Professional Documents

Culture Documents

A Portable 144 MHZ 4-Element Quad

Uploaded by

Tariq RahimOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Portable 144 MHZ 4-Element Quad

Uploaded by

Tariq RahimCopyright:

Available Formats

A Portable 144 MHz 4-Element Quad

Element spacing for quad antennas found in the literature ranges from 0.14 to 0.25 . Factors such as the number of elements in the array and the parameters to be optimized (F/B ratio, forward gain, bandwidth, etc), determine the optimum element spacing within this range. The 4-element quad antenna described here was designed for portable use, so a compromise between these factors was chosen. This antenna, pictured in Fig 56, was designed and built by Philip DAgostino, W1KSC. Based on several experimentally determined correction factors related to the frequency of operation and the wire size, optimum design dimensions were found to be as follows.

Reflector length (ft) = 1046.8 f MHz 985.5 fMHz

(Eq 8)

Driven element (ft) = 937.3 f MHz

(Eq 9)

Directors (ft) =

(Eq 10)

Cutting the loops for 146 MHz provides satisfactory performance across the entire 144MHz band.

VHF and UHF Antenna Systems 18-41

Fig 57The complete portable quad, broken down for travel. Visible in the foreground is the driven element. The pine box in the background is a carrying case for equipment and accessories. A hole in the lid accepts the mast, so the box doubles as a base for a short mast during portable operation. (W1MPO photo)

Table 17 Parts List for the 144 MHz 4-element Quad

Boom: 48-in. pine Driven element support (spreader): 21 in. pine Driven element feed point strut: 7 in. pine Reflector support (spreader): 22 in. pine Director supports (spreaders): 20 in. pine, 2 reqd Mast brackets: 1 12 in. heavy pine trim, 4 reqd Boom to mast bracket: 15/8 5 in. pine Element wire: Aluminum ground wire (Radio Shack no. 15-035) Wire clamps: in. electricians copper or zinc plated steel clamps, 3 reqd Boom hardware: 6 no. 8-32 1 in. stainless steel machine screws 6 no. 8-32 stainless steel wing nuts 12 no. 8 stainless steel washers Mast hardware: 8 hex bolts, -20 3 in. 8 hex nuts, -20 16 flat washers Mast material: 15/16 in. 6 ft wood clothes closet poles, 3 reqd Feed point support plate: 3 2 in. Plexiglas sheet Wood preparation materials: Sandpaper, clear polyurethane, wax Feed line: 52-W RG-8 or RG-58 cable Feed line terminals: Solder lugs for no. 8 or larger hardware, 2 reqd Miscellaneous hardware: 4 small machine screws, nuts, washers; 2 flat-head wood screws

Fig 56The 4-element 144-MHz portable quad, assembled and ready for operation. Sections of clothes closet poles joined with pine strips make up the mast. (Photo by Adwin Rusczek, W1MPO)

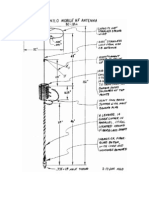

Materials The quad was designed for quick and easy assembly and disassembly, as illustrated in Fig 57. Wood (clear trim pine) was chosen as the principal building material because of its light weight, low cost, and ready availability. Pine is used for the boom and element supporting arms. Round wood clothes closet poles comprise the mast material. Strips connecting the mast sections are made of heavier pine trim. Elements are made of no. 8 aluminum wire. Plexiglas is used to support the feed point. Table 17 lists the hardware and other parts needed to duplicate the quad. Construction The elements of the quad are assembled first. The mounting holes in the boom should be drilled to accommodate 11/2 inch no. 8 hardware. Measure and mark the locations where the holes are to be drilled in the element spreaders, Fig 58. Drill the holes in the spreaders just

