Professional Documents

Culture Documents

Value Stream Mapping - Adapting Lean Management Principle in The ESO

Uploaded by

Ram GoyalOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Value Stream Mapping - Adapting Lean Management Principle in The ESO

Uploaded by

Ram GoyalCopyright:

Available Formats

Value Stream Mapping Adapting Lean Management Principle in the ESO

VALUE STREAM MAPPING - Adapting Lean Management Principle in the ESO

Kannan Jayaraman Manager L&T Integrated Engineering Services

Larsen & Toubro Limited

Integrated Engineering Services (IES) Chennai

The contents of this document are the excerpts collected from various sources with the perseverance of how such concepts/ ideas could be viewed with respect to the Engineering service industry and how effectively could get implemented solely from the authors point of view. This may enlighten the thinking process and trigger the direction that can be considered.

June 2010

Page 1 of 12

Value Stream Mapping Adapting Lean Management Principle in the ESO

Abstract:

In the recent years the word Lean has become a corporate buzzword. We could hear from every walls of the forum that getting lean is a must in this competitive market. Lean is a systematic approach in identifying and eliminating waste (muda in Japanese meaning non-value added activities) through continuous improvement by flow of the product / service at the pull of the customer. Simply lean means creating more value for customer with the optimum resources.

All we are doing is looking at the time line from the moment the customer gives us an order to the point when we collect the cash. And we are reducing that time line by removing the non-value-added wastes. Taichi Ohno

A lean organization understands customer value and focuses its key processes to continuously increase it. The ultimate goal is to provide the best value to the customer through a value creation process that has reduced waste. A popular misconception is that lean is suited only for manufacturing. Not true. Lean is applicable in every business and in every process. It is not a tactic or a cost reduction program, but a way of thinking and acting for an entire organization. Of course, Lean usage has been primarily focused on the production floor because of its tangible benefits that could be directly visualized in the production floor, and little consideration has been given to use it in other areas. Many companies from Banking & Financial Services, Healthcare, Retail, Hospitality, BPOs, Call Centre & ESO and Software Industries have already embarked on a Lean Programme or are evaluating and seriously considering one.

The challenge is to develop a systematic method of continuously identifying and eliminating waste. A sporadic removal will yield pockets of improvement, but the system wide benefits are achieved by following a cyclical method of continuous improvement.

Value stream mapping is a visualization tool used to analyze the flow of materials and information required to bring a product or service to a customer. This is basically a communication tool, but is also used as a strategic planning tool and a change management tool.

This needs a complete transformation on how the organization conducts business. This takes a long term perspective and perseverance. This paper briefly explains the lean management principles and the concept of value stream mapping. Also it briefs about the challenges beings faced by the typical Engineering Service Organization (ESO) Project Management Process and thinking process on the need of lean and the benefits that could get resulted by the adaptation of lean from the authors view.

Keywords:

Value Stream mapping, Lean, Process mapping, Toyota, and Non-Value added activities

June 2010

Page 2 of 12

Value Stream Mapping Adapting Lean Management Principle in the ESO

Introduction:

Lean Management is - defining the purpose of the organization in terms of the customer value. - designing and executing the right value streams and processes for achieving the purpose. - and aligning the people touching the process and building problem solving capability in them.

Developed by Toyota over 40 years ago to help standardize on a methodology for continuous improvement (established as Toyota Production System) with an objective of making the vehicles ordered by customers in the quickest and most efficient way, in order to deliver the vehicles as quickly as possible. This was established based on two concepts. The first is called jidoka (automation with a human touch) which means that when a problem occurs, the equipment stops immediately preventing defective products from being produced. The second is called Just-in-Time in which each process produces only what is needed by the next process in a continuous flow.

The same concept could be perceived with respect to the service industry as meeting the services required by the customers in the quickest and most efficient way, in order to deliver the services as quickly as possible. Again the same could be established by jidoka (establishing systems and processes such that when a problem occurs, the flow stops immediately preventing unintended services being delivered) and Just-in-Time (utilization of right resources & delivering of right services just at the right time).

