Professional Documents

Culture Documents

Hydraulic Design For Energy Generation

Uploaded by

masmello2011Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hydraulic Design For Energy Generation

Uploaded by

masmello2011Copyright:

Available Formats

Source: HYDRAULIC DESIGN HANDBOOK

CHAPTER 8

HYDRAULIC DESIGN FOR ENERGY GENERATION

H. Wayne Coleman C. Y. Wei James E. Lindell

Harza Company Chicago, Illinois

8.1 INTRODUCTION

This chapter describes the design aspects of hydraulic structures related to the production of hydroelectric power. These structures include headrace channels; intakes; conveyance tunnels; surge tanks; penstocks; penstock manifolds; draft-tube exits; tailtunnels, including tail-tunnel surge tanks and outlets; and tailrace channels. The procedures provided in this chapter are most suitable for developing the preliminary designs of hydraulic structures related to the development of the hydroelectric projects. To finalize designs, detailed studies must be conducted: for example, economic analysis for the determination of penstock diameters, computer modeling of hydraulic transients for surge tank design, and studies of physical models of intake and its approach.

8.2 HEADRACE CHANNEL

An open-channel called the headrace channel or power channel (canal) is sometimes required to connect a reservoir with a power intake when the geology or topography is not suitable for a tunnel or when an open-channel is more economical. The channel can be lined or unlined, depending on the suitability of the foundation material and the projects economics. Friction factors for various linings used for design are as follows: Mannings n Lining Unlined rock Shotcrete Formed concrete Grassed earth Minimum. 0.030 0.025 0.012 0.030 Maximum 0.035 0.030 0.016 0.100

8.1 Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) Copyright 2004 The McGraw-Hill Companies. All rights reserved. Any use is subject to the Terms of Use as given at the website.

HYDRAULIC DESIGN FOR ENERGY GENERATION

8.2

Chapter Eight

Headrace channels are generally designed and sized for a velocity of about 2 m/s (6.6 ft/s) at design flow conditions. Economic considerations may result in some variation from this velocity, depending on actual project conditions. Channel sections are normally trapezoidal because this shape is easier to build for many different geologic conditions. The bottom width should be at least 2 m (6.6 ft) wide. Side slopes are determined according to geologic stability as follows: earth, 2H:1V or flatter; and rock, 1H:1V or steeper. The channels proportionsbottom width versus depth are largely a matter of construction efficiency. In general, the minimum bottom width reduces excavation, but geologic conditions may require a wider, shallower channel. The channel slope will result from the conveyance required to produce design velocity for design flow. Channel bends should have a center-line radius of 3W to 5W or more, where W is the water surface width of the design flow. For this radius, head loss and the rise in the water surface at the outer bank (superelevation) will be minimal. If the radius must be reduced, the following formula can be used to estimate head loss hL: hL where Kb 2 (W/Rc), W channel width, Rc Kb V 2g

2

(8.1) mean velocity.

center-line radius, and V

Superelevation will be as follows (Chow, 1959): Z where Z 2W V2 Rc 2g (8.2)

rise in water surface above mean flow depth.

Freeboard must include allowances for the following conditions: (1) static conditions with maximum reservoir level (unless closure gates are provided to isolate the channel from the reservoir), (2) water surface rise (superelevation) caused by flow around a curve, and (3) surge resulting from shut-off of flow downstream or sudden increase of flow upstream. A forebay is provided at the downstream end of the headrace channel to facilitate one or more of the following: (1) low approach velocity to intake, (2) surge reduction, (3) sediment removal (desanding), or (4) storage. The forebay should be designed to maintain the approach flow conditions to the intake as smoothly as possible. As the minimum requirement, a small forebay should be provided to facilitate good entrance conditions to the intake. It should include a smooth transition to a section with a velocity not exceeding 0.5 m/s (1.64 ft/s) at the face of the intake structure A larger forebay could be required for upsurge protection during rapid closure of turbine gates for load rejection. The size would be determined on the basis of the freeboard allowance for the entire headrace channel and on a hydraulic transient analysis of the channel, if necessary. Surge calculations should consider maximum and minimum friction factors, depending on which is more critical for the case under study. Hydraulic transient (surge) studies are generally performed using a one-dimensional, unsteady open-channel-flow simulation program. The computer model developed should be capable of simulating the operation of various hydraulic structures, the effect of the forebay, and operation of the power plant. Several advanced open-channel flow-simulation programs have been described by Brater et al. (1996).

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) Copyright 2004 The McGraw-Hill Companies. All rights reserved. Any use is subject to the Terms of Use as given at the website.

HYDRAULIC DESIGN FOR ENERGY GENERATION

Hydraulic Design for Energy Generation 8.3

(a)

(b) Exhibit 8.1 Sun Koshi hydroelectric project, Nepal. (a) A view of the desanding basin (looking upstream) showing concrete guide vanes.( (b) Layout Of the desanding basin.

A large forebay is required if it will be used for diurnal storagesay, for a power peaking operation. In such a case, maximum and minimum operating levels would include the required water volume, with the intake located below the minimum level. Such a forebay also could accommodate the other three functions described above. When the flow carries too much sediment and its removal is required to protect the turbines, a still larger forebay would be provided to function as a desanding basin (also known as a desilting basin or desander). However, the desanding basin is more likely to be located at the upstream end of the headrace channel. Exhibit 8.1 Illustrates a desending basin. The basin can be sized using the following equation (Vanoni, 1977):

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) Copyright 2004 The McGraw-Hill Companies. All rights reserved. Any use is subject to the Terms of Use as given at the website.

HYDRAULIC DESIGN FOR ENERGY GENERATION

8.4

Chapter Eight

FIGURE 8.1 Settling velocity as a function of particle diameter. (Dingman, 1984)

LVs

(1

e VD )

100%

(8.3)

where P percentage of sediment of a particular size to be retained by the basin, L basin length, Vs settling (fall) velocity of suspended particles, V mean flow velocity, and D depth of the desanding basin. The settling velocity Vs for each particular sand particle size can be estimated from Fig. 8.1. A separate sluicing outlet (or outlets) would be provided to flush the desanding basin intermittently.

8.3 INTAKES

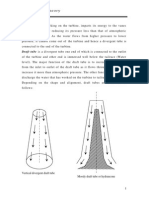

Most power intakes are horizontal, a few are vertical, and very few are inclined. Figures 8.2, 8.3, and 8.4 are examples of the three types of intakes. Exhibit 8.2 illustrates the layout of a hydroelectric project with the intakes. The horizontal intake is usually connected to a tunnel or penstock on a relatively small slope (up to 23 percent). The vertical intake is frequently used in pumped-storage projects when the upper reservoir is on high ground, such as a mountain top, and a vertical shaft-tunnel is the obvious choice. An inclined intake is used when the topography, geology, or type of dam dictate a steeper slope for the downstream tunnel or penstock. A variation on the three basic intake types is a tower structure, sometimes required for

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) Copyright 2004 The McGraw-Hill Companies. All rights reserved. Any use is subject to the Terms of Use as given at the website.

