Professional Documents

Culture Documents

Syllabus 2011 Ie416 Pmo Ie5110 Pdi Notes-2

Uploaded by

Rohit ReddyOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Syllabus 2011 Ie416 Pmo Ie5110 Pdi Notes-2

Uploaded by

Rohit ReddyCopyright:

Available Formats

1

Syllabus

1.1 Course Description

Dynamic Modelling, Optimization and Control is a combination of number of courses oered to the undergraduate and postgraduate students at the Instrumentation and Control department of the College of Engineering, Pune. These courses include IE401 Process Instrumentation, IE416 Process Modelling and Optimization, and IE5110 Process Dynamics and Identication. Refer to the updated curriculum for the detailed description of these courses. This course introduces students to the fundamental principles and systematic activities of systems engineering that include process modelling, optimization and control. The classroom theory and laboratory hours are dedicated to the understanding of basic concepts involved in designing and analyzing systems and processes by using dynamic mathematical models developed from knowing the underlined scientic and process phenomena as well as by means of parameter identication of empirical information. Course covers number of numerical techniques and optimization methods to solve design, decision making and control problems. Rigorous exercises are assigned to develop the skills in using computational tools and instrumentation to achieve process automation. for A semester long design project culminating in a written report is designed to help develop sound understanding and hands on experience.

1.2

Aim and Objectives

Upon completion of this class students will be able to Understand design concepts of instruments and process equipments. Build data acquisition system for variety of sensors. Analyze and manipulate response of actuators. Understand and implement data communication and transition protocols. Systematically analyze process plants using mathematical modeling. techniques Develop empirical models of complex plants using parametric identication methods. Write objectives and their cost functions for optimal plant operations. Formulate and solve optimization problems. Finally, be able to control and operate process plants to achieve key performance indicators such as settling time, disturbance attenuation, cost, safety and desired product quality while keeping in mind environmental impact and uncertainty.

1 Syllabus

1.3. Course Outline

1.3

Course Outline

1. Introduction to Mathematical Modeling 2. Modeling of Chemical Reactors 3. Modeling of Distillation Column 4. Introduction to Optimization 5. Unconstrained Optimization 6. Linear Programming 7. Quadratic Programming 8. Nonlinear Programming 9. Introduction to Identication 10. Introduction to Advanced Process Control 11. Unconstrained Optimal Control 12. Constrained Optimal Control 13. Model Predictive Control 14. Application Case Study I 15. Application Case Study II

1.4

1.4.1

Course Requirements

Prerequisites

Students must have completed all the previous 200, 300 and 400 level courses. Additionally, students must have completed all the home works, exams and labs of IE401 Process Instrumentation. Prerequisite for this course is knowledge of linear algebra, digital signal processing and Microcontroller based embedded systems.

1.4.2

Programming Skills

A Students must have sound knowledge of Matlab and working knowledge of C/C++ and L TEX.

1.4.3

Industrial Automation Knowledge

Students must have sound knowledge of Emerson Delta-V Distributed Control System or should be willing to gain expertise on using Delta-V system.

1.5

Grading Policy

There is weekly workload of tasks and assignments given as home works. Students are expected to write down and work on assignments given during every class. Weekly home works must be

2010 | Amit M. Manthanwar Process Automation | 7

1 Syllabus

1.6. Honor Policy

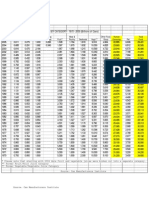

submitted on every Monday morning before the class begins. Additionally, there will be special laboratory assignments which must be submitted every fortnight. Finally, examinations will be conducted at the end of every month. Three weeks of time will be given to submit the take home exam. Overall grading policy is as follows. Activities Final Exam Midterm Exam Take Home Exam Homework Contributions to Class (Bonus) Class participation Submission of Quality Results Fair Play Award (Bonus) Arrival on Time 100% Attendance Character and Values 5% Percentage 40% 30% 10% 10% 5%

Note that the late submission to cost 5 marks per hour late. Also note that bonus points awarded for contribution to the class and overall code of conduct. Original thinking and implementation of theoretical concepts to your own research, novel problem formulation and its solution will be awarded additional bonus points.

