Professional Documents

Culture Documents

4.47 The Expansion Factor, Y: P, AP P, P2

Uploaded by

Enrico GambiniOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4.47 The Expansion Factor, Y: P, AP P, P2

Uploaded by

Enrico GambiniCopyright:

Available Formats

Previous Page

4.47 THE EXPANSION FACTOR, Y

219

The simultaneous solution of Eqs (4-173) and (4-174) eliminates M a and yields a value for r , the critical pressure ratio. Table 4-25 shows a wide variation in the critical values with respect to y (Le., ratio of specific heats, Cp/C,) and the loss coefficient K .

4.47 THE EXPANSION FACTOR, Y

The adiabatic flow Eq. (4-178) can be represented in a form:

4.46 ADIABATIC FLOW

If there is no heat transfer or energy dissipated in the gas when traversing from state 1 to state 2, the process is adiabatic and reversible, that is isentropic. However, the actual flow conditions are somewhere between isothermal and adiabatic and, as such, the flow behavior can be described by the isentropic equations, where the isentropic constant k replaced a polytropic constant y (e.g., 1 < y < k). For isothermal condition, y = 1, whereas truly isentropic flow corresponds to y = k . The density and temperature as a function of pressure are (4-177) The mass flow rate, G , by using Eq. (4-177) to eliminate p and T and solving for G gives (4- 179) where

p1= P , M w / R T l , A P = P , - P2 and Y is the expansion factor. Note that Eq. (1.179) without the Y term is the Bernoulli equation for an incompressible fluid of density p , . Therefore, the expansion factor Y = Gadiabatic/Gincompressible ratio of the adiabatic mass is the flux (Eq. (4-178)) to the corresponding incompressible mass flux, and is a unique function of P 2 / P , , k and Kf. Figure 4-38a shows values of Y for k = 1.3 and k = 1.4 as a function of A P / P , and Kf (which is denoted by simply K on these plots). Figures 4-38b and c show the expansion factor Y for compressible flow through nozzles and orifices, and plots of the critical pressure ratio for compressible flow through nozzles and venturi tubes respectively. The conditions corresponding to the lower ends of the lines on the plots (e.g., the nought) represent the sonic (choked flow) state where P2 = P2*. These same conditions are shown in the tables accompanying the plots, thus allowing the relationships for choked flow to be determined more accurately than is possible from reading the plots. Note: It is not possible to extrapolate beyond the nought at the end of the lines in Figures 4-38a and b as this represents the choked flow state, in which P2 = P2* (inside the pipe), and is independent of the external exit pressure. Figures 4-38a

where f =Fanning friction factor. If the system contains fittings as well as straight pipe, the term 4 f L I D (= Kf:pipe) can be replaced by C K,, that is the sum of all loss coefficients in the system.

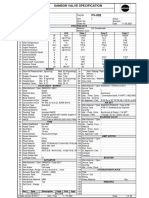

EXAMPLE 4-11 From the table listed below determine the status of flow (e.g., whether choking flow exists or not), (AP/P,),,, and the flow rate

Using the Excel spreadsheet Example 4- 11.xls, the calculated overall critical pressure ratio r is r = 0.04804 The critical pressure P2 is

WI.

Data

P2 = r x Po

Value

= 0.04804 x 6600

Upstream pressure, Po(kPaa) Downstream discharge pressure, PA (kPaa) Upstream specific volume, Vo(m3/kg) Isentropic coefficient, y Internal pipe diameter, D(mm) Length of pipe, rn Number of elbows Loss coefficient, K

= 317.06kPa 6600 200 0.01724 Test for choke flow 1.55 Since P2 > PA, the pipe will choke. 52.5 The critical expansion factor Y,, from Eq. (4-175) is

100

4 45

'"=

Solution For known isentropic coefficient y and loss coefficient K, a guessed value of M a , is used in Eq. (4-173) until the left side of the equation approximates to a value of zero. Otherwise, a new guess value of M a , is used in Eq. (4-173). Once the required value is known, Eqs. (4-174), (4-175), and (4-176) are subsequently used to determine r, P 2 , AP, Y,,, and W respectively. This procedure involves the use of the Excel spreadsheet with the Goal Seek or Solver add-in from the Tools menu and is given in Example 4-1 1 . ~ 1 ~ .

45 (1 0.04804) 2[45+2(1/0.04804)]

= 0.6795

The critical mass flow rate from Eq. (4-176) is

W = 0.1265 (52.5)' (0.6795)

= 21,320.96kg/h

6600-317.06 (45 x 0.01724)

Figure 4-37 gives the Excel spreadsheet snapshots of Example 4-1 1.

220 FLUID FLOW

Figure 4-37 The Excel spreadsheet snapshot of Example 4-1 1

4.47 THE EXPANSION FACTOR. Y

221

Figure 4-37-(conrinued)

222 FLUID FLOW

Figure 4-37-(conrinued)

4.48 MISLEADING RULES OFTHUMB FOR COMPRESSIBLE FLUID FLOW

223

k = 1.3

limiting Foctors For Sonic Volocity k = 1.3

--K hP Y Pr -1.2 1.5 2.0 3

4

325 ,550 I593 .642 .678 .722 .750 .773 .E07

,831

.612 ,631 ,635

.8 a .670 6.35

8

10 15

,698 .705

.718

20 40

loo .920 ---

.a77

.718 .718 .718

limiting Factors For Sonic Volocity

k = 1.4

Y

.588

1.2 1.5 2.0

.552 .576 .612

.6M

,622 ,639 .649 .671

3 1 6 8 10 15

20 40 100

.662

.697 .737 .761 .781 .El8 .e39

,883

,681 ,695 .702

.710 .710 ,710

.926

Figure 4-38a Net expansion factor, Y , for compressible flow through pipe to a larger flow area. (Reprintedadapted with permission from Flow of Fluids Through Valves, Fittings, and Pipe, Technical Paper No. 410, 1999, Crane Co. All rights reserved).

and b provide an alternative method of solving compressible adiabatic flow problems for piping systems. However, this procedure requires some iterations because the value of K , depends on the Reynolds number which cannot be determined until G is obtained.

calculations for compressible fluid flow can be grossly misleading and erroneous. The common rules are

1. That adiabatic and isothemal flow bracket all flowrates. These

conditions do not occur.

4.48 MISLEADING RULES OF THUMB FOR COMPRESSIBLE FLUID FLOW

In general, compressible fluid flow calculations are much more complicated than incompressible fluid flow. Recently, Walters [35, 361 has shown that rules of thumb that are applied in the design

2. If the pipe pressure drop in a compressible flow system is less

than 40% of the inlet pressure, then the incompressible flow calculation methods can be safely employed, with the average density along the pipe used in the equations. He further showed that this rule is invalid unless associated with a particular f L I D ratio.

224 FLUID FLOW

3. Choked air flow at 50% pressure drop. An equation often used to determine the likelihood of sonic choking is

yl(y-1)

(4-180)

where p a is the critical static pressure at sonic velocity and p o is the local stagnation pressure at the orifice/valve. Walters indicated that using Eq. (4-180) with y = 1.4 results in 47% pressure drop to obtain choking. Furthermore, he stated that Eq. (4-180) cannot be used with the supply pressure if there is any significant pressure drop from the supply to the orifice/valve.

4.50 FRICTION DROP FOR FLOW OF VAPORS, GASES, AND STEAM

225

The entire pipe is solved in one lumped calculation instead of coupling the governing equations in marching order. It is difficult to extend the equations to pipe networks. Walters developed compressible flow equations for single pipe [35]: Adiabatic flow equation and integrated solution are

soL

Ma2

kdx=/Ma

1 - Ma2 y Ma4 [ 1 Ma2] dMa2

(4-181)

(4- 182) Isothermal flow equation and integrated solution are

lLT lMa

kdx=

Ma2

I

(1 - yMa2) YMa4

dMa2

(4183)

(4- 184) Computer software has been developed that models pipe systems of compressible fluids and this can be obtained from the website www.aft.com.

k = cP/cv

Figure 4-38c Critical Pressure Ratio, rC, for compressible flow through

4.50 FRICTION DROP FOR FLOW OF VAPORS, GASES, AND STEAM See Figures 4-39a and 4-3913

nozzles and venture tubes. (ReprintedAdapted with permission from Flow of Fluids Through Valves, Fittings, and Pipe, Technical Paper No. 410, 1999, Crane Co. All rights reserved. Note: P = psia, p = ratio of small-tolarge diameter in orifices and nozzles, and contractions or enlargements in pipes).

