Professional Documents

Culture Documents

What Are Liposomes?

Uploaded by

BiosynthesisOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

What Are Liposomes?

Uploaded by

BiosynthesisCopyright:

Available Formats

What are liposomes? Liposomes were first described by Bangham in 1965 while studying cell membranes.

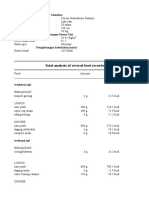

He found that lipsomes are vesicular structures consisting of hydrated bilalyers which form spontaneously when phospholipids are dispersed in water. Since this, further studies into liposomes and their application in various fields such as medicine and research have been explored. Phospholipids are the main component of naturally occurring bilayers. These phospholipids include phosphatidylcholines (PC), phosphatidylethanolamines (PE) and phosphatidylserines (PS) [1]. The key common feature that bilayer-forming compounds share is their amphiphilicity ie., they have defined polar and non-polar regions. This is the reason the non-polar regions orientate themselves towards the interior away from the aqueous phase, the polar regions being in contact with it. Liposomes can be classified by either their structural properties or the basis of their preparation. The main types are listed and their characteristics are outlined in the table below. Vesicle Types Small unilamellar vesicles Large unilamellar vesicles Multilamellar vesicles Oligolamellar vesicles Multivesicular vesicles Abbrev SUV LUV MLV OLV MMV Diameter Size Diameter of 20100nm. Diameter of 100nm. Diameter of 0.5m. Diameter of 0.11m. Diameter of 1m. Number of lipid bilayers One lipid bilayer One lipid bilayer Five to twenty lipid bilayers Approximately five lipid bilayers Multicompartmental structure [2]

Preparation of liposomes An important parameter to consider when addressing the formation process of liposomes is the rigidity of the bilayer. Hydrated-single component phospholipid bilayers can be in a liquid-crystalline (fluid) state or in a gel state. By increasing the temperature, the gel state bilayer melts and is converted into the liquid state. This occurs at a temperature known as the transition temperature (Tc). The Tc of a bilayer depends on: 1. Acyl chain length. 2. Degree of saturation. 3. Polar head group. The Tc can vary between 15C for egg yolk phosphatidylcholine (high degree of unsaturation) to over 50C for fully saturated distearolylphosphatidylcholine (DSPC) [3]. The raw material for liposome formation depends on the intended use of the liposome. Several companies supply reasonable grade and priced lipids which usually contain at least 98% phospholipid and less than 1% lysophospholipid, low endotoxin and microbial load and trace metals. It is up to the individual investigator to purify the lipid to acceptable standards. (see http://www.avantilipids.com/LipidsForLiposomeFormation.html for further info)

Prepared by Marion O' Doherty, Nanobiotechnology and Bioanalysis Group, 2004

There are five main groups of phospholipids that are available that can be used for liposome preparation. 1. 2. 3. 4. 5. Phospholipid from natural sources. Phospholipid modified from natural sources. Semi-synthetic phospholipid. Fully-synthetic phospholipid, Phospholipid with non-natural headgroups [2].

Phosphatidylcholine (PC), phosphatidylenolamine (PE) and phosphatidyserine (PS) are commonly used phospholipids for liposome preparation. Cholesterol can be added to the bilayer mixture to reduce the permeability of fluid crystalline state bilayers. There are many different strategies for the preparation of liposomes, which can be classified into 3 main groups. 1. Mechanical methods A. Film method. The original method of Bangham et al. is still the simplest procedure for the liposome formation but is limited because of its low encapsulation efficiency. This technique produces liposomes by hydrating thin lipid films deposited from an organic solution on a glass wall by shaking at temperatures above the Tc. The solvent is removed at reduced pressure in a rotary evaporator. The dry film of lipids which has been deposited onto the wall of a round-bottom flask is hydrated by adding a buffer with a water soluble marker. As the lipid becomes hydrated and starts to form into closed vesicles only a small amount of the solute becomes entrapped. This method yields a heterogeneous sized population of MLVs over 1m in diameter. Further procedures must be employed to achieve a homogeneous population, which will be discussed later [3]. B. Ultrasonication method. Ultrasonication of an aqueous dispersion of phospholipids with a strong bath sonicator or a probe sonicator will usually yield SUVs with diameters down to 15-25nm. 2. Methods based on replacement of organic solvent. A. Reverse-phase evaporation. In this method, several phospholipids (pure/mixed with cholesterol) can be used. The lipid mixture is added to a round bottom flask and the solvent is removed under reduced pressure by a rotary evaporator. The system is purged with nitrogen and the lipids are re-dissolved in the organic phase. This is the phase that the reverse phase vesicles will form. Diethly ether and isopropyl ether are the usual solvents of choice. After the lipids are re-dissolved in this phase the aqueous phase (contains compound to be encapsulated) is added. The system is kept under continuous nitrogen and the two-phase system is sonicated until the mixture becomes a clear one-phase dispersion. The mixture is then placed on the rotary evaporator and the organic solvent removed until a gel is formed. Non-encapsulated material is removed. The resulting liposomes are are called reverse-phase evaporation vesicles (REV). The large unilamellar and oligolamellar vesicles formed have the ability to encapsulate large macromolecular vesicles with high efficiency [4].

