Professional Documents

Culture Documents

Checklist QMS 9001 2008

Uploaded by

bananasheepOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Checklist QMS 9001 2008

Uploaded by

bananasheepCopyright:

Available Formats

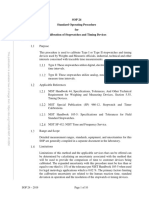

National Prequalification System for Civil (Road and Bridge) Construction Contracts Quality Management System Checklist for

Categories R1/B1

QUALITY MANAGEMENT SYSTEM CHECKLIST - ISO 9001:2008

(STATUS A = Acceptable; N = Not Acceptable; N/A = Not Applicable)

Item No.

1.

ISO Ref

4

4.2.1 & 5.1 & 5.3 & 5.4

Standard Requirements

Quality Management System (QMS)

Does the QMS documentation include: - documented statements of quality policy and objectives promulgated by management that are consistent and measurable and provide commitment to continual improvement - a quality manual. - required documented procedures (refer below) - documents, including records, to ensure planning, operation and control of processes and the sequence and interaction of these processes - required records. Does the Quality Manual include: - the scope of the QMS and exclusions - the documented procedures or references to them - a description of the interaction between the processes. Is there a procedure for the Control of Documents that defines: - the approval, review and update of documents - the identification of the revision status and format of changes to documents - the identification and use of obsolete documents - the identification and control of necessary external documents - how the latest version of the documents are available on site (if applicable). Is there a procedure for the Control of Records that covers the identification, storage, protection, retrieval, retention time and disposition. Are records readily identifiable and retrievable.

Status

A,N,N/A

Comments

2.

4.2.2

3.

4.2.3

4.

4.2.4

5

5. 5.5

Management Responsibility

Responsibility, authority and communication Has management ensured that Responsibility and Authority are defined and communicated within the organisation. Has a member of the organisations management been appointed with the responsibility and authority to manage the QMS. Are appropriate communication processes established within the organisation.

6.

5.6

Management Review Has management planned the review of the QMS including assessing opportunities for improvement using all available inputs. Are records of the reviews maintained/actioned?

6

7. 6.1

Resource management

Provision of Resources Are resources provided to implement, maintain and improve the QMS and to meet customer requirements. Human Resources Are personnel with the necessary competence performing work affecting the conformity of the product. Is training provided to meet required competencies Are personnel aware of the relevance and importance of their activities and their contribution to the quality objectives. Are appropriate records maintained.

8.

6.2

9.

6.4

Work Environment Does the organisation manage the conditions under which work is performed that are needed to achieve conformity to product requirements. Page 1 of 3

QMS Checklist November 2010

National Prequalification System for Civil (Road and Bridge) Construction Contracts Quality Management System Checklist for Categories R1/B1

7

10. 7.1

Product realization

Planning & product realization Is a quality plan prepared for a specific project/contract detailing the processes and documents, including as appropriate, the verification, validation, monitoring, measurement, inspection and test activities and the criteria for product acceptance. Are appropriate records maintained.

11.

7.2

Customer-related Processes Does the organisation determine and review requirements related to the product (including maintenance) prior to tendering. Are records and actions from the review maintained. Are documents amended and relevant personnel notified when changes are made to the product. Are there affective arrangements for dealing with customer complaints.

12.

7.3 7.3.1

Design and Development Does the organisation plan and control the development of a product by determining: - the stages - the appropriate review, verification and validation - the responsibilities and authorities. Are design and development inputs determined and records maintained for: - the functional and performance requirements - applicable statutory and regulatory requirements. Are design and development outputs approved and do they: - meet the input requirements - contain or reference acceptance criteria Are systematic review of design and development performed at suitable stages to: evaluate the ability of the results to meet requirements - identify any problems and propose necessary actions.

13.

7.3.2

14.

7.3.3

15.

7.3.4

16.

7.3.5 7.3.6

Are planned verification and/or validation requirements performed and are outcomes and necessary actions recorded. Are design and development changes identified, reviewed verified, validated as appropriate and approved. Are records maintained of the changes, review of the changes and necessary actions. Purchasing Does the organisation ensure that a purchased product confirms to specified requirements. Is the type and extent of control of the supplier dependant on the effect of the purchased product on the final product. Does the organisation evaluate and select suppliers on their ability to meet the organisation's selection criteria. Are results and actions of evaluations recorded.