HYDRAULIC DESIGN FOR ENERGY GENERATION

Hydraulic Design for Energy Generation 8.5

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) Copyright 2004 The McGraw-Hill Companies. All rights reserved. Any use is subject to the Terms of Use as given at the website.

FIGURE 8.2 A typical horizontal intake. (Harza Engineering Co.)

HYDRAULIC DESIGN FOR ENERGY GENERATION

8.6

Chapter Eight

FIGURE 8.3 A typical vertical intake. (Harza Engineering Co.)

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) Copyright 2004 The McGraw-Hill Companies. All rights reserved. Any use is subject to the Terms of Use as given at the website.

HYDRAULIC DESIGN FOR ENERGY GENERATION

Hydraulic Design for Energy Generation 8.7

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) Copyright 2004 The McGraw-Hill Companies. All rights reserved. Any use is subject to the Terms of Use as given at the website.

FIGURE 8.4 A typical inclined intake. (Harza Engineering Co.)

HYDRAULIC DESIGN FOR ENERGY GENERATION

8.8

Chapter Eight

Exhibit 8.2 (a)

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) Copyright 2004 The McGraw-Hill Companies. All rights reserved. Any use is subject to the Terms of Use as given at the website.

HYDRAULIC DESIGN FOR ENERGY GENERATION

Hydraulic Design for Energy Generation 8.9

(b) Exhibit 8.2 Karun hydroelectric project, Iran (a) A vew of the dam and control structure (looking donwnstream showing spillway crest, radial gates, power intakes, and diversion tunnel entrace structure. (b) Layout of dam showing spillway, intake and powerhouse.

selective withdrawal of water. The tower includes openings with trashracks and bulkheads at various levels, which permit water to be withdrawn from different depths to control temperature or water quality. Computer modeling of a reservoirs temperature and waterquality structure is generally required to finalize the required opening sites. Descriptions of several reservoir-simulation models can be found in Brater et al. (1996). Figure 8.5 is an example of a multilevel intake tower structure for selective withdrawal.Exhibit 8.3 illustrates the intake structure for a pumped storage project. Trashracks for power intakes are designed for a velocity of about 1 m/s (3.3 ft/s) when the intake is accessible for cleaning. If a trashrack is not accessible for cleaning, the allowable velocity is approximately 0.5 m/s (1.6 ft/s). Trashrack bar spacing is dictated by turbine protection requirements, but clear spacing of 5cm (2 in) is typical. Although head loss through trashracks depends heavily on the amount of clogging, the following can be used for a clean trashrack, (U.S. Bureau of Reclamation, 1987);

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) Copyright 2004 The McGraw-Hill Companies. All rights reserved. Any use is subject to the Terms of Use as given at the website.

HYDRAULIC DESIGN FOR ENERGY GENERATION

8.10

Chapter Eight

FIGURE 8.5 A typical multi-level intake tower structure for selective withdrawal. (Harza Engineering Co.)

2 Vn 2g

hL where Vn

Kt

(8.4)

velocity based on the net area, Kt

trashrack and support structure, and Ag

An An 2 ,A net area of Ag Ag n gross area of trashrack and support structure. 1.45 0.45

An intake gate is generally provided when the power tunnel or penstock is long or when a short penstock does not have a turbine inlet valve. This gate is provided for emergency closure against flow in case of runaway conditions at the turbine. The effective area of the gate is usually about the same as that of the power tunnel or penstock, but it is rectangular in shape, with a height that is the same as the conduits diameter and a width that is 0.8 the conduit diameter. A bulkhead (or stop log) is provided upstream of the intake gate for servicing the gate. The trashrack slot might be used for this function by first pulling the trashrack.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) Copyright 2004 The McGraw-Hill Companies. All rights reserved. Any use is subject to the Terms of Use as given at the website.

HYDRAULIC DESIGN FOR ENERGY GENERATION

Hydraulic Design for Energy Generation 8.11

(a)

(b) Exhibit 8.3 Rocky mountain pumped storage project, Georgia. (a) Intake structure of the upper reservoir. (b) Closed up view of the upper reservoir intake structure. (c) General layout of the project including upper reservoir intake, power tunnel, and power house.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) Copyright 2004 The McGraw-Hill Companies. All rights reserved. Any use is subject to the Terms of Use as given at the website.

HYDRAULIC DESIGN FOR ENERGY GENERATION

8.12

Chapter Eight

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) Copyright 2004 The McGraw-Hill Companies. All rights reserved. Any use is subject to the Terms of Use as given at the website.

Exhibit 8.3 (c)

HYDRAULIC DESIGN FOR ENERGY GENERATION

Hydraulic Design for Energy Generation 8.13

A hydraulic study is generally conducted for emergency closure of the intake gate. The maximum turbine flow or runaway flow should be considered. The runaway flow may be 50 percent higher than the normal turbine flow for a propeller turbine. In the hydraulic study, the water levels and pressures, as well as flow into and from the gate well, as a function of gate position are investigated (Fig. 8.6). With this information, critical gate loads can be determined for the gate and hoist. The gate also may be used for penstock filling. A minimum gate opening of 10 to 15 cm (4-6 in) is usually specified for this, but a special hydraulic study must be made to determine potential gate load and vibration if the gate opens continuously by accident. In such cases, a generous gate well or air vent must be provided downstream of the gate to provide relief once the tunnel or penstock fills. The head loss for a bulkhead or gate slot, including top opening, is generally about 0.1 of the local velocity head at the slot. The transition length (m or ft) Lt from gate section to tunnel or penstock should be approximately:

FIGURE 8.6 A typical intake gate arrangement. (Harza Engineering Co.)

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) Copyright 2004 The McGraw-Hill Companies. All rights reserved. Any use is subject to the Terms of Use as given at the website.

HYDRAULIC DESIGN FOR ENERGY GENERATION

8.14

Chapter Eight

Lt

VD C

(8.5)

where V tunnel/penstock velocity (m/s or ft/s), D tunnel/penstock diameter (m or ft), and C 3.00 for units in metric systems or 9.84 for units in English systems. The variation of velocity in the transition section should be as close to linear as practicable. Overall head loss for an intake includes trashrack, bellmouth (0.1 V2/2g), gate slots, and transition. The potential vortex formation for an intake should be checked using Fig. 8.7. Note that when the intake Froude number (V/ gD ) exceeds 0.5, submergence requirements increase dramatically, and the vortex formation is difficult to predict. In this case, a physical model study should be carried out.