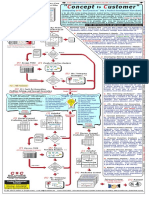

Fig .1

Lean Principles:

The lean principles can be briefly distilled down as - Solving the customer problem completely. - Not wasting the customers time. June 2010 Page 3 of 12

Value Stream Mapping Adapting Lean Management Principle in the ESO

- Providing exactly what the customer wants. - Delivering it where it is wanted. - Supplying it when it is wanted. - Continually aggregating the solutions to reduce the customers time and hassle.

The goal of value stream mapping is to identify, demonstrate and decrease waste in the process. Waste being any activity that does not add value to the final service.

Value Stream Mapping:

The foundation of the Toyota way is based upon identifying and eliminating waste in all work activities. If we look each and every process as a time line of activities, material and information flows and chart the process from start to end, we will find a depressing amount of waste usually far more waste than value-added activity. Apparently these reductions of waste are being handled with a short term strategy called the kaizen. A well executed kaizen workshop can be a step in teaching people what is possible. But this has to be handled as a longer term strategy for developing lean value systems and ultimately a lean enterprise.

Value stream mapping is one such long term philosophy lean technique used to analyze the flow of activities and information currently required to bring a service to a consumer.

Process series of activities for a desired outcome Value added time Actual time spent on the activity with an intended contribution / value addition. Non-Value added time Any time spent on the activity with an unintended contribution.

The use of waste removal to drive competitive advantage inside organizations is oriented fundamentally to productivity rather than to quality. The reason for this is thought to be that improved productivity leads to leaner operations which help to expose further wastes and quality problems in the system.

Typical Product Development Process:

A typical Product Development process being followed by the Engineering organization is depicted below in Fig.2 indicating the major flow of activities involves in the process. It starts with the capturing of customer voice, benchmarking, QFD, Product design, DFMEA, Design Verification, Validation, Process design , Sample development till it getting released for Mass production. Every organization will be having their own set of process with the inclusion of various Gates for review and decision analysis.

June 2010

Page 4 of 12

Value Stream Mapping Adapting Lean Management Principle in the ESO

Fig .2

Typical ESO Project Management Process:

A typical ESO Project Management processes is depicted below in Fig.3 indicating the major flow of activities evolved from the product development process that are being considered for outsourcing. These processes can be further split into various sub-processes under each major activity. Lean methodology could be applied for each of these processes by conducting value stream mapping exercise to identify and eliminate the non-value added activities involved in that process which is unintended for that particular service.

Major Challenges:

1. Demand on Significant reduction in product development cost and time - It is believed that a well defined engineering outsourcing initiative could reduce the product development cost significantly and the customers are demanding the ESOs to give a quick solution at a reduced time. Companies do also demand design productivity improvements from the established engineering outsourcing organizations.

June 2010

Page 5 of 12

Value Stream Mapping Adapting Lean Management Principle in the ESO

Fig .3

2. Constant Engagement of the Flexible pool of Talent resources It is understood that by outsourcing, the parent company can have a flexible re-sourcing arrangement to meet the cyclic nature of engineering and product development activities. At the same time, ESOs needs to keep engaging their flexible pool of talent resources and strike a balance between better utilization as well as to reduce the product development cost of the Customer.

The challenges could be better handled only with a long term systematic approach such as Value Stream mapping (VSM) in which we could frame the map of existing flow of activities, identify the nonvalue added activities and develop a plan to eliminate the unproductive effort and time which are unintended for the target product or service.

Implementation Approach:

1. Identify the target product or service. 2. Draw a current state value stream map, which shows the current steps, delays and information flows required to deliver the target product or service. 3. Assess the current state value stream map in terms of waste elimination. 4. Draw a future state value stream map. 5. Make a plan, and Implement the future state.