Prepared by Marion O' Doherty, Nanobiotechnology and Bioanalysis Group, 2004

B: Ether vaporisation method. In this method a mixture of lipids in an organic solvent (diethyl ether, ethanol, etc.) is slowly injected into a warm aqueous solution. This results in osmotically active, unilamellar vesicles with a well defined size distribution and high volume trapping efficiency (about ten times that of sonicated and hand shaken preparations [5]. 3. Methods based on size transformation or fusion of preformed vesicles. A: Freeze-thaw extrusion method. Liposomes formed by the film method are vortexed with the solute to be entrapped until the entire film is suspended and the resulting MLVs are frozen in a dry ice/acetone bath, thawed in lukewarm water and vortexed again. After two additional cycles of freeze-thaw and vortexing the sample is extruded three times. This is followed by six freeze-thaw cycles and an additional eight extrusions. The resulting liposomes are called large unilamellar vesicles by extrusion technique (LUVET) and they typically contain internal solute concentrations which are much higher than external solute concentrations ie. , they have entrapment ratios greater than one [6]. Proteins can be effectively encapsulated using this technique [7]. B: The dehydration-rehydration method. This method begins with empty buffer containing SUVs (handshaken MLVs can be also be used but are usually not preferred). These are mixed with the component to be entrapped, after which they are dried. Freeze-drying is often the method of choice but other methods such as by vacumn or under a stream of nitrogen can be used. The vesicles are then rehydrated. A mechanism has been proposed whereby as the vesicles become more concentrated during dehydration, they flatten and fuse forming multilamellar planes where the solute is sandwiched. Therefore on hydration, larger vesicles are formed. This technique is mild and simple, the main limitation being the heterogeneity of the size of the size of the liposomes [8]. Sizing of the liposomes. Size characteristics of liposomes have a major effect on their fate ie, what applications they can be used for. Therefore, liposome production procedures must generate predictable and reproducible particle size distributions within a certain size range. Sizing of liposomes (if the population is heterogeneous) is usually performed by sequential extrusion at relatively low pressures through polycarbonate membranes. It is easy, reproducible, no detectable degradation of the phospholipids takes place and it can double the encapsulation efficiency of the liposome preparation. Membranes of pore size 0.2m will yield liposomes of 0.27m. It is necessary to seal the membrane holder tightly to avoid leaks [9]. Gel chromatography can also be used to size liposomes but more typically used to remove un-encapsulated components by seperation [2]. Sonication is another process that is widely applied when sizing liposomes. Probe sonication is used rather than bath sonication and it produces small unilamellar vesicles of 20nm. There are many disadvantages associated with this technique: 1. Exclusion of oxygen is difficult which results in peroxidation reactions. 2. Titanium probes shed metal particles resulting in contamination. 3. They can generate aerosols which excludes them with from use with certain agents.