8.4 TUNNELS

When the powerhouse is situated a considerable distance from the intake and when geologic conditions permit, a tunnel is often used to convey the flow for power generation. The size of the tunnel is dictated by economics: that is, construction cost is added to the cost of head loss (loss of generating revenue) to obtain the minimum combined cost. This determination is usually obtained by trial and error because the process does not lend itself

FIGURE 8.7 Intake submergence and vortex formation. (Gulliver and Arndt, 1991)

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) Copyright 2004 The McGraw-Hill Companies. All rights reserved. Any use is subject to the Terms of Use as given at the website.

HYDRAULIC DESIGN FOR ENERGY GENERATION

Hydraulic Design for Energy Generation 8.15

to a simple formula. The resulting tunnel velocity with the economic diameter is usually in the range of 3 to 5 m/s (10 to 17 ft/s). The shape of the excavated tunnel normally will approximate a square bottom and a circular top. The diameter of the circular top (or the width of the square bottom) should be larger than the required diameter. If the tunnel is lined with concrete, its cross section is likely to be circular or have a square or trapezoidal bottom. If it is unlined or lined with shotcrete, the excavated shape will remain, with some smoothing by filling the larger overbreak sections. Lining is an economic consideration, balancing the cost of the lining with the power loss caused by friction. Even an unlined tunnel will have lined sections, such as portals, and sections where rock needs extra support for geologic stability. Friction factors for design are as follows: Mannings n Lining Unlined Shotcrete Formed concrete Minimum Maximum 0.030 0.025 0.012 0.035 0.030 0.016

Minimum friction corresponds to new conditions and is used for turbine-rating and pressure-rise calculations. Maximum friction corresponds to aging and is used for economic-diameter and pressure-drop calculations. Tunnel slope is dictated by construction suitability and geology, with a minimum of 1:1000 for drainage during dewatered condi-

(a)

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) Copyright 2004 The McGraw-Hill Companies. All rights reserved. Any use is subject to the Terms of Use as given at the website.

HYDRAULIC DESIGN FOR ENERGY GENERATION

8.16

Chapter Eight

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) Copyright 2004 The McGraw-Hill Companies. All rights reserved. Any use is subject to the Terms of Use as given at the website.

Exhibit 8.4 Bath County pumped storage project, Virginia. (a) Surge tank openings during construction (44-ft inside diamenter and 300-ft deep) (b) Layout of the project including upper reservor intake, control structure, surge tanks, power tunnel and powerhouse

HYDRAULIC DESIGN FOR ENERGY GENERATION

Hydraulic Design for Energy Generation 8.17

tions. Tunnel bends generally have large radii for convenience of construction. Vertical bends at shafts usually have a minimum radius of 3D to minimize head loss and to provide constructibility.

8.5 SURGE TANKS

Surge tanks generally are used near the downstream end of tunnels or penstocks to reduce changes in pressure caused by hydraulic transients (waterhammer) resulting from load changes on the turbines (ASCE, 1989; Chaudhry, 1987; Gulliver and Arndt, 1991; Moffat et al., 1990; Parmakian, 1955; Rich, 1951; Wylie and Streeter, 1993; Zipparro and Hasen, 1993). A surge tank should be provided if the maximum rise in speed caused by maximum load rejection cannot be reduced to less than 60 percent of the rated speed by other practical methods, such as increasing the generators inertia or the penstocks diameter or by decreasing the effective closing time of the wicket gates. In general, the provision of a surge tank should be investigated if

0 0

LiVi Hn

3 to 5 for units in m/s and m or 10 to 20 for units in ft/s and ft, (8.6)

where Li is the length of a penstock segment and Vi is the velocity for the segment (Dingman, 1984). The term LiVi is computed from the intake to the turbine and Hn is the minimum net head. Surge tanks normally are located as close as possible to the powerhouse for maximum effectiveness and may be free-standing or excavated in rock. The tanks are usually vented to atmosphere or can be pressurized as air chambers. The latter is not used frequently because of requirements of size, air compressors, and air tightness. Exhibit 8.4 illustrates a pumped storage project with a surge tank. Figure 8.8 shows typical installations of surge tanks for controlling hydraulic transients. Surge tanks usually are simple cylindrical vertical shafts or towers, but other geometric designs are used when the surge amplitude is to be limited. For instance, an enlarged chamber can be used at the top if upsurge might cause the water level to rise above the ground surface. Similarly, an enlargement or lateral tunnel or chamber is sometimes used near the bottom of the shaft if downsurge would caused the water level to drop below the tunnel crown. When the geometry is a cylinder, analysis is relatively simple and can be performed using design charts. If the geometry is more complicated, a hydraulic transient simulation model is required to carry out the study (Chaudhry, 1987; Wylie and Streeter, 1993; Brater et al., 1996). Hydraulic stability for a surge tank assures that surging is limited and brief after load changes (Rich, 1951; Parmakian, 1955; U.S. Bureau of Reclamation 1980; Zipparro and Hasen, 1993). The minimum cross-sectional area of a simple cylindrical surge tank required for stability can be determined using the Thoma formula: AST AL 2gcH (8.7)

where AST minimum tank area, A tunnel area between reservoir and surge tank, L tunnel length between reservoir and surge tank, g gravitational acceleration, c

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) Copyright 2004 The McGraw-Hill Companies. All rights reserved. Any use is subject to the Terms of Use as given at the website.

HYDRAULIC DESIGN FOR ENERGY GENERATION

8.18

Chapter Eight

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) Copyright 2004 The McGraw-Hill Companies. All rights reserved. Any use is subject to the Terms of Use as given at the website.

FIGURE 8.8A Typical vented surge tank installation. Bath County powerplant (1985): 2100 MW pumped storage development on Back Creek, Virginia. Moose River powerplant (1987): 12 MW development on Moose River, New York. (Harza Engineering Co.)