Mapping is the key in identifying the potential improvement

VSM is a system focused, or big-picture, tool designed to identify every step in the process across the company from the moment an order is taken to when the delivery is done. June 2010 Page 6 of 12

Value Stream Mapping Adapting Lean Management Principle in the ESO

Lean for non-manufacturing organizations begins with training in VSM and the basics of lean manufacturing. A first step is the choice of the cross-functional team with members that represent all areas to be mapped. The team creates a current map by following an orders path from customer (business enquiry and order) all the way to delivery of service. The current state map is created by capturing, with pencil on paper, the existing flow of data /information within the system. This visual map provides a real picture of the system that the organization uses to deliver the intended service to the Customer. This helps in analyzing the actual sources of waste so that that can be targeted for the improvement efforts. The current state map tends to be an eye opener for the team. By this one can understand the value added time and non-value added time in the process involved.

Subsequent to this a future state map is developed. The team then identifies the ways to improve the process flow that will eliminate waste and utilize time, talent and resource more efficiently. This invariably results in a better understanding of the entire process. The team can set a time frame for implementing the new future state map with the consent of the management.

The potential opportunities for improvement include: - Eliminating redundant approvals. - Efficient utilization of time and talent. - Restructuring the process flow.

The best strategy for implementing improvements is to start with a small project (process), record the progress the team made, share the success, and then move on and always maintain momentum. Communicating the teams progress and successes is very important, as is alerting people who will be affected by the changes.

Typical Non-Value Adding Activities identified by Toyota related to an ESO:

Toyota has identified seven major types of non-value adding activities in any business / processes. This could be broadly related to the Engineering Service organization.

Sl.no

Wastes (Non-Value Added activities)

Toyotas definition

Relation with respect to ESO

Overproduction

- Producing items earlier or in greater quantities than needed by the Customer.

- Producing unintended services for the target service. (Non-value added efforts). This should not get confused with Customers delight.

June 2010

Page 7 of 12

Value Stream Mapping Adapting Lean Management Principle in the ESO

Sl.no

Wastes (Non-Value Added activities)

Toyotas definition

Relation with respect to ESO

Waiting (time on hand)

- Workers merely serving as watch persons for an automated machine, or having to stand around waiting for the next processing step.

- Waiting for data / information from the Customer. - Waiting for approvals or direction from leadership.

Transportation or Conveyance

- Moving work in process (WIP) from place to place in a process even if it is only a short distance.

- Complicated internal systems for the for the accomplishment of data storage, retrieval, resource allocation etc. - Internal waiting for the receipt of required information. -Lack of standardization for the highly repetitive tasks. Lot of similar activities being done through different processes. - Re-inventing the desired state of process across the teams. - Imbalances of work between individuals which results in high cost. - Waiting for the decision from the superiors / Customers.

Over processing or incorrect processing

- Taking unneeded steps to process the parts.

Excess inventory

- Excess raw material, WIP or finished goods causing longer lead times, obsolescence, damaged goods, transportation and storage costs, and delay.

Unnecessary movement

- Any motion employees have to perform during the course of their work other than adding value to the part, such as reaching for, looking for, or stacking parts, tools etc.

- Unnecessary flow of data and movement of individuals. - Lack of automation tools / systems for the repetitive tasks.

Defects

- Production of defective parts or correction. Repairing of rework, scrap, replacement production, and inspection means wasteful handling, time and effort.

- Errors in the drawing, design, calculation, executing something different that of the customer requirements which results in rework.

Apart from the basic seven types, we could include the following other waste also for our consideration which may be more appropriate particular for the service industry.

Unused Employee creativity

- Losing time, ideas, skills, improvements and learning opportunities by not engaging or listening of employees. - Not utilizing right resources for the right job.