A. DARCY RATIONAL RELATION FOR COMPRESSIBLE FLOW FOR ISOTHERMAL PROCESS [41

AP -- - 0.000336fw2v - 0.000336 f W2 lOOft

or

d5 d5P

For gases with different specific heat ratios, the pressure drop ratio will differ somewhat, in accordance with Eq. (4-180). In addition, Eq. (4-180) breaks down for pipe-system analysis when pipe friction becomes a factor. This is because the stagnation pressure in the equation is the pressure at the upstream side of the shock wave. However, if there is any pressure drop in the pipe from the supply pressure to the shock wave, then the supply pressure cannot be used in Eq. (4-180). Instead, the local stagnation pressure at the shock wave must be used, which is unknown unless the pressure drop is determined from alternative means. Therefore, Eq. (4-180) cannot be used to predict the supply and discharge pressures necessary for sonic choking unless the piping has negligible friction loss.

4.49 OTHER SIMPLIFIED COMPRESSIBLE FLOW METHODS

(4-65)

AP -100f t In SI units,

0.000001959 f (qL)2Sg2

d5P

(4-185)

AP/100m = or

62,530 f W 2 v - 62,530 f W 2 d5 d5P

(4-66)

As shown earlier, most gases are not isothermal and, therefore, it is impossible to know how much error is introduced by the assumption of constant temperature. Simplified equations typically do not address sonic-choking conditions, and cannot address the delivery temperature. These equations break down at high Mach numbers.

(4- 186) The general procedures outlined previously for handling fluids involving the friction factor, f , and the Re chart are used with the above relations. This is applicable to compressible flow systems under the following conditions [4].

226 FLUID FLOW

APnm

.4

API 100 ft = 0.000336 f WPld6p

V

40

Ind

.5

.S .l .8 .9 1.0

30

.04

d

30 7

Figure 4-39a Pressure drop in compressible flow lines. (Reprinted/Adaptedwith permission from Flow of Fluids Through Valves, Fittings, and Pipe, Technical Paper No. 410, 1999, Crane Co. All rights reserved.)

where W = rate of flow, Ib/h (kgh) V = specific volume of fluid, Ib/ft3(m3/kg) f = friction factor d = internal pipe diameter, in. (mm) p = fluid density, Ib/ft3(kg/m3) S, = specific gravity of gas relative to air = the ratio of molecular weight of the gas to that of air q; = rate of flow, ft3/h(m3/h) at standard conditions (14.7psia and 60 F), SCFH (m3/s at metric standard conditions (MSC) -1.01325bara and 15C). Babcock formula for steam flow at isothermal condition is

q; = 24,700 [Yd/S,]

K = loss coefficient for all valves, fittings, and pipe (resistance coefficient)

r=fittings+valves

qi = flow rate, ft3/h at 14.7 psia and 60 F S, = specific gravity of a gas relative to air = the ratio of the molecular weight of the gas to that of air P = pressure, lb,/in.2 abs A P = pressure drop, psi T , = inlet temperature, abs ( R = F 460) p1 = upstream density of steam, lb/ft3.

(APp,/K), CFH at 14.7psia and 60F

(4- 187)

In SI units,

qh = 1.0312 [YdlS,]

(AppI/K)I2

(4-1 89)

or

qh = 40,700Yd [ ( A P ) ( P i ) / ( K T I S g ) ] *

or (4-188)

qi = 19.31 Yd2 [ ( A p ) ( p ; ) / ( K T 1 S , ) ] / 2 1

(4- 190)

where

d = internal pipe diameter, in. Y = net expansion factor for compressible flow through orifices, nozzles, or pipe (see Figures 4-38a-c)

where d = internal pipe diameter, mm Y = net expansion factor for compressible flow through orifices, nozzles, or pipe

4.50 FRICTION DROP FOR FLOW OFVAPORS, GASES, AND STEAM

227

Pressure Equivalent: Ibar = 105pa

IO0kPa

W

T o o

[w

Index 2

- 40 r30

1001 05 80 .

.01

Figure 4-39b Pressure drop in compressible flow lines (Metric units). (ReprintedAdapted with permission from Flow of Fluids Through Valves, Fittings, and Pipe, Technical Paper No. 410, 1999, Crane Co. All rights reserved.)

K = loss coefficient (resistance coefficient) p = pressure, bara qi, = flow rate, m3/h at MSC (metric standard conditions 1.01325bar at 15C) S, = specific gravity of a gas relative to air = the ratio of the molecular weight of the gas to that of air Ap = pressure drop, bar T , = inlet temperature, abs ( K = C 273) p1 = upstream density of steam, kg/m3.

Figures 4-40a and b (SI) are useful in solving the usual steam or any vapor flow problem for turbulent flow based on the modified Darcy friction factors. At low vapor velocities the results may be low; then use Figure 4-39a or b (SI). For steel pipe the limitations listed in (A) above apply.

B. ALTERNATE VAPOR/GAS FLOW METHODS

Note that all specialized or alternate methods for solving are based on simplified assumptions or empirical procedures presented earlier. They-are not presented as better approaches to solving the specific problem.

1. Determine C1 and C from Figure 4-40a or b (SI units) and , Table 4-26 for the steam flow rate and assumed pipe size respectively. Use Table 4-6 or 4-19 to select steam velocity for line size estimate. 2. Read the specific volume of steam at known temperature and pressure from steam tables. 3. Calculate pressure drop (Figure 4-40a or b) per lOOft of pipe from

AP/lOOft = CIC,v (4- 191)

228 FLUID FLOW

II'

C I

The Darcy formula can be written in the following form :

1i.I---u)

ii'

-7

6

.07 .06

.35

.04

c l = APioo -=Cv z

APioop

c * =APwo-=

ClV

APmP

C1

'X

4 0

.03

5

,025

C Z

2

U v)

C1 = discharge factor from chart at right. C, = size factor, from table on next page.

The limitations of the Darcy formLila for compressible flow, as outlined on page 3-3, apply also to the simplified flow formula.

B

f

c VI

G a

.02

.015

3.5

3

>

.7

a c 0

= .-

.o 1 .no9

.008

Example 1

Given: Steam a t 345 psig and 500 F flows through 8-inch Schedule 40 pipe a t a rate of 240,000 pounds per hour.

Find: The pressure drop per Soluiion: CI = 57

io0

feet of pipe.

' 0 01

CT

225

2

.m7

.@I6

.005

.004

.a3

.0025

C = 0.146 e V = 1.4j . . . . _ . . . .agc 3-17cr A-16 p APioo = 57 x c.146 x 1.4j = 12

L5

.no2

.0015

Example 2

la . 9

.8

Given: Pressure drop is 5 psi with 100 psig air a t go F flowing through 1 0 0 feet of 4-inch Schedule 40 pipe.

Find: The flow rate in standard cubic feet per minute. Solution: APloo = 5.0 C = j.17 z

p =

0. j64

.001 .In09

.owe

.COO7

.OW6

. . . . . . . . . . . . . .page .<%lo

For

qfm = qfm =

w

23

( 5 . 0 x 0.564) + j . 1 7 = 0 . j 4 j Ci W = 2 3 OCO . . . . . . . . . . . . . . .page B-2 f (4.58 s,) ooo + (4.58 x 1.0) = 5000 scfm

,

C? values and

an example on "determining pipe dxe", see the opposite page.

Figure 4-40a Simplified flow formula for compressible fluids. (Reprinted/adapted with permission from "Flow of Fluids Through Valves, Fittings, and Pipe". Technical Paper No. 410, 1999, Crane Co. All rights reserved.)

4.50 FRICTION DROP FOR FLOW OFVAPORS. GASES, AND STEAM

229

The Darcy formula can be written in the following form;

ktcl = E and c2= 62 530 x 10 L

10

d5

The simplified flow formula can then be written:

C = disduuge factor, from chart at right a C =size factor from tables on pages 3-23 to 3-25 z

The limitations of the &cy formula for compressible flaw, as outlined on page 3-3 apply also to the simplified flow formula.

Example 1

Given: Steam at 24 bar absolute and 250C flows through an &inch Schedule 40 pipe at a rate of 100 000 kilograms per

hour.