1.6

Honor Policy

You are expected to work independently on your home works and exams. On the contrary laboratory assignments, take home exams and projects are group activities and you are recommended to form appropriate study groups and collaborate on assigned tasks. Team activities and and discussions are highly encouraged but you must submit your original work. Praiseworthy ethical standards and professional practices are expected from every student. Feel free to discuss your diculties with Amit, but by no means cheap malpractices will be allowed.

1.7

Reference Books

1. Anderson, N. A. Instrumentation for Process Measurement and Control, Third Editon. CRC Press, 1997. 2. Bequette, B. W. Process Control: Modeling, Design and Simulation. Prentice Hall, 2003.

2010 | Amit M. Manthanwar Process Automation | 8

1 Syllabus

1.7. Reference Books

3. Bertsekas, D. P. Dynamic Programming and Optimal Control (3 Vol Set). Athena Scientic, 2007. 4. Bird, R. B., Stewart, W. E., and Lightfoot, E. N. Transport Phenomena, second ed. John Wiley and Sons, 2006. 5. Boyd, S., and Vandenberghe, L. Convex Optimization. Cambridge University Press, 2004. 6. Burl, J. B. Linear Optimal Control. Prentice Hall, 1998. 7. Coughanowr, D. R., and LeBlanc, S. E. Process Systems Analysis and Control. McGraw-Hill, 2008. 8. Depablo, J., and Schieber, J. Thermodynamics. 2011. McGraw-Hill Higher Education,

9. Dunn, W. Fundamentals of Industrial Instrumentation and Process Control. McGrawHill Professional, 2005. 10. Edgar, T. F., Himmelblau, D. M., and Lasdon, L. Optimization of Chemical Processes, second edition ed. McGraw-Hill Inc., New York,, 2001. 11. Erickson, K. T., and Hedrick, J. L. Plant-Wide Process Control. Wiley-Interscience, 1999. 12. Fogler, H. S. Elements of Chemical Reaction Engineering, fourth ed. Prentice Hall, 2005. 13. Gelfand, I. M., and Fomin, S. V. Calculus of Variations. 2000. 14. Glad, T., and Ljung, L. Control Theory. CRC Press, 2000. 15. Green, D. W., and Perry, R. H. Perrys Chemical Engineers Handbook, Eighth Edition (Chemical Engineers Handbook). McGraw-Hill Professional, 2007. 16. Johnson, C. D. Process Control Instrumentation Technology (8th Edition). Prentice Hall, 2005. 17. Kirk, D. E. Optimal Control Theory: An Introduction. Dover Publications, 2004. 18. Kwakernaak, H., and Sivan, R. Linear Optimal Control Systems. Wiley-Interscience, 1972. 19. Liptk, B. G. Instrument Engineers Handbook, Fourth Edition, Volume Two: Process Control and Optimization. CRC Press, 2005. 20. Ljung, L. System Identication: Theory for the User (2nd Edition). Prentice Hall, 1999. 21. Love, J. Process Automation Handbook: A Guide to Theory and Practice. 2007. 22. Luenberger, D. G. Optimization by Vector Space Methods. Control. Wiley-Interscience, 1997. Springer,

Series in Decision and

23. Luenberger, D. G., and Ye, Y. Linear and Nonlinear Programming. Springer US, 2009.

2010 | Amit M. Manthanwar Process Automation | 9

1 Syllabus

1.8. Useful Links

24. Luyben, W. L. Plantwide Dynamic Simulators in Chemical Processing and Control (Chemical Industries). CRC Press, 2002. 25. Luyben, W. L., Tyreus, B. D., and Luyben, M. L. Plantwide Process Control. McGraw-Hill Professional Publishing, 1998. 26. Marlin, T. E. Process Control: Designing Processes and Control Systems for Dynamic Performance. McGraw-Hill, 2000. 27. McCabe, W. L., Smith, J. C., and Harriott, P. Unit Operations of Chemical Engineering. McGraw-Hill Education, 2005. 28. McMillan, G., and Considine, D. Process/Industrial Instruments and Controls Handbook, 5th Edition. McGraw-Hill Professional, 1999. 29. Nocedal, J., and Wright, S. Numerical Optimization (Springer Series in Operations Research and Financial Engineering). Springer, 2006. 30. Northrop, R. B. Analysis and Application of Analog Electronic Circuits to Biomedical Instrumentation (Biomedical Engineering) by Robert B. Northrop. CRC Press, 2003. 31. Ogunnaike, B. A., and Ray, W. H. Process Dynamics, Modeling, and Control (Topics in Chemical Engineering). Oxford University Press, USA, 1994. 32. Papadimitriou, C. H., and Steiglitz, K. Combinatorial Optimization: Algorithms and Complexity. Dover Publications, 1998. 33. P.N.Modi, and Seth, S. Hydralulics And Fluid Mechanics Including Hydraulics Machines. Standard Book House, 2009. 34. Rao, S. S. Engineering Optimization: Theory and Practice. Wiley, 2009. 35. Seborg, D. E., Mellichamp, D. A., Edgar, T. F., and III, F. J. D. Process Dynamics and Control. Wiley, 2010. 36. Stephanopoulos, G. Chemical Process Control: An Introduction to Theory and Practice. PTR Prentice Hall, 1984.