June 2010

Page 8 of 12

Value Stream Mapping Adapting Lean Management Principle in the ESO

Fig .4

Refer Fig.4. The objective of the activity is to generate 3D model and detail the 2D drawing in a particular software from the given hard copy 2D drawing input. The above table shows a side-by-side comparison of value added and non-value added activities of a typical situation. There will generally be few items on the value added side and many on non-value added side. This provides a large selection to capture lost time opportunity by shifting from the non-value added to the value added side. Of course, some of the activities identified on the right side are necessary but they do not help in achieving the end objective. From the non-value added list we first focused on in-cycle losses those occurring during the execution. By giving proper practice / procedure and responsibility some of the activities could be eliminated from the non-value added side.

Specific Tools and Methodologies for waste reduction in the Value Stream:

Value Stream mapping gives us a picture on how the individual value added items get together to have a connected value stream. The creation of lean processes requires a methodical, step-by-step approach. The first step is to create a stable process capable of meeting customer requirements. The subsequent step is to create a flow, standardize and do incremental leveling of the process.

1. Create Initial Process Stability The primary objective in developing stable processes is to reach a consistent level of capability by removing the random activities thus establishing a foundation for true improvement. A simple indicator would be the ability to meet the customer requirements with quality service the first time through on time. June 2010 Page 9 of 12

Value Stream Mapping Adapting Lean Management Principle in the ESO

2. Create Connected Process flow Products / Services that move continuously through the processing steps with minimal waiting time in between, and the shortest distance traveled will be produced / delivered with the highest efficiency. Flowing reduces throughput time, which shortens the cost to cash cycle and can lead to quality improvements.

3. Establish Standardized processes and procedures The establishment of standardized processes and procedures is the greatest key in creating consistent performance. It is only when the process is stable that one can begin the creative progression of continuous improvement. The creation of standardized processes is based on defining, clarifying (making visual) and consistently utilizing the methods that will ensure the best possible results.

4. Leveling of resources This could be termed as heijunka meaning to deliver the product / service aligned inline with the Customer requirement. Constantly changing demand creates many issues within the value stream, namely the alignment of resources to the constantly changing need. The resources need to be utilized in balance at the definite pace in anticipation of the changing demand.

5. Build a Culture that stops to fix problems A system has to be built that provides the long term benefits of stopping the process, and minimize the negative effect by building a support structure to quickly identify, respond and correct problems. Toyota core philosophy has to be developed which begins with the thinking to focus on waste elimination (in this case waste of correction), the natural extension of that philosophy is to develop a system in getting Quality right for the first time.

Benefits of the Value Stream Mapping Approach:

1. It helps us to visualize more than just the single process level that one can see on the flow. 2. It helps to see the flow of the value stream, wastes, and sources of waste in the flow 3. It helps us to understand both material and information flow of a value stream. 4. It helps us to draw a blueprint for Lean transformation the future state map. 5. It helps us to prioritize activities needed to achieve the future state. 6. It is focused on no cost or expense able improvements. 7. It is based on objective information. 8. It provides a common language to talk about the process.

Limitations of the Value Stream Mapping Approach:

1. Unrealistic expectations and excess prevailed over-hype about the value stream mapping divert the attention from important aspects of complex problems.

June 2010

Page 10 of 12

Value Stream Mapping Adapting Lean Management Principle in the ESO

2. Value Stream mapping is a technical tool that examines the physical system processes. But organizations are complex socio-technical systems that require an integrated approach. Moreover ESOs are demand fluctuating orient and this needs a complex and integrated approach to address the issue as an enterprise wide. 3. This requires high teamwork for motivation, coordination and problem solving. It requires an effective mobilization of the collective intelligence of the organization.

Expected Operational Improvements arriving out on Implementation of Lean:

1. Giving more value to the Customer with the lesser resources. 2. Increased Customer Satisfaction. 3. Reduced Cycle time between project start and completion. 4. On-time delivery performance can be increased. 5. Cost of Quality of products and services can be reduced. 6. Increased Employee Satisfaction. 7. Better utilization of the resources. 8. By doing Quality right at the first time, customer gets delighted.