HYDRAULIC DESIGN FOR ENERGY GENERATION

Hydraulic Design for Energy Generation 8.19

FIGURE 8.8B Typical pressurized surge tank installation. Moose River powerplant (1987): 12 MW development on Moose River, New York. (Harza Engineering Co.)

head loss coefficient

H 1 H H minimum head loss from reservoir to V2 2g V2 / 2g 2/2g, and H = minimum net operating head on surge tank, including tunnel velocity head V turbine. For a simple surge tank (without an orifice), increase the diameter obtained from the Thoma formula by 50 percent. For a typical surge tank with a restricted orifice, increase the diameter by 25 percent. These increases are necessary to provide damping of the oscillation in a reasonable period of time. Maximum upsurge in a cylindrical surge tank can be determined from Fig. 8.9. For a given tank size, the optimum size of the orifice is based on the balanced head design so that the maximum tunnel pressure below the surge tank equals the maximum upsurge level. Maximum downsurge in a cylindrical surge tank can be determined from Fig. 8.10. Here again, the size of the orifice should be based on balanced head design as a first attempt. However, since downsurge may differ from upsurge, and the required orifice size may be different for the two purposes, shaping the orifice (i.e., changing the discharge coefficient) by rounding the top or bottom may satisfy the two area requirements approximately. For maximum upsurge, use the maximum normal headwater, minimum head loss between reservoir and surge tank, and maximum plant flow. Assume full plant load-rejection (tripout) in the shortest reasonable time. For maximum downsurge, use the minimum normal headwater, maximum head loss, and accept load from 50 percent to 100 percent in the shortest reasonable time. At some projects, such as pumped-storage plants, the load acceptance is criterion is more extreme; full load acceptance, is 0 percent to 100 percent in the shortest reasonable time. The controlling criterion will be used to design the orifice on downsurge. When the surge tank geometry is complex (noncylindrical), a computer model should be used to determine the limiting surge levels. (See Brater et al., 1996, for available computer models). Freeboard

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) Copyright 2004 The McGraw-Hill Companies. All rights reserved. Any use is subject to the Terms of Use as given at the website.

HYDRAULIC DESIGN FOR ENERGY GENERATION

8.20

Chapter Eight

FIGURE 8.9 Maximum surge in surge tank due to instantaneous stopping of flow. (Parmakian, 1955)

FIGURE 8.10 Maximum surge in a surge tank resulting from instantaneous starting of flow. (Parmakian, 1955)

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) Copyright 2004 The McGraw-Hill Companies. All rights reserved. Any use is subject to the Terms of Use as given at the website.

HYDRAULIC DESIGN FOR ENERGY GENERATION

Hydraulic Design for Energy Generation 8.21

for the surge tank is 10 percent of the computed rise in the water level in the surge tank for upsurge and 15 percent of the drop in the water level for downsurge to maintain. submergence of the tank invert or the orifice to avoid admitting air into the penstock. Pressurized air chambers are often used in pumping plants for surge protection. They are used occasionally for power plants when the generating flow is not excessive. The hydraulic characteristics of the chambers are complicated by the compressibility effects of air and temperature, and the analysis does not lend itself to simple formulas and charts. A computer model is required to verify performance. Fig. 8.8(B) shows a typical air chamber design for a hydropower plant.

8.6 PENSTOCK

A penstock generally refers to a steel conduit or steel-lined tunnel connecting a reservoir or surge tank to a powerhouse (ASCE, 1989, 1993; U.S. Bureau of Reclamation, 1967; Chaudhry, 1987; Gulliver, and Arndt, 1991; Warnick et al., 1984; Wylie and Streeter, 1993; Zipparro and Hasen, 1993). It is used when the internal pressure is high enough to make a concrete-lined tunnel or unlined rock tunnel uneconomical, particularly where cover is low. Penstock size is usually governed by project economics. The economical diameter is determined by the minimum combined cost of construction and energy reduction caused by head loss in the penstock. The energy loss decreases as the diameter of the penstock increases while construction cost increase. As with tunnels, the most economical diameter can be determined more accurately by a trial-and-error procedure. The following variables are generally considered (U.S. Bureau Reclamation, 1967; Gulliver and Arndt, 1991): 1. Cost of pipe 2. Value of energy loss 3. Plant efficiency 4. Minor loss factor 5. Average head 6. Waterhammer effect For the assessment of a preliminary design or a feasibility level, the most economical diameter can be estimated using the following formula (Moffat et al., 1990). De CP0.43 H0.60 (8.8) 7. Surface roughness (friction factor) 8. Weight of steel penstock 9. Design discharge 10.Allowable hoop stress

where De the most economical penstock diameter (m or ft), H = the rated head (m or ft), P = the rated capacity of the plant (kW or hp), and C = 0.52 (for metric units) or 3.07 (for English units). If the project is a small hydropower installation, the following simple equation can be used (Warnick et al., 1984). De CQ0.5 (8.9)

where De = the most economical penstock diameter (m or ft), Q = the design discharge (m3/s or ft3/sec), and C = 0.72 (for metric units) or 0.40 (for English units).

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) Copyright 2004 The McGraw-Hill Companies. All rights reserved. Any use is subject to the Terms of Use as given at the website.

HYDRAULIC DESIGN FOR ENERGY GENERATION

8.22

Chapter Eight

For large hydroelectric projects with heads varying from approximately 60 m (190 ft) to 315 m (1,025 ft) and power capacities ranging from 154 MW to 730 MW, the following equation can be used (Warnick et al., 1984). De Cp0.43 h0.63 (8.10)

where De the most economical penstock diameter (m or ft), p the rated turbine capacity (kW or hp), h the rated net head (m or ft), and C 0.72 ( for metric units) or 4.44 (for English units). The maximum velocity in the penstock is normally kept lower than 10 m/s (33 ft/s). To determine the minimum thickness of the penstock, based on the need for stiffness, corrosion protection, and handling requirements, the following formula can be used (U.S. Bureau of Reclamation, 1967; Warnick et al., 1984). tmin D K 400 (8.11)

where tmin the minimum thickness of the penstock (mm or in), D = penstock diameter (mm or in), and K = 500 (for metric units) or 20 (for English units). After determining the economic diameter, check for the operating stability of the generating unit-penstock combination using the following steps (Chaudhry, 1987; U.S. Bureau of Reclamation, 1980; Warnick et al., 1984). 1. Determine the mechanical starting time in seconds for the unit Tm as Tm or Tm (WR2)N2 1.6 106 P1 (8.13) (GD2) N2 36 104 P (8.4)

where GD2 flywheel effect of the turbine and generator rotating parts used in metric system (kg-m2), WR2 flywheel effect of the turbine and generator rotating parts in English system (lb-ft2) 5.932 GD2, G weight of rotating parts (kg), D 2 radius of gyration of the rotating parts (m), W weight of rotating parts (lb), R radius of gyration of the rotating parts (ft), N turbine speed (rpm), P maximum turbine output (kW), and P1 maximum turbine output (hp). Tm is the time for torque to accelerate the rotating mass from zero to rotational speed. Together, the turbine runner in water, connecting shafts, and the generator develop the flywheel effect WR2 or GD2. The WR2 can be determined using on the following formulas: WR 2 turbine and WR2 normal 356,000

generator

23,800

Pd N3/2

5/4

(8.14)

KVA N3/2

5/4

(8.15)

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) Copyright 2004 The McGraw-Hill Companies. All rights reserved. Any use is subject to the Terms of Use as given at the website.

