Professional Documents

Culture Documents

Question-Answer For Degree of Galvanizing

Uploaded by

IFan SageOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Question-Answer For Degree of Galvanizing

Uploaded by

IFan SageCopyright:

Available Formats

Home/Sitemap you are here:

Forum => letter 24568

Question on Hot Dip Galvanising

+++ In hot dip galvanising, why we use, lower layer of lead along with Zinc with other metal composition in metal pot and what is the basic function of lead in hot dip galvanising.

Vipin Jain galvanised steel manufacturing - Biratnagar, Morang, Nepal +++ Hot-dip Galvanizing is based on alloying Iron with zinc. Traces of iron introduced into the zinc kettle(carry-over with the material to be galvanized from wet pre-treatment, from the steel zinckettle-wall and the material to be galvanized will alloy with the zinc too, thus forming zinc-iron alloy particles called dross. This dross is some heavier than the zinc and will slightly sink to bottom of the kettle. Lead has two functions: 1. dissolved lead in the zinc-melt has influence on the fluidity of the zinc and will help dross particles sink to the bottom - floating dross particles

will cause roughness on the material to be galvanized(bad quality) 2. The lead layer on the bottom of the kettle will prevent dross will be stuck to the iron kettle-bottom and makes it possible to remove the dross from the bottom of the kettle, because lead is heavier than the dross and will not alloy with the dross and zinc - so dross floats on the lead-layer.

Dolf van den Berg - Leusden, The Netherlands +++ In my previous question, I asked, why we use lower layer of lead in zinc kettle, I got satisfactory answer. Now will anyone please tell me, can we use another metal in place of lead in zinc kettle for such functionality in galvanising process. Regards, Vipin Jain galvanised steel manufacturing - Biratnagar, Morang, Nepal +++ Coming back on your second question I don't know the reason why you like to change lead for something else, but in Scandinavia lead will be forbidden for environmental reasons. Bismuth or Tin could be elements to replace the function of dissolved lead. These elements cause a high fluidity of the zinc and a good wetting of the steel. De-drossing of the kettle is hardly a problem. Cominco - Canada made investigations adding Bismuth to Zinc for hot-dip galvanizing. Regards,

Dolf van den Berg - Leusden, The Netherlands +++ Regarding to the question of dross forming, how to minimize the dross forming? Is the

temperature of the zinc bath influence the dross formation? Or should we put some additive element like aluminium to minimize? Catherine Sim Li Ling - Kuching, Sarawak, Malaysia +++ Temperature has influence on dross forming (the higher the more iron loss), but with normal galvanizing temperatures (around 450 degr.C) there is hardly no difference. At a temperature 490-520 degr.C your kettle is in danger (high iron loss. Aluminium makes zinc more fluid, influences the structure of the alloy layer, reduces zinc-ash forming and gives a better color and gloss of galvanized material. Biggest influence on dross forming is carry over of dissolved iron from pickling via rinse and flux. Finally I have to tell you the whole process is too complicated to explain everything via finishing.com. Maybe you need a galvanizing course.

Dolf van den Berg - Leusden, The Netherlands ++++ Aluminium have the function in cleaning oil of cold roll steel sheets. Anyone can rectified this statement? If true, how is the process? FY Fong - Malaysia ++++++ Which of the parameters responsible for dross generation and how to reduce top and bottom dross? actually I'm doing thesis on reduction of dross generation . So I want to know the parameter on which the dross generation depends and also how to reduce the dross generation ? please give the response as soon as possible. Bharat Kumar Lautre SLIET COLLEGE OF ENGG - PUNJAB, INDIA ++++++ Dear Mr LAUTRE Please write Title of your project, & faculty you belong. In research You have to carry out lot of literature survey. & potentiality of investigation has to be ascertained. Hearing from you I may provide little clue & rest is your dedication BEST WISHES, Dr Pradeep kumar Maitra

