50 Hz UNITS

FIELD ACCESSORY WIRING

Fig. 4 Field Wiring Diagram; 30HK,HL Units

Fig. 5 Component Arrangement; 30HW Units

Fig. 6 Power Schematic; 30HW Units

Fig. 7 Control Schematic; 30HW Units

10

11 Fig. 8 Control Schematic; 30HW Units

Copyright 1999 Carrier Corporation Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations. PC 903 Catalog No. 533-015 Printed in U.S.A. Form 30H-2W Pg 12 7-99 Replaces:30H-1W Book 2 Tab 5c

You might also like

- SM6 - 24 - CT CatalogueDocument20 pagesSM6 - 24 - CT Catalogueluutrudulieu3100% (2)

- Chiller CGAH 060 - 1Document1 pageChiller CGAH 060 - 1dotronganhtuan100% (1)

- SM6 Catalog2006 enDocument92 pagesSM6 Catalog2006 enwilliam huaytaNo ratings yet

- MVSSS Gate Driver CardDocument1 pageMVSSS Gate Driver CardMohammad yasinNo ratings yet

- 30rb 1wDocument24 pages30rb 1wmlozadabastNo ratings yet

- Honeywell ml7420 User ManualDocument8 pagesHoneywell ml7420 User ManualLaurensius ArdiNo ratings yet

- How To Use Test PenDocument2 pagesHow To Use Test PenrkhayrenNo ratings yet

- SM SM830206-00Document134 pagesSM SM830206-00stiven lopezNo ratings yet

- Controls Operation and TroubleshootingDocument138 pagesControls Operation and TroubleshootingAnup SurendranNo ratings yet

- EASY PCB TROUBLESHOOTINGDocument14 pagesEASY PCB TROUBLESHOOTINGSteven J. SelcukNo ratings yet

- Aby 30 LbagDocument24 pagesAby 30 LbagbahmanNo ratings yet

- PIDcontrollers2007 VDocument5 pagesPIDcontrollers2007 VPardeep KhosaNo ratings yet

- ABB UniGear MV SwitchgearsDocument70 pagesABB UniGear MV SwitchgearsShung Tak ChanNo ratings yet

- MODELS YCWS0100, 0120, 0140, 0180, 0200, 0220 and YCWS0240 SC Remote Condenser Models Ycrs0100, 0120, 0140, 0180, 0200, 0220 and YCRS0240 SCDocument52 pagesMODELS YCWS0100, 0120, 0140, 0180, 0200, 0220 and YCWS0240 SC Remote Condenser Models Ycrs0100, 0120, 0140, 0180, 0200, 0220 and YCRS0240 SCHectorFalconLlenderrozos0% (1)

- Parts Manual: Date Group Fig. 4Document20 pagesParts Manual: Date Group Fig. 4ruslanNo ratings yet

- ENGINEERING LAB REPORT ON FORWARD REVERSE STARTER MOTOR CONTROLDocument6 pagesENGINEERING LAB REPORT ON FORWARD REVERSE STARTER MOTOR CONTROLTay Poh JingNo ratings yet

- CVGF Svu02a E4 Iom Ch530Document88 pagesCVGF Svu02a E4 Iom Ch530Emerson PenaforteNo ratings yet

- McQuay Controller HandbookDocument70 pagesMcQuay Controller HandbookAna Gil Pinto Brás100% (2)

- Technical YLCSDocument34 pagesTechnical YLCSnairam2003No ratings yet

- Water Heater SelectionDocument57 pagesWater Heater SelectionEric0% (1)

- Product Drawing: MillenniumDocument13 pagesProduct Drawing: Millenniumjuan991No ratings yet

- 160 80-PW3Document5 pages160 80-PW3juan991No ratings yet

- 30gtn 4tDocument104 pages30gtn 4tMichel TaniousNo ratings yet

- Trane Zn523Document48 pagesTrane Zn523Zgripcescu AndreiNo ratings yet

- Mitsubishi Products 2022 Price ListDocument116 pagesMitsubishi Products 2022 Price Listahmed HOSNYNo ratings yet

- FRENICDocument136 pagesFRENICkaporaluNo ratings yet

- MC 35E / MC 45 / MC 65 / MC 90: InnovensDocument12 pagesMC 35E / MC 45 / MC 65 / MC 90: Innovenskoscoloi365No ratings yet

- D2-250-1 Key Features: DL250-1 CPUDocument3 pagesD2-250-1 Key Features: DL250-1 CPUVladimir Aliro Quezada CidNo ratings yet

- 30XA Product Data PDFDocument36 pages30XA Product Data PDFanoopkumar1231150100% (2)

- Electronic Expansion Valves Type TQPHTQDocument2 pagesElectronic Expansion Valves Type TQPHTQvickersNo ratings yet

- 3RW33460EC34 Datasheet enDocument1 page3RW33460EC34 Datasheet enFelipe FrancoNo ratings yet