Summary:

In the early days, Lean practice has begun in the manufacturing industries involving huge assembly lines and interchangeable parts. In the recent past, every type of organization irrespective of the business started practicing lean across various disciplines within their organization.

Lean methods and tools could be applied in any process where An employee is constantly interrupted when trying to complete a task. An employee chases information in order to complete a task. He/she must jump though multiple decision loops.

Value Stream mapping helps in understanding how a current process operates with a openness in uncovering the steps that contribute value to the customer and the one that does not give value.

Application of Lean practice need not get restricted to project management per say rather it can be applied to any process either external or internal, back office processes such as accounting and finance, human resources, facilities management or records management.

The essential steps to conduct a value stream mapping exercise include: (a) Observe and document the flow of material. (b) Understand and capture the flow of information. (c) Observe the trouble points. June 2010 Page 11 of 12

Value Stream Mapping Adapting Lean Management Principle in the ESO

(d) Identify the areas for improvement. (e) Create the vision of how the net flow will operate. (f) Conduct workshop on specific parts of the processes. (g) Simulate the new processes.

Lean is a business philosophy centered on reducing waste and focusing on value in the business. Lean creates an environment where the organization is committed to continuous improvement. Lean also shifts the organizations thinking from Push to Pull where the customers can retrieve or request products / services on their time schedule based on their needs.

References:

1. The Toyota Way Field book A Practical guide for implementing Toyotas 4P by Jeffrey K.Liner and David Meier. 2. Lean Six Sigma for Service by George Michael L. 3. www.lean.org - The Lean Enterprise Institute 4. Lean Thinking by Womack James P. and Daniel T.Jones. 5. Learning to See Value Stream mapping by Mike Rother and John Shook. 6. The Seven value stream mapping tools White paper from Lean Enterprise Research Centre, Cardiff Business School, Cardiff, UK

June 2010

Page 12 of 12

You might also like

- Euro NCAP 2020 Roadmap outlines safety focus areasDocument19 pagesEuro NCAP 2020 Roadmap outlines safety focus areasRoxana Elizabeth Valencia NavarrteNo ratings yet

- ERM - PrezDocument75 pagesERM - PrezatiqNo ratings yet

- The Goal/Question/Metric Method: A Practical Guide For Quality Improvement of Software DevelopmentDocument216 pagesThe Goal/Question/Metric Method: A Practical Guide For Quality Improvement of Software DevelopmentJoel MontoyaNo ratings yet

- Internet of Things: Visualise The ImpactDocument34 pagesInternet of Things: Visualise The ImpactPetarKrešimirBarbaNo ratings yet

- Euroncap 2019 Porsche Taycan DatasheetDocument15 pagesEuroncap 2019 Porsche Taycan DatasheetFred LamertNo ratings yet

- Lean KaizenDocument23 pagesLean KaizenMasha_Davidoff09No ratings yet

- BCG-Lean Services - A Primer For Success PDFDocument13 pagesBCG-Lean Services - A Primer For Success PDFKevin MoysNo ratings yet

- 5 Dysfunctions of TeamDocument15 pages5 Dysfunctions of TeamsumitsethNo ratings yet

- Ernest - Adding Value To The It Organization With The CBM - 1Document17 pagesErnest - Adding Value To The It Organization With The CBM - 1tessioyudi2070No ratings yet

- CS201 Lecture on Analyzing System RequirementsDocument60 pagesCS201 Lecture on Analyzing System RequirementsKitambulio abdullyNo ratings yet

- 7 Step Guide - ERP TransformationDocument11 pages7 Step Guide - ERP TransformationPaul Vintimilla CarrascoNo ratings yet

