Professional Documents

Culture Documents

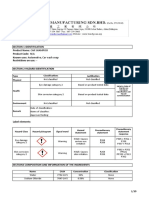

Morton Specialist Seed and Grain

Uploaded by

Jyoti HoodaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Morton Specialist Seed and Grain

Uploaded by

Jyoti HoodaCopyright:

Available Formats

Re-Tooling for Climate Change

Mortons oat hulls replace LPG

Mortons Specialist Seed & Grain has found a way of turning production waste into energy, using funding from the Re-Tooling for Climate Change Program. The Western Australian company received $115,000 in funding to replace its LPG-fuelled boiler with one powered by waste oat hulls. The hulls are a by-product of the companys production of instant, quick and rolled oats cereal products. Mortons processes some 60,000 tonnes of oat grain each year. Oat kernels or groats are first separated from the hulls, then kiln dried or converted into rolled oat flakes. The process results in 20,000 tonnes of waste hulls, which offer limited value to the business as a saleable by-product, but vast potential as a renewable energy source. Independent research commissioned by Mortons showed that by using just 8 per cent of the biomass waste the company could eliminate the use of imported LPG as a fuel source for the boiler. This will reduce its annual greenhouse gas emissions from the burning of LPG by more than 1000 tonnes of CO2 equivalent. Mortons Managing Director Jonnie Morton says this is just the beginning. We will save around $400,000 a year by removing the need for LPG but my real excitement is in the improved competitiveness and sustainability of the company. There is the potential to use all of our waste biomass to fuel a larger electricity co-generation system, once the performance of this project has been evaluated. This will make us more competitive on the international stage, and its positive from so many angles reducing costs of our products, new growth and more employment and a better environmental footprint, he said. Mortons employs 65 people and export makes up 90 per cent of its business. jonnie@mortongrain.com.au 08 9434 2024

Top, oat hulls which are used as fuel for Mortons boiler. Below, the factory has reduced its greenhouse gas emissions.

Astor shining out in its field

Astor Metal Finishes is using $109,650 in Retooling for Climate Change funding to deliver electricity savings of more than 50 per cent at its NSW-based electroplating plant. The companys Managing Director, Richard Hammond, said the project involved installing solar collection tubes on the roof of the main plating shop to heat electroplating process tanks. A gas-fired hot water generator will supplement solar power heating. This will remove the need for mains grid electrical power for heating the tanks, Richard said. The project will also conserve power by using insulated pipelines to deliver heated water to either heat exchangers or in-tank coils. The previous process resulted in lost energy, due to water evaporation. The new combined solar/gas source will maintain heat in plating tanks, eliminating precipitation of salts when tanks are not in use, thereby reducing maintenance costs. Conserving heat allows Astor to maintain hot solutions for plating any type of finish at any time, Richard said. This means well have greater flexibility in our production and can provide a better service to our customers. With this project, Astor is striving to compete with the world leaders in electroplating. Astor has shown it is possible to reverse the tide of products being chrome plated overseas. Better heating control and heat transfers will allow us to expand our operations in the future without the need for expensive power substation upgrades. Astors main business is chrome plating but it also provides gold, silver, copper, nickel, bronze and antique finishes, polishes stainless steel, electropolishes and wet paints all metals. It employs more than 50 staff members. www.astormetalfinishes.com/ 02 9727 5622

Above, verifying the plating thickness of a chrome-plated aluminium truck wheel. Below, a close-up of the chrome-plated steel wheels.

Below, inspecting and cleaning a restored motor bike petrol tank. Left, Astors gas and solar hot water generator and storage vessel.

Water-saving leaders in morphine production

TPI Enterprises has made environmental sustainability a cornerstone for its growth as an internationally competitive manufacturing business. The Tasmanian company extracts and processes poppy straw concentrate to produce morphine, codeine and other pharmaceuticals. Since beginning in 2004, it has invested $25 million in building a world-class manufacturing facility. Supported by two Australian Government innovation grants and the R&D Tax Concession, it has developed an innovative manufacturing process that uses water instead of toxic solvents for the extraction process. TPIs latest project is integrating plant and equipment to recapture and minimise the water used in production. With a grant of $128,666 from the Re-Tooling for Climate Change Program, TPI is installing water storage and filtration systems, and a recording and monitoring system fully integrated with plant level control systems. This will recycle water formerly lost to evaporation or filtration, or as purged and waste water, delivering a 50 per cent saving. This water-based production process gives us a competitive advantage over other plants in the world. Our plant is a world first, TPIs Managing Director Jarrod Ritchie said. Optimising our water efficiency is critical, especially given recent drought conditions in Tasmania. TPI started manufacturing on a trial basis in 2008, processing 200 tonnes of poppy straw with a projected increase to 6000 tonnes by 2010. TPI employs 35 staff. www.tpienterpises.com/ 03 6398 5254

Above, sampling clean water from the filtration system. Below, inspecting the colour difference between dirty and purified water.

Applications will be considered in several rounds each year. Closing dates are available at www.ausindustry.gov.au

Astors main business is chrome plating. The company is working on a project to cut its electricity use by more than 50 per cent.

TPI is installing water storage and filtration systems to recycle water and cut its water bill by 50 per cent.

Mortons Managing Director, Jonnie Morton, is saving $400,000 a year in fuel costs by using waste oat hulls.

Re-tooling for Climate Change

The Re-tooling for Climate Change Program provides grants of $10,000 to $500,000 to small and medium sized businesses undertaking manufacturing in Australia. The grants aim to assist manufacturers reduce their environmental footprint, by improving the energy and/ or water efficiency of their production processes. The program will fund up to half the cost of each project. Examples of eligible projects could include: application of water capture, recycling and filtration technologies process re-engineering to reduce energy or water use application of energy efficient technologies energy generation from production waste. Re-tooling for Climate Change Program applications will be considered on a competitive basis against the program merit criteria in rounds (criteria and closing dates are available from the AusIndustry web site).

