Professional Documents

Culture Documents

250 K W

Uploaded by

Tapan KapoorOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

250 K W

Uploaded by

Tapan KapoorCopyright:

Available Formats

WG No.

To:

TECHNICAL SPECIFICATIONS OF ELECTRICAL EQUIPMENT FOR A 250kW PHOTOVOLTAIC GENERATION POWER PLANT

(FOR REFERENCE) 250kW Grid-Connected Photovoltaic Inverter (ModelPVGL0250)

APPROVED BY CHECKED DRAFTING BY

ORDER

NO.

SPECIFICATION BY 1 DATE 2 3

NO.(QUOT.NO.)

REVISION DATE

WG No.

CHAPTER 1

GENERAL

1.1 APPLICATION The equipment described in the specifications below is intended to be used as a Grid-Connected Photovoltaic Inverter System for a photovoltaic generation plant. 1.2 PLACE TO BE INSTALLED Location is to be specified by customer. 1.3 SCOPE The specifications cover the design, fabrication, commissioning and supply of Inverter The equipment and work will be provided from Japan. 1.4 APPLICABLE STANDARDS 1.4.1 COMPLIANCE (CE CONFORMITY) This equipment complies with the provisions of the Low-voltage directive 2006/95/EC and the EMC directive 2004/108/EC, thus fulfilling the requirements of the EU legislation for CE Marking. 1.4.2 GUIDELINES AND STANDARDS The following harmonized standards have been applied to comply with the provisions of the Low-voltage directive 2006/95/EC and the EMC directive 2004/108/EC. EN 50178:1997 EN 61000-6-2:2005 EN 61000-6-4:2007 EN 55011:1998 (Electronic equipment for use in power installations) (Electromagnetic Compatibility (EMC)-Part 6-2: Generic Standards-Immunity for industrial environments) (Electromagnetic Compatibility (EMC)-Part 6-4: Generic Standards-Emission standard for industrial environments) (Limits and methods of measurement of radio disturbance characteristics of industrial, scientific and medical(ISM) radio-frequency equipment)

In addition, the following standards may be applied for the equipment under certain conditions. IEC 62103:2003 IEC 62109-1:2007 IEC 62116 Ed. 1.0:2008 IEC 62446 Ed. 1.0:2009 (Electronic equipment for use in power installations) (Safety of power conversion equipment for use in photovoltaic power systems-Part 1: General Requirements) (Test procedure of islanding prevention measures for utility-interconnected photovoltaic inverters) (Grid connected photovoltaic systems-Minimum requirements for system documentation, comissioning tests and inspection)

-1-

WG No.

IEC/TS 61000-3-4 Ed. 1.0:1998 (Electromagnetic Compatibility (EMC)-Part 3-4: Limits-Limitation of emission of harmonic currents in low-voltage power supply systems for equipment with rated current greater than 16A) IEC 61000-6-1 Ed. 2.0:2005 (Electromagnetic Compatibility (EMC)-Part 6-1: Generic Standards-Immunity for residential, Commercial and light industrial environments) IEC 61000-6-3 Ed. 2.0:2006 (Electromagnetic Compatibility (EMC)-Part 6-3: Generic Standards-Emission standard for residential, commercial and light-industrial environments) IEC 61683 Ed. 1.0:1999 (Photovoltaic systems - Power Conditioners - Procedure for measuring efficiency) IEC/TS 61836 Ed. 2.0:2007 (Solar photovoltaic energy systems Terms, definitions and symbols) All bolts, nuts and screws will conform to the METRIC THREAD of ISO (International Organization for Standardization). Metric system will be used for design and manufacturing of the equipment. 1.5 DOCUMENTS TO BE SUBMITTED All of documents and drawings will be submitted in an original paper copy or in electronic form on CD. 1.5.1 FOR APPROVAL Specifications OUTLINE DRAWING SCHEMATIC DIAGRAMS 1.5.2 FOR FINAL Specifications OUTLINE DRAWING SCHEMATIC DIAGRAMS Test records of main equipment Instruction manuals ( Equipment, Operation, Display, Installation )

1.6 PACKING The equipment will be divided into several sections for protection in transportation when necessary, and it will be properly packed or prepared for transportation by ship and truck. Special notations such as "Fragile", "This Side Up", "Center of Gravity", "Weight", etc., when necessary, will be clearly described on each package. 1.7 PRODUCTION TEST Test will be carried out at manufacturer's factory for each part of equipment. Test records of main parts of equipment will be submitted.