Prepared by Marion O' Doherty, Nanobiotechnology and Bioanalysis Group, 2004

These problems can be avoided with the use of bath sonicators but reproducible results are difficult because of the number of varying parameters associated with such baths ( level and temperature of water, position of liposome in the bath, etc.) [3]. Liposomes in immunoassays. The liposome immunoassay system is usually based on membrane immunochemistry and the release of a detectable marker. In an enzyme linked immunosorbent assay (ELISA) the enzyme label generates a measurable amount of product which is proportional to the unknown concentration of an antigen. These ELISAs can be either competitive or non-competitive, direct or indirect of which there are many variations. In a non-competitive assay an antigen is sandwiched between two antibodies. The solid phase antibodies attach onto the plate surface where they capture the antigen (usually the component being measured) and the detecting antibody is added which is labelled with enzyme. A substrate is then added which generates a signal. The amount of antigen is proportional to the signal produced In a competitive assay the two reactants are competing to bind a third, the third of which is limited. The reactants can be two antibodies (one labelled) or two antigens (one labelled). The assay is called an immunoassay is the antibody is labelled and an immunometric assay if the antigen is labelled. In a direct ELISA, the primary antibody is labelled whereas in an indirect ELISA the primary antibodies are not labelled, secondary antibodies which are directed against the antigen [10]. A substrate is usually added as the last step to develop the colour and results in detection of the unknown component. There are a number of limitations with ELISAs. An indirect sandwich assay can take up to six hours complete and the sensitivity of the assay is limited to one label per molecule to be detected. It is possible to create a liposome immunoassay similar to ELISA by replacing the enzyme which is conjugated to the antibody with a liposome which has encapsulated many marker molecules. In this way the amount of maker molecules can be multiplied and the sensitivity of the assay can be increased [11]. As aforementioned the liposomal interior aqueous pocket can encapsulate many molecules of interest, drugs, genes and in the case of analytical applications marker molecules such as enzymes or flurophores. In immunoassays antibodies can be incorporated into the lipid bilayer and in this way when they attach to their target the liposome is typically lysed by detergent, releasing the encapsulated molecule. Complement-mediated lysis assays [12] comprise of the largest group of liposome immunoassays however it is advantageous if they can self-lyse, eliminating the need for addition of a lysing agent. This has been studied in the case of temperature sensitive liposomes, where the immunoliposomes undergo a rapid destabilisation reaction at an elevated temperature [13]. In these liposomes additional reagents are added when preparing the liposomes to make them stable in all conditions except when heated. These liposome assays are useful, nevertheless there is a final type of immunoliposomes that can be used in immunoassays, these are target sensitive liposomes. In this design the antibodies are used as stabilisers in the phospholipid bilayer. The orientation of the antibody in the bilayer is a major factor in stabilisation.

Prepared by Marion O' Doherty, Nanobiotechnology and Bioanalysis Group, 2004

Target specific binding to the antigen is sufficient to induce bilayer destabilisation ie. The liposomes are destabilised by antigen binding [14]. When the marker molecule is released, for example the enzyme, the substrate for the enzyme may be immobilised on the surface, which would make the assay reagentless, washless and target specific. This type of immunoassay is very fast and easy to use , untrained personnel can perform it as one easy step.

Markers. The main markers of interest in immunoassays are enzymes and flurophores, both of which can be easily incorporated in to the aqueous interior of liposomes. Enzymes are the traditional marker molecules, examples of which are alkaline phosphatase (AP), horseradish peroxidase (HRP) and glucose oxidase (GOX). These molecules are quite large therefore the maximum that can be encapsulated is between 10-100 molecules in 200nm LUVs. Fluorophores such as carboxyfluorescein (CF), FITC, sulforhodamine and calcein are widely used as markers and because of their small molecular weight many thousands may be encapsulated leading to an extremely high sensitivity of detection. However their size can lead to one main limitation which enzymes do not encounter. Smaller fluorophore molecules tend to leak through the liposome membrane more so than larger enzyme molecules [2]. Conjugation of antibodies to the liposome. In all applications of immunoliposomes in immunassays, the amount of liposome uncapsulated marker must be related to the amount of antigen of unknown concentration. Though antibody molecules are known to bind non-specifically to liposomes and can be sonicated into the liposomal membrane, covalent attachment should prove a better method for antibody association with vesicles since the process should be controllable and should yield more stable liposomes that could displace nonspecifically adsorbed immunoglobulins [15] There is one main strategy for the coupling of antibodies to liposomes. The functional groups on the liposomes are conjugated with a heterobifunctional crosslinker to a functional group on the antibody. The functional group can be an amino in PE, DPPE and most proteins, a thiol group in Fab fragments or a hydroxyl group in glycolipids and glycoproteins. In an antibody a thiol group can be introduced by first performing a pepsin digestion yielding Fab dimmers followed by reduction with dithiothreitol (DTT). This step generates thiol-terminated Fab monomer fragments. Following removal of the DTT the Fab fragments are mixed with the liposome vesicles resulting in a stable thioether cross-linkage [3]. Another method of covalently attaching antibodies to liposomes is by using dehydration-rehydration vesicles to covalently attach antibodies to liposomes under conditions in which contact of solutes fated for entrapment with reagents used in the coupling process is avoided. In the first step the antibody is covalently attached to empty buffer containing SUVs. Next the solute to be entrapped is added to the antibody bearing empty SUVs and the mixture is freeze-dried. On rehydration, dehydrationrehydration vesicles (DRV) are formed with most of the antibody exposed on the outer bilayer capable of interacting with the target antigen. Following conversion of the SUVs to DRVs most (84.9%) of SUV bound antibody is recovered in the DRVs [16]. As mentioned there are also non-covalent methods of attaching antibodies to liposomes which can offer milder approaches to antibody-liposome association. One