Fmd: The pressure drop per 1Do met= of pipe. Solufion: CI = 100 C = 0.257 . . . . . . . . . . . . . . . . facing page 2 = 0.091 m3/kg. . . . . . . .page 3-17 or A 4 5 Ap ,oo = 100 x 0.257 x 0.091 Ap = 2.34bar

Exampte 2

Given: Pressure drop is 1 bar with 7 bar gauge air at 3OoC flowing through 100 metres of 4 inch nominal size IS0 steel pipe, 6.3 mm wall thickness. Fd: The flow rate i cubic metres per minute at metric n standard conditions ( . 1 325 bar and 15C). 10 SblUtfoR: &,a, = 1 Cz = 9 . 4 2 . . . . . . . . . . . . . . . .page 3-24 = 9.21 . . . . . . . . . . . . . . . . p g e A - 1 0 P

For C values s opposite page , e and pager 3-24, 3-23. For example on determining pipe

m see oppomtc page. e

w

q,,,

q,,,

= 9900 = W + (73.5 Sg) . . . . . . . . . . .page B-2 = 9 9 0 0 + ( 7 3 . 5 ~ 1 ) = 134.7m3/min

Figure 4-40b Simplified flow formula for compressible fluids (Metric units). (Reprintedadapted with permission from Flow of Fluids Through Valves, Fittings, and Pipe, Technical Paper No. 410, 1999, Crane Co. All rights reserved.)

4. Determine the loss coefficient K of all fittings, valves, and so on, and hence the equivalent length ( K = f L,,/D) or, alternatively, from Figure 4-24 or 4-25. 5. Determine expansion and contraction losses, fittings and at vessel connections. 6. Determine pressure drops through orifices and control valves. 7 Total system pressure drop .

C. AIR

For quick estimates for air line pressure drop and through an orifice, see Tables 4-21a and b.

D. BABCOCK EMPIRICAL FORMULA FOR STEAM

Comparison of results between the various empirical steam flow formulas suggests the Babcock equation is a good average for most design purposes at pressure 500 psia and below. For pipe lines smaller than 4in., this relation may be 0 4 0 % high [38].

p l - p z =AP=0.000131(1+3.6/d)-

APTOTAL (L+L,,) (AP/lOO)+Item5+Item6 =

(4-192)

8. If pressure drop is too large (or greater than a percentage of the

inlet system pressure), re-estimate line size and repeat calculations (see paragraph (A) above) and also examine pressure drop assumption for orifices and control valves.

w2 L

Pd5

(4-193) (4-194)

AP/100 ft = w2F/p

230 FLUID FLOW

TABLE 4-26 Simplified Flow Formula For Compressible Fluids Pressure Drop, Rate of flow, and pipe sizes (use with figure 4-40a)

Values of C,

Nominal Pipe Size Inches 1 8 4 1 3 8 1 2 Schedule Number 40 s 80 x 40 s 80 x 40 s 80 x 40 s 80 x 160 Value of C,

~; : ;1

Pipe Size

Schedule Number Inches 40 s 80 x 120 160 16 2.04 2.69 3.59 4.93 0.610 0.798 1.015 1.376 1.861 0.133 0.135 0.146 0.163 0.185 0.21 1 0.252 0.289 0.317 0.333 0.0397 0.0421 0.0447 0.0514 0.0569 0.0661 0.0753 0.0905 0.1052 0.0157 0.0168 0.0175 0.0180 0.0195 0.0206 0.0231 0.0267 0.0310 0.0350 0.0423 0.00949 0.00996 0.01046 0.01099 0.01155 0.01244 0.01416 18

jchedulc Number 10 20 30 s 40 x 60 80 100 120 140 160 10 20

Value of c, 0.00463 0.00421 0.00504 0.00549 0.00612 0.00700 0.00804 0.00926 0.01099 0.01244 0.00247 0.00256 0.0 0266 0.00276 0.00287 0.00298 0.00335 0.00376 0.00435 0.00504 0.00573 0.00669

26,200,000.00 1,590,000.00 4,290,000.00 319,000.00 718,000.00 93,500.00 186,100.00 4,300,000.00 11,180,000.00 21,200.00 36,900.00 100,100.00 627,000.00 5,950.00 9,640.00 22,500.00 114,100.00 1,408.00 2,110.00 3,490.00 13,640.00 627.00 904.00 1,656.00 4,630.00 169.00 236.00 488.00 899.00 66.70 91.80 146.30 380.00 21.40 28.70 48.30 96.60 10.00 37.70 5.17 6.75 8.94 11.80 18.59

...xx

40 s 80 x 120 160 ... xx 20 30 40 s 60 80 x 100 120 140 160 20 30 40 s 60 x 80 100 120 140 160 20 30 40

... xx

3 4

40 s 80 x 160 40 s 80 x 160

...s

30 ...x 40

60 80 100 120 140 160 20

...xx

...xx

... xx

!.I

40 s 80 x 160

...xx

! I 2

2

40 s 80 x 160 ...xx 40 s 80 x 160 ...xx 40 s 80 x 160

10 20 s 30 x 40 60 80 100 120 140 160

0.00141 0.00150 0.00161 0.00169 0.00191 0.00217 0.00251 0.00287 0.00335 0.00385 0.000534 0.000565 3.000597 3.000614 3.000651 3.000741 1.000835 1.000972 1.001119 3.001274 1.001478

...s

...x

2_!

2

60 80 100 120 140 160 10 20 30 s 40 ... x 60 80 100 120 140 160

24

10 20 s

... xx

...x

30 40 60

40 s 80 x 160 ...xx 40s 80 x 40 s 80 x 120 160 ...xx

3_1

2 4

80 100 120 140 160

Note:

of Schedule Numbers indicate

I1

Source: By permission from Crane Co., Technical Paper No. 410, Engineering Div., 1957. See authors note at Figure 2-31.

Figure 4-41 is a convenient chart for handling most in-plant steam line problems. For long transmission lines over 200 ft. the line should- be calculated in sections in order to re-establish the steam-specific density. Normally an estimated average p should be selected for each line increment to obtain good results. Table 4-28 is used to obtain the value for F in Eq. (4-194).

4.51 DARCY RATIONAL RELATION FOR COMPRESSIBLE VAPORS AND GASES

1. Determine first estimate of line size by using suggested velocity from Table 4-6. 2. Calculate Reynolds number Re and determine the friction factor, f,using Figure 4-5, 4-42a, or b (SI) (for steel pipe).

4.51 DARCY RATIONAL RELATION FOR COMPRESSIBLE VAPORS AND GASES

231

TABLE 4-27a

Flow of Air Through Sch. 40 Pipe' (use for estimating; for detailed calculations use friction factors f)

arcdAil QbiC Feet ubic Feel Y Minute :r Minutc Per at 60 F and 60Fanc 14,7psia 100 psig

Qn '

For lengths of pipe other than 100 feet, 'the pressure drop is roportional to the length. hS 50 feet Of pipe, the U for , P m drop is a F C " ~ ~ l one-half thevaluegiveninthe for 300 feet, three table times the given value, etc.

Air

corn-

. ..

--

Pre-ure Drop of Air I n Pounds per Square Inch Per 100 Feet of Schedule 40 P i p For Air at 100 Pounds per Square Inch Gaul %ss.m e and 60 F Teml ature - - -

-1M 0.020 0.042 0.071 0.106

0.148 0.255

The ressuredropisalsoinverseyy proportional to the absolute pressure and directly .proportional to the ahsolute temperature. Therefore, to determine the pressure drop for inlet or average pressures other than 100 psi and at temperatures other thanMF, multiply thevalues given in the table by the ratio: 100+14.7 460+1 P+14.7 520 where: "P" is the inlet or average gauge pressure in pounds per square inch, and, "t" is the temperature in degrees Fahrenheit under consideration.

w

2

3

---

1/11

0.083 0.285 0.605 1.04 1.68 2.23 3.89 6.96 3.0 2.8 5.6

3/8'

0.018 0.064 0.133 0.226

0.12s

4 6

6

0.m 0.384

0.613 0.641 0.769 1.025 1.282 1.922 2.663 3.204 3.845 4.5.126 6.767

0.361 1.31 3.06 4.83 7.46 .0.6 .8.6 s.7

3A'

0.027 0.037 0.062 0.094 0.201 0.346 0.526 0.748 1.00 1.30 1.62

1.99 2.85 3.83

4.96

0.343

1"

3.019 1.029 1.062 3.102

8 10 16 20

)(

1 30 3s 40

4

... ... ... *.. *.. ... ...