- BHILAI, Chhattisgarh, INDIA ++++++ SIRI WANT TO KNOW - HOW TO REFINE THE LEAD FROM THE BOTTOM LAYER OF LEAD USED IN HOT DIP GALVANISING TANK I.E ZINC BASED LEAD, CONTAINS DROSS ALSO ? AND WHAT WILL BE THE RECOVERY EFFICIENCY ? GULSHAN RAM - HYDERABAD, INDIA September 25, 2008 Hello Sir, I have seen earlier question & answer for earlier question, its very impressive. I need some clarification. 1. Regarding Coating We are repeatedly facing problem in galvanizing hardened & tempered low alloy steel. Coating will not be uniform, un galvanized patches & all, but in case of mild steel there is no such problem, what shall be the reason. Also if the material is having grinding finish, is galvanizing coating makes any difference. 2. what's the roll of flux in galvanizing & what's the correct fluxing method & how to make & use flux. Hope you will do the needful at the earliest. Thanks & Regards Prashanth PRASHANTH - INDIA August 3, 2009 How to minimize dross formation? Sami Allen - Saudi Arabia August 21, 2009 Hi, Cousin Sami. Mr. Van den Berg has invested a bit of his time answering that question. In the interest of not starting over, and to show thankfulness for his effort, please try your best to express your question in terms of what has already been said. Thanks!

Regards,

Ted Mooney, P.E. finishing.com Brick, New Jersey September 13, 2009 DEAR SIR, IN HOT DIP GALVANIZING, PURE LEAD CHARGES IN POT FOR SAVE THE LIFE OF POT, LEAD BEHAVE AS A CUSHION EFFECT. rajkumar singh - bombay, India October 19, 2010 So what would be the ideal amount of Lead to charge in a Zinc bath (lead layer thickness or % zinc)? Jaydip Atodaria - Harare, Zimbabwe October 19, 2010 Hi, Jaydip. Some people think the ideal amount is zero :-) You can search the site for "lead-free" galvanizing. Good luck. Regards,

Ted Mooney, P.E. finishing.com Brick, New Jersey October 26, 2010 Dear Sir, Thanks for your reply. Our problem is we have a zinc tank 10x1.0x1.5m deep which leaked and

we are in the process of changing the kettle. From the pot wear it seems it weared out due to dross. Will adding a layer of lead increase the effectiveness of drossing? Then in that case we need to know when charging the new bath how much lead should be added? Thanking you. Jaydip Atodaria - Harare, Zimbabwe October 26, 2010 Sorry Jaydip, I can't answer that. You can wait for someone more experienced in this area to stumble across your inquiry, or you can patiently search the site because similar subjects have been discussed at length by true experts several times. Good luck. Regards,

Ted Mooney, P.E. finishing.com Brick, New Jersey

Top of Form

partner-pub-5713 FORID:9 w w w .finishing.c

ISO-8859-1

Search

Bottom of Form

Home/Sitemap

Contact

- Privacy Policy

1995-2011 finishing.com, Brick, New Jersey, USA

You might also like

- Galvanizing and Mechanical Preparation of Steel - 1Document4 pagesGalvanizing and Mechanical Preparation of Steel - 1Saurabh SinghNo ratings yet

- Technical Differences Between General or Batch Type and Continues Sheet Hot Dip GalvanizingDocument3 pagesTechnical Differences Between General or Batch Type and Continues Sheet Hot Dip GalvanizingNestramiNo ratings yet

- DP Test ReportDocument1 pageDP Test ReportSanjay KumarNo ratings yet

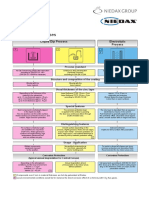

- Agro Engineering Works: Process Flow DiagramDocument1 pageAgro Engineering Works: Process Flow DiagramkdfdfybNo ratings yet

- Hot Dip GalvanizingDocument3 pagesHot Dip Galvanizingapply19842371No ratings yet

- Hot Dip Coating, CladdingDocument18 pagesHot Dip Coating, Claddingazim turanNo ratings yet