HYDRAULIC DESIGN FOR ENERGY GENERATION

Hydraulic Design for Energy Generation 8.23

where Pd amperes).

turbine rated output (hp) and kVA

generator rated output (kilovolt-

2. Determine the water column starting time for the penstock TW as follows: Tw (LV) gH (8.16)

where (LV) summation of product of length (measured from nearest open water surface) and velocity for each segment of penstock from intake or surge tank to tailrace (m2/s or ft2/sec), g gravitational acceleration (m/s2 or ft/sec2), and H minimum net operating head (m or ft). 3. In general, Tm/Tw2 should be maintained greater than 2 for good operating stability and to have reasonably good responses to load changes. If Tm/Tw2 is less than 2, there are three possible solutions: Increase WR2 or GD2 for the generator; this is relatively inexpensive for increases of up to 50. Increase the penstock diameter; this is probably not economical, except for a narrow range. Add a surge tank or move the surge tank closer to the powerhouse. A combination of these three possible solutions may be the most cost-effective solution. The following friction factors are recommended for designing steel penstocks:

Exhibit 8.5 A typical steel penstock branch structure being fabricated

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) Copyright 2004 The McGraw-Hill Companies. All rights reserved. Any use is subject to the Terms of Use as given at the website.

HYDRAULIC DESIGN FOR ENERGY GENERATION

8.24

Chapter Eight

Penstock Age New Old

Mannings n 0.012 0.016

Use the value for new penstock to calculating turbine-rating and pressure-rise. To calculate pressure drop use the higher values. Design pressure is determined on the basis of the turbines characteristics and the closure rates of the wicket gates or needle valves. For Pelton turbines, closure rates are slow, and design pressure rise is usually of the order of 20 percent of the static pressure head. For Francis turbines, design pressure rise is usually 30 to 40 percent of the static pressure head, depending on the cost of steel lining required. A fast closure is desirable to minimize speed rise and the potential for runaway conditions in the turbine. Detailed pressure conditions are determined by a computer model that includes the water conductors and surge tank as well as the turbine discharge-speed characteristics and generator inertia. Many computer programs capable of simulating hydraulic transients are described in Wylie and Streeter, 1993. Such computer simulation studies are often required of turbine or governor manufacturers now as a part of the specifications. Ultimately, the predicted pressure conditions are verified in the load rejection tests during unit start-up. The profile for a free-standing penstock is based on the topographic and geologic conditions of the ground. In other cases, the penstock may consist of shaft and tunnel sections that are largely lined with concrete, with a relatively short section of steel-lined penstock near the powerhouse. If the penstock is free-standing, the risk of penstock rupture is greater than it is for the shaft and tunnel system. If there is a long tunnel section upstream of the free-standing penstock, an emergency closure valve is often added near the tunnel outlet. A hydraulic transient study is necessary to determine closure conditions (by accident or because of penstock rupture). A vent must be provided to admit air just downstream of the valve for penstock rupture and must be large enough to prevent collapse of the penstock from internal subatmospheric pressure caused by water-column separation. A free-standing penstock also requires small air inlet-outlet valves at local high points to remove air during filling and admit air during dewatering.

8.6.1 Penstock Branches A penstock often delivers water to more than one turbine. In such cases, the penstock is branched in various ways to subdivide the flow.Exhibit 8.5 illustrates a typical steel penstock branch structure. When the powerhouse is normal to the penstock, several configurations are possible (Fig. 8.11). If the powerhouse is at an angle with the penstock, a manifold is used (Fig. 8.12). Head losses in branches and manifolds depend on precise geometry and often are developed by model studies. However, for a typical well-designed layout, the following head loss coefficients can be used to estimate the head loss hb from the main into a branch: hb Kb V2 2g (8.17)

where V = branch velocity (m/s or ft/s); g = gravitational acceleration (m/s2 or ft/sec2); and Kb = head loss coefficient 0.2 for symmetrical bifurcation, 0.3 for symmetrical trifurcation, and 0.2 for manifold branch.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) Copyright 2004 The McGraw-Hill Companies. All rights reserved. Any use is subject to the Terms of Use as given at the website.

HYDRAULIC DESIGN FOR ENERGY GENERATION

Hydraulic Design for Energy Generation 8.25

FIGURE 8.11A Example penstock branch configurations for powerhouse normal to the penstock.

The diameters of branched penstocks are usually determined so that the velocity is increased significantly relative to the main penstock. Here again, the branch size is determined by economics so that construction and material costs added to cost of energy loss are at a minimum. The lower limit for the size of the branch is the size of the turbine inlet that is normally provided by the turbine manufacturer. If a turbine inlet valve is provided, its diameter will either be equal to the inlet diameter or be between the inlet diameter and the penstock branch diameter. This valve is usually a spherical type, and, as such, no head loss occurs in the fully open position. Friction losses in the branch penstocks are calculated using the same friction factors used for the main penstock and the conduit lengths up to the net head taps in the turbine inlet.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) Copyright 2004 The McGraw-Hill Companies. All rights reserved. Any use is subject to the Terms of Use as given at the website.

HYDRAULIC DESIGN FOR ENERGY GENERATION

8.26

Chapter Eight

FIGURE 8.11B Configurations for single bifurcated, double y-branching, and trifurcated penstocks. (Harza Engineering Co.).

8.7 DRAFT-TUBE EXITS

Draft-tubes are designed by considering the turbines characteristics. The net head for the turbine is based on pressure taps at the spiral-case inlet and near the draft-tube exit. Therefore, any head losses which occur after the draft-tube pressure tap are subtracted from the turbine net head. Because the exit head loss is generally considered to be the average velocity head at the end of the draft-tube, a longer draft-tube with expansion to a larger area would, in theory, reduce this loss. In actuality, however the flow is not uniform

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) Copyright 2004 The McGraw-Hill Companies. All rights reserved. Any use is subject to the Terms of Use as given at the website.

HYDRAULIC DESIGN FOR ENERGY GENERATION

Hydraulic Design for Energy Generation 8.27

FIGURE 8.12A Examples penstock manifold configurations for a powerhouse oriented at an angle with the penstock.

FIGURE 8.12B Penstock manifold for an installation with six units. (Harza Engineering Co.)

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) Copyright 2004 The McGraw-Hill Companies. All rights reserved. Any use is subject to the Terms of Use as given at the website.