17.

7.3.7

18.

7.4 7.4.1

19.

7.4.2

Does the purchase information define the specified requirements Does the organisation establish and implement the inspection of other activities to ensure product verification.

20.

7.4.3

QMS Checklist November 2010

Page 2 of 3

National Prequalification System for Civil (Road and Bridge) Construction Contracts Quality Management System Checklist for Categories R1/B1 Production and Service Provision 21. 7.5 7.5.1 Has the organisation controlled processes for planning and production that include, as applicable: - the specifications of the product - the availability of work instructions, as necessary - the use of suitable equipment - the availability and use of monitoring and measuring devices - the implementation of monitoring and measuring and - the release of hold points. 22. 7.5.2 Are processes validated where the resulting output cannot be verified by subsequent monitoring or measurement. Is the product identified where appropriate. Is the product status identifiable with respect to monitoring and measuring requirements. 24. 7.6 Control of Monitoring and Measuring Equipment Where necessary, is measurement equipment identifiable and calibrated to appropriate standards and at nominated intervals and are calibration records maintained.

23.

7.5.3

8

25. 8.1

Measurement, analysis and improvement

General Does the organisation plan and implement the monitoring, measurement , analysis and improvement processes needed to: - demonstrate conformity of product - ensure conformity of the QMS - continually improve the effectiveness of the QMS. Monitoring and measurement Customer Satisfaction Are methods determined for the monitoring of Contractor Performance Reports. Internal Audits Is there a planned audit program covering and including processes relative to their status and importance. Is there a documented procedure defining the responsibilities and requirements for planning and conducting audits, and for reporting results and maintaining records. Are the actions to eliminate detected nonconformities followed up and verified. Is there evidence of specification criteria in ITPs and the authorisation for release of the product (including Hold Points if appropriate) Control of nonconforming product Is there a documented procedure defining the controls and related responsibilities and authorities for dealing with a nonconforming product. Are there records of nonconformities, actions taken, including concessions obtained. Analysis of data Are records available from processes to verify conformity to product requirements. Improvement Does the organisation continually improve the effectiveness of the QMS through the use of quality policy, quality objectives, audit results, corrective and preventative actions and management reviews. Is there a procedure to manage nonconformities and potential nonconformities. Any ambiguity in this checklist shall be referred to the International standard for resolution.

26.

8.2 8.2.1

27.

8.2.2

28.

8.2.2 (cont.)

29.

8.2.2 (cont.) 8.2.4

30.

31.

8.3

32.

8.3

33.

8.4

34.

8.5 8.5.1

35.

8.5.2 8.5.3 NOTE:

36.

QMS Checklist November 2010

Page 3 of 3

You might also like

- Department of Education Doña Asuncion Lee Integrated School: Division of Mabalacat CityDocument2 pagesDepartment of Education Doña Asuncion Lee Integrated School: Division of Mabalacat CityRica Tano50% (2)

- Exiting Employee Checklist: Type of TerminationDocument2 pagesExiting Employee Checklist: Type of TerminationsalmanquNo ratings yet

- Control of Nonconforming Outputs ProcessDocument18 pagesControl of Nonconforming Outputs Process124th EAGLECOM KimJaveroNo ratings yet

- Graphic Organizers for Organizing IdeasDocument11 pagesGraphic Organizers for Organizing IdeasMargie Tirado JavierNo ratings yet

- Risk Management PlanDocument7 pagesRisk Management Planapi-3525765840% (1)

- Job Description / Roles & ResponsibilitiesDocument2 pagesJob Description / Roles & ResponsibilitiesParveen (Atam Valves)No ratings yet

- High Work Permit FormDocument1 pageHigh Work Permit Formjeas grejoyNo ratings yet

- Monitoring Measurement and Self-AssessmentDocument3 pagesMonitoring Measurement and Self-AssessmentVijaya Seharan NairNo ratings yet

- Iso 9187 1 1991Document9 pagesIso 9187 1 1991Muhammad ImranNo ratings yet

- MFGMD202269530 Dtechdental Final CARDocument1 pageMFGMD202269530 Dtechdental Final CARD Tech Dental TechnologiesNo ratings yet