Prepared by Marion O' Doherty, Nanobiotechnology and Bioanalysis Group, 2004

method exploits the high affinity of streptavidin for biotin. It is a two step protocol which involves the initial attachment of streptavidin to liposomes containing biotin PE followed by the coupling of biotinated antibodies to the strepavidin liposomes. The association is a swift two step method of attacking biotinated antibodies to biotinated liposomes in a mild incubation procedure. The main advantage is that it can be readily extended to couple any biotinated antibody or protein to lioposomal systems [17].

Characterisation of liposomes. After preparation and before use in an immunoassay the liposomes must be characterised. The most important things to be characterised are size, stability, captured volume and organic phosphorous content. Starting with size characterisation, this can be done by dynamic light scattering (DLS). In this method the scattering of laser light is influenced by the Brownian movement of the liposomes which is used as a measure for the diffusion co-efficient, this can then be used to calculate the liposome size. Size can also be determined by measuring an elelectrical current across a flow of liposomes. The current is propotional to the size of the liposomes. Electron microscopy can also be used to visualise the size of liposomes [2]. The stability of the liposomes is also of great importance and needs to be considered when characterising the batch of liposomes. There are many aspects of stability namely chemical and physical stability. The chemical instability mainly concerns two degradation pathways, oxidative and hydrolytic. Oxidation of phospholipids in liposomes mainly takes place in unsaturated fatty acyl chain-carrying phosphlipids. These chains are oxidised via a free radical chain mechanism in the absence of particular oxidants. Storage at low temperatures and protection from light and oxygen will reduce the chance of oxidation. Further protection could be enhanced with the addition of antioxidants such as -tocopherol and butyl hydroxy toluene. Working under nitrogen or argon also minimises the oxidation of lipids during preparation. The hydrolysis of ester bonds can also be reduced by optimising the pH, temperature, ionic strength, chain length and headgroup and the amount of cholesterol incorporated into the bilayer [18]. There are many aspects to physical instability. Stabilisation may be achieved by careful selection of the bilayer components, for example cholesterol is added to permeable bilayers to decrease leakage rates [19]. The captured volume of the liposome is another parameter that needs to be characterised. The most common approach has been to incorporate an impermeable aqueous marker in the hydrating buffer solution. Once the liposomes are formed the distribution of the solute is measured by comparing the solid/lipid ratio before and after removal of the unencapsulated marker. The internal volume can be found if Vtotal and Vout are determined. Vtotal=Vin +Vout +Vlipid [20]. The phosphate content needs to be determined to characterise the amount of phospholipid in the liposomal bilayer. Most protocols for this assay have been taken from the work of Chen et al. where the phosphate is first digested by concentrated acis and then is complexed by ascorbic acids and ammonium molybdate which yields a coloured compound that is readily detected spectrophotometrically [21].