HYDRAULIC DESIGN FOR ENERGY GENERATION

8.28

Chapter Eight

at this point; it is highly turbulent and swirling, and the true exit loss is difficult to define. Current thinking is that further extension of the draft-tube is not economical. The rule of thumb is to end the draft-tube when the mean velocity is about 2m/s and to base the exit head loss on this velocity. A trashrack is usually provided at the end of the draft-tube at a pumped-storage project to prevent entry of coarse debris during the pumping mode. However, during the generating mode with the trashrack in place, the trashrack is subject to vibration caused by the concentration of flow and by swirling. This complicates the design of the trashrack and increases its cost. The analysis of the rack is a combined hydraulic and structural one. The hydraulic loadings consist of drag forces on rack bars that are dependent on velocity patterns along with pulsation of pressure caused by swirling flow. The data on hydraulic conditions can be obtained from a physical model (usually the model from the pump-turbine manufacturer) because fully developed mathematical models are not readily available to predict these forces. A structural mathematical model is then applied using the hydraulic loadings obtained from the hydraulic model tests. By trial and error, the trashrack is designed to withstand the flow-induced vibrations.

8.8 TAIL-TUNNELS

An underground power plant will have a tail-tunnel to deliver the flow to the downstream river or lake. For a pumped-storage project, this tunnel provides flow both ways, because it acts as the inlet tunnel during pumping. For a conventional hydroelectric plant with generating only, the tunnel is usually pressurized.. However, if the turbines are the Pelton type, the tunnel is likely to be free flow to maintain freeboard on the turbine. For a pumped-storage plant, the tunnel is most likely to be pressurized, because it must deliver water both ways. If the tunnel is pressurized and is long enough, a surge chamber will be required to prevent large fluctuations of pressure on the turbines during load changes. The number of tail-tunnels, usually one or two, is based on economics and constructability. From an operational standpoint, two tunnels are desirable to allow partial operation of the plant even during maintenance or inspection of one of the tunnels. However, two tunnels are usually more expensive than one, and usually only one will be used unless its size becomes unmanageable. The limiting size is dictated by available equipment and tunneling methods. These factors must be evaluated carefully when estimating the costs of one tunnel versus two tunnels. A manifold is used to collect the flow from the individual draft-tubes and guide the flow through a transition section to the tail-tunnel proper. This manifold is similar in concept to the penstock manifold, but generally the velocities are much lower. The velocity at the end of the draft-tube is typically 2 m/s (7 ft/s) and 3 m/s (10 ft/s) at the tail-tunnel. Therefore, head losses are not significant and the flow conditions are generally acceptable. A typical tail-tunnel manifold design is shown on Fig. 8.13.

8.8.1 Tail-Tunnel Surge Tanks When an underground power plant has a significant length of pressurized tail-tunnel, a surge tank is likely to be required. The procedures for sizing and determining extreme surges are similar to the procedures used for surges in the head-tunnel, using the hydraulic characteristics of the tail-tunnel instead of the head-tunnel. (Refer to Sec. 8.5). Figure 8.14 shows a typical tail-tunnel surge chamber.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) Copyright 2004 The McGraw-Hill Companies. All rights reserved. Any use is subject to the Terms of Use as given at the website.

HYDRAULIC DESIGN FOR ENERGY GENERATION

Hydraulic Design for Energy Generation 8.29

FIGURE 8.13 A typical tail-tunnel manifold arrangement. (Harza Engineering Co.)

8.8.2 Tail-Tunnel Outlet Structures The tail-tunnel outlet structure is typically a bulkhead structure, which might incorporate some flow spreading for energy recovery. The spreading of the flow is an economic decision based on construction costs and the value of energy loss. Figure 8.15 shows a typical structure of a tail-tunnel outlet. If the project is the pumped-storage type, the outlet structure will incorporate trashracks at the face of the structure, and the velocity at the trashracks will be approximately 1.0 m/s (3.3 ft/s), because the racks tend to be self-cleaning during the generating mode.

8.9 TAILRACE CHANNELS

If the outlet structure is a significant distance from the receiving waterway, a tailrace channel will be required (Fig. 8.16). The sizing of the channel will be similar to that of the headrace channel. (Refer to Sec. 82).

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) Copyright 2004 The McGraw-Hill Companies. All rights reserved. Any use is subject to the Terms of Use as given at the website.

HYDRAULIC DESIGN FOR ENERGY GENERATION

8.30

Chapter Eight

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) Copyright 2004 The McGraw-Hill Companies. All rights reserved. Any use is subject to the Terms of Use as given at the website.

FIGURE 8.14 A typical tail-tunnel surge chamber. (Harza Engineering Co.)

HYDRAULIC DESIGN FOR ENERGY GENERATION

Hydraulic Design for Energy Generation 8.31

FIGURE 8.15 A typical tail-tunnel outlet structure. (Harza Engineering Co.)

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) Copyright 2004 The McGraw-Hill Companies. All rights reserved. Any use is subject to the Terms of Use as given at the website.

HYDRAULIC DESIGN FOR ENERGY GENERATION

8.32

Chapter Eight

FIGURE 8.16 Tailrace channels of the Guri Project. (EDELCA, Venezuela)

REFERENCES

American Society of Civil Engineer (ASCE), Civil Engineering Guidelines for Planning and Designing Hydroelectric Developments: Vol. 2 Waterways, American Society of Civil Engineers, New York, 1989. American Society of Civil Engineer (ASCE), Steel Penstock, ASCE Manuals and Reports on Engineering Practice No. 79, American Society of Civil Engineers, New York, 1993. Brater, E. F., King, H. W., J. E. Lindell, and C. Y. Wei, Handbook of Hydraulics, 7th ed., McGraw-Hill, New York, 1996. Chaudhry, M. H., Applied Hydraulic Transients, 2nd ed., Van Nostrand Reinhold, New York, 1987. Chow, V. T., Open-Channel Hydraulics, McGraw-Hill, New York, 1959. Dingman, S. L., Fluvial Hydrology, W. H. Freeman, New York, 1984. Gulliver, J. S., and R. E. A. Arndt, Hydropower Engineering Handbook, McGraw-Hill, New York, 1991. Henderson, F. M., Open Channel Flow, Macmillan, New York, 1966. Moffat, A. I. B., C. Nalluri, and R. Narayanan, Hydraulic Structures, Unwin Hyman, London, UK, 1990. Parmakian, J., Waterhammer Analysis, Dover Publications, New York, 1955. Rich, G. R., Hydraulic Transients, Dover Publications, New York, 1951. U. S. Army Corps of Engineer (USACE), Hydraulic Design Criteria, U.S. Army Corps of Engineers, Waterways Experiment Station, Vicksburg, MS, 1988. U.S. Bureau of Reclamation, Selecting Hydraulic Reaction Turbines, Engineering Monograph No.20, Department of the Interior, 1980.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) Copyright 2004 The McGraw-Hill Companies. All rights reserved. Any use is subject to the Terms of Use as given at the website.