- Project Plan For Implementation of The Quality Management SystemDocument6 pagesProject Plan For Implementation of The Quality Management SystemTomas MoralesNo ratings yet

- ISO-Control of Non Conforming ProductsDocument3 pagesISO-Control of Non Conforming Productsnoufal27100% (1)

- Integrated Management Systems ManualDocument26 pagesIntegrated Management Systems Manualdas_joydeb100% (1)

- Compare ISO 9001 and ISO 13485Document2 pagesCompare ISO 9001 and ISO 13485umarNo ratings yet

- ISO 9000 2015 (En) Quality Management Systems - Fundamentals and VocabularyDocument23 pagesISO 9000 2015 (En) Quality Management Systems - Fundamentals and VocabularyPaulino MutomboNo ratings yet

- How To Environmental AuditDocument5 pagesHow To Environmental AuditarjmandquestNo ratings yet

- N Quality Management System Planning Section 14Document3 pagesN Quality Management System Planning Section 14Ngonidzashe ZvarevasheNo ratings yet

- ISO 13485: 2016 Planner and Delta Checklist: InstructionsDocument10 pagesISO 13485: 2016 Planner and Delta Checklist: InstructionsYogesh H NarkhedeNo ratings yet

- Canadian Safety and Effectiveness Requirements (Cser)Document9 pagesCanadian Safety and Effectiveness Requirements (Cser)aymohamad2020No ratings yet

- Installation, servicing and on-site support proceduresDocument3 pagesInstallation, servicing and on-site support proceduresBPG ServiceNo ratings yet

- PT-Liquid Penetrant Testing Procedure R01 - 2 2Document12 pagesPT-Liquid Penetrant Testing Procedure R01 - 2 2George Ogbeche100% (1)

- RACS SOP43 Rev02 Product Certification Scheme HALAL ProductsDocument10 pagesRACS SOP43 Rev02 Product Certification Scheme HALAL ProductsrahmathNo ratings yet

- Jharkhand Steel Casting CompaniesDocument6 pagesJharkhand Steel Casting CompaniesCatherine Jovita50% (2)

- QP-001 Control of DocumentsDocument4 pagesQP-001 Control of DocumentsMartinNo ratings yet

- SOP On Handling of Critical and Non-Critical DeviationsDocument6 pagesSOP On Handling of Critical and Non-Critical DeviationsRajnish PatilNo ratings yet

- Writing Simple Sentences to Describe ScenariosDocument5 pagesWriting Simple Sentences to Describe Scenariosepol67% (3)

- Human Factor and Reliability Analysis to Prevent Losses in Industrial Processes: An Operational Culture PerspectiveFrom EverandHuman Factor and Reliability Analysis to Prevent Losses in Industrial Processes: An Operational Culture PerspectiveNo ratings yet

- SAC-SINGLAS 002 (JUNE 2018) : Guidelines For The Application of ISO/IEC 17025: 2017Document8 pagesSAC-SINGLAS 002 (JUNE 2018) : Guidelines For The Application of ISO/IEC 17025: 2017Michael AngNo ratings yet

- Pharmacovigilance and Risk Management Chapter 17 Objectives and Reporting RequirementsDocument22 pagesPharmacovigilance and Risk Management Chapter 17 Objectives and Reporting RequirementsKaty SanchezNo ratings yet

- Conformity Assessment (Management System Certification)Document5 pagesConformity Assessment (Management System Certification)Talal AhmedNo ratings yet

- Neptune Orthopaedics Standard Operating Procedure-ProductionDocument2 pagesNeptune Orthopaedics Standard Operating Procedure-Productiondhir.ankurNo ratings yet

- BS Iso 27427-2013Document60 pagesBS Iso 27427-2013Mohamed Wahby HusseinNo ratings yet

- 93 42 EEC ChecklistDocument15 pages93 42 EEC ChecklistdulichsinhthaiNo ratings yet

- MANUFACTURER DATA REPORT REGISTRATION CHECKLISTDocument1 pageMANUFACTURER DATA REPORT REGISTRATION CHECKLISTMuhammadShabbirNo ratings yet

- Implementation of A QMS Within The MRF IndustryDocument35 pagesImplementation of A QMS Within The MRF IndustryAlexis RancesNo ratings yet