-2-

WG No.

1.8 MAINTENANCE CONTRACT Performing scheduled periodical inspections and maintenance will improve the reliability of the equipment and will prolong its service life. It is recommended that periodical inspections and maintenance should be performed by specialists of service representative. (Such maintenance will be implemented under a separate agreement, offering the buyer to pay additional fee for maintenance.) 1.9 TESTING AND COMMISSIONING Testing and commissioning will be implemented under a separate agreement. 1.10 WARRANTY (1) The Seller warrants that the Product shall be free from defects in design (other than a design made, furnished or specified by the Buyer for which the Seller has disclaimed responsibility in writing), material and workmanship for eighteen (18) months from the date of shipment or twelve (12) months from the date on which the Product is put into operation, whichever period shall first expire, provided that the Buyer gives the Seller written notice of any defect and satisfactory proof thereof promptly upon discovery of such defect but in no case later that fifteen (15) days after expiration of the aforesaid warranty period. (2) The Sellers obligation under the aforesaid warranty shall be limited to, at the Sellers option, (a) repairing, (b) replacing or (c) supplying a replacement part for any part of the Product which, if properly installed, used and maintained, proves defective owing solely to causes attributable to the Sellers design, material or workmanship. (3) The Sellers obligation under Paragraphs (1) and (2) hereof shall not apply to the Product or any part thereof which is normally consumed in operation or has a normal life inherently shorter than the warranty period stated herein. (4) The total liability of the Seller on any claim whether in contract, tort (including negligence) or otherwise, arising out of, connected with or resulting from the performance or breach of any contract based upon the Quotation shall not exceed the price of the Product or the value of any part thereof which gives rise to the claim. (5) In no event, whether as a result of breach of contract, warranty, alleged negligence or liability without fault, shall the Seller be liable for special, indirect or consequential damages. 1.11 DISPATCH OF TMEIC ENGINEERS Except for the purpose of implementing the repair under the warranty set forth in 1.10, the dispatch of TMEIC engineer for any service whatsoever will be made under a separate agreement offering the buyer to pay additional fee for services.

-3-

WG No.

CHAPTER 2

GENERAL CONDITIONS

2.1 GROUNDING SYSTEM The inverter should be grounded providing a grounding resistance less than 2 ohms. 2.2 INSTALLATION AND OPERATION ENVIRONMENT When installing or operating the inverter and related devices, ensure that the installation and operation environment complies with Table 1. Failing to observe these standards may deteriorate insulation, causing short life and malfunctions. Before installation, measure and evaluate the environment of the installing location. If the standards are not satisfied, it is recommended to take necessary action before installing or operating the inverter.