- 1 Intro To SCM Strategy and ValueDocument38 pages1 Intro To SCM Strategy and ValueDerv BreenNo ratings yet

- MSD-Sure Step MethodologyDocument8 pagesMSD-Sure Step Methodologypsarathy02No ratings yet

- Thesis MVZ v1.0 PDFDocument134 pagesThesis MVZ v1.0 PDFericNo ratings yet

- The Empower ProcessDocument1 pageThe Empower ProcessAdam LindellNo ratings yet

- Week1 - Introduction To Business Process ManagementDocument29 pagesWeek1 - Introduction To Business Process ManagementRamsky Baddongon PadigNo ratings yet

- Data DictionaryDocument11 pagesData DictionarySAP JOBS ForumNo ratings yet

- World Class EA A Leader's Approach To Establishing and Evolving An EA Capability W160Document112 pagesWorld Class EA A Leader's Approach To Establishing and Evolving An EA Capability W160Faqih ZulfikarNo ratings yet

- Ey Is Your Business Transforming Its Technology or Is Technology Transforming Your BusinessDocument6 pagesEy Is Your Business Transforming Its Technology or Is Technology Transforming Your BusinessakashNo ratings yet

- Re-Inventing Business Analysis: New Skills?: Planning and MonitoringDocument11 pagesRe-Inventing Business Analysis: New Skills?: Planning and MonitoringknotseloNo ratings yet

- The Intelligent Enterprise For The High Tech IndustryDocument28 pagesThe Intelligent Enterprise For The High Tech IndustryLuis RamosNo ratings yet

- Business Process Lifecycle ManagementDocument12 pagesBusiness Process Lifecycle ManagementOrlando100% (1)

- Lean Vs Six SigmaDocument23 pagesLean Vs Six SigmabowbeforeallahNo ratings yet

- Thebusinessanalystshandbookchapter 3 StandardsandguideDocument18 pagesThebusinessanalystshandbookchapter 3 Standardsandguideapi-101303155No ratings yet

- Forrester Wave RES138050Document20 pagesForrester Wave RES138050Jorge GarzaNo ratings yet

- PMI Exam CA0-001: Certified Associate in Project Management (CAPM) CertificationDocument198 pagesPMI Exam CA0-001: Certified Associate in Project Management (CAPM) CertificationHélio NhanalaNo ratings yet

- Accenture Outlook From Analog To Digital How To Transform The Business ModelDocument6 pagesAccenture Outlook From Analog To Digital How To Transform The Business ModelMoybul AliNo ratings yet

- Digital Transformation Published ArticleDocument5 pagesDigital Transformation Published ArticleAnjoNo ratings yet

- " Oncept Ustomer": SolutionsDocument1 page" Oncept Ustomer": SolutionsJac DNo ratings yet

- Agile M I 9.7.20 Class 1Document19 pagesAgile M I 9.7.20 Class 1priyanka kumar100% (1)

- Business Process Reengineering: A Guide to Radically Improving Customer ServiceDocument32 pagesBusiness Process Reengineering: A Guide to Radically Improving Customer ServiceSiddhant AggarwalNo ratings yet

- BFSI Business CapabilitiesDocument5 pagesBFSI Business Capabilitiestejat4uNo ratings yet

- Define Phase PDFDocument159 pagesDefine Phase PDFtata sudheerNo ratings yet

- Industry 4.0 Chances and Challenges of Digital TransformationDocument50 pagesIndustry 4.0 Chances and Challenges of Digital TransformationShared AxNNo ratings yet

- Business Process Management: Speaker by Agus Hendrawan, Se, MsiDocument40 pagesBusiness Process Management: Speaker by Agus Hendrawan, Se, MsiKimshinNo ratings yet

- Microsoft PowerPoint - 02 - TOGAF 9 Overview v1.1Document13 pagesMicrosoft PowerPoint - 02 - TOGAF 9 Overview v1.1Guang Ming LiNo ratings yet