- Construction - Method Statement Format - I Whattam 2007Document2 pagesConstruction - Method Statement Format - I Whattam 2007alaaNo ratings yet

- Iso 14971 8-B2017065Document6 pagesIso 14971 8-B2017065Mircod SenseNo ratings yet

- BMI WI 5711 01 Cutting ProcedureDocument3 pagesBMI WI 5711 01 Cutting ProcedureMacelNo ratings yet

- Neptune Orthopaedics Standard Operating Procedure-ProductionDocument2 pagesNeptune Orthopaedics Standard Operating Procedure-Productiondhir.ankurNo ratings yet

- Assessment Report/Checklist: Isfahan, IranDocument19 pagesAssessment Report/Checklist: Isfahan, IranAnonymous q8lh3fldWMNo ratings yet

- NABL 600 Directory of Accredited Medical Testing Laboratories As On 01 05 2015 PDFDocument100 pagesNABL 600 Directory of Accredited Medical Testing Laboratories As On 01 05 2015 PDFektasharma123No ratings yet

- BD MSDS Sodium Citrate Buffer SolutionDocument6 pagesBD MSDS Sodium Citrate Buffer SolutionsubinbioNo ratings yet

- FDA Volume II - Audits Ora-Lab.4.14Document7 pagesFDA Volume II - Audits Ora-Lab.4.14nilayNo ratings yet

- Application For The Accreditation of Medical Laboratories ACCORDING TO EN ISO 15189:2012Document13 pagesApplication For The Accreditation of Medical Laboratories ACCORDING TO EN ISO 15189:2012arvindNo ratings yet

- BVC Halal Certified Client List April 2017-For WebDocument6 pagesBVC Halal Certified Client List April 2017-For WebZohaib Alam WarraichNo ratings yet

- SOP 24 Standard Operating Procedure For Calibration of Stopwatches and Timing DevicesDocument10 pagesSOP 24 Standard Operating Procedure For Calibration of Stopwatches and Timing DevicesAli RizviNo ratings yet

- Medical Protective Clothing GuideDocument6 pagesMedical Protective Clothing Guidesutu ram100% (1)

- EMEA EtO GuidelineDocument3 pagesEMEA EtO GuidelineSpectre SpectreNo ratings yet

- ISO-10334-1994 For Stainless SuturesDocument8 pagesISO-10334-1994 For Stainless SuturesDoaa KhalilNo ratings yet

- USFDA Guidance For Industry - PSURDocument50 pagesUSFDA Guidance For Industry - PSURErshad Shafi AhmedNo ratings yet

- State of The Art Review Proposal GuidelinesDocument1 pageState of The Art Review Proposal Guidelineshesam khorramiNo ratings yet

- ISO 13485 Quality Management System Requirements ComparisonDocument3 pagesISO 13485 Quality Management System Requirements ComparisonBharathNo ratings yet

- ISOupdate January 2020Document46 pagesISOupdate January 2020projectrik roomNo ratings yet

- ECPD - DT03 - ISO 13485 - 2016 LA - Day 3 Daily TestDocument5 pagesECPD - DT03 - ISO 13485 - 2016 LA - Day 3 Daily TestSandeep kulkarniNo ratings yet

- PPN-SOP-CAI Corrective Action and ImprovementDocument4 pagesPPN-SOP-CAI Corrective Action and ImprovementpagaqNo ratings yet

- MBA Palm Trade Sdn Bhd Record Control SOPDocument6 pagesMBA Palm Trade Sdn Bhd Record Control SOPAna Hidayah SyuhadaNo ratings yet

- Alabama Specialty Products, Inc.Document24 pagesAlabama Specialty Products, Inc.qmicertificationNo ratings yet

- Standard For Gowns and DrapesDocument4 pagesStandard For Gowns and DrapesRonak choksiNo ratings yet

- Name of Document Quality Policy Scope and Exclusion Org - Chart Responsibility and AuthorityDocument15 pagesName of Document Quality Policy Scope and Exclusion Org - Chart Responsibility and AuthoritySandeep kulkarniNo ratings yet

- Whistle Blower PolicyDocument8 pagesWhistle Blower PolicysaadhyamNo ratings yet

- Neptune Orthopaedics Standard Operating Procedure-ProductionDocument4 pagesNeptune Orthopaedics Standard Operating Procedure-Productiondhir.ankurNo ratings yet

