Professional Documents

Culture Documents

05 - Pneumatic Instrumentation

Uploaded by

Lester James Ugsod AgumOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

05 - Pneumatic Instrumentation

Uploaded by

Lester James Ugsod AgumCopyright:

Available Formats

PNEUMATIC INSTRUMENTATION

PREPARED BY: ENGR. LESTER JAMES U. AGUM

Lessons in industrial instrumentation chap 11

INSTEAD OF ELECTRONIC

WE CAN HAVE PNEUMATIC

Application

The indicator in this case would be a special pressure gauge, calibrated to read in units of process pressure although actuated by the pressure of clean compressed air from the transmitter instead of directly by process fluid. The most common range of air pressure for industrial pneumatic instruments is 3 to 15 PSI.

3 PSI - represents the low end of the process measurement scale 15 PSI - represents the high end of the measurement scale

APPLICATION

PNEUMATIC FLOW CONTROLLER

Pneumatic sensing elements

Most pneumatic instruments use a simple but highly sensitive mechanism for converting mechanical motion into variable air pressure: the baffleand-nozzle assembly (sometimes referred to as a flapper-and-nozzle assembly).

NOZZLE BACK PRESSURE

PRINCIPLE BEHIND BAFFLE AND NOZZLE

WIDER CLEARANCE, PRESSURE GAUGE WILL INDICATE A LOWER VALUE

Self-balancing pneumatic instrument principles

A great many precision instruments use the principle of balance to measure some quantity.

LOAD

=

LOAD

LOAD

INSTEAD OF PRESSURE IT WILL INDICATE MASS

Plain and baffle mechanism

it also limits the air flow rate available to fill the bellows, which makes the system slower to respond.

decreasing orifice size is a corresponding decrease in the nozzles ability to provide increasing backpressure to fill a bellows of significant volume.

sensitive by reducing the size of the orifice.

As the control rod is moved up and down by an outside force, the distance between the plug and the seat changes.

The combination of two restrictions changing in opposite direction results in a much more aggressive change in output pressure as registered by the gauge.

inverse relationship between control rod motion and pressure compare to the previous pilot valve

Pneumatic relay

To amplify the pneumatic signal, we must have some way of allowing an air pressure signal to control the motion of a pilot valves control rod. Equivalent to electronic transistor.

Direct acting relay

Reverse acting relay

Foxboro corporation designed a great many of their pneumatic instruments

ball-plug allowed supply air to go to the output port

cone-shaped stem valve plug vented excess air pressure to the vent port.

Fischer corporation design

non-bleeding type meaning it possessed the ability to close both supply and vent valves at the same time, allowing it to hold an output air pressure between saturation limits without bleeding a substantial amount of compressed air to atmosphere through the vent.

Analogy to Op-Amp Circuit

Gain = A = Output/Input

Analysis of a practical pneumatic instrument POPULARITY

RUGGED

EASY TO CALIBRATE

QUITE ACCURATE

FULCRUM

As the baffle approaches the nozzle, air flow through the nozzle becomes more restricted, accumulating backpressure in the nozzle. This backpressure increase is greatly amplified in the relay, which sends an increasing air pressure signal both to the output line and to the bellows at the bottom of the range bar. Increasing pneumatic pressure in the bellows causes it to push harder on the bottom of the range bar, counterbalancing the initial motion and returning the range bar (and force bar) to their near-original positions.

BAFFLE AND NOZZLE

DIAPHRAGM

You might also like

- BCN 3224 - Exam 3 ReviewDocument34 pagesBCN 3224 - Exam 3 Reviewmgwin17No ratings yet

- CH11 InstDocument220 pagesCH11 Instali amr100% (1)

- Test of An Air Compressor ME LAB 2Document27 pagesTest of An Air Compressor ME LAB 2nibin venugopal0% (1)

- AIR SYSTEM BASICS: THE FUNDAMENTALSDocument11 pagesAIR SYSTEM BASICS: THE FUNDAMENTALSpbhat83No ratings yet

- Introduction To Static PressureDocument4 pagesIntroduction To Static Pressure63ragtop100% (2)