- Is 6158 - 1984 Recommended Practice For Safeguarding Against Embrittlement of Hot-Dip Galvanized Iron and Steel ProductsDocument10 pagesIs 6158 - 1984 Recommended Practice For Safeguarding Against Embrittlement of Hot-Dip Galvanized Iron and Steel ProductsNadeem KhanNo ratings yet

- HDG Fact Sheet 2017 V4Document6 pagesHDG Fact Sheet 2017 V4Ra'oufAli-zadehNo ratings yet

- Saudi Aramco Oil Company: SECTION 05500 Miscellaneous MetalsDocument14 pagesSaudi Aramco Oil Company: SECTION 05500 Miscellaneous MetalsgulzamanNo ratings yet

- Inspeccion de GalvanizadoDocument22 pagesInspeccion de GalvanizadoacuaroscarNo ratings yet

- 05 12 00 Structural Steel FramingDocument15 pages05 12 00 Structural Steel FramingAbdul RafiqueNo ratings yet

- Flux Skimming PDFDocument6 pagesFlux Skimming PDFpbp2956No ratings yet

- Galvanizing WeldDocument11 pagesGalvanizing WeldSivaNo ratings yet

- Chemical Quality of TMT Bars: View Previous Topic View Next TopicDocument6 pagesChemical Quality of TMT Bars: View Previous Topic View Next Topicpatrik710No ratings yet

- Alishar SP 2Document84 pagesAlishar SP 2Alam MD SazidNo ratings yet

- Technical Seminar For Galvanizers March 2012 Mike Ainsley - Update PDFDocument146 pagesTechnical Seminar For Galvanizers March 2012 Mike Ainsley - Update PDFTalal JameelNo ratings yet

- 2013 How Much Does Galvanizing CostDocument2 pages2013 How Much Does Galvanizing CosttassanaiNo ratings yet

- Astm G85Document6 pagesAstm G85Abdul MunirNo ratings yet

- Quality Level CDocument17 pagesQuality Level CUgonnaNo ratings yet

- 1 Specification For Hot Dip Zinc Galvanization of Steel (Rolled & Fabricated) ScopeDocument8 pages1 Specification For Hot Dip Zinc Galvanization of Steel (Rolled & Fabricated) ScopeRajneesh KatochNo ratings yet

- Thanh Long Steel ProfileDocument35 pagesThanh Long Steel ProfileHai NguyenNo ratings yet

- TMT Bars (Friends ISI) PDFDocument3 pagesTMT Bars (Friends ISI) PDFPiyushiNo ratings yet

- Wet Storage Stain On Galvanized SteelDocument5 pagesWet Storage Stain On Galvanized Steele.vicente.caballeroNo ratings yet

- Swe TB d11 0003010 Hot Dip Galvanizing SteelDocument7 pagesSwe TB d11 0003010 Hot Dip Galvanizing SteelArun SharmaNo ratings yet

- Cast IronDocument15 pagesCast IronJohnNo ratings yet

- Galvanizing Processes: Liquid Dip Process Electrolytic ProcessDocument3 pagesGalvanizing Processes: Liquid Dip Process Electrolytic ProcessAlin MoicaNo ratings yet

- Hot Dip Galvanizing Processes Process Guidance Note 2-12-13Document38 pagesHot Dip Galvanizing Processes Process Guidance Note 2-12-13dorin serbanNo ratings yet

- Extending Kettle LifeDocument7 pagesExtending Kettle LifeSky Ong CwNo ratings yet

- CATALOGO - 2015 Hot Dip Galvanized Steel, AlloyedDocument26 pagesCATALOGO - 2015 Hot Dip Galvanized Steel, AlloyedLeandro BarrosNo ratings yet

- Analysis On The Cause of Longitudinal Crack On The Hot-Rolled Ribbed Bar SurfaceDocument5 pagesAnalysis On The Cause of Longitudinal Crack On The Hot-Rolled Ribbed Bar SurfaceTanjidul IslamNo ratings yet