Prepared by Marion O' Doherty, Nanobiotechnology and Bioanalysis Group, 2004

Bibliography. [1] D. Chapman. Liposomal technology, 1:1-18, 1983. [2] H.A.H Rongen, A. Bult and W.P van Bennekom. J. Immuno. Methods, 204:105-133, 1997. [3] D.J.A Crommelin. Liposomes, 3:73-190. [4] Jr. F. Szoka and D. Papahadjopoulos. Proc. Natl. Acad. Sci. USA, 60:4194-4198, 1978. [5] D. Deamer and A. D. Bangham. Biochem. Biophys. Acta, 443:629-34, 1976. [6] C. J. Chapman et al. Chem. Physic. Lipid, 60:201-208, 1991. [7] K. Sou et al. Biotechnol. Prog, 19:1547-1552, 2003. [8] C. Kirby and G. Gregoriadis. Biotechnology, ?:979-984, 1984. [9] F. Olsen et al. Biochem. Biophys. Acta, 557:9-23, 1979. [10] J. R. Crowther. ELISA, theory and practice, 42:36-39, ?. [11] K. Horton. Disertation for degree of Advanced Studies in Chemical Engineering, Universitat Rovira I Virgili, 2003. [12] C. K. Kim and S. J. Lim. J. Immuno. Methods, 159:101-106, 1993. [13] P. Pinnaduwage and L. Huang. Biochemistry, 31:2850-2855, 1992. [14] R. J. Y. Ho, B. T. Rouse and L. Huang. Biochemistry, 25:5500-5506, 1986. [15] T. D. Heath et al. Biochem. Biophys. Acta, 599:42-62, 1980. [16] J. Senior and G. Gregoriadias. Biochem. Biophys. Acta, 1003:58-62, 1989. [17] H. Loughrey, M. B. Bally and P.R. Cullis. Biochem. Biophys. Acta, 901:157-160, 1987. [18] M. Grit and D. J. A. Crommelin. Chem. Physic. Lipid, 64:3-18, 1993. [19] D. J. A. Crommelin et al. Physical Stability on long-term storage, ?:335-344, ?. [20] W.R. Perkins et al. Chem. Physic. Lipid, 64:197-217, 1993. [21] P.S. Chen, T.Y. Toribara and H. Warner. Anal.Chem., 28:1756-1758, 1956.

Prepared by Marion O' Doherty, Nanobiotechnology and Bioanalysis Group, 2004

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Quant Job Application ChecklistDocument4 pagesQuant Job Application Checklistmetametax22100% (1)

- Questions To Client On SAP HCMDocument19 pagesQuestions To Client On SAP HCMeurofighterNo ratings yet

- Tumor Suppressor APC Blocks DNA Polymerase - Dependent Strand Displacement Synthesis During Long Patch But Not Short Patch Base Excision Repair and Increases Sensitivity To Methylmethane SulfonateDocument8 pagesTumor Suppressor APC Blocks DNA Polymerase - Dependent Strand Displacement Synthesis During Long Patch But Not Short Patch Base Excision Repair and Increases Sensitivity To Methylmethane SulfonateBiosynthesisNo ratings yet

- And + Peptide That Is Recognized by Human CD4 Characterization of ADocument13 pagesAnd + Peptide That Is Recognized by Human CD4 Characterization of ABiosynthesisNo ratings yet

- Induction of Hepatitis A Virus-Neutralizing Antibody by A Virus-Specific Synthetic PeptideDocument4 pagesInduction of Hepatitis A Virus-Neutralizing Antibody by A Virus-Specific Synthetic PeptideBiosynthesisNo ratings yet

- A Simple Method For Displaying The Hydropathic Character of A ProteinDocument28 pagesA Simple Method For Displaying The Hydropathic Character of A ProteinBiosynthesisNo ratings yet

- Silencing of microRNAs in Vivo With Antagomirs'Document5 pagesSilencing of microRNAs in Vivo With Antagomirs'BiosynthesisNo ratings yet

- Eim s2000 Series Brochure PDFDocument16 pagesEim s2000 Series Brochure PDFHumbertoOtaloraNo ratings yet

- Pioneer Deh-P4850mp p4850mphDocument76 pagesPioneer Deh-P4850mp p4850mphVxr GsiNo ratings yet