18-42 Chapter 18

large enough to accept the #8 wire elements. It is important to drill all the holes straight so the elements line up when the antenna is assembled. Construction of the wire elements is easiest if the directors are made first. A handy jig for bending the elements can be made from a piece of 2 3-inch wood cut to the side length of the directors. It is best to start with about 82 inches of wire for each director. The excess can be cut off when the elements are completed. (The total length of each director is 77 inches.) Two bends should initially be made so the directors can be slipped into the spreaders before the remaining corners are bent. See Fig 59. Electricians copper-wire clamps can be used to join the wires after the final bends are made, and they facilitate adjustment of element length. The reflector is made the same way as the directors, but the total length is 86 inches. The driven element, total length 81 inches, requires special attention, as the feed attachment point needs to be adequately supported. An extra hole is drilled in the driven element spreader to support the feed-point strut, as shown in Fig 60. A Plexiglas plate is used at the feed point to support the feed- point hardware and the feed line. The feed-point support strut should be epoxied to the spreader, and a wood screw used for extra mechanical strength. For vertical polarization, locate the feed point in the center of one side of the driven element, as shown in Fig 60. Although this arrangement places the spreader supports at voltage maxima points on the four loop conductors, DAgostino reports no adverse effects during operation. However, if the antenna is to be left exposed to the weather, the builder may wish to modify the design to provide support for the loops at current maxima points, such as shown in Fig 60. (The element of Fig 60 should be rotated 90 for horizontal polarization.) Orient the driven element spreader so that it mounts properly on the boom when the antenna is assembled. Bend the driven element the same way as the reflector

and directors, but do not leave any overlap at the feed point. The ends of the wires should be 3/4 inch apart where they mount on the Plexiglas plate. Leave enough excess that small loops can be bent in the wire for attachment to the coaxial feed line with stainless steel hardware. Drill the boom as shown in Fig 61. It is a good idea to use hardware with wing nuts to secure the element spreaders to the boom. After the boom is drilled, clean all the wood parts with denatured alcohol, sand them, and give them two coats of glossy polyurethane. After the polyurethane dries, wax all the wooden parts. The boom to mast attachment is made next. Square the ends of a 6-foot section of clothes closet pole (a miter box is useful for this). Drill the center holes in both the boom

Fig 59Illustration showing how the aluminum element wires are bent. The adjustment clamp and its location are also shown.

Fig 58Dimensions for the pine element spreaders for the 144-MHz 4-element quad.

Fig 60Layout of the driven element of the 144-MHz quad. The leads of the coaxial cable should be stripped to in. and solder lugs attached for easy connection and disconnection. See text regarding impedance at loop support points. VHF and UHF Antenna Systems 18-43

Fig 61Detail of the boom showing hole center locations and boom to mast connection points.

Fig 62Boom to mast plate for the 144-MHz quad. The screw hole in the center of the plate should be countersunk so the wood screw attaching it to the mast does not interfere with the fit of the boom.

Fig 63Mast coupling connector details for the portable quad. The plates should be drilled two at a time to ensure the holes line up.

Fig 64Typical SWR curve for the 144MHz portable quad. The large wire diameter and the quad design provide excellent bandwidth.

attachment piece and one end of the mast section (Fig 62). Make certain that the mast hole is smaller than the flat-head screw to be used to ensure a snug fit. Accurately drill the holes for attachment to the boom as shown in Fig 62. Countersink the hole for the flat-head screw to provide a smooth surface for attachment to the boom. Apply epoxy cement to the surfaces and screw the boom attachment piece securely to the mast section. One 6 foot mast is used for attachment to the other mast sections. Two additional 6-foot mast sections are prepared next. This brings the total mast height to 18 feet. It is important to square the ends of each pole so the mast stands straight when assembled. Mast-section connectors are made of pine as shown in Fig 63. Using 31/2 1/4-inch hex bolts, washers, and nuts, sections may be attached as needed, for a total height of 6, 12 or 18 feet. Drill the holes in two connectors at a time. This ensures good align18-44 Chapter 18

ment of the holes. A drill press is ideal for this job, but with care a hand drill can be used if necessary. Line up two mast sections end to end, being careful that they are perfectly straight. Use the predrilled connectors to maintain pole straightness, and drill through the poles, one at a time. If good alignment is maintained, a straight 18-foot mast section can be made. Label the connectors and poles immediately so they are always assembled in the same order. When assembling the antenna, install all the elements on the boom before attaching the feed line. Connect the coax to the screw connections on the driven element support plate and run the cable along the strut to the boom. From there, the cable should be routed directly to the mast and down. Assemble the mast sections to the desired height. The antenna provides good performance, and has a reasonable SWR curve over the entire 144 MHz band (Fig 64).