About AusIndustry

AusIndustry is the Australian Governments principal business program delivery division in the Department of Innovation, Industry, Science and Research. AusIndustry delivers more than 30 products, worth about $2 billion a year, to more than 12,000 businesses and 85,000 individuals. AusIndustry products include innovation grants, tax and duty concessions, support for industry competitiveness, venture capital, and small business skills development programs. Visit www.ausindustry.gov.au, call 13 28 46 or email hotline@ausindustry.gov.au for more information.

November 2009

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 01 Waterpedia 10 Step Design WWTDocument74 pages01 Waterpedia 10 Step Design WWTLia Khusnul KhotimahNo ratings yet

- Lec 6 CombustionDocument18 pagesLec 6 Combustionkhloud rafat100% (1)

- Accelerated Aging Versus Realistic Aging in Aerospace Composite Materials. V. The Effects of Hot/Wet Aging in A Structural Epoxy CompositeDocument10 pagesAccelerated Aging Versus Realistic Aging in Aerospace Composite Materials. V. The Effects of Hot/Wet Aging in A Structural Epoxy CompositeOussama El BouadiNo ratings yet

- Work and Power - AnsDocument32 pagesWork and Power - AnsSurbhi DungraniNo ratings yet

- Phase Equilibria and the Phase Rule ExplainedDocument65 pagesPhase Equilibria and the Phase Rule ExplainedFritzel Pallon SusbillaNo ratings yet

- Diesel Fuel AdditivesDocument23 pagesDiesel Fuel AdditivesVikrant Bhalerao100% (1)

- RSA Industries, India - Products - Paper Chemicals - Tissue Softener - Finishing Softener For Tissue Paper (RSF-TS-50)Document3 pagesRSA Industries, India - Products - Paper Chemicals - Tissue Softener - Finishing Softener For Tissue Paper (RSF-TS-50)crplzNo ratings yet

- SDS-06559 - 21nov23 - American English - AGHS - TangoGray - FLX950Document12 pagesSDS-06559 - 21nov23 - American English - AGHS - TangoGray - FLX950souhard36No ratings yet

- Desalination Advaced CourseDocument249 pagesDesalination Advaced CourseIslam Buhidma100% (4)

- Astm D7066.1667593-1Document9 pagesAstm D7066.1667593-1maximilianoNo ratings yet

- Concept of Ecology and Ecosystem PresetationDocument58 pagesConcept of Ecology and Ecosystem PresetationPRASANT KUMAR BIPRA100% (1)

- Chapter 11 Guided ReadingDocument8 pagesChapter 11 Guided Readingapi-239466415No ratings yet

- Sika PDS - E - Sikagard - 705 LDocument3 pagesSika PDS - E - Sikagard - 705 Llwin_oo2435No ratings yet

- Test Bank For Environment and You 1st Edition ChristensenDocument12 pagesTest Bank For Environment and You 1st Edition ChristensenPeggy Gebhart100% (33)

- Safety Data Sheet Car Shampoo: Type Classifications Justification Data Source PhysicalDocument10 pagesSafety Data Sheet Car Shampoo: Type Classifications Justification Data Source PhysicalmiradesNo ratings yet

- SW (Adventure Edition) Deadlands - Lost Colony - WidowmakerDocument32 pagesSW (Adventure Edition) Deadlands - Lost Colony - WidowmakerJacobo Cisneros100% (1)

- Gfps 00046 Brochure Pvcsystems enDocument16 pagesGfps 00046 Brochure Pvcsystems enOmar GuillenNo ratings yet

- Wettability in Oil and Gas ReservoirsDocument3 pagesWettability in Oil and Gas ReservoirsArumNo ratings yet

- Material Safety Data SheetDocument16 pagesMaterial Safety Data Sheetaya sofiaNo ratings yet

- 22 Environmental Chemistry: SolutionsDocument14 pages22 Environmental Chemistry: SolutionsAnil AggaarwalNo ratings yet

- HYPAM Fixer Technical Data SheetDocument7 pagesHYPAM Fixer Technical Data Sheetbwrzt6xhskNo ratings yet

- 4 - Module-II - Meteorological DisastersDocument60 pages4 - Module-II - Meteorological DisastersN AlamNo ratings yet

- Bilogy Investigatory ProjectDocument13 pagesBilogy Investigatory ProjectMoghanNo ratings yet

- Oil-Fuel SeparatorDocument24 pagesOil-Fuel SeparatorSiva SubramaniyanNo ratings yet

- Huber Dissolved Air Flotation Plant HDFDocument5 pagesHuber Dissolved Air Flotation Plant HDFTrung HanNo ratings yet

- Test of Integrated Science Process SkillsDocument13 pagesTest of Integrated Science Process SkillsArnulfo Villasfer Santiago100% (1)

- Seamanship Inspect and Report Defects and Damage To Cargo Spaces and Hatch Covers and Ballast Tanks PDFDocument8 pagesSeamanship Inspect and Report Defects and Damage To Cargo Spaces and Hatch Covers and Ballast Tanks PDFAjay Singh0% (1)

- Water ActivityDocument5 pagesWater ActivityJALAJ'S WORLDNo ratings yet

- Brick 3Document7 pagesBrick 3mah0809No ratings yet

- Potassium Hydroxide PDFDocument4 pagesPotassium Hydroxide PDFMartiNo ratings yet