0.408 0.848 1.26 2.73 4.76

0.356

0.834 1.43

%*

), 026

1H'

0.019 0.026 0.036 0.044 0.056 0.067 0.094 0.126 0.162 0.203

0.247 0.380 0.537 0.727 0.937

...

... ...

...

7.34 L0.5 14.2 18.4 13.1

L8.5 w.7

2.21 3.15 4.24 5.49 6.90 8.49 2.2 6.5 .1.4 ,7.0 13.2

0.156 D.219 D ,293 D.379 D.474 0.578 Q.819

1.10

).039 ). 055 ).073 1.095 1.116 1.149 1.200 1.270 1.350 1.437 1.534 1.825 1.17 1.58 1.05 1.59 I8 3.83 1.56 5.39

2 .

0.019 0.027 0.036 0.046 0.068

0.070 0.107 0.161 0.208 0.264

8 70

90 100 12S 160 176

80

6.408 7.690 8.971 1o.Zs 11.63 12.82 16.02 19.22 22.43 25.63

234'

0.019 0.023 0.029 0.044 0,062 0.063 0.107 0.134 0.164 0.191 0.232 0.270 0.313 0.356 0.402 0.462 0.507 0.562 0.623 0.749 0.887 1.04 1.19 1.36 1.55 1.74 1.96 2.18 2.40 2.89 3.44 4.01 4.65 5.31 6.04 7.65 9.44 14.7 21.1 28.8 37.6 47.6

...

... ...

3'

0.011 0.028

6.25

1.43 1.80

lW

0.036

3lh"

0.022 0.027 0.032 0.037 0.043

... ... ...

t..

7.69 1.9 7.0 3. I 0.0 7.9

2.21 3.39 4.87 6.60 8.54

0.8 3.3 6.0 9.0 2.3

The cubic feet per minute of compressed air a t any pressure is inversely pmportiohal to the absolute pressure and directly proportional to the absolute temhrature. To determine the cubic feet per minute o compressed air f at any temperature and pressure other than standard conditions, multiply the value of cubic feet per minute of free air by the ratio:

12S

lso

276 3%

300

28.84 32.04 36.24

38.45

41.65 44.87 48.06 51.26 54.47 57.67

0.045 0.055 0.064 0.078 0.090

0.104 0.119 0.134 0.151 0.168

4'

0.030 0.034 0.038 0.042 0.047 0.052 0.062 0.073 0.086

0.099 0.113 0.127 0.144 0.160

... ... ... ...

... ... ... ... ...

5"

?.

1.19 1.45 1.75 2.07 2-42 2.80 3.20 3.64 4.09 4.59

5.09 5.61 6.79 8.04 9.43

0.331 0.404 0.484 0.673 0.673 0.776 0.887 1.00 1.13 1.26 1.40 1.68 1.87 2.21 2.60 3.00 3.44 3.90 4.40 4.91

350 376 4 w 4 % 480

476

0.050 0.057 0.064 0.072 0.081

5.8 9.6 3.6 7.9

5.17 1.05 5.02

9.01

...

...

...

D.2

600 660 600 650

700

60.88 64.08 70.49 76.90 83.30

102.5 108.9 115.3

0.187 0.206 0.24 0.293 0.341

0.089 0.099 0.118 0.139 0.163

0.188 0.214 0.244 0.274 0.305

...

...

. .

1.3 1.5 5.1 8.0 1.1 4.3

7.9 1.8 5.9 0.2

a

SKI 900 9110 1000 1100

%.I2

89.71

0.395 0.451 0.513 0.576 0.641 0.718 0.788 0.9M 1.13 1.32 1.52 1.74 1.97 2.50 3.06 4.76 6.82 9.23 12.1 15.3 18.8 27.1 36.9

0.032 0.036 0.041 0.046 0.051 0.057 0.063 0.075 0.089 0.103 0.119 0.1% 0.154 0.198 0.239 0.m 0.524 0.7s 0.91! 1.16 1.42 2.03 2.76 3.59 4.54 5.60 6-78 8.07 9.47 11.0 12.6 14.3 18.2 22.4 27.1 32.3 37.9

6"

0.02:

0.025 0 03( 0: 03! 0.041 0.04: 0.05~ 0.06'

0.9 2.6 4.2 6.0 8.0

!O.O

1lW

1300 1100 1600 1600 1800 1000

121.8 128.2 141.0 163.8 166.6 179.4 192.2 205. 1 230.7 256.3 320.4 384.5 448.6

0.340 0.375 0.451 0.533 0.626 0.718 0.824 0.931 1.18 1.45 2.25 3.20 4.33 5.66 7.16

8.85 12.7 17.2 22.6 28.5

0.178 0.197 0.936 0.279 0.327 0.377 0.431 0.490 0.616 0.757 1.17 1.67 2.26 2.94 3.69 4.56 6.57 8.94 11.7 14.9 18.4 22.2 26.4 31.O 36.0

... ... ... ...

0"

0.02;

0.03I 0.051 0.061 0.W 0.11:

...

12.1 16.7

11.8

17.3

6.47 6.06 7.29 8.63 0.1

1.8 3.6 5.3 .9.3 u.9

Calculations for Plpr Olhw than Schodulo 40

0.07! 0.09,

10"

0.016 0.021 0.024 0.W

0.04: 0.06! 0.08, 0. lb; 0.13

0.16 0.19; 0.23 0.27; 0.31(

1600

3000 3600

To determine the velocit Of water, or the pressure &p of water or air, through p ~ p e other than Schedule 40, use the following formulas:

4000 4600

6000 6000 7000 8000 9000

512.6

676.7 W 8 769:O 897.1

0.14. 0.20. 0.271 0.35 0.45

0.55 0.79 1.07 1.39 1.76

17.3

12"

0.018 0.0.034 0.044 0.W

0.067 0.w1 0.M 0.112 0.129

...

IO25

118

Subscript "a" refers to the Schedule of pipe through which velocity or pressure drop is desired. Subscript "40" refers to the velocity or ressure drop t h r o u e Schelule 40 pipe, a3 given in the tables on these facing pages.

10 000 1 000 1 12 000 13 000 14 000

1282 1410 1638 1666 1794 1922 2051 2307 3076 3332

20000 22 000 u0 00 16 000 28000 30ooo

16 000 16 000 18 000

2563

2820

3688 384s

... ... ... ... ... ... -

... ... ... ... ... ... ... ... ... ... ... ...

... ...

... ... ...

0.13( 0.191 0.26' 0.33' 0.42' 0.52' 0.63. 0.75,

0.88

36.2

... ... ... ... ... ... ... ... ... ... ... -

... ...

... ...

... ... ... ...

2.16 2.a 3.09 3.63 4.21 4.84 5.50 6.96 8.66 10.4 12.4 14.5 16.9 19.3

1.02 1.17 1.33 1.68 2.01 2.50 2.97 3.49 4.04 4.64

...

... ... ... ... -

... ... ... ... ... ... ... ...

0.F 0.41 0.521

0.64

0.77 0.91 1.12

1,5

0.148 0.167 0.213 0.260 0.314

...

...

1.42 ... - - -

0.605 0.620

0:u5

0 371

*By permission Technical Paper No. 410, Crane Co., Engineering Div., Chicago, 1957.

232 FLUID FLOW

TABLE 4-27b Discharge of Air Through an Orifice" in Cubic Feet of Free Air per minute at Standard Atmospheric Pressure of 14.7 Ib in.2abs and 700 F

Gauge Pressure Before Orifice in Pounds Per square inch 1 2 3 4 5 6 7 9 12 15 20 25 30 35 40 45 50 60 70 80 90 100 110 120 125

Diameter of Orifice (in.)