HYDRAULIC DESIGN FOR ENERGY GENERATION

Hydraulic Design for Energy Generation 8.33 U. S. Bureau of Reclamation, Design of Small Dams, U.S. Department of the Interior, Denver, Co, 1987. U. S. Bureau of Reclamation Welded Steel Penstocks, Engineering Monograph No.3, U.S. Department of the Interior, Denver, Co, 1967. Vanoni, V. A., ed., Sedimentation Engineering, American Society of Civil Engineers, New York 1977. Warnick, C. C., H. A. Mayo Jr., J. L. Carson, and L. H. Sheldon, Hydropower Engineering, Prentice-Hall, NJ, 1984. Wylie, E. B., and V. L. Streeter, Fluid Transients in Systems, Prentice-Hall, Englewood Cliffs, NJ, 1993. Zipparro, V. J., and H. Hasen, Davis' Handbook of Applied Hydraulics, 4th ed., McGraw-Hill, New York, 1993.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) Copyright 2004 The McGraw-Hill Companies. All rights reserved. Any use is subject to the Terms of Use as given at the website.

You might also like

- Pipeline Design for Water EngineersFrom EverandPipeline Design for Water EngineersRating: 5 out of 5 stars5/5 (1)

- Is 4622 2003Document27 pagesIs 4622 2003Apurba Haldar100% (1)

- Civil Works Guidelines For Micro Hydropower in NepalDocument185 pagesCivil Works Guidelines For Micro Hydropower in Nepaljayusman100% (3)

- Diversion Head WorkDocument71 pagesDiversion Head WorkHarish Dutt100% (6)

- Penstock Presentation - PpsDocument42 pagesPenstock Presentation - PpsGourav KhudasiaNo ratings yet

- Bridge Design BasicsDocument16 pagesBridge Design BasicsTanvir Shahrier MahmudNo ratings yet

- Branch CalcDocument111 pagesBranch CalcAnonymous 6S9tcbh100% (2)

- Analysis of Hydraulic Pressure Transients in The Waterways of Hydropower StationsDocument77 pagesAnalysis of Hydraulic Pressure Transients in The Waterways of Hydropower Stationskamran1340No ratings yet

- Hydraulics and Design of TrashrackDocument25 pagesHydraulics and Design of TrashracksapkotamonishNo ratings yet

- New Trends Design in Francis Turbines Type With Vertical ShaftDocument23 pagesNew Trends Design in Francis Turbines Type With Vertical Shaftmarcelo.sNo ratings yet

- Optimum Design of Penstock For Hydro Projects PDFDocument12 pagesOptimum Design of Penstock For Hydro Projects PDFTharindu Nuwan JayakodyNo ratings yet

- Waterman Tilting Weir GatesDocument3 pagesWaterman Tilting Weir Gatessandaldm100% (1)

- Economics of Haul Road ConstructionDocument8 pagesEconomics of Haul Road Constructionhendri sulistiawan100% (1)

- Surge Shaft - Design ConceptDocument65 pagesSurge Shaft - Design Conceptpankaj100% (2)

- Hydraulic Turbine and Associated EquipmentDocument47 pagesHydraulic Turbine and Associated Equipmentpavankumar0010% (1)

- Report DSO-11-06 - Seismic Induced Loads On Spillway Gates - Literature ReviewDocument40 pagesReport DSO-11-06 - Seismic Induced Loads On Spillway Gates - Literature Reviewchutton681No ratings yet

- Spillway Gate RelibilityDocument5 pagesSpillway Gate RelibilityDheeraj ThakurNo ratings yet

- Design Criteria For Exposed Hydro Penstocks - Gordon1978 PDFDocument12 pagesDesign Criteria For Exposed Hydro Penstocks - Gordon1978 PDFDavid DelgadoNo ratings yet

- Gates and HoistsDocument184 pagesGates and HoistsVikas Shrimali86% (7)

- Asce Hydropower Task Committee-Civil Works For Hydroelectric Facilities - Guidelines For Life Extension and Upgrade-American Society of Civil Engineers (2007) PDFDocument490 pagesAsce Hydropower Task Committee-Civil Works For Hydroelectric Facilities - Guidelines For Life Extension and Upgrade-American Society of Civil Engineers (2007) PDFJhonatanAlexanderMogollonUlloaNo ratings yet

- Hydro Turbine Manual 2009.2Document44 pagesHydro Turbine Manual 2009.2Archil Kokhtashvili100% (1)

- Hydraulic Design of Small Hydro PlantsDocument63 pagesHydraulic Design of Small Hydro Plantsmassi99100% (3)

- Bottom OutletsDocument36 pagesBottom OutletsNikom Kraitud100% (3)

- Lewin J., Hydraulic Gates and Valves in Free Surface Flow and Submerged Outlets, 2nd Ed, 2001Document301 pagesLewin J., Hydraulic Gates and Valves in Free Surface Flow and Submerged Outlets, 2nd Ed, 2001sebastian100% (2)

- Asce Epri Guides 1989Document59 pagesAsce Epri Guides 1989david_rosemberg50% (2)

- Design of Hydraulic WorksDocument23 pagesDesign of Hydraulic WorksHowell Danner Peña Chaquila100% (1)

- Selection of Pump Turbine For Pump Storage Power PlantDocument7 pagesSelection of Pump Turbine For Pump Storage Power PlantSunil MaharjanNo ratings yet

- GBT 8564-2003 Specification For Installation of Hydraulic Turbine Generator UnitsDocument104 pagesGBT 8564-2003 Specification For Installation of Hydraulic Turbine Generator Unitsearizabal100% (3)

- Kap 07 - Design of Hydraulic Steel Structure Equipment2009-0Document20 pagesKap 07 - Design of Hydraulic Steel Structure Equipment2009-0Lasandu Wanniarachchi100% (1)

- 3 Bottom OutletsDocument36 pages3 Bottom OutletsCarlosNo ratings yet

- AHEC Hydaulic Design of Small Hydro 2011Document116 pagesAHEC Hydaulic Design of Small Hydro 2011dunlcaaNo ratings yet

- EM41 - Air Water FlowDocument160 pagesEM41 - Air Water FlowIoannis SanoudosNo ratings yet

- Kochi Metro-DPR Part 1Document110 pagesKochi Metro-DPR Part 1Achuth GangadharanNo ratings yet

- Sickle PlateDocument24 pagesSickle PlateanjnaNo ratings yet

- Hydropower Intake Design and CriteriaDocument6 pagesHydropower Intake Design and CriteriaManikandanNo ratings yet

- 3D Hydro Mechanical (Gates)Document52 pages3D Hydro Mechanical (Gates)api-19871259100% (2)

- Trends: Present in Surge Tank DesignDocument34 pagesTrends: Present in Surge Tank DesignashishroshanNo ratings yet