1.8

Useful Links

Course Website iPAL Website Creative Problem Solving Advice on Academic Writing Assignment Calculator

1.9

Key Journals

IEEE Transactions on Automatic Control Automatica

2010 | Amit M. Manthanwar

Process Automation | 10

1 Syllabus SIAM Journal on Control and Optimization Systems and Control Letters Journal of Process Control International Journal of Control Industrial and Engineering Chemistry Research International Journal of Robust and Nonlinear Control Nature Science

1.10. Digital Libraries

1.10

Digital Libraries

ACS Publications Elsevier ScienceDirect IEEE Xplore Springer Link Wiley Online Library SIAM Online Informa World CiteSeer Google Scholar Web of Knowledge List of academic databases and search engines List of mathematics journals

1.11

Professional Organizations

American Chemical Society (ACS) American Institute of Chemical Engineers (AIChE) Institution of Chemical Engineers (IChemE) Institute of Electrical and Electronics Engineers (IEEE) Institution of Engineering and Technology (IET) American Society Of Mechanical Engineers (ASME) International Society of Automation (ISA)

2010 | Amit M. Manthanwar

Process Automation | 11

You might also like

- PronounsDocument6 pagesPronounsRohit ReddyNo ratings yet

- JSIR 65 (9) (Book Review)Document0 pagesJSIR 65 (9) (Book Review)Rohit ReddyNo ratings yet

- The Nadis of The Human Psychic BodyDocument7 pagesThe Nadis of The Human Psychic BodyRohit Reddy100% (1)

- Outwitting ResistanceDocument54 pagesOutwitting ResistanceRohit Reddy100% (2)

- CMI SHIPMENTS BY CATEGORY - 1970 - 2005 (Billions of Cans)Document1 pageCMI SHIPMENTS BY CATEGORY - 1970 - 2005 (Billions of Cans)Rohit ReddyNo ratings yet

- B Resources - Conducting A Life Cycle Assessment (LCA)Document7 pagesB Resources - Conducting A Life Cycle Assessment (LCA)Rohit ReddyNo ratings yet

- 0680 Air Pollution Engineering Manual Part1 1973Document110 pages0680 Air Pollution Engineering Manual Part1 1973gfrank9970No ratings yet

- Btech Metallurgy 2010-11Document7 pagesBtech Metallurgy 2010-11Rohit ReddyNo ratings yet

- QuantsDocument3 pagesQuantsGeetika RajputNo ratings yet

- Nominal Composition of Some Common Grades of Stainless SteelDocument5 pagesNominal Composition of Some Common Grades of Stainless Steelmichaeljcurtin2638No ratings yet

- Pro-Eutectoid Ferrite KinetisDocument34 pagesPro-Eutectoid Ferrite KinetisRohit ReddyNo ratings yet

- Laser Assisted Micro FormingDocument8 pagesLaser Assisted Micro FormingRohit ReddyNo ratings yet

- 12 Ways To Change Your LifeDocument24 pages12 Ways To Change Your LifeAK7464No ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Short Sensory ProfileDocument11 pagesShort Sensory ProfileNurul Izzah Wahidul Azam100% (1)

- Haryana Staff Selection Commission: (WWW - Hssc.gov - In) Bays No. 67-70, Sector-2, Panchkula-134154Document34 pagesHaryana Staff Selection Commission: (WWW - Hssc.gov - In) Bays No. 67-70, Sector-2, Panchkula-134154JessiNo ratings yet