- Chapter 7 - Transient Heat Conduction PDFDocument64 pagesChapter 7 - Transient Heat Conduction PDFhaqjmiNo ratings yet

- All You Need To Know About FansDocument10 pagesAll You Need To Know About FansgertibajNo ratings yet

- Pressure Control TrainerDocument44 pagesPressure Control TrainerAjeet KumarNo ratings yet

- Lesson 1Document52 pagesLesson 1Bravo NovemberNo ratings yet

- Apelco Fishfinder 365Document83 pagesApelco Fishfinder 365Ivan Campione100% (1)

- Hvac Testing Adjusting BalancingDocument7 pagesHvac Testing Adjusting Balancingarour.mokraneNo ratings yet

- Car Wash Wastewater Treatment and Water ReuseDocument8 pagesCar Wash Wastewater Treatment and Water Reuserocotroncoso100% (1)

- Anti Surge ControlDocument33 pagesAnti Surge Controlgopinath87100% (1)

- Aircraft Instruments SystemsDocument25 pagesAircraft Instruments SystemsERRAMESH1989No ratings yet

- Air Fin Cooler Discharge Temperature Control OptionsDocument13 pagesAir Fin Cooler Discharge Temperature Control OptionsMuhammad ImranNo ratings yet

- Design DocumentDocument10 pagesDesign DocumentLiza WoodsNo ratings yet

- Pitot-Static System: Muhammad Asyraf Bin Ghazali 53259207033 Mohamad Noruddin Bin Mohamad Ramli 5359207043Document30 pagesPitot-Static System: Muhammad Asyraf Bin Ghazali 53259207033 Mohamad Noruddin Bin Mohamad Ramli 5359207043Mohamad NoruddinNo ratings yet

- Recommended Design Criteria For Sedimentation... : General Considerations..Document5 pagesRecommended Design Criteria For Sedimentation... : General Considerations..Ahmed WagihNo ratings yet

- Wetex Middle East Exhibitors 2016Document7 pagesWetex Middle East Exhibitors 2016Dinkar JoshiNo ratings yet

- (Developments in Geotechnical Engineering 75) Sven Hansbo (Eds.) - Foundation Engineering-Academic Press, Elsevier (1994) PDFDocument534 pages(Developments in Geotechnical Engineering 75) Sven Hansbo (Eds.) - Foundation Engineering-Academic Press, Elsevier (1994) PDFপ্রিয়দীপ প্রিয়মNo ratings yet

- Air VelocityDocument10 pagesAir VelocityMorkechoNo ratings yet

- Lecture VI - PID Controller in Pneumatic System (Use Case)Document21 pagesLecture VI - PID Controller in Pneumatic System (Use Case)R.W. Saputra100% (1)

- Chapter.5.ENV HYDRAULICS Students HandoutDocument53 pagesChapter.5.ENV HYDRAULICS Students HandoutTimothy KiryaNo ratings yet

- Pneumatic ControllersDocument9 pagesPneumatic Controllerspavan_1988No ratings yet

- Process Calculations and Reactor Calculations For Environmental EngineeringDocument144 pagesProcess Calculations and Reactor Calculations For Environmental EngineeringBAO008No ratings yet

- 16 Anaerobic Wastewater TreatmentDocument42 pages16 Anaerobic Wastewater TreatmentJose SuarezNo ratings yet

- Global Water Market 2017Document35 pagesGlobal Water Market 2017Padawan De Wookiee100% (1)

- Wastewater Design Criteria 2Document104 pagesWastewater Design Criteria 2Lakshya Gupta100% (1)

- Air Velocity MeasurementDocument8 pagesAir Velocity Measurementfakursanat3618No ratings yet

- John Deere 9650 Sts Parts CatalogDocument20 pagesJohn Deere 9650 Sts Parts CatalogDennis100% (56)

- AI 210 InstrumentationDocument52 pagesAI 210 InstrumentationRaju SkNo ratings yet

- CTK 651Document33 pagesCTK 651nhonghoiNo ratings yet

- Water Pollution Control Federation Yearbook: 1973Document204 pagesWater Pollution Control Federation Yearbook: 1973Auren7No ratings yet