Table 1

No. 1 2

The Solar Inverter System installation and operation environment

Item Installation location Ambient temperature rang

3 4 5

7 8

Environment standard Indoors -20 to +40 Frosting is not allowed. May need optional cabinet heating. Maximum Ambient +50 A derating of 10% per degree apply for temperatures over 40 temperature The relative humidity must be held between 15 and 95%. There must be no condensation Relative humidity due to temperature changes. Altitude Up to 1000 meters above sea level. (2000 meters optional) Air pressure The air pressure must be maintained in the range 860 to 1060 hPa. Vibrations in the installation environment must have frequencies either lower than 10 Hz, Vibration and or higher than 20 Hz. mechanical shock For vibrations under 10 Hz, the acceleration due to those vibrations must not exceed 0.5G. For vibrations over 20 Hz and under 50Hz, the acceleration due to those vibrations must not exceed 0.5G. For vibrations over 50Hz and under 100Hz, the total amplitude must not exceed 0.1 mm. Dust in the air in the room where the Inverter is installed must not exceed normal Dust atmospheric dust levels. In particular, that dust must not include electrically conductive particles, oils or fats, or organic materials such as silicone. Flammability There should be no inflammable/explosive gas. Maximum Average Allowable 0.003 PPM 0.01 PPM Hydrogen sulfide(H2S) 0.01 PPM 0.03 PPM Sulfurous acid gas (SO2) Chlorine gas (Cl2) 0.0005 PPM 0.001 PPM Corrosive factors (Relative humidity50%) Chlorine gas(Cl2) 0.002 PPM 0.01 PPM (Relative humidity50%) 0.001 PPM 0.005 PPM Hydrogen fluoride(HF) 1 PPM 5 PPM Ammonia gas (NH3) 0.05 PPM 0.1 PPM Nitrogen oxide (NOx) 0.002 PPM 0.005 PPM Ozone (O3)

10

Other climatic conditions

3K3(EN 60721-3-3)

-4-

WG No.

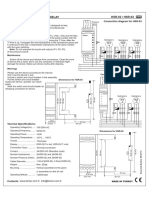

CHAPTER 3 EQUIPMENT SPECIFICATIONS The Inverter employs IGBT switches and continuously converts DC power to AC power . The inverter output voltage will automatically be synchronized with the grid AC source as long as the source is within a tolerable frequency and voltage range. Regarding the detail of the unit configurationrefer to the Inverter single line diagram (Fig.1), the outline 0f 250kW Inverter (Fig.2) . 3.1 250kW INVERTER UNIT 3.1.1 Main circuit type Conversion method Swiching method Inverter configuration Isolation method

Cooling method 3.1.2 Control method DC side control functions Grid side control functions Operation Other functions

: Voltage source inverter with instantaneous current control : Pulse Width Modulation(PWM) control : Three-phase bridge : Galvanic isolation provided for isolated type. External transformer is required for Transformerless type. : Forced cooling

: Maximum Power Point TrackingMPPT control : Active power control, reactive power control, grid voltage compensation : Auto start/stopsoft-start at startup : Output power limier. (If the capacity of solar power exceed the generation capacity of the Inverter the Inverter limits the output power.)

3.1.3 Protective functions (1) Input(DC) side Ground fault, DC reverse current, Over voltage, Over current (2) Grid(AC) side Anti-islanding, Over/under voltage, Over/under frequency, Over current

-5-

WG No.

3.1.4 Electrical ratingsEuropean Model ITEM System type Maximum DC power Inpu Maximum DC voltage t side MPPT operating range (DC) Maximum DC current Nominal AC output power Outp ut Nominal AC voltage side Nominal AC frequency (AC) Nominal AC current Tare losses (Stand-by) Tare losses (Night consumption) External auxiliary voltage Power factor Harmonic distortion of AC current Maximum efficiency European efficiency SPECIFICATION Grid-connected system 275kW 1000Vdc 450 850Vdc 580Adc 250kW 300Vac 3-Phase, 3-wire system 50Hz 481Arms < 700W < 100W 230V, 50Hz 0.99 (Rated power) 3% (Rated power) 98.2% 97.8%

3.1.5 Grid connection features In order for protection and management of grid connection, functions such as Anti-Islanding Protection, Fault Ride Through, Power Factor Control, Active Power Control are embedded to meet each plant specification. Fault Ride Through needs to be specified either "Voltage Ride Through Time Duration" or "Off Nominal Frequency Capability Curve" based upon guideline of national regulatory or power company of which PV system is installed and connected to. (1) Anti-islanding protection The objective of this system is to detect the islanding condition and drive the system to an stable operation condition.

-6-

WG No.

(2) Fault Ride Through Voltage Ride Throughby each country standards

Voltage Ride-Through Time Duration CurvesSample

Frequency Ride Throughby each country standards

Off Nominal Frequency Capability CurveSample

-7-

WG No.