- DRRM Narrative ReportDocument6 pagesDRRM Narrative ReportnutmegNo ratings yet

- Module 1 - Triangle CongruenceDocument25 pagesModule 1 - Triangle CongruenceJuan Lorenzo50% (2)

- Md. Ariful IslamDocument2 pagesMd. Ariful IslamshoiloNo ratings yet

- Sca-Mhs Newsletter Vol II Issue 1 FinalDocument6 pagesSca-Mhs Newsletter Vol II Issue 1 Finalapi-284639268No ratings yet

- Class Record: IV Learners' Names Written Works Performance TasksDocument29 pagesClass Record: IV Learners' Names Written Works Performance TasksLance Aldrin AdionNo ratings yet

- Proda ResumeDocument2 pagesProda Resumeapi-243290864No ratings yet

- Vocabulary Lesson 25Document6 pagesVocabulary Lesson 25Liz Rabaya IntiaNo ratings yet

- A Mock Board Examination Is A Simulation For The Actual Board ExaminationDocument3 pagesA Mock Board Examination Is A Simulation For The Actual Board ExaminationVictoria V. Dela Cruz100% (1)

- P66940 GCSE Turkish 1TU0 2H Teacher Picture Cards 2022Document20 pagesP66940 GCSE Turkish 1TU0 2H Teacher Picture Cards 2022byaylagul20No ratings yet

- Scholarly Research in Marketing: Exploring The "4 Eras" of Thought DevelopmentDocument16 pagesScholarly Research in Marketing: Exploring The "4 Eras" of Thought Developmentneptune04No ratings yet

- Ped 121Document171 pagesPed 121Selenai SelenaiNo ratings yet

- Letter of ReferenceDocument2 pagesLetter of ReferenceMuhammed ÇakmakNo ratings yet

- Copy (2) of Verbal - Reasoning - 01Document42 pagesCopy (2) of Verbal - Reasoning - 01RahulSonavane UpscNotesNo ratings yet

- Application Process: PurdueDocument4 pagesApplication Process: PurdueYandi LayadiNo ratings yet

- Rubrics For Musical PlayDocument2 pagesRubrics For Musical Playfaber vb80% (5)

- Jenny JournalDocument27 pagesJenny JournalmaviinreyNo ratings yet

- Employment Opportunities: The Nelson Mandela African Institute of Science and Technology (NM-AIST)Document8 pagesEmployment Opportunities: The Nelson Mandela African Institute of Science and Technology (NM-AIST)Rashid BumarwaNo ratings yet

- MGMT 222Document13 pagesMGMT 222h9904680No ratings yet

- Strategic Training - PPT 2Document25 pagesStrategic Training - PPT 2alpsdsouzaNo ratings yet

- Jaime Sioson Jonathan Livingston Seagull 2Document3 pagesJaime Sioson Jonathan Livingston Seagull 2toubanetworkingNo ratings yet

- Accenture - Offer Letter TutorialDocument2 pagesAccenture - Offer Letter TutorialtriratnacomNo ratings yet

- Composing An Annotated BibliographyDocument1 pageComposing An Annotated Bibliographyapi-244367791100% (1)

- Alliance Ascent College Bangalore - MBA - Alliance UniversityDocument11 pagesAlliance Ascent College Bangalore - MBA - Alliance UniversityRakeshKumar1987No ratings yet

- Lesson Plan 2Document3 pagesLesson Plan 2api-283836471100% (1)

- Physical Education (048) Class XI (2019-20) : (Children With Special Needs-Divyang)Document6 pagesPhysical Education (048) Class XI (2019-20) : (Children With Special Needs-Divyang)Akanksha akuNo ratings yet

- Resume Emylyn Walter 1Document2 pagesResume Emylyn Walter 1api-335618579No ratings yet

- How Can I Improve The Reading Skills of Grade 7 Students Through SPEAK UP? (Sharing Proactive Events and Knowledge For Understanding and Progress)Document5 pagesHow Can I Improve The Reading Skills of Grade 7 Students Through SPEAK UP? (Sharing Proactive Events and Knowledge For Understanding and Progress)Psychology and Education: A Multidisciplinary JournalNo ratings yet

- My Reflection On Work Immersion ExperienceDocument1 pageMy Reflection On Work Immersion ExperienceRonayla Gandulan Usman93% (14)