Professional Documents

Culture Documents

Tile Standards Explanations

Uploaded by

rahul_ranjan_3Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tile Standards Explanations

Uploaded by

rahul_ranjan_3Copyright:

Available Formats

TILE STANDARDS EXPLANATIONS (courtesy of Interceramic ) Abrasion Resistance: ASTM C-1027-84 describes the standard test method for

determining visible abrasion resistance of glazed ceramic tile. Breaking Strength: ASTM C-648 describes the standard test method for determining structural strength of ceramic tile as related to its ability to withstand installation procedures, such as the beating in process to develop proper bond, when installed in accordance with published ANSI Al 08 series of installation standards. Minimum breaking strength for glazed wall tile is 90 pounds and 250 pounds for all floor tiles. Interceramic products exceed these minimum breaking strengths. Tiles with higher breaking strengths can usually be expected to withstand impact and breakage better when installed on floors with adhesives. Coefficient of Friction: ASTM C-1028-84 describes the standard test method for evaluating the static coefficient of friction of ceramic tile and other like surfaces by the horizontal dynamometer pull meter method. Coefficient of friction is a mathematical term used to describe the effect of dragging one substance (i.e.: shoe sole material) over another substance (i.e.: flooring surface). This coefficient is a measure of the relative ability of various surfaces to resist the sliding or slipping of the selected materials. Please note that any tile or other hard surface flooring can become slippery when wet or improperly maintained. Slip resistance varies with the many types of footwear. Judgment should be used when any hard surface flooring is installed in areas where dampness, water, or inadequate maintenance is likely to be encountered. Craze Resistance: ASTM C-424 describes the standard test method for determining the ability of ceramic tile glazes to withstand exposure to high pressure steam without cracking or "crazing". This determines the glaze's ability to withstand thermal shock such as steam cleaning, or placement of a hot pan on a tile counter top. Glazes that resist crazing by this test usually will not craze. Glaze Hardness: Scratch resistance of glazes is measured by scratching the glaze with a mineral of known hardness. Hardness of minerals is classified by Moh's Scale, which lists 10 minerals according to their hardness. Each mineral in this scale will scratch those with lower numbers in the scale, but will not scratch mineral with higher numbers. Talc is classified as a number one on the Mohs scale and diamond ten. Resilient flooring materials, such as vinyl and asphalt tile, are relatively soft and can be scratched by talc, number one on the scale. Polished marble can be scratched by calcite, which is number three. Black marble rates a four and can be scratched by fluorite. Most glazes used on ceramic tile fall in the five to six range, which is also slightly harder than steels. Case hardened steel, such as what is used in drill bits used for drilling holes in steel, is approximately six and will scratch most glazes. Some glazes used on ceramic tiles, designed for floor use, cannot be scratched by a case hardened drill bit. Quartz, number 7 on Moh's Scale, will scratch most glazes and all but the hardest unglazed ceramic tile. Sand is a common example of natural quartz.

Frost Resistance: ASTM C-1026-84 describes the standard test method for determining ceramic tile's ability to withstand repeated cycles of freezing and thawing. Ability of tile to resist damage or deterioration when tested in freezing and thawing situations such as those found in central and northern sections of the United States. Thermal Shock: ASTM C-484 describes the standard test method for determining ceramic tile's ability to withstand exposure to high temperature and rapid cooling without glazes showing failure, or the body of the tile showing evidence of disintegration. This determines the tile's ability to withstand such things as a hot pan on a counter top; hot water applied to a cold floor or cold water applied to hot tile, such as a sudden summer shower on a 100 degree day. Water Absorption: The percentage of water absorption by the tile body determines whether ceramic tile is impervious, vitreous, semi-vitreous, or nonvitreous. ASTM C-373 describes the standard test method for determining the percentage of water absorbed by the body of a ceramic tile. Results are expressed as a percent of the weight of water absorbed to the weight of dry tile. Impervious tile has a water absorption of 0.5 percent or less; vitreous tile more than 0.5 percent, but not more than 3.0 percent; semi-vitreous: more than 3.0 percent but not more than 7.0 percent; and non-vitreous tile has water absorption of more than 7.0 percent. The body of glazed wall tile is normally non-vitreous with water absorption often exceeding 15 percent. The body of glazed floor tile is normally vitreous or semi-vitreous with water absorption between 2.0 and 6.0 percent. Generally, unglazed ceramic tile with lower absorption rates are easier to maintain because they are more resistant to staining. They do not readily absorb grease, food/beverage spills and other staining agents.