- Decorative Chromium Plating BasicsDocument8 pagesDecorative Chromium Plating Basicsm daneshpour100% (1)

- D H - D G: Esigning For OT IP AlvanizingDocument40 pagesD H - D G: Esigning For OT IP AlvanizingNarasimha Dvl100% (1)

- HDG Datasheet 4a - Specifying Hot Dip Galvanized SteelDocument1 pageHDG Datasheet 4a - Specifying Hot Dip Galvanized SteelCheah Hon KeongNo ratings yet

- Astm A 123 - 2013Document8 pagesAstm A 123 - 2013JOSENo ratings yet

- Highlight HDG Inspection CoursaaaaaaaaaaaaaaaaaDocument44 pagesHighlight HDG Inspection CoursaaaaaaaaaaaaaaaaaAyman Hamed MalahNo ratings yet

- Cost Benefit Analysis of Steel Protection OptionsDocument4 pagesCost Benefit Analysis of Steel Protection Optionsmgonelli14No ratings yet

- Heat Treatment of SteelDocument3 pagesHeat Treatment of SteelKristine ReyesNo ratings yet

- Structure and PropertiedDocument43 pagesStructure and PropertiedJalaj GaurNo ratings yet

- HK CS2 - 2012Document50 pagesHK CS2 - 2012bobbyccwNo ratings yet

- Sheet Metal WorkDocument29 pagesSheet Metal WorkSolcastic SoulNo ratings yet

- 277 - Galvanised Steel SheetsDocument10 pages277 - Galvanised Steel SheetsKaushik SenguptaNo ratings yet

- AGA 2007 Acid Purification Chemistry Kleingarn CurveDocument12 pagesAGA 2007 Acid Purification Chemistry Kleingarn CurveRaj KumarNo ratings yet

- Market Study Metals AssignmentDocument21 pagesMarket Study Metals AssignmentAanchal MukherjeeNo ratings yet

- Defects in GalvanizingDocument10 pagesDefects in GalvanizingBalaji GuruNo ratings yet

- Standard Specification For Hot Dip GalvanizingDocument4 pagesStandard Specification For Hot Dip GalvanizingNuzul Furqony100% (1)

- Australian/New Zealand Standard: Hot-Dip Galvanized (Zinc) Coatings On Fabricated Ferrous ArticlesDocument7 pagesAustralian/New Zealand Standard: Hot-Dip Galvanized (Zinc) Coatings On Fabricated Ferrous ArticlesMoriyasu NguyenNo ratings yet

- The Development of The Surface Finish StandardDocument7 pagesThe Development of The Surface Finish StandardSunilNo ratings yet

- Paint Guide For GI SteelDocument12 pagesPaint Guide For GI SteelDiLungBanNo ratings yet

- Good Practices With TMT BarsDocument87 pagesGood Practices With TMT BarsNIBEDITA DEYNo ratings yet

- Effect of Elements in SteelDocument3 pagesEffect of Elements in SteelJayakrishnan Radhakrishnan100% (1)

- Surface Preparation Metallizing ProcedureDocument6 pagesSurface Preparation Metallizing ProcedureCorrosion FactoryNo ratings yet

- Indiana PresentationDocument62 pagesIndiana PresentationRahulNo ratings yet

- The Role of Niobium in Austenitic and Duplex Stainless SteelsDocument25 pagesThe Role of Niobium in Austenitic and Duplex Stainless SteelsZoe SideriNo ratings yet

- Hot-Dip Galvanizing Vs Continuous Sheet GalvanizingDocument2 pagesHot-Dip Galvanizing Vs Continuous Sheet GalvanizingSreedhar Patnaik.M100% (1)

- According To DIN ISO 2768-1: Branco Engineering BureauDocument1 pageAccording To DIN ISO 2768-1: Branco Engineering BureauPHUONGNo ratings yet