- Kontrol Pneumatik dan Komponen Kontroler PneumatikDocument18 pagesKontrol Pneumatik dan Komponen Kontroler PneumatikM SONY JAYA WISUDANo ratings yet

- BASIC AIRCRAFT INSTRUMENTSDocument20 pagesBASIC AIRCRAFT INSTRUMENTSKarren Joy CostalesNo ratings yet

- Controllers and Final Control ElementsDocument27 pagesControllers and Final Control Elementsکبری ادریس رسولNo ratings yet

- Volume Booster, Qev and Fail Safe OperationDocument16 pagesVolume Booster, Qev and Fail Safe OperationharishcsharmaNo ratings yet

- Pressure Fundamentals PDFDocument14 pagesPressure Fundamentals PDFSadhana VermaNo ratings yet

- Pneumatic InstrumentationDocument5 pagesPneumatic Instrumentationabhijith_r5060No ratings yet

- Centrifugal Air Compressor Sizing and Control BasicsDocument7 pagesCentrifugal Air Compressor Sizing and Control BasicsAatish ChandrawarNo ratings yet

- Measuring Industrial Process Air Velocity & VolumeDocument6 pagesMeasuring Industrial Process Air Velocity & Volumeamerican_guy10No ratings yet

- LMW Lakshmi Latest Machines: Pneumatic Air CompressorDocument8 pagesLMW Lakshmi Latest Machines: Pneumatic Air CompressorMuhammad JunaidNo ratings yet

- Pressure Measurement Part1Document7 pagesPressure Measurement Part1salemNo ratings yet

- How Does A Pneumatic Solenoid Valve WorkDocument4 pagesHow Does A Pneumatic Solenoid Valve Worksushant_jhawerNo ratings yet

- 06 Mem341Document17 pages06 Mem341Muhammad AbdullahNo ratings yet

- Lab Manual: Instrumentation and ControlDocument42 pagesLab Manual: Instrumentation and ControlJu Naid MalikNo ratings yet

- Chapter 1 - FullDocument60 pagesChapter 1 - FullMohamad Zulamirulfaha100% (1)

- Measure Pressure and Flow: Install The EMANT300 USB DAQ and Stepper Motor Training KitDocument13 pagesMeasure Pressure and Flow: Install The EMANT300 USB DAQ and Stepper Motor Training KitakashawalkerNo ratings yet

- Volumetric EfficiencyDocument7 pagesVolumetric EfficiencyDumithJayathilaka100% (1)

- Pressure MeasurementDocument3 pagesPressure Measurementvijay kumar honnaliNo ratings yet

- Cermak AMCA Web FanDocument6 pagesCermak AMCA Web Fanbigi1234No ratings yet

- Bourdon TubeDocument22 pagesBourdon TubemgskumarNo ratings yet

- Anaesthesia Ventilators: Presenter: Priya S Nair Moderator: DR - ShivanandDocument40 pagesAnaesthesia Ventilators: Presenter: Priya S Nair Moderator: DR - ShivanandCrystieNo ratings yet

- Chapter 2Document105 pagesChapter 2Yip Tuck WaiNo ratings yet

- IIT Dhanbad Student Paper on Current to Pressure TransducerDocument9 pagesIIT Dhanbad Student Paper on Current to Pressure TransducerSandeep ReddyNo ratings yet

- Kele - Solutions Articles - The Instability of VAV SystemsDocument5 pagesKele - Solutions Articles - The Instability of VAV SystemsKumudu PereraNo ratings yet

- Centrifugal Air Compressor Basics: Key Concepts, Choke, Surge, CapacityDocument7 pagesCentrifugal Air Compressor Basics: Key Concepts, Choke, Surge, CapacityCésarNo ratings yet

- Glossary - Education - CAGI - Compressed Air and Gas InstituteDocument6 pagesGlossary - Education - CAGI - Compressed Air and Gas InstituteminiongskyNo ratings yet

- Measure Air Velocity Accurately with Dwyer InstrumentsDocument10 pagesMeasure Air Velocity Accurately with Dwyer InstrumentsCarlosNo ratings yet

- Design Principles:: Mechanical VentilatorsDocument41 pagesDesign Principles:: Mechanical VentilatorsSailu KatragaddaNo ratings yet