You might also like

- How to Make Electrical Machines: Containing Full Directions for Making Electrical Machines, Induction Coils, Dynamos, and Many Novel Toys to Be Worked by ElectricityFrom EverandHow to Make Electrical Machines: Containing Full Directions for Making Electrical Machines, Induction Coils, Dynamos, and Many Novel Toys to Be Worked by ElectricityNo ratings yet

- TH 3 MKDocument20 pagesTH 3 MKAdrianoAmadorNo ratings yet

- How to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideFrom EverandHow to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideNo ratings yet

- E Plus Kit ManualDocument27 pagesE Plus Kit ManualJCMNo ratings yet

- ManualAntenna V 2RDocument8 pagesManualAntenna V 2RToto W. JuniartoNo ratings yet

- How Two Boys Made Their Own Electrical Apparatus Containing Complete Directions for Making All Kinds of Simple Apparatus for the Study of Elementary ElectricityFrom EverandHow Two Boys Made Their Own Electrical Apparatus Containing Complete Directions for Making All Kinds of Simple Apparatus for the Study of Elementary ElectricityNo ratings yet

- Fractal Magic DIY HDTV AntennaDocument56 pagesFractal Magic DIY HDTV Antennadetroit_me2553100% (3)

- Travel AntennaDocument5 pagesTravel Antennanw2sNo ratings yet

- Steam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversFrom EverandSteam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversRating: 5 out of 5 stars5/5 (2)

- Construir Antena OmniDocument18 pagesConstruir Antena Omnianon-771596No ratings yet

- 6m MoxonDocument4 pages6m MoxonwcantrellNo ratings yet

- Antenna HandoutDocument8 pagesAntenna HandoutPhil BoxxNo ratings yet

- Fractal Magic DIY HDTV Antenna PDFDocument56 pagesFractal Magic DIY HDTV Antenna PDFDarin ArmsteadNo ratings yet

- th6 DXXDocument22 pagesth6 DXXNenad PetrovicNo ratings yet

- VB 214FMDocument10 pagesVB 214FMyu3zaNo ratings yet

- Antenna Wifi Omni VerticalDocument15 pagesAntenna Wifi Omni VerticalFaziri Abdul HaqNo ratings yet

- M2 Antenna Systems, Inc. Model No: 222-5WL: SpecificationsDocument6 pagesM2 Antenna Systems, Inc. Model No: 222-5WL: SpecificationsAndhi AerosupplyNo ratings yet

- Varied 2 Meter Homebrew Antennas-ERC TrainingDocument15 pagesVaried 2 Meter Homebrew Antennas-ERC TrainingIndika WithanageNo ratings yet

- GPS Helical Antenna DesignDocument6 pagesGPS Helical Antenna DesignGuadalajara Jalisco100% (1)

- 70 CM DuplexerDocument7 pages70 CM DuplexerEdgardo Valdez100% (1)

- Vertical Rev HDocument10 pagesVertical Rev HMiguel OyarzabalNo ratings yet

- Antennas - 2M Moxon AntennaDocument4 pagesAntennas - 2M Moxon AntennaIacob LaurentiuNo ratings yet

- CollantDocument2 pagesCollantpogee752No ratings yet

- Hy Gain AntenaDocument7 pagesHy Gain AntenaIrwan Wiradinata SondaNo ratings yet

- Copper Loops For 222 and 440MHzDocument5 pagesCopper Loops For 222 and 440MHzBenjamin Dover100% (1)

- TH 3jrs ManualDocument11 pagesTH 3jrs ManualOscar NavaNo ratings yet

- Dual Core Balun Construction ProjectDocument7 pagesDual Core Balun Construction ProjectCarlos MerelloNo ratings yet

- Pacific Antenna 20 and 40M Lightweight Dipole Kit: Diagram Showing Configuration and Approximate LengthsDocument6 pagesPacific Antenna 20 and 40M Lightweight Dipole Kit: Diagram Showing Configuration and Approximate LengthsedosviracNo ratings yet

- Endfed6 40Document8 pagesEndfed6 40Leopoldo AlvarezNo ratings yet

- 2 Meter Phased Vert AntDocument6 pages2 Meter Phased Vert AntBenny SNo ratings yet

- Fractal Magic DIY HDTV AntennaDocument33 pagesFractal Magic DIY HDTV AntennaLeonel RodriguezNo ratings yet

- Bow Tie AntennaDocument17 pagesBow Tie AntennaReen LeeNo ratings yet

- Antennas 40M3FS-125Document15 pagesAntennas 40M3FS-1257c3c conteststationNo ratings yet

- 2 Meter Sling Shot AntennaDocument7 pages2 Meter Sling Shot AntennaNiko DiamesisNo ratings yet