- LMI Liquitron DC4500 Series Conductivity Controller ManualDocument43 pagesLMI Liquitron DC4500 Series Conductivity Controller Manualاحمد همامNo ratings yet

- Epcos PFC Catalog 14Document1 pageEpcos PFC Catalog 14Ursula JohnsonNo ratings yet

- Wecon Manual Variador VBDocument62 pagesWecon Manual Variador VBsonirichnaviNo ratings yet

- 30XW-VZE/30XWHVZE: Water-Cooled Variable-Speed Screw Chillers Water-Sourced Variable-Speed Screw Heat PumpsDocument19 pages30XW-VZE/30XWHVZE: Water-Cooled Variable-Speed Screw Chillers Water-Sourced Variable-Speed Screw Heat PumpsMechanical PowerNo ratings yet

- Hallscrew Replacement Parts List: July 2006Document8 pagesHallscrew Replacement Parts List: July 2006Annika Cass100% (1)

- LEC1Document17 pagesLEC1christophermrequintoNo ratings yet

- York Yoea36fs36adhDocument20 pagesYork Yoea36fs36adhjean_carlos_abreu_rNo ratings yet

- 1.4 File - 20210328 - 180749 - 002 Cncq Series Tc Set-free σ (Vrf), CoDocument335 pages1.4 File - 20210328 - 180749 - 002 Cncq Series Tc Set-free σ (Vrf), Cokhanh phanNo ratings yet

- RE50214 Nivometer PDFDocument16 pagesRE50214 Nivometer PDFCaspar Heerkens100% (1)

- Analog and Interface Product Selector GuideDocument68 pagesAnalog and Interface Product Selector GuideLibroLivroNo ratings yet

- Relay Relay: Protection Relay Protection RelayDocument151 pagesRelay Relay: Protection Relay Protection RelayHanadi AnkaNo ratings yet

- Model Building and Simulation of Thermoelectric Module Using Matlab-SimulinkDocument7 pagesModel Building and Simulation of Thermoelectric Module Using Matlab-Simulinkmegustalazorra100% (1)

- ZXV Launch Presentation - Jan, 2020Document22 pagesZXV Launch Presentation - Jan, 2020Dương Tấn TàiNo ratings yet

- Spesifikasi HITACHI RCUG200AHYZ1-Heat RecoveryDocument1 pageSpesifikasi HITACHI RCUG200AHYZ1-Heat RecoveryBaelish PeterNo ratings yet

- Water-cooled Screw Chiller WZY SERIES Features Cutting-Edge TechDocument11 pagesWater-cooled Screw Chiller WZY SERIES Features Cutting-Edge TechAbdulSattar100% (1)

- Tae Evo 015 - 351 EnglDocument39 pagesTae Evo 015 - 351 EnglMantenimientoValdezGutierrezNo ratings yet

- Manual Controlli MVB56Document2 pagesManual Controlli MVB56dwNo ratings yet

- Hermetic Compressors Guide for R134a 50HzDocument40 pagesHermetic Compressors Guide for R134a 50HzFrancisco Edivando Agostinho AraujoNo ratings yet

- Carrier Serie 50TC (15-27.5 Ton) PDFDocument98 pagesCarrier Serie 50TC (15-27.5 Ton) PDFRafael CentenoNo ratings yet

- FOCSWATER.C Water Cooled Chiller - R134aDocument8 pagesFOCSWATER.C Water Cooled Chiller - R134antt_121987No ratings yet

- Manual Piromax 25-125 KWDocument34 pagesManual Piromax 25-125 KWzlata dora0% (1)

- Hankison H-Unit March06Document40 pagesHankison H-Unit March06SAUL OSPINONo ratings yet

- KX2 Manual PDFDocument212 pagesKX2 Manual PDFhungstampNo ratings yet

- So Do On AP LiOa (Nen)Document1 pageSo Do On AP LiOa (Nen)Anhtu Pham100% (1)

- Westinghouse R-410A Package Unit Service ManualDocument118 pagesWestinghouse R-410A Package Unit Service ManualWisam Ankah0% (1)

- Rtxa 209 - 212 Iom E30im001-Gb - 1098Document32 pagesRtxa 209 - 212 Iom E30im001-Gb - 1098DianaNo ratings yet

- 6BSB000930Document4 pages6BSB000930OnofreNo ratings yet

- E DMT 341534Document844 pagesE DMT 341534Rinette MarcanoNo ratings yet

- Thermostatic Expansion Valves - Alco: Operating Principles ProcedureDocument34 pagesThermostatic Expansion Valves - Alco: Operating Principles ProcedureMeher YoussfiNo ratings yet

- The Silicon-Controlled Rectifier (SCR) - ThyristorsDocument12 pagesThe Silicon-Controlled Rectifier (SCR) - ThyristorsKapila WijayaratneNo ratings yet