- Tool 10 Template Working Papers Cover SheetDocument4 pagesTool 10 Template Working Papers Cover Sheet14. Đỗ Kiến Minh 6/5No ratings yet

- Structral DatasheetDocument254 pagesStructral DatasheetdeepakNo ratings yet

- Green Partnership of The Future: DieselfactsDocument12 pagesGreen Partnership of The Future: DieselfactsKamal WanniarachchiNo ratings yet

- While & Dewsbury (2011 Online) Nursing & ICT-A Discussion of Trends & Future DirectionsDocument9 pagesWhile & Dewsbury (2011 Online) Nursing & ICT-A Discussion of Trends & Future DirectionsGuy DewsburyNo ratings yet

- Potential Prospect 1.7Document6 pagesPotential Prospect 1.7Joshua M. GenoviaNo ratings yet

- Day Case Open Appendectomy: A Safe and Cost-Effective ProcedureDocument9 pagesDay Case Open Appendectomy: A Safe and Cost-Effective ProcedureAcademecian groupNo ratings yet

- Sim Medium 2 (English)Document2 pagesSim Medium 2 (English)TheLobitoNo ratings yet

- Surgical Management in LeprosyDocument33 pagesSurgical Management in Leprosynsv.epicNo ratings yet

- Chapter 23Document9 pagesChapter 23Trixie Myr AndoyNo ratings yet

- Aircraft Noise Management: Graduation Project Defense For The Diploma of Air Traffic Management EngineerDocument46 pagesAircraft Noise Management: Graduation Project Defense For The Diploma of Air Traffic Management Engineerchouchou chamaNo ratings yet

- PL 806aDocument45 pagesPL 806acesar luis gonzalez rodriguezNo ratings yet

- Radiador y Sus Partes, Motor Diesel 504BDTDocument3 pagesRadiador y Sus Partes, Motor Diesel 504BDTRamón ManglesNo ratings yet

- Learners ' Health and Safety Practices and Their Academic PerformanceDocument10 pagesLearners ' Health and Safety Practices and Their Academic PerformanceHira SaddozaiNo ratings yet

- ANNEX I of Machinery Directive 2006 - 42 - EC - Summary - Machinery Directive 2006 - 42 - CE - Functional Safety & ATEX Directive 2014 - 34 - EUDocument6 pagesANNEX I of Machinery Directive 2006 - 42 - EC - Summary - Machinery Directive 2006 - 42 - CE - Functional Safety & ATEX Directive 2014 - 34 - EUAnandababuNo ratings yet

- Tugas Gizi Caesar Nurhadiono RDocument2 pagesTugas Gizi Caesar Nurhadiono RCaesar 'nche' NurhadionoNo ratings yet

- Daikin Sky Air (RZQS-DV1) Outdoor Technical Data BookDocument29 pagesDaikin Sky Air (RZQS-DV1) Outdoor Technical Data Bookreinsc100% (1)

- All About 304 Steel (Properties, Strength, and Uses)Document7 pagesAll About 304 Steel (Properties, Strength, and Uses)ZebNo ratings yet

- UNICEF Annual Report - Water 2018Document20 pagesUNICEF Annual Report - Water 2018Ross WeistrofferNo ratings yet

- Cdd161304-Manual Craftsman LT 1500Document40 pagesCdd161304-Manual Craftsman LT 1500franklin antonio RodriguezNo ratings yet

- Naming Alcohols, Aldehydes. EtcDocument1 pageNaming Alcohols, Aldehydes. Etcim_mikezNo ratings yet

- Screenshot 2019-10-30 at 12.44.00Document25 pagesScreenshot 2019-10-30 at 12.44.00Miền VũNo ratings yet

- Information Technology Solutions: ADMET Testing SystemsDocument2 pagesInformation Technology Solutions: ADMET Testing Systemskrishgen biosystemsNo ratings yet

- PCB Engraver Operator Manual PDFDocument41 pagesPCB Engraver Operator Manual PDFmyoshkeuNo ratings yet

- ASHRAE52Document8 pagesASHRAE52ImranAtheeqNo ratings yet

- Achievement Test Science 4 Regular ClassDocument9 pagesAchievement Test Science 4 Regular ClassJassim MagallanesNo ratings yet