- Homemade RF Step AttenuatorDocument8 pagesHomemade RF Step Attenuatorngt881No ratings yet

- Sheet Metal Ar15 LowerDocument12 pagesSheet Metal Ar15 LowerCharles Keeney100% (4)

- Balun Intro and Construction 1Document6 pagesBalun Intro and Construction 1Robson Batista do nascimentoNo ratings yet

- Build A 9dB, 70cm Collinear AntennaDocument3 pagesBuild A 9dB, 70cm Collinear Antennadr3x100% (1)

- A Small Bench Lathe Made of PipeDocument2 pagesA Small Bench Lathe Made of PipeCicero Milan100% (3)

- In The Workshop: Duplex "Document6 pagesIn The Workshop: Duplex "johnboy183No ratings yet

- Bicycle Generator Stand Directions (5!10!2014)Document12 pagesBicycle Generator Stand Directions (5!10!2014)Stefan CosminNo ratings yet

- M2 Antenna Systems, Inc. Model No: 7&10-30LP8-125: SpecificationsDocument20 pagesM2 Antenna Systems, Inc. Model No: 7&10-30LP8-125: Specificationsfox7878No ratings yet

- Stacked Dipole With Gamma MatchDocument29 pagesStacked Dipole With Gamma MatchRexter Reeve Rocapor100% (1)

- End Fed 40meter Half Wave AntennaDocument4 pagesEnd Fed 40meter Half Wave AntennaDefaultAnomoly100% (1)

- 5EL 6m LFA Yagi PDFDocument10 pages5EL 6m LFA Yagi PDFآكوجويNo ratings yet

- Satcom Part 2Document5 pagesSatcom Part 2zulubaconNo ratings yet

- Manual de Rait KitDocument4 pagesManual de Rait KitFrancisco SanchezNo ratings yet

- A Plumber's Delight 3-Element 6-Meter Yagi: Article HavingDocument10 pagesA Plumber's Delight 3-Element 6-Meter Yagi: Article HavingMinorNo ratings yet

- Antena Movil HFDocument10 pagesAntena Movil HF10sd156100% (1)

- A Simple 2 m/70 CM Vertical Dipole Antenna Video InstructionsDocument4 pagesA Simple 2 m/70 CM Vertical Dipole Antenna Video InstructionsMuhammad SunartoNo ratings yet

- Make A Simple 2.425GHz HelicalDocument12 pagesMake A Simple 2.425GHz Helicalf.lastNo ratings yet

- Popular Mechanics - Homemade DC GeneratorDocument5 pagesPopular Mechanics - Homemade DC GeneratorWilliam CoteNo ratings yet

- Ununtenna Assy 082217Document5 pagesUnuntenna Assy 082217kushanv1984No ratings yet

- Motor Whittle V8 PDFDocument39 pagesMotor Whittle V8 PDFBorralla Cinza100% (1)

- 2.4Ghz Low-Power 5dbi Vertical Collinear AntennaDocument4 pages2.4Ghz Low-Power 5dbi Vertical Collinear AntennaJosepNo ratings yet

- End Fed 6 - 40 Meter Multiband HF AntennaDocument6 pagesEnd Fed 6 - 40 Meter Multiband HF AntennalimazulusNo ratings yet

- Homemade Bandsaw From Pipe Fittings and Auto PartsDocument4 pagesHomemade Bandsaw From Pipe Fittings and Auto PartsJan Steinman100% (2)

- ATrulyPortableMoxonRectangleForNearlyNo toolFieldAssemblyDocument12 pagesATrulyPortableMoxonRectangleForNearlyNo toolFieldAssemblyJeff BeardenNo ratings yet

- European Catalog Direct Operated Solenoid Valves Series 126 Asco en 7029040Document6 pagesEuropean Catalog Direct Operated Solenoid Valves Series 126 Asco en 7029040Yasser Al NasrNo ratings yet

- Global Institute of Technology: Department of Electrical EngineeringDocument3 pagesGlobal Institute of Technology: Department of Electrical EngineeringDebabrato MukherjeeNo ratings yet

- Electronic Inclinometer: Danei-300Document2 pagesElectronic Inclinometer: Danei-300insinyurNo ratings yet

- Lesson 3 - FiltersDocument29 pagesLesson 3 - FiltersRennel MallariNo ratings yet