(3) Power factor control Power factor can be controlled according to the following figure. It is important to notice that since the apparent power remains constant, reducing the power factor also reduces the active power.

(4) Reactive power control Reactive power can be injected to the grid according to the grid voltage as in the following figure.

-8-

WG No.

(5) Active power control Frequency fluctuations can be compensated by controlling the active power as in the following example.

-9-

WG No.

3.1.6 Panel display outline and description (1) Main The display contents for the MAIN tab are explained referring to the following picture.

Main Tab

Measurement Display for Status supervision

Circuit Status Diagram

Measurement Display for Status supervision In order to see the equipment status at a glance, the following information is displayed. PV(DC) DC Voltage(V), DC current(A) GRID(AC) AC Voltage(V), AC Current(A), Frequency(Hz) POWER Instantaneous Active Power(kW) DAILY Power harvested during the day(kWh) TOTAL Total power harvested(kWh) Circuit Status Diagram In order to see the equipment connection and operation status at a glance, a circuit status diagram is displayed showing switches status and converter operation status. The following information is displayed. PV Photovoltaic array CB DC input circuit breaker Inverter(DC/AC converter) INV Grid connection switch(Contactor) MC Utility Grid GRID Start/Stop Operation When operating in local mode and in normal conditions, by pressing the START/STOP button, to stop the inverter press theSTOPbutton.

-10-

WG No.

(2) Measurement Selecting the MEASUREMENTtab, the following screen appears.

Measurement items are as follows DC Voltage, DC current, DC Power DC RS AC Voltage (R-S Line-to-line) ST AC Voltage (S-T Line-to-line) TR AC Voltage (T-R Line-to-line) R AC Current (R Phase) S AC Current (S Phase) T AC Current (T Phase) P Active Power (kW) Q Reactive Power (kVAR) pf Power Factor (Not indication) Frequency (Hz)

(3) LED indicator The Inverter is equipped with a LED indicator. The following items are displayed on LED. Inverter running <RUN> (greenInverter stand-by <STAND-BY> (green) DC breaker on (72B1 or 72B2) <DC ON> (green)Grid on <AC ON> (green) Failure on LCD <LCD FAULT> (orange)Failure on the inverter <INV FAULT> (red)

Touch Panel Display (LCD)

LCD Status

RUN

STAND -BY

DC ON

AC ON

LCD FAULT

INV FAULT

Status Display LED

-11-

WG No.

3.1.7 Relay signal for remote use (1) Output signal for remote use will be furnished as the followings (minimum items): Major Failure normally open (1a) Running normally open (1a) Restricted running normally open (1a) Stop normally open (1a) Minor Failure normally open (1a) Stand-by normally open (1a) (2) Relay input signal for remote use will be furnished as the followings (minimum items): Ready normally open (1a) (Relay signal will be dry contact with rating of DC24V 1A or AC100V 0.2A.) 3.1.8 Communication interface Communication system : Ethernet The PLC(Programable Logic Controler) is necessary for anather communication I/F. 3.1.9 Utility interactive protection item Protection item Over Voltage Relay(OVR Under Voltage Relay(UVR) Over Frequency Relay(OFR) Under Frequency Relay(UFR) Passive anti-islanding Detection (voltage phase jump detection)PDR Active anti-islanding detection (frequency shift)

(1) (2)

Detection phase number 3 3 1 1 1

Operating conditions GB(1)

CB(2)

Notes

indicates inverter gate block. indicates trip of the grid side circuit breaker.

-12-

WG No.

3.1.10 Structual specifications (1)General construction of equipment (2) Inverter Cabinet Dimensions (HeightWidthDeoth) (3)Weight (4)Paint Outside general surface Inside surface Base Decorative plate Other components (5)Wiring terminal colors : Metal-enclosed, free standing cubicle, indoor-use IP2X. : 74.8047.2535.45 (1,900mm1,200mm900mm) : approx. 1,000(kg) 1 set : : : : : : Manufacturer's standard. Manufacturer's standard. Manufacturer's standard. Manufacturer's standard. Manufacturer's standard. L1 : redL2 : whiteL3 : blue Positive : redNegative : blue (only input and output terminal) bottom bottom bottom bottom part part part part of of of of cubicle cubicle cubicle cubicle

(6)Input/output interface DC input wire AC output wire Control wire Grounding wire

: : : :

-13-

WG No.