- Preparatory Lights and Perfections: Joseph Smith's Training with the Urim and ThummimDocument9 pagesPreparatory Lights and Perfections: Joseph Smith's Training with the Urim and ThummimslightlyguiltyNo ratings yet

- Asian Studies For Filipinos The Philippines in The Asian CenturyDocument15 pagesAsian Studies For Filipinos The Philippines in The Asian CenturyGlaizza QuintonNo ratings yet

- Acc418 2020 2Document3 pagesAcc418 2020 2faithNo ratings yet

- The Clàsh The 0nly Band That MatteredDocument255 pagesThe Clàsh The 0nly Band That MatteredNikos VaxevanidisNo ratings yet

- Snorkeling: A Brief History and Guide to This Underwater AdventureDocument3 pagesSnorkeling: A Brief History and Guide to This Underwater AdventureBernadette PerezNo ratings yet

- Sight Reduction Tables For Marine Navigation: B, R - D, D. SDocument12 pagesSight Reduction Tables For Marine Navigation: B, R - D, D. SGeani MihaiNo ratings yet

- Videocon ProjectDocument54 pagesVideocon ProjectDeepak AryaNo ratings yet

- Delhi Mumbai Award Status Mar 23Document11 pagesDelhi Mumbai Award Status Mar 23Manoj DoshiNo ratings yet

- PA2 Value and PD2 ValueDocument4 pagesPA2 Value and PD2 Valueguddu1680No ratings yet

- OTGNNDocument13 pagesOTGNNAnh Vuong TuanNo ratings yet

- OsmanabadDocument5 pagesOsmanabadKirankumar MutnaliNo ratings yet

- Beyond VaR OfficialDocument76 pagesBeyond VaR OfficialmaleckicoaNo ratings yet

- Kara&Suoglu ProjectreportDocument4 pagesKara&Suoglu ProjectreportRicard Comas xacnóNo ratings yet

- EINC ChecklistDocument3 pagesEINC ChecklistMARK JEFTE BRIONESNo ratings yet

- PPC2000 Association of Consultant Architects Standard Form of Project Partnering ContractDocument5 pagesPPC2000 Association of Consultant Architects Standard Form of Project Partnering ContractJoy CeeNo ratings yet

- New Company Profile.Document8 pagesNew Company Profile.Allen AsirNo ratings yet

- Acid content in fruitsDocument2 pagesAcid content in fruitsbone fire100% (1)

- Intraoperative Nursing Care GuideDocument12 pagesIntraoperative Nursing Care GuideDarlyn AmplayoNo ratings yet

- Biomérieux 21342 Vitek 2 GP: Intended UseDocument19 pagesBiomérieux 21342 Vitek 2 GP: Intended UserezaNo ratings yet

- Ir Pc-1: Pre-Check (PC) Design Criteria For Freestanding Signs and Scoreboards: 2019 CBCDocument15 pagesIr Pc-1: Pre-Check (PC) Design Criteria For Freestanding Signs and Scoreboards: 2019 CBCAbrar AhmadNo ratings yet

- Theory Is An Explanation Given To Explain Certain RealitiesDocument7 pagesTheory Is An Explanation Given To Explain Certain Realitiestaizya cNo ratings yet

- TOS 22402 Winter 19th I SCHEME Paper Model Answer PaperDocument25 pagesTOS 22402 Winter 19th I SCHEME Paper Model Answer Paperirshadmirza753No ratings yet

- Active Disturbance Rejection Control For Nonlinear SystemsDocument8 pagesActive Disturbance Rejection Control For Nonlinear SystemsTrần Việt CườngNo ratings yet

- The Daily Tar Heel For September 18, 2012Document8 pagesThe Daily Tar Heel For September 18, 2012The Daily Tar HeelNo ratings yet

- Fictional Narrative: The Case of Alan and His FamilyDocument4 pagesFictional Narrative: The Case of Alan and His Familydominique babisNo ratings yet

- Assignment of A Glass Transition Temperature Using Thermomechanical Analysis: Tension MethodDocument4 pagesAssignment of A Glass Transition Temperature Using Thermomechanical Analysis: Tension MethodEric GozzerNo ratings yet