- Design of Tail Race System of Rampur HEPDocument9 pagesDesign of Tail Race System of Rampur HEPengineerramanNo ratings yet

- Hydraulic Design of Hollow Jet Valve-PAP-0152Document19 pagesHydraulic Design of Hollow Jet Valve-PAP-0152laherrans100% (1)

- Variable Speed OperationDocument10 pagesVariable Speed Operationmunagala balasubramanyamNo ratings yet

- 2.2 GL For Hydraulic Design of SHP PDFDocument117 pages2.2 GL For Hydraulic Design of SHP PDFChristian HerreraNo ratings yet

- 2 - 1 - Civil Works - Guidelines For Layout of Small Hydro PlantsDocument24 pages2 - 1 - Civil Works - Guidelines For Layout of Small Hydro PlantsjmiguelmenaNo ratings yet

- Guide On How To Develop A Small Hydropower Plant (ESHA 2004)Document296 pagesGuide On How To Develop A Small Hydropower Plant (ESHA 2004)Mile Gorgievski0% (1)

- Penstocks DesignDocument36 pagesPenstocks DesignTaher Mohiuddin100% (1)

- GD2Document14 pagesGD2youknows50% (2)

- Spherical Valve Foundation ForceDocument1 pageSpherical Valve Foundation ForceRakesh SapkotaNo ratings yet

- Tyrolean IntakeDocument9 pagesTyrolean Intakezulkifli1220No ratings yet

- Bifurcation Design PDFDocument51 pagesBifurcation Design PDFMadhav BaralNo ratings yet

- Highspeed Railway PDFDocument213 pagesHighspeed Railway PDFRajNo ratings yet

- Design of PenstockDocument25 pagesDesign of PenstockSalman Shuja100% (1)

- HYDG20749Document108 pagesHYDG20749NARENDER KUMARNo ratings yet

- HydromechanicalDocument31 pagesHydromechanicalJennifer HudsonNo ratings yet

- Draft Tube Theory PDFDocument3 pagesDraft Tube Theory PDFDeva Raj100% (2)

- Trashrack DesignDocument4 pagesTrashrack DesignpicottNo ratings yet

- 9 Design of Permanent, Final Linings: EM 1110-2-2901 30 May 97Document32 pages9 Design of Permanent, Final Linings: EM 1110-2-2901 30 May 97Prem Singh RawatNo ratings yet

- Rubberdamnew 140214103433 Phpapp02Document24 pagesRubberdamnew 140214103433 Phpapp02Mukhlish AkhatarNo ratings yet

- Air Cushion Surge ChambersDocument2 pagesAir Cushion Surge ChambersAli AlengineerNo ratings yet

- Sedicon Sluicers As Effective MethodDocument9 pagesSedicon Sluicers As Effective Methodप्रवीण देशारNo ratings yet

- Disclosure To Promote The Right To InformationDocument22 pagesDisclosure To Promote The Right To InformationDodik IstiantoNo ratings yet

- INDIAN - Hydaulic - Design - of - SHP - ProjectDocument116 pagesINDIAN - Hydaulic - Design - of - SHP - ProjectYasir IqbalNo ratings yet

- Cross Drainage: Topic 821 - GeneralDocument13 pagesCross Drainage: Topic 821 - GeneralBlessed ZiyambeNo ratings yet

- Spillway DesignDocument54 pagesSpillway DesignAstritTahiriNo ratings yet

- Literature Review and Objectives of StudyDocument34 pagesLiterature Review and Objectives of Studyyaseen90azizNo ratings yet

- 2019 Summer Model Answer Paper (Msbte Study Resources)Document13 pages2019 Summer Model Answer Paper (Msbte Study Resources)ShantanuNo ratings yet

- Geometric Design PDFDocument107 pagesGeometric Design PDFvedant chavanNo ratings yet

- In2Smart: Requirements and KPIS D10.1Document50 pagesIn2Smart: Requirements and KPIS D10.1Miguel Ivan Acosta MondragonNo ratings yet

- Problem Set (GD)Document4 pagesProblem Set (GD)yadoleNo ratings yet

- Superelevation Calculation (New Standard) PDFDocument16 pagesSuperelevation Calculation (New Standard) PDFsahriNo ratings yet

- Curve Details Stn-Jaj New Calculation SR - Den IIDocument79 pagesCurve Details Stn-Jaj New Calculation SR - Den IIAMRISH MOHANNo ratings yet

- 02 Horizontal AlignmentDocument22 pages02 Horizontal AlignmentNurul QurratuNo ratings yet

- Saqib Imran 0341-7549889Document24 pagesSaqib Imran 0341-7549889Saqib imranNo ratings yet

- Chapter 2 - GEOMETRIC DESIGN OF HIGHWAYSDocument52 pagesChapter 2 - GEOMETRIC DESIGN OF HIGHWAYSAfricana RoyalNo ratings yet

- Ometric Design of Highways-1Document72 pagesOmetric Design of Highways-1Rajas AthalyeNo ratings yet

- NIPR-2618.1 Alignment Design On RFR CorridorsDocument10 pagesNIPR-2618.1 Alignment Design On RFR CorridorsCK TangNo ratings yet

- Track: System RequirementsDocument78 pagesTrack: System RequirementsCezary P.No ratings yet

- Highway Practice QuestionsDocument3 pagesHighway Practice QuestionsFazelah YakubNo ratings yet

- Route TD For All Student Learner's Highway EngineeringDocument25 pagesRoute TD For All Student Learner's Highway Engineeringkrishy19sNo ratings yet

- Railway Engineering Tutorials NiravDocument2 pagesRailway Engineering Tutorials Niravpinakramanuj1110% (1)

- Highway Engineering Section 1Document9 pagesHighway Engineering Section 1Eric NagumNo ratings yet

- Highway EngineeringDocument50 pagesHighway Engineeringarpit_089No ratings yet

- Mi TSDocument37 pagesMi TSwhoammeNo ratings yet

- Railway and Tunnel EngineeringDocument8 pagesRailway and Tunnel EngineeringSAKHI U 20MLCE11No ratings yet

- Highway EngineeringDocument26 pagesHighway EngineeringhariNo ratings yet

- Addendum Report Publication VersionDocument30 pagesAddendum Report Publication VersionRadu BriaNo ratings yet

- AM I - MicroprojectDocument16 pagesAM I - MicroprojectKavita AldarNo ratings yet

- Highway Engineering Feb Mar 2022Document2 pagesHighway Engineering Feb Mar 2022Sobha Ranjith KumarNo ratings yet

- En 13803-1Document6 pagesEn 13803-1a74engNo ratings yet

- Superelevation Complete Final3Document1 pageSuperelevation Complete Final3TarunNo ratings yet