64

32

16

1 -

3 8

1 -

5 8

3 -

7 -

0.028 0.040 0.048 0.056 0.062 0.068 0.073 0.083 0.095 0.105 0.123 0.140 0.158 0.176 0.194 0.211 0.229 0.264 0.300 0.335 0.370 0.406 0.441 0.476 0.494

0,112 0.158 0.194 0.223 0.248 0.272 0.293 0.331 0.379 0.420 0.491 0.562 0.633 0.703 0.774 0.845 0.916 1.06 1.20 1.34 1.48 1.62 1.76 1.91 1.98

0.450 0.633 0.775 0.892 0.993 1.09 1.17 1.32 1.52 1.68 1.96 2.25 2.53 2.81 3.10 3.38 3.66 4.23 4.79 5.36 5.92 6.49 7.05 7.62 7.90

1.80 2.53 3.10 3.56 3.97 4.34 4.68 5.30 6.07 6.72 7.86 8.98 10.1 11.3 12.4

7.18 10.1 12.4 14.3 15.9

16.2 22.8 27.8

1

1 1

28.7 40.5 49.5

45.0 63.3 77.5 89.2 99.3

64.7 91.2

111 128 143 156 168 191 218 242 283 323 440 496 329 430 503 575 213 230 278 300 175 228

17.4 18.7 21'2 24.3 26.9 31.4 35.9 40.5 45.0 49.6

39.1 42.2 47.7 54.6 60.5 70.7 80.9 91.1 101 112 122 132 152 173 193 213 234 254 274 284

69.5 75.0 84.7 97.0 108 126 144 162 180 198 216 235 271 307 343 379 415 452 488 506

109 117 132 152 168 196 225

662 366 423 528 609 939 1050 1161 649 934 1016 762 1097 1138 1272 1383 1494 1549 718 938 1082 1227 1371 1516 1661 1806 1951 2023

Notes: Table is based on 100% coefficient of flow. For well-rounded entrance multiply values b y 0.97. For sharp-edged orifices a multiplier of 0.65 may be used for approximate results. Values for pressures from 1 to 15 Ibs gauge calculated b y standard adiabatic formula. Values for pressures above 15 Ib. gauge calculated by approximate formula proposed by S.A. Moss.

W, = 0.5303

where W,=discharge

'

aCPl

Tl

in Ibis

a =area of orifice in.2 C =Coefficient of flow Pi =Upstream total pressure in Ib/in.2 abs Tl =Upstream temperature i n O F , abs

Values used in calculating above table were: C= 1.0, P, =gauge pressure + 14.7 Ib/in2. Weights ( W )were converted t o volume using density of factor of 0.07494 Ib/ft. This is correct for dry air at 14.7 Ib/in2. absolute pressure and 70F. Formula cannot be used where Pl is less than t w o times the barometric pressure. (Source: By permission from F.W. O'Neil, ed., "Compressed Air Data", Compressed Air Magazine, 5th Ed. New York, 1939 [371.)

:LIJlDS IN PIPE

233

PRESSURE LOSS IN LB PER SQ INCH PER I00 FEET

Based on Babcock Formula: .P~O.000131 (Itx)dL d P& Figure 4-41 Steam flow chart. (By permission from Walworth Co. Note: Use for estimating only (Ludwig [19].)

3. Determine total straight pipe length, L. 4. Determine equivalent pipe length for fittings and valves, Leq. 5. Determine or assume losses through orifice plates, control valves, equipment, contraction and expansion, and so on. 6. Calculate pressure drop, AP/lOOft (or use Figure 4-39a or b (SI)).

AP/100ft = 0.000336 f W2

P d5

4.52 VELOCITY OF COMPRESSIBLE FLUIDS IN PIPE

See Figures 4-43a and 4-43b 2.40Wv 3.06Wv urn=-.---a d2 In SI units,

- 3.06W

d2P

(4-196)

(4-65)

um =

16,670W a

v - 21,220Wv - 21,220W -d2 d2P

(4- 196a)

, - 0.000000726f T S (q;) Pd5

7 Total pressure drop, AP total .

= ( L + L e g )(APllOO)

(4-65a)

+ Item5

(4-195)

8. If total line or system pressure drop is excessive (or greater than a percentage of the inlet system pressure), examine the portion of pressure drop due to pipe friction and that due to other factors in the system. If the line pressure drop is a small portion of the total, little will be gained by increasing pipe size. Consider reducing losses through items in step 5 above. Recheck other pipes sizes as may be indicated.

where v, = mean velocity in pipe, at conditions stated for (ds) a = cross-sectional area of pipe, in.2 (m2) W = flow rate, I b h (kgh) = fluid specific volume, ft3/lb (m3/kg) d = inside pipe diameter, in. (mm) p = fluid density, lb/ft3 (kg/m3) at T and P.

v,ftlmin

Note that determining the velocity at the inlet conditions to a pipe may create significant error when results are concerned with the outlet conditions, particularly if the pressure drop is high. Even the average of inlet and outlet conditions is not sufficiently accurate for some systems; therefore conditions influenced by pressure drop

234 FLUID FLOW

TABLE 4-28 FactorF For Babcock Steam Formula

Nominal Pipe Size (in.) Standard Weight Pipe Extra Strong Pipe+

can produce more accurate results when calculations are prepared for successive sections of the pipe system (long or high pressure).

~~

I2

3i4

1 1 114 1 12

I2

2 2

3 3 I2 4

5

6

8

10 12 14 OD 16 OD 18 OD

20 OD 24 OD

955.1 x 184.7 x I 0-3 45.7 x 10-3 9.432 x 10-3 3.914 x 951.9 x 351.0 x 104.7 x 46.94 x 23.46 x 6.854 x 10-6 2.544 x 587.1 x IO- 176.3 x 70.32 10-9 42.84 x 10-9 21.39 x IO- 11.61 x IO- 6.621 x IO- 2.561 x IO-

2.051x 340.8 10-3 77.71 x 14.67 x I 0-3 5.865 10-3 1.365x 493.8 x 143.2 x 62.95 x 31.01 x 8.866 x 3.354 x 10-6 748.2 x 10-9 225.3 10-9 90.52 10-9 55.29 x 10-9 27.28 10-9 14.69 x I 0-9 8.469 10-9 3.278 10-9

EXAMPLE 4-12 Pressure Drop for Vapor System

The calculations are presented in Figure 4-44, Line Size Specification Sheet. Figure 4-45 is convenient when using Dowtherm vapor.

4.53 ALTERNATE SOLUTION TO COMPRESSIBLE FLOW PROBLEMS

There are several good approaches to recognizing the effects of changing conditions on compressible flow [39, 401.

FRICTION DROP FOR AIR

Table 4-27a is convenient for most air problems, noting that both free air (60F and 14.7psia) and compressed air at 1OOpsig and 60F are indicated. The corrections for other temperatures and pressures are also indicated. Figure 4-46 is useful for quick checking. However, its values are slightly higher (about 10%) than the rational values of Table 4-26, above about 1OOOcfm of free air. Use for estimating only.

(Source: By permission from The Walworth Co.) * Factors are based upon ID listed as Schedule 40 Factors are based upon ID listed as Schedule 80

EXAMPLE 4-13 Steam Flow Usine Babcock Formula Determine the pressure loss in 138ft of 8-in. Sch. 40 steel pipe,

Y

w = 1891Ydi2JAPpl/K, Ib/h

In

units,

(4-198)

flowing 86,000 lblh of 150 psig steam (saturated). Use Figure 4-41, w = 86,000/60 = 14321b/min Reading from top at 150 psig, no superheat, down vertically to intersect the horizontal steam flow of 1432 Ib/min, follow diagonal line to the horizontal pipe size of 8 in., and then vertically down to the pressure drop loss of 3.5 psi/lOOft. For 138ft (no fittings or valves), total A P is 138(3.5/100) = 4.82psi. For comparison, solve by equation, using value of F = 587.1 x from Table 4-28. AP/lOOft = (1432)* (587.1 x 10-9)/0.364

w = 1.111 x 10-6Yd1? - kg/s

/g>

Ib/s

(4-199)

w = 1.265 Y d 1 2 / F kg/h ,

For nozzles and orifices (vapors/gases):

(4-200)

u = 0.525 Y dI2 3 C,/?,

= 3.31 psi/lOOft

(4-201)

AP,,,,, = (3.31/100) (138) =4.57psi

In SI units, w = 1 . 1 1 1 x 1 0 - 6 Y d , 2 C - kg/s

These values are within graphical accuracy. For the discharge of compressible fluids from the end of a short piping length into a larger cross section, such as a larger pipe, vessel, or atmosphere, the flow is considered adiabatic. Corrections are applied to the Darcy equation to compensate for fluid property changes due to the expansion of the fluid, and these are known as Y net expansion factors [4]. The corrected Darcy equation is: For valves, fittings, and pipe (vapordgases):

{g>

(4-202)

For fittings$and Pipe (liquids): English Engineering units

(4-203)

w = 0.525 Y d

i 2 d m Ib/s ,

(4-197)