- Difference Between Stainless Steel Grade SS316 & SS316LDocument1 pageDifference Between Stainless Steel Grade SS316 & SS316LSableen SinghNo ratings yet

- Iso12944 PDFDocument10 pagesIso12944 PDFSujay HariNo ratings yet

- Finishing 19Document5 pagesFinishing 19Sontosh BhattacharjeeNo ratings yet

- Frequently Asked Questions About Tool Steel Heat TreatingDocument2 pagesFrequently Asked Questions About Tool Steel Heat Treatingmp87_ingNo ratings yet

- QCS 2010 Section 18 Part 3 Structural TimberDocument5 pagesQCS 2010 Section 18 Part 3 Structural Timberbryanpastor106No ratings yet

- Method Statement Machnical, Electrical PlumbingDocument11 pagesMethod Statement Machnical, Electrical Plumbingmangeshshinde124No ratings yet

- Casting PresentationDocument34 pagesCasting Presentationvijaykumarn100% (1)

- Common Problems in DesizingDocument4 pagesCommon Problems in DesizingGopal Krishnan100% (1)

- Plumbing PipesDocument7 pagesPlumbing PipesRay Marionn Linao100% (1)

- Info Pack For New SizeDocument10 pagesInfo Pack For New Sizeapi-254670035No ratings yet

- Painting SpecificationDocument40 pagesPainting SpecificationIkram Syed100% (4)

- 2395 2 PaintingDocument8 pages2395 2 Paintingmrraee4729No ratings yet

- Cement Additives Cross Reference PDFDocument23 pagesCement Additives Cross Reference PDFnightwindowNo ratings yet

- Uses of MetalsDocument6 pagesUses of Metalsdan964No ratings yet

- TIGArqDocument44 pagesTIGArqzulNo ratings yet

- NHBC StandardsDocument378 pagesNHBC StandardsalexisNo ratings yet

- Kayu KompositDocument41 pagesKayu KompositGalihNo ratings yet

- IPE Master Workbreakdown Structure (WBS)Document112 pagesIPE Master Workbreakdown Structure (WBS)AdelChNo ratings yet

- BR Coloration of Plastics and RubberDocument86 pagesBR Coloration of Plastics and RubberHuynh Nam QuangNo ratings yet

- 440C DS CarpenterDocument5 pages440C DS CarpenterdaymonNo ratings yet

- Yarn Manufacturing - IDocument1 pageYarn Manufacturing - ISiva Jagadish Kumar M100% (2)

- Single-Ply RoofingDocument45 pagesSingle-Ply RoofingCroitoru IonNo ratings yet

- 50 - PCC Handbook 22 October 2015 PDFDocument118 pages50 - PCC Handbook 22 October 2015 PDFMohan SamarasingheNo ratings yet

- Practical 2Document4 pagesPractical 2June Lee Wong MYNo ratings yet

- Rotafix Crack RepairDocument12 pagesRotafix Crack RepairNorthstar71No ratings yet

- Chapter 4 Introduction To Prestressed ConcreteDocument9 pagesChapter 4 Introduction To Prestressed ConcreteMesfin DerbewNo ratings yet

- Fiber Reinforced ConcreteDocument11 pagesFiber Reinforced ConcreteIhtesham HussainNo ratings yet

- List of Is CodesDocument3 pagesList of Is CodesShikhin GargNo ratings yet

- 1-49 RoofNavDocument25 pages1-49 RoofNavMartin MorenoNo ratings yet

- Scope of Work Required For HDB RenovationDocument1 pageScope of Work Required For HDB RenovationgalacinNo ratings yet

- Lake PDFDocument3 pagesLake PDFaryopoorNo ratings yet

- Code For Awning DesignDocument38 pagesCode For Awning DesignmdeenkNo ratings yet

- Growing Importance of Cotton Blends in Apparel MarketDocument10 pagesGrowing Importance of Cotton Blends in Apparel Marketchamp2357No ratings yet