- Indian Institute of Technology (Indian School of Mines) DhanbadDocument10 pagesIndian Institute of Technology (Indian School of Mines) DhanbadSandeep ReddyNo ratings yet

- Navigate Instrument FlightDocument48 pagesNavigate Instrument Flightখালিদহাসান100% (1)

- Fan Systems: Fan and System MatchingDocument28 pagesFan Systems: Fan and System Matchingvalerio.garibayNo ratings yet

- AC 61-23C Chapter 3 CanadaDocument15 pagesAC 61-23C Chapter 3 Canadafarrukhhussain2006No ratings yet

- Measurement of Pressure - Direct ReadingDocument12 pagesMeasurement of Pressure - Direct ReadingVedanta NairNo ratings yet

- Fan CurveDocument11 pagesFan CurveMouayad AlaliNo ratings yet

- Unit IDocument104 pagesUnit IAnshul jainNo ratings yet

- Last Name, First CHE426:: F C V C V C F + F F CDocument6 pagesLast Name, First CHE426:: F C V C V C F + F F Clợi trầnNo ratings yet

- Furniture Plans How To Build A Rocking ChairDocument10 pagesFurniture Plans How To Build A Rocking ChairAntónio SousaNo ratings yet

- Description Wincc Project Scanner enDocument9 pagesDescription Wincc Project Scanner enDugPigeonNo ratings yet

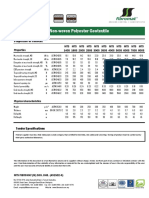

- FibrotexDocument2 pagesFibrotexMan ChupingNo ratings yet

- Foundation DesignDocument7 pagesFoundation DesignPrasad GNNo ratings yet

- Price ListDocument2 pagesPrice ListCHeng SOngco TAlosigNo ratings yet

- Class Room Allotment SystemDocument7 pagesClass Room Allotment SystemPRABANo ratings yet

- 90ma012 - CarrierDocument32 pages90ma012 - Carrierrafaelpaiva871531No ratings yet

- MPTO Charts566662Document25 pagesMPTO Charts566662andres ortizNo ratings yet

- Best Practices in PL/SQL: Karthikeyan MDocument15 pagesBest Practices in PL/SQL: Karthikeyan MranusofiNo ratings yet

- ITU Rec. BT.709-5 Defines Parameters for HDTV StandardsDocument31 pagesITU Rec. BT.709-5 Defines Parameters for HDTV StandardsHarold Coila VillenaNo ratings yet

- 72.core Cut Reference SP-24Document1 page72.core Cut Reference SP-24DMJ NagpurNo ratings yet

- Building A Big Data Platform For Smart Cities: Experience and Lessons From SantanderDocument8 pagesBuilding A Big Data Platform For Smart Cities: Experience and Lessons From SantanderDylan GuedesNo ratings yet

- HOMOLOGOUS SERIES ORGANIC CHEMISTRY BASICS-past-paper-questionsDocument12 pagesHOMOLOGOUS SERIES ORGANIC CHEMISTRY BASICS-past-paper-questionsJo PatrickNo ratings yet

- Course Handout SADocument9 pagesCourse Handout SAValiveti KumariNo ratings yet

- 9.1 LoLog LL VistaDocument2 pages9.1 LoLog LL VistaMais OmarNo ratings yet

- Geotech Final ReportDocument38 pagesGeotech Final Reportapi-320590292No ratings yet

- AWS CWI For NSRP at NSRP PDFDocument7 pagesAWS CWI For NSRP at NSRP PDFTuấn PhạmNo ratings yet

- What Is Transmission Channel ?Document12 pagesWhat Is Transmission Channel ?tusharNo ratings yet

- 7 New Management ToolsDocument6 pages7 New Management ToolsKarthik SivaNo ratings yet

- Commissioning Report Generator - SAMPLEDocument5 pagesCommissioning Report Generator - SAMPLEMax JohnNo ratings yet

- HE Hydra Jar Manual 6-80Document31 pagesHE Hydra Jar Manual 6-80Yuri KostNo ratings yet

- High-Efficiency Controllers for Notebook ComputersDocument28 pagesHigh-Efficiency Controllers for Notebook ComputerscNo ratings yet