You might also like

- AstmDocument4 pagesAstmHilal kan uyarNo ratings yet

- Tile Testing Basics: ASTM C370: Moisture ExpansionDocument4 pagesTile Testing Basics: ASTM C370: Moisture ExpansionLucky KhanNo ratings yet

- Tile PropertiesDocument5 pagesTile PropertiesEverton GustavoNo ratings yet

- Ceramic / Porcelain Tile SpecificationsDocument2 pagesCeramic / Porcelain Tile SpecificationsCharles Lawrence DadizonNo ratings yet

- Method OgyDocument7 pagesMethod OgyClairole Marie QuilantangNo ratings yet

- WhitePaper CeramicPorcelainTileTestingDocument3 pagesWhitePaper CeramicPorcelainTileTestingravi 127No ratings yet

- The Properties of Roof TilesDocument9 pagesThe Properties of Roof TilesSingh is KingNo ratings yet

- Ceramic Tiles For FloorsDocument55 pagesCeramic Tiles For FloorsKhalid YousafNo ratings yet

- Ceramic Tiles LabelDocument2 pagesCeramic Tiles LabelAsemota OghoghoNo ratings yet

- Ceramic Porcelain Test Methods GlossaryDocument1 pageCeramic Porcelain Test Methods GlossaryHsaam HsaamNo ratings yet

- A Guide To Specifying Limestone Tiles: DurabilityDocument4 pagesA Guide To Specifying Limestone Tiles: Durabilitysanchit2203No ratings yet

- Abrasion ResistanceDocument37 pagesAbrasion ResistanceNabeel WasimNo ratings yet

- HRE-Midterm 1Document14 pagesHRE-Midterm 1Mayvrick SangacenaNo ratings yet

- LAB LESSON 2 Types of AggregatesDocument5 pagesLAB LESSON 2 Types of AggregatesajaytrixNo ratings yet

- Ceramic Tiles - Important Characteristics - Part 1Document1 pageCeramic Tiles - Important Characteristics - Part 1Manjeet KhannaNo ratings yet

- StandardsDocument3 pagesStandardsOckto Ferry Harahap EtsfNo ratings yet

- Crossville 2014 - List PriceDocument94 pagesCrossville 2014 - List PriceCervantesquijoteNo ratings yet

- Slip Resistance of Hard FlooringDocument12 pagesSlip Resistance of Hard FlooringKalyanasundaram ThirugnanasambandamNo ratings yet

- Soil NailingDocument12 pagesSoil NailingManash Protim Gogoi100% (1)

- Building Surveys and ReportDocument6 pagesBuilding Surveys and ReportFaldiNo ratings yet

- Impact Resistance of Ceramic Tiles & FlooringDocument12 pagesImpact Resistance of Ceramic Tiles & FlooringGanesh BhisteNo ratings yet

- Testing Application Standard No 112-95Document12 pagesTesting Application Standard No 112-95batteekhNo ratings yet

- Brickmasonry 150812062642 Lva1 App6891Document21 pagesBrickmasonry 150812062642 Lva1 App6891ZEC LIMITEDNo ratings yet

- If Your Refractory Is CrackedDocument5 pagesIf Your Refractory Is CrackedBilly S. SaramosingNo ratings yet

- 7-Properties of Hard ConcreteDocument62 pages7-Properties of Hard ConcreteZELALEMNo ratings yet

- Brick PropertiesDocument6 pagesBrick Propertiesswathia09No ratings yet

- Cement and Concrete: History Composition Testing Key TermsDocument19 pagesCement and Concrete: History Composition Testing Key TermsElsa Adilla PutriNo ratings yet

- Tiling Over Wall Surface Ceramic TilesmfdsoDocument3 pagesTiling Over Wall Surface Ceramic Tilesmfdsoflatlaugh93100% (1)