- 5998 - 5998 - Carrier 30 GH 100 PDFDocument16 pages5998 - 5998 - Carrier 30 GH 100 PDFbilal almelegyNo ratings yet

- 48 50tj-2wDocument64 pages48 50tj-2wsclstc89No ratings yet

- Ioties Document No:-Mccpl-Pctl-Acc-Doc-M-0001 - Rev. P3Document23 pagesIoties Document No:-Mccpl-Pctl-Acc-Doc-M-0001 - Rev. P3pramodtryNo ratings yet

- Hd785-3 Electric OptionalDocument13 pagesHd785-3 Electric OptionalBima Dwi UtomoNo ratings yet

- APP008 - Hitachi Screw Point List and Startup SequenceDocument6 pagesAPP008 - Hitachi Screw Point List and Startup Sequencemarcyel Oliveira WoliveiraNo ratings yet

- 3022Document2 pages3022markjparrNo ratings yet

- Annexure IV - QCP - Electrical - and - C&I 2021 07 05 02 - 57 - 28 1 100Document100 pagesAnnexure IV - QCP - Electrical - and - C&I 2021 07 05 02 - 57 - 28 1 100mrherp153No ratings yet

- Controlador SolarDocument11 pagesControlador SolarprozincoNo ratings yet

- OEM Type Instrument Transformers Reference GuideDocument34 pagesOEM Type Instrument Transformers Reference Guideap00No ratings yet

- 2 Three-Phase AC Motor Architecture PDFDocument15 pages2 Three-Phase AC Motor Architecture PDFFRANCISCO JAVIER MEJIA TASCONNo ratings yet

- 1customer Pricelist 2012Document61 pages1customer Pricelist 2012math_0222No ratings yet

- Blackburn Text Problems 9.4 10.1 10.2 Relay SettingsDocument4 pagesBlackburn Text Problems 9.4 10.1 10.2 Relay SettingsAbhishek JoshiNo ratings yet

- Grounding Methods for Electric Supply and Communications FacilitiesDocument10 pagesGrounding Methods for Electric Supply and Communications Facilitiesrvasileva100% (1)

- Call 800-DIESELS (343-7357) : Cummins Inc. - Box 3005 - Columbus, Indiana 47202-3005 USADocument9 pagesCall 800-DIESELS (343-7357) : Cummins Inc. - Box 3005 - Columbus, Indiana 47202-3005 USAreycoeleNo ratings yet

- Unsw Spree 040719 SmaDocument78 pagesUnsw Spree 040719 Smasurag1982No ratings yet

- MSA5T0726A161948 Power Window System PDFDocument4 pagesMSA5T0726A161948 Power Window System PDFMishu MishuNo ratings yet

- The Authoritative Dictionary of IEEE Terms ML12089A535Document4 pagesThe Authoritative Dictionary of IEEE Terms ML12089A535EnformableNo ratings yet

- MD Singh Power Electronics Solution Manual To Chapter 12Document6 pagesMD Singh Power Electronics Solution Manual To Chapter 12Anoop MathewNo ratings yet

- EE8353 - EDC Anna University Old Question PapersDocument16 pagesEE8353 - EDC Anna University Old Question PapersveenaNo ratings yet

- Report on VFD (Variable Frequency DriveDocument5 pagesReport on VFD (Variable Frequency DriveZohaib MehmoodNo ratings yet

- New Microsoft Office Word DocumentDocument34 pagesNew Microsoft Office Word DocumentMd NadeemNo ratings yet

- Wet Conditions SafetyDocument7 pagesWet Conditions SafetyALMusriALSudaniNo ratings yet

- Endurabay HPK138Document5 pagesEndurabay HPK138wilber ticona0% (1)

- System Sensor 2WTA-B, 2WTR-B, 4WTA-B, 4WTR-B Data SheetDocument2 pagesSystem Sensor 2WTA-B, 2WTR-B, 4WTA-B, 4WTR-B Data SheetAlarm Grid Home Security and Alarm MonitoringNo ratings yet

- WEG Brake Motor Instruction Manual For Installation Operation and Maintenance of Brake Motors 50021973 Brochure English Spanish WebDocument2 pagesWEG Brake Motor Instruction Manual For Installation Operation and Maintenance of Brake Motors 50021973 Brochure English Spanish WebLuis angel RamirezNo ratings yet

- Speed Control DC Motors BenchDocument3 pagesSpeed Control DC Motors Bencharafath uzzamanNo ratings yet

- Amplificador de Bulbos de Bajo CostoDocument6 pagesAmplificador de Bulbos de Bajo CostoNaelectronic UONo ratings yet

- Silicon NPN Power Transistors: Savantic Semiconductor Product SpecificationDocument3 pagesSilicon NPN Power Transistors: Savantic Semiconductor Product Specificationmarcelo giussaniNo ratings yet

- RI-9000 English Manual 2019.12.03Document209 pagesRI-9000 English Manual 2019.12.03steven MelgarejoNo ratings yet