- Limiting LM662Document5 pagesLimiting LM662rhaumeoNo ratings yet

- IEEE STD 259-1999 PDFDocument18 pagesIEEE STD 259-1999 PDFEdwin CapdepomtNo ratings yet

- Quasar Electronics Kit No. 1065 Inverter 12 VDC To 220 Vac: General DescriptionDocument6 pagesQuasar Electronics Kit No. 1065 Inverter 12 VDC To 220 Vac: General Descriptionapi-3864578No ratings yet

- Magnetic FieldsDocument14 pagesMagnetic FieldsKid KaitoNo ratings yet

- Ts A300dDocument42 pagesTs A300dEvgeniy KotNo ratings yet

- SIM900 at Command Manual V1.03Document229 pagesSIM900 at Command Manual V1.03Ben BenjiNo ratings yet

- HCPL-7800A: Isolation AmplifierDocument9 pagesHCPL-7800A: Isolation AmplifierkarkonNo ratings yet

- Laboratory 7Document4 pagesLaboratory 7Priyamdas123No ratings yet

- Overhead Distribution System DesignDocument5 pagesOverhead Distribution System DesignPhel FloresNo ratings yet

- Quiescent Current DrainDocument5 pagesQuiescent Current DrainCmj LennonNo ratings yet

- ANPC-5L Technology Applied To Medium Voltage Variable Speed Drives ApplicationsDocument8 pagesANPC-5L Technology Applied To Medium Voltage Variable Speed Drives ApplicationsRen Hong GiangNo ratings yet

- Resimold Resiglas CRT DryType CommercialBrochure enDocument12 pagesResimold Resiglas CRT DryType CommercialBrochure engreyllom9791No ratings yet

- Gas Analyzer - YokogawaDocument22 pagesGas Analyzer - YokogawaM.K.KARTHIKEYANNo ratings yet

- Ad4329 ManualDocument54 pagesAd4329 ManualHasan KendekNo ratings yet

- Flow Control ValvesDocument2 pagesFlow Control ValvesAnik FaisalNo ratings yet

- News 210 Spanish Etl Etc EflDocument2 pagesNews 210 Spanish Etl Etc EflespernancacionNo ratings yet

- How Did Bill Gates and Steve Jobs Differ in Their Leadership StyleDocument4 pagesHow Did Bill Gates and Steve Jobs Differ in Their Leadership StyleDip Kumar Dey67% (9)

- Installers Manual Sliding Door AutomationDocument55 pagesInstallers Manual Sliding Door AutomationSidney Moraes AlvesNo ratings yet

- Gree-44814 09K 12K (LCLH)Document87 pagesGree-44814 09K 12K (LCLH)MatyoJNo ratings yet

- WPT 2 e 33Document4 pagesWPT 2 e 33Julio Juarez RodriguezNo ratings yet

- Brushless DC MotorsDocument21 pagesBrushless DC MotorsKiran KumarNo ratings yet

- Manual: iSTAT I400 Standard TransducerDocument62 pagesManual: iSTAT I400 Standard TransducerMehdi_Mashayekhi_172No ratings yet

- Practical Guide To InstrumentationDocument12 pagesPractical Guide To InstrumentationradiobrunoNo ratings yet

- 2N5320 2N5321 NPN 2N5322 2N5323 PNP Complementary Silicon Switching Transistors DescriptionDocument3 pages2N5320 2N5321 NPN 2N5322 2N5323 PNP Complementary Silicon Switching Transistors Descriptionfabian orozNo ratings yet

- Ieee Standard 1016Document3 pagesIeee Standard 1016Juan Carlos Cabrera GudiñoNo ratings yet

- GDS-2000A User Manual 2013 1003Document261 pagesGDS-2000A User Manual 2013 1003Antonio Carlos ZimmermannNo ratings yet

- The Arm: Inside the Billion-Dollar Mystery of the Most Valuable Commodity in SportsFrom EverandThe Arm: Inside the Billion-Dollar Mystery of the Most Valuable Commodity in SportsRating: 4 out of 5 stars4/5 (49)

- Bloodlines: The True Story of a Drug Cartel, the FBI, and the Battle for a Horse-Racing DynastyFrom EverandBloodlines: The True Story of a Drug Cartel, the FBI, and the Battle for a Horse-Racing DynastyRating: 4 out of 5 stars4/5 (8)

- Crazy for the Storm: A Memoir of SurvivalFrom EverandCrazy for the Storm: A Memoir of SurvivalRating: 3.5 out of 5 stars3.5/5 (217)