(continued)

4.53 ALTERNATE SOLUTIONTO COMPRESSIBLE FLOW PROBLEMS

235

EXAMPLE 4-13-(continued)

In SI units,

W=

where

1.111 x 10-dl2/;,kg/s AP(P1)

(4-204)

English Engineering units For nozzles and orifices (liquids):

d A q T

t k

w = 0.525 d I 2C d m , lb/s

In SI units,

(4-205)

P W

v

= internal diameter of pipe, in. (mm) = cross section of pipe, ft2 (m2) = ft3/sc (m3/s) at flowing conditions = temperature, R(K = 273 t ) = fluid temperature, C = y = ratio of specific heats (C,/C,) = pressure, psia (N/m2 abs) = flow, lb/h (kg/h) = velocity, mean or average, ft/s ( d s ) .

w = 1.111 x lo- di2C J m , kg/s

(4-206)

where d, = pipe inside diameter, in. (mm) p 1 = upstream fluid density, lb/ft3(kg/m3) w = rate of flow, lb/s (kg/s) AP = pressure drop across the system, psi (bar) (inlet-discharge) K = total resistance (loss) coefficient of pipe, valves, fittings, and entrance and exit losses in the line Y = net expansion factor for compressible flow through orifices, nozzles, and pipes [4] (see Figure 4-38a, b, or c) AP = pressure drop ratio in AP/P, used to determine Y from Figure 4-38a and b. The AP is the difference between the inlet pressure and the pressure in the area of larger cross section C = flow coefficient for orifices and nozzles (Figures 4-19 and 4-20). For example, for a line discharging a compressible fluid to atmosphere, the AP is the inlet gauge pressure or the difference between the absolute inlet pressure and the atmospheric pressure absolute. When AP/P falls outside the limits of the K curves on the charts, sonic velocity occurs at the point of discharge or at some restriction within the pipe, and the limiting value for Y and AP must be determined from the tables in Figures 4-38a and b and used in the velocity equation, u s , above [4]. Figures 4-38a and b are based on the perfect gas laws and for sonic conditions at the outlet end of a pipe. For gaseshapors that deviate from these laws, such as steam, the same application will yield about 5% greater flow rate. For improved accuracy, use the charts in Figures 4-38a and b (SI) to determine the downstream pressure when sonic velocity occurs. Then use the fluid properties at this condition of pressure and temperature in:

us =

These conditions are similar to flow through orifices, nozzles, and venturi tubes. Flow through nozzles and venturi devices is limited by the critical pressure ratio, r, = downstream pressurehpstream pressure, at sonic conditions (see Figure 4-38c). For nozzles and venturi meters, the flow is limited by critical pressure ratio and the minimum value of Y is to be used. For flow of gases and vapors through nozzles and orifices:

(4-209)

orq=YCA

J2,,

---,m3/s

(4-210)

where

p = ratio of orifice throat diameter to inlet diameter

C = flow coefficient for nozzles and orifices

(see Figures 4-19 and 4-20), when used as per ASME specification for differential pressure p = fluid density, lb/ft3 (kg/m3) A = cross-sectional flow area, ft2 (m2).

Note: The use of C eliminates the calculation of velocity of , approach. The flow coefficient C is C = C , / m , C = discharge coefficient for orifices and nozzles [4]. For compressible fluids flowing through nozzles and orifices use Figures 4-19 and 4-20, using h, or AP as differential static head or pressure differential across taps located one diameter upstream, and 0.5 diameters downstream from the inlet face of orifice plate or nozzles, when values of C are taken from Figures 4-19 and 4-20 [4]. For any fluid:

JksRr = \/kg144Ptv, ft/s

= \ / ~ P I vm/s ,

(4-207) (4-208)

or v, =

(4-21 1)

to determine the flow rate at this condition from

u = q / A = 183.3 q/d2 = 0.0509 W / ( p )(d) , ft/s

(4-30)

In SI units,

In SI units,

u = q / A = 1.273 x 10 q / d 2 = 21.22-

d2

= 354 -,

pd2

m/s

(4-31)

q = CIA/=,

m3/sflow

(4-2 12)

(continued)

Next Page

236 FLUID FLOW

EXAMPLE 4-13-(continued) For estimating purposes in liquid flow with viscosity similar to water through orifices and nozzles, the following can be used [7]: ; J A ' C

(4-213)

In SI units, q =Y where m'/s (4-222)

In SI units,

Q = 0.2087C'd12&

1

4,

Vmin

(4-214)

I-($)

(4-215) (4-216)

do . where - is greater than 0.3

di

Y = net expansion factor from Figure 4-38a or b A P = differential pressure (equal to inlet gauge pressure when discharging to atmosphere) p = weight density of fluid, lb/ft3 (kg/m3) at flowing conditions A = cross-sectional area of orifice or nozzle, ft3 (m2) C' = flow coefficient from Figure 4-38a or 4-38b.

Q = 19.636C'dO2& where - is less than 0.3 do . di

W = 1891YdO2C'/~,lb/h

(4-223) (4-224)

In SI units,

Q = 0 . 2 0 8 7 C ' d O 2 h Llmin ,

or W = 1.265 do2C'&, (4-217) (4-21 8) (4-219)

kg/h

or [4], W = 1 5 7 . 6 d O 2 C ' m

= 1891 do2 C

'

In SI units,

W = 0 . 0 1 2 5 2 d O 2 C m 1.265dO2C& =

where do = internal diameter of orifice, in. (mm) VI = specific volume of fluid, ft3/lb (m3/kg) p1 = density of fluid, Ib/ft3 (kg/m3) A p = pressure drop, psi (bar).

(4-220) q'= l l . 3 0 Y d ~ C ' & ,APP; , a t ft3/s 14.7 psia and 60F (4-225) where

where

Q = liquid flow, gpm (Ymin)

C = flow coefficient for orifices and nozzles = discharge coefficient corrected for velocity of approach = C, do = diameter of orifice or nozzle opening, in. (mm) di = pipe inside diameter in which orifice or nozzle is installed, in. (mm) h = static pressure head existing at a point, in. (m) of fluid. h, = loss of static pressure head due to fluid flow, m of fluid. C' = flow coefficient (see Figure 4-47 for water and Figures 4-20 and 4-21 for vapors or liquids) q = ft3/s (m3/s) at flowing conditions rc = critical pressure ratio for compressible flow, = P;/Pi A P = pressure drop, psi A p = pressure drop, bar (hL and Ap measured across taps at 1 diameter and 0.5 diameter) W = flow rate, lb/h (kg/h).

/-

S = sp gr of gas relative to air = mol wt of gad29 , TI = absolute temperature, 'R = (460 +' F)

Pi = pressure, psia.

In SI units,

q = 0.005363YdO2 .I/""";.

TI s,

m3/s

(4-226)

where T, = 273.15+t t = fluid temperature, a C pi = pressure, bara A p = pressure drop, bar S, = sp gr of gas relative to air = mol wt of gad29 Y = net expansion factor compressibility flow through orifices, nozzles, or pipe.

Flow of gases and vapors (compressible fluids) through nozzles and orifices (for flow field importance, see [41]). From [4]: (4-221) (at flowing conditions)

You might also like

- Z - Soave Redlich KwongDocument3 pagesZ - Soave Redlich KwongHarjasa AdhiNo ratings yet

- Phase Equilibria: Basic Principles, Applications, Experimental TechniquesFrom EverandPhase Equilibria: Basic Principles, Applications, Experimental TechniquesNo ratings yet

- High Pressure Flange Design 236313199Document133 pagesHigh Pressure Flange Design 236313199Karthikeyan VisvakNo ratings yet

- High-Pressure Fluid Phase Equilibria: Phenomenology and ComputationFrom EverandHigh-Pressure Fluid Phase Equilibria: Phenomenology and ComputationNo ratings yet

- Ejectors and Jet Pumps - Design For Steam Driven FlowDocument92 pagesEjectors and Jet Pumps - Design For Steam Driven FlowtjutjuNo ratings yet

- Analisis of Stress in BellowsDocument101 pagesAnalisis of Stress in BellowsOswaldo GuerraNo ratings yet

- Pan, Hanratty - 2002 - Correlation of Entrainment For Annular Flow in Horizontal PipesDocument24 pagesPan, Hanratty - 2002 - Correlation of Entrainment For Annular Flow in Horizontal PipesJohn Doe100% (1)