CHAPTER 4 SPARE PARTS 4.1 START UP & COMMISIONING SPARE PARTS OF INVERTER One hundred(100)% of fuses for control circuitcovers single inverter unit only 4.2 RECOMMENDED SPARE PARTS OF INVERTER One(1) set of IGBT stackfor 1-phase One hundred(100)% of fuses for main circuitcovers single inverter unit only One(1) set of Cooling fan One(1) set of Main control board One(1) set of Control power boardDC15V24V One(1) set of External interface board Two(2) set of DC surge protector Two(2) set of AC surge protector Two(2) set of Dust filter CHAPTER 5 COMPLEMENTARY TECHNICAL CLARIFICATIONS

5.1 Equipment Grounding This inverter should be connected to an IT system according to IEC 60364, which means that the inverter should be connected to an ungrounded AC system. The step up transformer may have either delta or wye connection for the low voltage winding. However, in case the low voltage winding of the transformer is wye connected, the neutral point should not be grounded. Grounding through a high impedance resistance may be allowed if designed according to IEC 60364. 6.2 Step-up Transformer requirements kVA Frequency Primary Voltage Taps Secondary Voltage Static shield 250kVA 50 Y 2-2.5% taps above and 2-2.5% taps below nominal 300 Delta 300 Delta The transformer shall have static shields between primary windings and secondary windings.

-14-

- 1 6 -

Fig.1

Inverter Single line Diagram (Transformerless type)

- 1 7 -

Fig.2 Outline of 250kW Inverter

You might also like

- Solargen Solar PV Homekit Assembly ManualDocument32 pagesSolargen Solar PV Homekit Assembly Manualj3ffr3yNo ratings yet

- Energy Efficiency Improvement and Cost Saving Opportunities For TheDocument120 pagesEnergy Efficiency Improvement and Cost Saving Opportunities For TheAmer AlkalaifhNo ratings yet

- Eks Energy PresentationDocument17 pagesEks Energy PresentationFrancisco Javier Marín SuárezNo ratings yet

- PV Power Plants 2010 WebDocument45 pagesPV Power Plants 2010 WebKetan ChhedaNo ratings yet

- Project ChandruDocument33 pagesProject ChandruBhavaniNo ratings yet

- IEC61727 - Characteristics of The Utility Interface - Design Qualification For Invertors PDFDocument28 pagesIEC61727 - Characteristics of The Utility Interface - Design Qualification For Invertors PDFCliffNo ratings yet

- How To Calculate or Design A SolarDocument8 pagesHow To Calculate or Design A Solarhammad engineeringNo ratings yet

- Asset ManagementDocument4 pagesAsset ManagementJohan TadlasNo ratings yet

- Voltage SagDocument77 pagesVoltage SagDedi Nugroho50% (2)

- Renewable Energy - Solar Electrical Energy SystemsDocument76 pagesRenewable Energy - Solar Electrical Energy SystemsGhenoiu PaulNo ratings yet

- Automatic Power Supply Control: Eit-MDocument7 pagesAutomatic Power Supply Control: Eit-MsamuelNo ratings yet

- Unit V Emerging Solar Cell TechnologiesDocument16 pagesUnit V Emerging Solar Cell TechnologiesArchana Diwakar RanjishNo ratings yet

- 001 - Performance Analysis of Solar Drying System For Red Chili PDFDocument8 pages001 - Performance Analysis of Solar Drying System For Red Chili PDFAlex Samuel SilvaNo ratings yet

- Training Report ORIGiNALDocument151 pagesTraining Report ORIGiNALAnkit BansalNo ratings yet

- Maintenance ManagementDocument13 pagesMaintenance ManagementMohola Tebello GriffithNo ratings yet