- K07199 02 - Process - Defs - DevelopAndManageProductServices - Aug2016 - Ver-2 PDFDocument6 pagesK07199 02 - Process - Defs - DevelopAndManageProductServices - Aug2016 - Ver-2 PDFisolongNo ratings yet

- Agile Suitability FiltersDocument11 pagesAgile Suitability FiltersbinvinNo ratings yet

- OPC UA Security Advise EN PDFDocument24 pagesOPC UA Security Advise EN PDFDaniel Sánchez De MarcosNo ratings yet

- Agile Product Lifecycle ManagementDocument70 pagesAgile Product Lifecycle ManagementRavi Tripathi0% (1)

- Standard CMMI Appraisal Method For Process Improvement (Scampi), Method Definition DocumentDocument245 pagesStandard CMMI Appraisal Method For Process Improvement (Scampi), Method Definition DocumentSahar MohammadiNo ratings yet

- ITIL Beginners Guide - A Six Sigma BonusDocument68 pagesITIL Beginners Guide - A Six Sigma Bonusfiveten510No ratings yet

- Value Stream Mapping: Management Is EssentialDocument26 pagesValue Stream Mapping: Management Is Essentialjohn2307No ratings yet

- Week 1 Content: Welcome and IntroductionsDocument59 pagesWeek 1 Content: Welcome and IntroductionsnickNo ratings yet

- ASQ Lean LeadershipDocument22 pagesASQ Lean LeadershipSelvaraj SimiyonNo ratings yet

- Training Program On Lean Manufacturing by Addvalue Consulting-AhmedabadDocument11 pagesTraining Program On Lean Manufacturing by Addvalue Consulting-AhmedabadumeshjmangroliyaNo ratings yet

- 2 Keynote John Moavenzadeh World Economic ForumDocument57 pages2 Keynote John Moavenzadeh World Economic ForumNé MrgsfNo ratings yet

- Business Strategy BasicsDocument23 pagesBusiness Strategy Basicsturusan94256No ratings yet

- Digital Transformation - Takeouts 1Document25 pagesDigital Transformation - Takeouts 1ahmad_shishan2584No ratings yet

- Green Belt Analyse PhaseDocument71 pagesGreen Belt Analyse PhaseAarav MishraNo ratings yet

- Principles of Lean Six Sigma OverviewDocument85 pagesPrinciples of Lean Six Sigma OverviewSivalingam DineshNo ratings yet

- Process Improvement Calculations ToolsDocument65 pagesProcess Improvement Calculations ToolsNevets Nonnac100% (1)

- MSF For Cmmi Process Improvement v5 Process GuidanceDocument68 pagesMSF For Cmmi Process Improvement v5 Process GuidancesemiariNo ratings yet

- Senior Leadership Lean Transformation PDFDocument48 pagesSenior Leadership Lean Transformation PDFMario Alejandro Charlin SteinNo ratings yet

- Lean 6-Sigma - Value Stream MappingDocument8 pagesLean 6-Sigma - Value Stream MappingAhmmad AwadNo ratings yet

- Integrated Business Planning A Complete Guide - 2020 EditionFrom EverandIntegrated Business Planning A Complete Guide - 2020 EditionNo ratings yet

- Grow Through Disruption: Breakthrough Mindsets to Innovate, Change and Win with the OGIFrom EverandGrow Through Disruption: Breakthrough Mindsets to Innovate, Change and Win with the OGINo ratings yet

- PowerGrip GT2 Design ManualDocument233 pagesPowerGrip GT2 Design ManualAndre AlmeidaNo ratings yet

- Lean and Industry 4.0Document9 pagesLean and Industry 4.0lucas washingtonNo ratings yet

- Kitting TrolleyDocument31 pagesKitting TrolleyShubham Jain100% (1)

- Toyota by Toyota Reflections FromDocument231 pagesToyota by Toyota Reflections FromEvandro MinatoNo ratings yet