- International Thermodynamic Tables of the Fluid State: Propylene (Propene)From EverandInternational Thermodynamic Tables of the Fluid State: Propylene (Propene)No ratings yet

- Calculation of Heater-Tube Thickness in Petroleum RefineriesDocument4 pagesCalculation of Heater-Tube Thickness in Petroleum Refineriesck19654840No ratings yet

- Samson Valve Specification: Process DataDocument49 pagesSamson Valve Specification: Process DataMuhammed TamerNo ratings yet

- Calculating Heat Loss From Bare Hot SurfacesDocument5 pagesCalculating Heat Loss From Bare Hot SurfacesarjmandquestNo ratings yet

- Investigations of Butterfly Control Valve Flow CharacteristicsDocument16 pagesInvestigations of Butterfly Control Valve Flow CharacteristicsKalimuthu Ps100% (1)

- Circulation Heaters Engineering InformationDocument3 pagesCirculation Heaters Engineering InformationWaqasNo ratings yet

- ESDU 73031 Convective Heat Transfer During Crossflow of Fluids Over Plain TubeDocument31 pagesESDU 73031 Convective Heat Transfer During Crossflow of Fluids Over Plain TubeArley Salazar HincapieNo ratings yet

- 2017 Ijts Cavitating-Flow PDFDocument12 pages2017 Ijts Cavitating-Flow PDFAdam AnugrahesaNo ratings yet

- Cubic Equations of StateDocument17 pagesCubic Equations of StatevenkieeNo ratings yet

- 5 3 17Document14 pages5 3 17Raymond de WeeverNo ratings yet

- Optimization Design of The U-Shaped Metal BellowsDocument5 pagesOptimization Design of The U-Shaped Metal BellowsdaymonNo ratings yet

- Side Mounted HandwheelDocument20 pagesSide Mounted HandwheelaaaNo ratings yet

- ASME MFC 21 2-2010 Measurement oDocument40 pagesASME MFC 21 2-2010 Measurement ojayarammvNo ratings yet

- Tema2007 140806051822 Phpapp02 PDFDocument298 pagesTema2007 140806051822 Phpapp02 PDFAjit PatilNo ratings yet

- Z - Peng RobinsonDocument1 pageZ - Peng RobinsonMuhammadTanzeeLUsmanNo ratings yet

- Controlling Ejector Performance: BY C. G. Blatchley Schutte & KoertingDocument9 pagesControlling Ejector Performance: BY C. G. Blatchley Schutte & KoertingCan YıldırımNo ratings yet

- Allowable Vapor Control ValveDocument9 pagesAllowable Vapor Control Valvejohn VilladaNo ratings yet

- Improved Analysis of External Loads On Flanged JointsDocument1 pageImproved Analysis of External Loads On Flanged JointsTiHoRNo ratings yet

- Joule Thomson EffectDocument2 pagesJoule Thomson EffectElliott100% (1)

- Blowdown of Pipelines Carryng Flashing LiquidsDocument10 pagesBlowdown of Pipelines Carryng Flashing LiquidsMilson GomezNo ratings yet

- FLANGE - A Computer Program For The Analysis of Flanged Joints With Ring-Type GasketsDocument149 pagesFLANGE - A Computer Program For The Analysis of Flanged Joints With Ring-Type GasketsJaveed A. KhanNo ratings yet

- 6 23 0Document13 pages6 23 0hlagos123No ratings yet

- Heat Transfer in Packed BedDocument10 pagesHeat Transfer in Packed BedNidhi JainNo ratings yet

- Piping - Design - Chemical - Engineering - Robert Kern - Articles 1974 67pDocument67 pagesPiping - Design - Chemical - Engineering - Robert Kern - Articles 1974 67pJhon Coello100% (1)

- Pyrogel XTE DatasheetDocument2 pagesPyrogel XTE DatasheetLe Thanh HaiNo ratings yet

- The Use of Control Valve Sizing Equations With Simulation Based Process DataDocument14 pagesThe Use of Control Valve Sizing Equations With Simulation Based Process DataJimmyNo ratings yet

- Crane Fluid Flow Problems Hof MasterDocument292 pagesCrane Fluid Flow Problems Hof MasterFrancisco Renteria100% (1)

- Hydrodynamic Calculation Butterfly Valve Lenticular Disc $S - D$ 0.16Document30 pagesHydrodynamic Calculation Butterfly Valve Lenticular Disc $S - D$ 0.16Eng-CalculationsNo ratings yet

- A Generalized Method For Predicting The Minimum Fluidization Velocity - C. Y. WEN and Y. H. YUDocument3 pagesA Generalized Method For Predicting The Minimum Fluidization Velocity - C. Y. WEN and Y. H. YUJoão Vitor Apolinário FerreiraNo ratings yet

- Analysis Elevated Temperature Creep SteelDocument66 pagesAnalysis Elevated Temperature Creep SteelematlisNo ratings yet

- Smith Et al-1958-AIChE Journal PDFDocument3 pagesSmith Et al-1958-AIChE Journal PDFAlastairNo ratings yet

- Orifice Flow Calculator For Gases, Steam, and VaporsDocument2 pagesOrifice Flow Calculator For Gases, Steam, and Vaporsbakhtyar21No ratings yet

- Mehran University of Engineering and Technology SZAB Campus Khairpur Mir'sDocument64 pagesMehran University of Engineering and Technology SZAB Campus Khairpur Mir'sMarcusHuynh88No ratings yet

- Wong Sandler (1992)Document10 pagesWong Sandler (1992)Anonymous PO7VwbBnNo ratings yet

- Process Industry Practices Machinery: Pip Reec001 General Guidelines For Compressor SelectionDocument62 pagesProcess Industry Practices Machinery: Pip Reec001 General Guidelines For Compressor SelectionalainNo ratings yet

- DS59 - (1980) Evaluations of The Elevated Temperature Tensilde and Creep-Rupture Properties of 12 To 27 Percent Chromium Steels PDFDocument338 pagesDS59 - (1980) Evaluations of The Elevated Temperature Tensilde and Creep-Rupture Properties of 12 To 27 Percent Chromium Steels PDFJacques StrappeNo ratings yet

- Aga 3 Orifice Metering of Natural Gas and Other Related Hydrocarbon Fluids Part 1 General Equations and UncertaintiesDocument55 pagesAga 3 Orifice Metering of Natural Gas and Other Related Hydrocarbon Fluids Part 1 General Equations and UncertaintiesLogan PerezNo ratings yet

- Flange Leakage Check: Equivalent Pressure / Kellogg MethodDocument3 pagesFlange Leakage Check: Equivalent Pressure / Kellogg Methodtom hNo ratings yet

- Sizing Calculation FCVDocument3 pagesSizing Calculation FCVYawar QureshiNo ratings yet

- BS ISO 6336-1-1996 Spur and Helical Gear CapacityDocument5 pagesBS ISO 6336-1-1996 Spur and Helical Gear CapacityT ThirumuruganNo ratings yet

- Old Noise ManualDocument28 pagesOld Noise ManualChristo KellermanNo ratings yet

- Compressibility Factor Z CalcDocument3 pagesCompressibility Factor Z CalcSrihari KodimelaNo ratings yet

- Boiler Reference SOPDocument13 pagesBoiler Reference SOPfaiq AlfaniNo ratings yet

- Flowmeter Installation EffectsDocument12 pagesFlowmeter Installation EffectsgykataiNo ratings yet

- Chien1995 PDFDocument6 pagesChien1995 PDFFelipeMorenoNo ratings yet

- Pressure Drops Two PhasesDocument13 pagesPressure Drops Two PhasesSandro Goisis100% (1)

- Two Phase Flow BibliographyDocument41 pagesTwo Phase Flow BibliographyShiv Pratap SinghNo ratings yet

- Cooling Tower Lewis FactorDocument6 pagesCooling Tower Lewis Factorshivajireturns100% (1)

- Calculs CV & KVDocument13 pagesCalculs CV & KVradiopascalgeNo ratings yet

- Two-Phase Flow Pressure DropDocument4 pagesTwo-Phase Flow Pressure DropStevenMvuyana100% (1)

- A Procedure For The Calculation of The Natural Gas Molar Heat CapacityDocument9 pagesA Procedure For The Calculation of The Natural Gas Molar Heat Capacityjlg314No ratings yet