- 1MW and 1 25MWPV Grid ConnectedInverter Operation ManualDocument111 pages1MW and 1 25MWPV Grid ConnectedInverter Operation ManualNguyễn ChínNo ratings yet

- Microgrids Enhancing The Resilience of The European MegagridDocument9 pagesMicrogrids Enhancing The Resilience of The European MegagridSorin MiuNo ratings yet

- Report Batteries Solar Photovoltaic ApplicationsDocument87 pagesReport Batteries Solar Photovoltaic ApplicationsMohd Zulfika AbdolkaderNo ratings yet

- Solar PV Module Reliability Scorecard 2016-2-1473940821Document21 pagesSolar PV Module Reliability Scorecard 2016-2-1473940821Ankit SahaNo ratings yet

- Energy - Efficiency en Data PDFDocument15 pagesEnergy - Efficiency en Data PDFscribd99190No ratings yet

- Itrpv 2023Document83 pagesItrpv 2023Ananda LagoNo ratings yet

- Huawei Smart PV Plant References PDFDocument20 pagesHuawei Smart PV Plant References PDFinfo8709No ratings yet

- Company Overview - Elum Energy - Power Plants PDFDocument17 pagesCompany Overview - Elum Energy - Power Plants PDFCyrilColinNo ratings yet

- Customer Satisfaction Project of Green TechDocument52 pagesCustomer Satisfaction Project of Green TechRajkamalChichaNo ratings yet

- Energy Storage For Solar PV BrochureDocument4 pagesEnergy Storage For Solar PV BrochureVijay PrabhuNo ratings yet

- Solar Energy Au1910330 AasthagalaniDocument15 pagesSolar Energy Au1910330 AasthagalaniAastha GalaniNo ratings yet

- DPR Govt. Polytechnic College - Althino 50 KW PDFDocument22 pagesDPR Govt. Polytechnic College - Althino 50 KW PDFBADRI VENKATESHNo ratings yet

- Electricity (Grid and Distribution Codes) GN. No. 451 (Contd.)Document83 pagesElectricity (Grid and Distribution Codes) GN. No. 451 (Contd.)IulianNo ratings yet

- Microgrid Architectures For Low Voltage Distributed GenerationDocument10 pagesMicrogrid Architectures For Low Voltage Distributed Generationhafiz858No ratings yet

- Rural ElectrificationDocument12 pagesRural ElectrificationRavikanth ReddyNo ratings yet

- Grid-Connected Photovoltaic Systems: An Overview of Recent Research and Emerging PV Converter TechnologyDocument15 pagesGrid-Connected Photovoltaic Systems: An Overview of Recent Research and Emerging PV Converter TechnologyLukas Ramírez MarínNo ratings yet

- Proposal For 1kwp Roof-Top Solar PV PlantDocument5 pagesProposal For 1kwp Roof-Top Solar PV PlantAnonymous kw8Yrp0R5rNo ratings yet

- Solar Energy Services BrochureDocument4 pagesSolar Energy Services BrochureAnkit MaheshwariNo ratings yet

- Powerengineering201604 DL LargeScale CO2PPDocument57 pagesPowerengineering201604 DL LargeScale CO2PPJuan RiveraNo ratings yet

- Pestle Analysis Power Plant SummaryDocument1 pagePestle Analysis Power Plant SummarySiddharth Jain0% (2)

- 41 Self ConsumptionDocument2 pages41 Self Consumptioncrico1535No ratings yet

- Ida Fahani MD Jaye - Renewable, Local Electricity Generation From Palm Oil Mill Residues A Case Study From Peninsular MalaysiaDocument289 pagesIda Fahani MD Jaye - Renewable, Local Electricity Generation From Palm Oil Mill Residues A Case Study From Peninsular MalaysiaFred LukeNo ratings yet

- Danfoss String Inverters Vs Central InvertersDocument14 pagesDanfoss String Inverters Vs Central InvertersJacinto Benavente FuertesNo ratings yet