- Becky Lynch: The Man: Not Your Average Average GirlFrom EverandBecky Lynch: The Man: Not Your Average Average GirlRating: 4.5 out of 5 stars4.5/5 (15)

- Merle's Door: Lessons from a Freethinking DogFrom EverandMerle's Door: Lessons from a Freethinking DogRating: 4 out of 5 stars4/5 (326)

- Elevate and Dominate: 21 Ways to Win On and Off the FieldFrom EverandElevate and Dominate: 21 Ways to Win On and Off the FieldRating: 5 out of 5 stars5/5 (7)

- Life Is Not an Accident: A Memoir of ReinventionFrom EverandLife Is Not an Accident: A Memoir of ReinventionRating: 3.5 out of 5 stars3.5/5 (7)

- Welcome to the Goddamn Ice Cube: Chasing Fear and Finding Home in the Great White NorthFrom EverandWelcome to the Goddamn Ice Cube: Chasing Fear and Finding Home in the Great White NorthRating: 4 out of 5 stars4/5 (59)

- The Last Dive: A Father and Son's Fatal Descent into the Ocean's DepthsFrom EverandThe Last Dive: A Father and Son's Fatal Descent into the Ocean's DepthsNo ratings yet

- Badasses: The Legend of Snake, Foo, Dr. Death, and John Madden's Oakland RaidersFrom EverandBadasses: The Legend of Snake, Foo, Dr. Death, and John Madden's Oakland RaidersRating: 4 out of 5 stars4/5 (15)

- Survive!: Essential Skills and Tactics to Get You Out of Anywhere—AliveFrom EverandSurvive!: Essential Skills and Tactics to Get You Out of Anywhere—AliveNo ratings yet

- Relentless: From Good to Great to UnstoppableFrom EverandRelentless: From Good to Great to UnstoppableRating: 5 out of 5 stars5/5 (787)

- What Winners Won't Tell You: Lessons from a Legendary DefenderFrom EverandWhat Winners Won't Tell You: Lessons from a Legendary DefenderRating: 4.5 out of 5 stars4.5/5 (7)

- Peak: The New Science of Athletic Performance That is Revolutionizing SportsFrom EverandPeak: The New Science of Athletic Performance That is Revolutionizing SportsRating: 5 out of 5 stars5/5 (97)

- The Perfect Mile: Three Athletes, One Goal, and Less Than Four Minutes to Achieve ItFrom EverandThe Perfect Mile: Three Athletes, One Goal, and Less Than Four Minutes to Achieve ItNo ratings yet

- Patriot Reign: Bill Belichick, the Coaches, and the Players Who Built a ChampionFrom EverandPatriot Reign: Bill Belichick, the Coaches, and the Players Who Built a ChampionRating: 3.5 out of 5 stars3.5/5 (30)

- Can't Nothing Bring Me Down: Chasing Myself in the Race Against TimeFrom EverandCan't Nothing Bring Me Down: Chasing Myself in the Race Against TimeRating: 4 out of 5 stars4/5 (1)

- House of Nails: A Memoir of Life on the EdgeFrom EverandHouse of Nails: A Memoir of Life on the EdgeRating: 3 out of 5 stars3/5 (4)

- Body Confidence: Venice Nutrition's 3 Step System That Unlocks Your Body's Full PotentialFrom EverandBody Confidence: Venice Nutrition's 3 Step System That Unlocks Your Body's Full PotentialRating: 4 out of 5 stars4/5 (2)

- Endure: How to Work Hard, Outlast, and Keep HammeringFrom EverandEndure: How to Work Hard, Outlast, and Keep HammeringRating: 4.5 out of 5 stars4.5/5 (285)

- Earnhardt Nation: The Full-Throttle Saga of NASCAR's First FamilyFrom EverandEarnhardt Nation: The Full-Throttle Saga of NASCAR's First FamilyRating: 3.5 out of 5 stars3.5/5 (7)

- Strength Training Over 40: The Only Weight Training Workout Book You Will Need to Maintain or Build Your Strength, Muscle Mass, Energy, Overall Fitness and Stay Healthy Without Living in the GymFrom EverandStrength Training Over 40: The Only Weight Training Workout Book You Will Need to Maintain or Build Your Strength, Muscle Mass, Energy, Overall Fitness and Stay Healthy Without Living in the GymRating: 4 out of 5 stars4/5 (6)