- Ceramic Tile in An Exterior InstallationDocument2 pagesCeramic Tile in An Exterior InstallationHeriberto Yau BNo ratings yet

- Correct Answer Liquid LimitDocument46 pagesCorrect Answer Liquid LimitMiguel Balunsat Sabban Jr.100% (3)

- Tile Association UK - Tiling-With-Resin-Agglomerated-Tiles-Updated-16Document27 pagesTile Association UK - Tiling-With-Resin-Agglomerated-Tiles-Updated-16pankajNo ratings yet

- Life Is Full of Challenges So Be Brave & Face ItDocument48 pagesLife Is Full of Challenges So Be Brave & Face Itrams221209No ratings yet

- 8 Road MaterialsDocument21 pages8 Road MaterialsLovely Mae Cruza GawinganNo ratings yet

- Water Absorption and AbrasionDocument6 pagesWater Absorption and AbrasionMarielle Jane B. TapangNo ratings yet

- Damage and Deterioration Problems of Ceramic Floor TilesDocument3 pagesDamage and Deterioration Problems of Ceramic Floor Tilesمحمد محمود مهديNo ratings yet

- Water Absorption and AbrasionDocument6 pagesWater Absorption and AbrasionKing ShilNo ratings yet

- Bulking of Sand Means Increase in ItDocument6 pagesBulking of Sand Means Increase in ItDENCONo ratings yet

- E Cera Ceramic Porcelain Test Methods GlossaryDocument1 pageE Cera Ceramic Porcelain Test Methods GlossaryHasmukh KoringaNo ratings yet

- Crack Repair in Marine StructuresDocument1 pageCrack Repair in Marine Structureszxcv7890No ratings yet

- A TO Z of TILESDocument10 pagesA TO Z of TILESuffshezy4No ratings yet

- Typical Methods of Moisture Intrusion: Little Pigs? The Big Bad Wolf Blew The StickDocument8 pagesTypical Methods of Moisture Intrusion: Little Pigs? The Big Bad Wolf Blew The StickaliNo ratings yet

- Wet Cladding: Yashwant N 3 SEM Tosa USN-1OQ20AT029Document6 pagesWet Cladding: Yashwant N 3 SEM Tosa USN-1OQ20AT029Sharath KumarNo ratings yet

- How To Fix Leaks On Clay Tile Roofs PDFDocument4 pagesHow To Fix Leaks On Clay Tile Roofs PDFNishith ReddyNo ratings yet

- NOTA BAB 5-Ujian BataDocument8 pagesNOTA BAB 5-Ujian BataNorsuzilawate Binti Zulkapli0% (1)

- Floor Slip ResistanceDocument8 pagesFloor Slip ResistanceZarko KacakovNo ratings yet

- Causes and Repair of CracksofDocument16 pagesCauses and Repair of CracksofBharath PbbpNo ratings yet

- SGC Tempered Glass Product DataDocument3 pagesSGC Tempered Glass Product DataaaryankorlekarNo ratings yet

- Properties of CementDocument6 pagesProperties of CementAngelica Fontamillas SuicoNo ratings yet

- Technical Manual WholeDocument93 pagesTechnical Manual WholeVincent MutambirwaNo ratings yet

- A Case Study On BricksDocument7 pagesA Case Study On BricksAritro Roy MitraNo ratings yet

- Structural Clay Products: Standard Terminology ofDocument5 pagesStructural Clay Products: Standard Terminology ofIrene AdlerNo ratings yet

- Tank Coatings Covering The Basics of Selection and SpecificationDocument4 pagesTank Coatings Covering The Basics of Selection and SpecificationHugo Fernando Solis100% (1)

- Abrasion Testing of Cementitious Floors - Technical Note 2Document4 pagesAbrasion Testing of Cementitious Floors - Technical Note 2BamsiamNo ratings yet

- Dr. Fixit Institute: of Structural Protection & RehabilitationDocument16 pagesDr. Fixit Institute: of Structural Protection & RehabilitationSanjay KambleNo ratings yet

- Chapter 02Document51 pagesChapter 02Ala ThajilNo ratings yet

- Concrete PavementDocument63 pagesConcrete PavementDenver Lee DiazNo ratings yet