- Bahrain Economic Vision 2030Document26 pagesBahrain Economic Vision 2030Thanasate PrasongsookNo ratings yet

- Lean Supply Chain and Its Effect On Product Cost and Quality: A Case Study On Ford Motor CompanyDocument7 pagesLean Supply Chain and Its Effect On Product Cost and Quality: A Case Study On Ford Motor CompanyHarshad ShahNo ratings yet

- LegoDocument30 pagesLegomzai2003No ratings yet

- ECM PresentationDocument33 pagesECM PresentationBabarkhan Mujawar100% (1)

- NPO Services PDFDocument1 pageNPO Services PDFIjaz Ul HasanNo ratings yet

- Eicher ReportDocument46 pagesEicher ReportTushar BansalNo ratings yet

- Boldt-VM Redefining CM at RiskDocument73 pagesBoldt-VM Redefining CM at RiskRuth Mery PQNo ratings yet

- When Lean Meets Industry 4.0: Achieving Operational ExcellenceDocument17 pagesWhen Lean Meets Industry 4.0: Achieving Operational ExcellenceYun Fung YAPNo ratings yet

- 2010 07 HOS Overview Slides Abu Dhabi Rev 2Document20 pages2010 07 HOS Overview Slides Abu Dhabi Rev 2Mazen FakhfakhNo ratings yet

- Dwnload Full Supply Chain Focused Manufacturing Planning and Control 1st Edition Benton Test Bank PDFDocument36 pagesDwnload Full Supply Chain Focused Manufacturing Planning and Control 1st Edition Benton Test Bank PDFpamelalogan7sp86w100% (10)

- Value-Adding: 5% Muda: 95%: Inventory Motion Waiting Knowledge DisconnectionDocument5 pagesValue-Adding: 5% Muda: 95%: Inventory Motion Waiting Knowledge DisconnectionDavid Osiris Fernandez AvalosNo ratings yet

- Oim552-Lean Manufacturing Question BankDocument6 pagesOim552-Lean Manufacturing Question BankRaagul SNo ratings yet

- BSI Training Academy Public Training Schedule 2018Document17 pagesBSI Training Academy Public Training Schedule 2018Anonymous TYGiADNo ratings yet

- LSS Measure Tollgate TemplatesDocument38 pagesLSS Measure Tollgate TemplatesCarlos Oliver Montejano100% (1)

- 03 Assignment 1-Group6Document3 pages03 Assignment 1-Group6Kaka BaltazarNo ratings yet

- 1 PDFDocument202 pages1 PDFMario Alejandro Charlin Stein100% (1)

- SAFe 4.6 - My NotesDocument13 pagesSAFe 4.6 - My NotesDheera Settipalli100% (1)

- Dmgt206 Production and Operations ManagementDocument302 pagesDmgt206 Production and Operations ManagementFerisal Firmansyah100% (1)

- JIT and Lean OperationDocument54 pagesJIT and Lean OperationBipin GurungNo ratings yet

- Em-Cijj200014 447..470Document24 pagesEm-Cijj200014 447..470Maria Luiza AbathNo ratings yet

- Implementing Standardized Work Routines Using Lean ToolsDocument15 pagesImplementing Standardized Work Routines Using Lean ToolsDebashishDolonNo ratings yet

- Humanitarian AidDocument6 pagesHumanitarian AidHumair KhanNo ratings yet

- Transforming Design And: ConstructionDocument14 pagesTransforming Design And: ConstructionQUARCISSUSNo ratings yet

- Simple Process Mapping TechniquesDocument14 pagesSimple Process Mapping TechniquesStephen Deas92% (13)

- Shruti Assignment 4,5Document20 pagesShruti Assignment 4,5Shruti SuryawanshiNo ratings yet

- Operations Management IntroductionDocument317 pagesOperations Management IntroductionAnonymousNo ratings yet