- Microgrids Smart Grids and Energy Storage SolutionsDocument28 pagesMicrogrids Smart Grids and Energy Storage SolutionsDGGNo ratings yet

- 1MZB100055 PowerStore Battery Product Manual 1.0 PDFDocument47 pages1MZB100055 PowerStore Battery Product Manual 1.0 PDFaashish bissaNo ratings yet

- 6 Seminar Report - 07Document25 pages6 Seminar Report - 07vikasNo ratings yet

- Self-Integration Fluence PDFDocument7 pagesSelf-Integration Fluence PDFRambabuNo ratings yet

- Micro InverterDocument28 pagesMicro InverterAatish KoulNo ratings yet

- Design and Implementation of An Independent Renewable Energy Source (5kva Solar Powered Inverter)Document17 pagesDesign and Implementation of An Independent Renewable Energy Source (5kva Solar Powered Inverter)BayeNo ratings yet

- Iec 6756 59 - 23072014Document10 pagesIec 6756 59 - 23072014Daniel GnanaselvamNo ratings yet

- Photovoltaic Thermal Hybrid Power System: Prepared By: Nirav Patel Guided By: Prof - Kinal PatelDocument22 pagesPhotovoltaic Thermal Hybrid Power System: Prepared By: Nirav Patel Guided By: Prof - Kinal PatelNirav PatelNo ratings yet

- Grid Tie Inverter MarketDocument8 pagesGrid Tie Inverter MarketSubhrasankha BhattacharjeeNo ratings yet

- Power Quality AnalysisDocument71 pagesPower Quality AnalysisFikre HailuNo ratings yet

- Summer Industrial Training ReportDocument26 pagesSummer Industrial Training ReportAbhishek SinghNo ratings yet

- MiniGrid Regulations 2016Document18 pagesMiniGrid Regulations 2016Sasha Vikas JainNo ratings yet

- A Comprehensive Solar PV Hosting Capacity in MV and LV Radial Distribution NetworksDocument6 pagesA Comprehensive Solar PV Hosting Capacity in MV and LV Radial Distribution Networkskasundp88No ratings yet

- Captive Power PlantDocument26 pagesCaptive Power PlantAshish Thakur100% (1)

- Solar Photovoltic ModuleDocument32 pagesSolar Photovoltic ModulelokendraNo ratings yet

- Evaluating The Technical and Economic Performance of PV Plus Storage Power PlantsDocument36 pagesEvaluating The Technical and Economic Performance of PV Plus Storage Power PlantssamNo ratings yet

- WKV Turbinen 2010 EN-rev1Document32 pagesWKV Turbinen 2010 EN-rev1mig22ismagoNo ratings yet

- Unit IV Wind and Solar Energy System 7thDocument12 pagesUnit IV Wind and Solar Energy System 7thmalik shafkatNo ratings yet

- Proposal of Solar: PV System For: 19.80 KWDocument4 pagesProposal of Solar: PV System For: 19.80 KWGajju Gulsher BhaiNo ratings yet

- India Solar EPC Blueprint Preview PDFDocument56 pagesIndia Solar EPC Blueprint Preview PDFVivek AgarwalNo ratings yet

- CSC-103 Line Protection IED Technical Application Manual (0SF.451.083E) - V1.02Document392 pagesCSC-103 Line Protection IED Technical Application Manual (0SF.451.083E) - V1.02duonzaNo ratings yet

- SJ-20111107090012-007 ZXR10 M6000 (V1.00.60) Carrier-Class Router Hardware Installation Guide (M6000-8S&5S&3S)Document227 pagesSJ-20111107090012-007 ZXR10 M6000 (V1.00.60) Carrier-Class Router Hardware Installation Guide (M6000-8S&5S&3S)Nishchal AgarwalNo ratings yet

- APC APCRBC140 DatasheetDocument9 pagesAPC APCRBC140 DatasheetAji Dezi DestiajiNo ratings yet