- Design Parameters For SubsonicAir Air Ejectors PDFDocument64 pagesDesign Parameters For SubsonicAir Air Ejectors PDFEnrico GambiniNo ratings yet

- Heat Transfer TheoryDocument12 pagesHeat Transfer Theorykapare1209100% (2)

- Key Aspects Hsg253Document38 pagesKey Aspects Hsg253Enrico GambiniNo ratings yet

- Basic Calculations Piping System Design PDFDocument14 pagesBasic Calculations Piping System Design PDFjeff_shawNo ratings yet

- Pneucon PositionerDocument1 pagePneucon PositionerEnrico GambiniNo ratings yet

- 2 Sim Hydraulics ReferenceDocument430 pages2 Sim Hydraulics ReferenceEnrico GambiniNo ratings yet

- Flow MeasurementDocument113 pagesFlow Measurementprasathesr100% (1)

- Worcester Controls ActuatorDocument16 pagesWorcester Controls ActuatorEnrico GambiniNo ratings yet

- Power Control With Thyristors and TriacsDocument121 pagesPower Control With Thyristors and TriacsEnrico GambiniNo ratings yet

- Basic CalculationsDocument14 pagesBasic CalculationsleenmeijiNo ratings yet

- Refrigeration Basics and LNGDocument43 pagesRefrigeration Basics and LNGEnrico GambiniNo ratings yet

- ATC-20 Safety Assesment BuildingsDocument2 pagesATC-20 Safety Assesment BuildingsEddie ArgeñalNo ratings yet

- Vernacular Construction TechniquesDocument18 pagesVernacular Construction TechniquesAnupama ChawlaNo ratings yet

- 2001 Concrete Slab Track State of The Practice - D. Tayabji LIDODocument10 pages2001 Concrete Slab Track State of The Practice - D. Tayabji LIDORodrigo Souza FreitasNo ratings yet

- Worked Pre-Tender Example: PreliminariesDocument6 pagesWorked Pre-Tender Example: PreliminariesMuhammad IqbalNo ratings yet

- 3.1 Water Distribution in Building - Building Utilities 1 (Course Materials)Document5 pages3.1 Water Distribution in Building - Building Utilities 1 (Course Materials)SHYRA APRIL JOY DELA CRUZNo ratings yet

- Sample L Pile OutputDocument10 pagesSample L Pile OutputManikumar Chebolu100% (1)

- IS - 8110 - 2000 - Well Screens and Slotted Pipes SpecificationDocument19 pagesIS - 8110 - 2000 - Well Screens and Slotted Pipes SpecificationInsta PumpsNo ratings yet

- Accoustic Induced VibrationDocument10 pagesAccoustic Induced VibrationcpsankarNo ratings yet

- Seismic Problem Statement: Building in GeneralDocument5 pagesSeismic Problem Statement: Building in GeneralBenmark JabayNo ratings yet

- KEDIRDocument40 pagesKEDIRMarkos KochitoNo ratings yet

- DIA 3 - 5 - Research On 40-Year Life Pavement ExtensionDocument32 pagesDIA 3 - 5 - Research On 40-Year Life Pavement ExtensionAnton AbdurrahmanNo ratings yet

- Truss Arches & Frame Portal FrameDocument19 pagesTruss Arches & Frame Portal FrameRia Gurbani0% (1)

- KP 200 PDFDocument2 pagesKP 200 PDFrangass70100% (2)

- Structural CalculationsDocument43 pagesStructural CalculationsjologscresenciaNo ratings yet

- Evaluation of Epoxy Injection Method For Concrete Crack RepairDocument7 pagesEvaluation of Epoxy Injection Method For Concrete Crack RepairMohamed Ismail ShehabNo ratings yet

- Ultratech Cement: P.O. - Baikunth - 493 116, Distt - Raipur (Chhattisgarh)Document1 pageUltratech Cement: P.O. - Baikunth - 493 116, Distt - Raipur (Chhattisgarh)hemantNo ratings yet

- The 2017 AISI Cold-Formed Steel Design ManualDocument11 pagesThe 2017 AISI Cold-Formed Steel Design ManualFelipe0% (1)

- RBT - Schedule of Doors and Windows - 20211212Document3 pagesRBT - Schedule of Doors and Windows - 20211212Kathleen RunasNo ratings yet

- CV Sem-5-Civil Engineering-2019-2020-SOE-RKU PDFDocument16 pagesCV Sem-5-Civil Engineering-2019-2020-SOE-RKU PDFAkshay PatelNo ratings yet

- 1 Work ScheduleDocument17 pages1 Work ScheduleBinod ThapaNo ratings yet

- CE 362 - Topic 1 - Student'sDocument76 pagesCE 362 - Topic 1 - Student'sJohn Joseph SuanNo ratings yet

- TCVN 4513-1988 Internal Water Supply - Design Standard PDFDocument37 pagesTCVN 4513-1988 Internal Water Supply - Design Standard PDFDoThanhTungNo ratings yet

- Abutment Design Example To BD 30Document18 pagesAbutment Design Example To BD 30Yatri PérezNo ratings yet

- L2CIV003Document23 pagesL2CIV003Sanchay Singhal100% (1)

- RE Module 1 and 2Document175 pagesRE Module 1 and 2Abhi ShettyNo ratings yet

- Unit HydrographsDocument11 pagesUnit HydrographshajihuzefaNo ratings yet

- Types of Earthquake ResistantDocument5 pagesTypes of Earthquake ResistantGio BattadNo ratings yet

- VSL Post Tensioning SystemsDocument28 pagesVSL Post Tensioning SystemsSelcuk ZenginNo ratings yet

- Practical Reservoir Engineering and CharacterizationFrom EverandPractical Reservoir Engineering and CharacterizationRating: 4.5 out of 5 stars4.5/5 (3)

- Well Integrity for Workovers and RecompletionsFrom EverandWell Integrity for Workovers and RecompletionsRating: 5 out of 5 stars5/5 (3)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Internal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesFrom EverandInternal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesRating: 4 out of 5 stars4/5 (2)

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Machine Learning Guide for Oil and Gas Using Python: A Step-by-Step Breakdown with Data, Algorithms, Codes, and ApplicationsFrom EverandMachine Learning Guide for Oil and Gas Using Python: A Step-by-Step Breakdown with Data, Algorithms, Codes, and ApplicationsRating: 4 out of 5 stars4/5 (4)

- Casing and Liners for Drilling and Completion: Design and ApplicationFrom EverandCasing and Liners for Drilling and Completion: Design and ApplicationRating: 5 out of 5 stars5/5 (3)

- Well Testing Project Management: Onshore and Offshore OperationsFrom EverandWell Testing Project Management: Onshore and Offshore OperationsNo ratings yet

- Case Studies of Material Corrosion Prevention for Oil and Gas ValvesFrom EverandCase Studies of Material Corrosion Prevention for Oil and Gas ValvesNo ratings yet

- Guide to the Practical Use of Chemicals in Refineries and PipelinesFrom EverandGuide to the Practical Use of Chemicals in Refineries and PipelinesRating: 5 out of 5 stars5/5 (1)

- The Petroleum Engineering Handbook: Sustainable Operations: Sustainable OperationsFrom EverandThe Petroleum Engineering Handbook: Sustainable Operations: Sustainable OperationsRating: 3.5 out of 5 stars3.5/5 (5)

- Heat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsFrom EverandHeat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsRating: 4 out of 5 stars4/5 (6)

- Petroleum Production Engineering, A Computer-Assisted ApproachFrom EverandPetroleum Production Engineering, A Computer-Assisted ApproachRating: 4.5 out of 5 stars4.5/5 (11)

- Advanced Production Decline Analysis and ApplicationFrom EverandAdvanced Production Decline Analysis and ApplicationRating: 3.5 out of 5 stars3.5/5 (4)

- Advanced Biomass Gasification: New Concepts for Efficiency Increase and Product FlexibilityFrom EverandAdvanced Biomass Gasification: New Concepts for Efficiency Increase and Product FlexibilityRating: 3 out of 5 stars3/5 (2)

- Gas and Oil Reliability Engineering: Modeling and AnalysisFrom EverandGas and Oil Reliability Engineering: Modeling and AnalysisRating: 4.5 out of 5 stars4.5/5 (6)

- Heavy and Extra-heavy Oil Upgrading TechnologiesFrom EverandHeavy and Extra-heavy Oil Upgrading TechnologiesRating: 4 out of 5 stars4/5 (2)