- CMTDocument2 pagesCMTjayco ReyaNo ratings yet

- C2 Curado Del Concreto - PCADocument7 pagesC2 Curado Del Concreto - PCAJancarlo Mendoza MartínezNo ratings yet

- Floor SystemsDocument67 pagesFloor SystemsAnonymous oUoJ4A8x100% (3)

- Coalpot and Canawi Traditional Creole Pottery in The Contemporary Commonwealth CaribbeanDocument21 pagesCoalpot and Canawi Traditional Creole Pottery in The Contemporary Commonwealth Caribbeanitell_sriNo ratings yet

- Craft DocumentationDocument37 pagesCraft DocumentationIsha GargNo ratings yet

- Ceramic Tile Manufacturing ProcesssDocument20 pagesCeramic Tile Manufacturing ProcesssMike Cajes AsiadoNo ratings yet

- GargoylesDocument5 pagesGargoylesapi-316491463No ratings yet

- Tite 2008 A CerambicDocument16 pagesTite 2008 A CerambicZeeshan ShaikhNo ratings yet

- Blue PotteryDocument43 pagesBlue PotteryAditya0% (1)

- WilconDocument24 pagesWilconMervin BritanicoNo ratings yet

- SCB 12 - 19V1 PDFDocument40 pagesSCB 12 - 19V1 PDFMonowar HossainNo ratings yet

- Microwave ManualDocument43 pagesMicrowave ManualKen MillerNo ratings yet

- BMC IV - Module 02 Finishes 200912Document56 pagesBMC IV - Module 02 Finishes 200912Fidha SulfiNo ratings yet

- Richter Et Al 2012Document20 pagesRichter Et Al 2012HULIOSMELLANo ratings yet

- High Gloss GlazesDocument58 pagesHigh Gloss Glazesawadalla100% (1)

- 15 Cone 10 RecipesDocument10 pages15 Cone 10 RecipesInga NowakNo ratings yet

- Haddon 3429Document469 pagesHaddon 3429Carolyn HardyNo ratings yet

- 20th Century Design - Skinner Auction 2603BDocument140 pages20th Century Design - Skinner Auction 2603BSkinnerAuctions100% (1)

- An Illustrated and Descriptive Catalogue of Rare Old Persian PotteryDocument126 pagesAn Illustrated and Descriptive Catalogue of Rare Old Persian PotteryPuiu Vasile ChiojdoiuNo ratings yet

- Is 4457 2007 PDFDocument27 pagesIs 4457 2007 PDFParameswaran MadhuNo ratings yet

- Expressive Self Portrait Clay Bust Project DescriptionDocument6 pagesExpressive Self Portrait Clay Bust Project Descriptionapi-233396734No ratings yet

- Content ServerDocument3 pagesContent ServerLINA KATHERIN ESPINOSA OSPINANo ratings yet

- IPS InLine System PDFDocument12 pagesIPS InLine System PDFFloare79No ratings yet

- T E G B K W: He Ssential Uide To Asic Iln OrkDocument8 pagesT E G B K W: He Ssential Uide To Asic Iln OrkscmfarmerNo ratings yet

- (2014) Colour and Technology in Historic Decorated Glazes and Glasses PDFDocument117 pages(2014) Colour and Technology in Historic Decorated Glazes and Glasses PDFtariq.toffa4760No ratings yet

- Time Team - Llancaiach Fawr, GwentDocument42 pagesTime Team - Llancaiach Fawr, GwentWessex Archaeology100% (1)

- Decorative Arts Part IIDocument360 pagesDecorative Arts Part IIGigi Moraras100% (1)

- JyhtDocument14 pagesJyhtAnonymous s6WwRJVSxmNo ratings yet

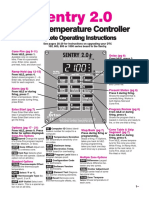

- Manual Horno Sentry 2.0 PDFDocument32 pagesManual Horno Sentry 2.0 PDFJose BacaNo ratings yet

- Channel of DistributionDocument122 pagesChannel of Distributioncursorkkd100% (1)

- Methods of Paragraph DevelopmentDocument6 pagesMethods of Paragraph DevelopmentJacqueline Gregorio RamosNo ratings yet