- Emotron VSX VSM VSR Vse Vss User Manual .EnDocument180 pagesEmotron VSX VSM VSR Vse Vss User Manual .EnVinay SharmaNo ratings yet

- Signal FinalDocument31 pagesSignal FinalVikas Srivastav100% (2)

- SadsadDocument2 pagesSadsadMahmoud shawkyNo ratings yet

- HVTDocument54 pagesHVTUtku YıldırımNo ratings yet

- Secure Meters CatalogueDocument40 pagesSecure Meters CatalogueHarman Preet100% (1)

- Automotive Charging System: Chapter FourDocument23 pagesAutomotive Charging System: Chapter FourIsaac TesfayeNo ratings yet

- Nema SG4-2009Document41 pagesNema SG4-2009Nicol Belén Escobar100% (1)

- NPS/001/032 Technical Specification For 11 & 20kV Pole Mounted Auto Sectionalising LinksDocument11 pagesNPS/001/032 Technical Specification For 11 & 20kV Pole Mounted Auto Sectionalising LinkskotiniNo ratings yet

- Laboratory Name: Accreditation Standard Certificate Number Page No Validity Last Amended OnDocument75 pagesLaboratory Name: Accreditation Standard Certificate Number Page No Validity Last Amended OnVikram BillalNo ratings yet

- (62-110kV) NKT 1x630mm2 XLPE AlDocument4 pages(62-110kV) NKT 1x630mm2 XLPE AlFahad UsmanNo ratings yet

- Free Energy CatalogDocument18 pagesFree Energy CatalogCaleb06866No ratings yet

- AIML VR20uptofirstyear15022023Document82 pagesAIML VR20uptofirstyear15022023Nageswara Rao VemulaNo ratings yet

- Design Basis 2Document25 pagesDesign Basis 2Krishnan KrishNo ratings yet

- Hydrophore Sequencing Relay: Connection Diagram For HSR-03Document1 pageHydrophore Sequencing Relay: Connection Diagram For HSR-03Pa'd Edy Sustiyono0% (1)

- VS1MD User ManualDocument168 pagesVS1MD User ManualWero LugoNo ratings yet

- Motors: Why Starters Are Not Used For Land Based Installations?Document12 pagesMotors: Why Starters Are Not Used For Land Based Installations?avm4343100% (1)

- RBU 100H Operation Manual - V1.7Document33 pagesRBU 100H Operation Manual - V1.7Muhammad TaimoorNo ratings yet

- "Handycam" Handbook DCR-PJ5/SR21/SX21: 2011 Sony Corporation 4-290-836-11Document101 pages"Handycam" Handbook DCR-PJ5/SR21/SX21: 2011 Sony Corporation 4-290-836-11Mocanu AdrianNo ratings yet

- Doble F6150sv - TechSpecsDocument3 pagesDoble F6150sv - TechSpecsjlcegarraNo ratings yet

- On AC Voltage ControllersDocument25 pagesOn AC Voltage ControllersSahil ChoudharyNo ratings yet

- Eubiq Catalog - 2019 6 PDFDocument1 pageEubiq Catalog - 2019 6 PDFTYNo ratings yet

- Manual & Automatic Chemical ControlDocument36 pagesManual & Automatic Chemical ControlKhaled SaadnehNo ratings yet

- Rme Reviewer1 Tom Henry XXXDocument44 pagesRme Reviewer1 Tom Henry XXXJonathan Ampis100% (1)

- SM VRF IuDocument302 pagesSM VRF IuСергейNo ratings yet

- Basic Electrical Engineering - Question Bank For Term End ExamDocument8 pagesBasic Electrical Engineering - Question Bank For Term End Examkrishnaprasad908312No ratings yet

- Imc 35 MLD Dep Ee Dat 08 r2Document4 pagesImc 35 MLD Dep Ee Dat 08 r2Electrical RadicalNo ratings yet

- Catalogue Indexing - E&IDocument36 pagesCatalogue Indexing - E&Iahmer baigNo ratings yet

- Ration DistributionDocument46 pagesRation Distributionvishalmate10No ratings yet