Professional Documents

Culture Documents

Nonlinear Finite Element Analysis of Reinforced Concrete Deep Beams

Uploaded by

Samir DirarOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nonlinear Finite Element Analysis of Reinforced Concrete Deep Beams

Uploaded by

Samir DirarCopyright:

Available Formats

VIII International Conference on Computational Plasticity COMPLAS VIII E. Oate and D. R. J.

Owen (Eds) CIMNE, Barcelona, 2005

NONLINEAR FINITE ELEMENT ANALYSIS OF REINFORCED CONCRETE DEEP BEAMS

* Samir M. O. Hassan Dirar and Chris T. Morley

Department of Engineering University of Cambridge Cambridge, CB2 1PZ, England e-mail: sh394@eng.cam.ac.uk, web page: http://www-civ.eng.cam.ac.uk/abstract/shabst.html Department of Engineering University of Cambridge Cambridge, CB2 1PZ, England e-mail: ctm1@eng.cam.ac.uk, web page: http://www-civ.eng.cam.ac.uk/ctm/ctm_web.htm

Key words: Deep Beam, Finite Element, Reinforced Concrete. Summary. This paper describes a series of nonlinear finite element analyses carried out using the commercial package, DIANA7, to predict the ultimate load and mode of failure for three different types of reinforced concrete continuous two-span deep beams. Only one parameter, the shear retention factor, was varied during the analyses. The predicted results were in good agreement with the experimental results. 1 INTRODUCTION

In spite of the sophisticated state-of-the-art attained in nonlinear finite element (FE) analysis of reinforced concrete (RC) structures in terms of material models and solution techniques, the dependency of the method on too many parameters has always been a shortcoming. For the analyses described hereinafter, the FE package DIANA7 has been applied to estimate the ultimate load and the mode of failure for a series of RC two-span continuous deep beams. Most of the nonlinear analytical parameters were fixed according to experimental values or logical reasoning and the only variable tuned was the shear retention factor, which was given a value about 0.1 in most of the analyses. 2 EXPERIMENTAL PROGRAM The experimental program consisted of testing three different types of deep beams, S1, S2 and S3. All beams, which were identical in geometry and longitudinal reinforcement, had a thickness of 90 mm and dimensions as shown in Figure 1. The Figure also depicts the test setup and gives the reinforcement yield strength (Y) and Youngs modulus (E). The differences between the three series were in the vertical reinforcement patterns and the concrete properties. Beams of series S1 had no vertical stirrups while those of series S2 and

Samir M. O. Hassan Dirar and Chris T. Morley

T o 0 c n rd 2 m f o w 1, ete 3 m rm t p Y = 5 0 Ma E = 2 0 G a o, 3 P, 0 P

S i r p ,Y = 3 5 M a E = 1 5G a trus 5 P, 9 P T o , w b r i f r e e t w 8 e enocmn, Y=3 5M a 5 P ,E=1 5G a 9 P

T o 2 1 0 m l n ,c n r d 3 m w 1, 80 m og ete 5 m fo tp Y=40Ma E=15Ga rm o , 7 P, 9 P

625

T o 2 c nr d 2 m f o w 1 , et e 5 m r m b t o , Y = 4 0M a E = 1 5 G a otm 7 P, 9 P

1 01 0 0 2

50 0

20 0

50 0

10 6

50 0

20 0

50 0

10 10 2 0

Figure 1: Test setup and specimen dimensions (Not to scale. All dimensions in mm.)

S3 had 6 mm and 8 mm diameter stirrups at 150 mm and 130 mm spacing respectively. Table 1 gives the basic concrete properties for the analyzed beams. The first row in the table refers to the serial number and the year of testing while the second and third rows gives the concrete cube compressive strength and split tensile strength respectively in MPa.

S1/95 40 N/A S1/96 39 3.10 S1/97 36 2.75 S1/98 42 3.60 S2/95 26 2.40 S2/96 37 2.70 S3/95 34 2.70 S3/98 31 2.60 S3/99 45 3.40 S3/03 37 2.90

Table 1: Concrete properties of modeled specimens

Further information about the experimental setup, testing apparatus and instrumentations can be found elsewhere1. 3 FINITE ELEMENT MODELING A 3-D FE model capable of predicting the ultimate loads and modes of failure of the three series was built. The model was kept as simple as possible in terms of element selection and usage of default integration schemes, without detracting from the accuracy of the results. FE modeling of these beams has been reported elsewhere2. This paper, however, models the support plates better and gives better agreement over the whole range of behaviour. The concrete body and the steel loading plates were modeled by 8-noded brick elements. The supports were modeled by 6-noded wedge elements, which were connected by their base to the 8-noded elements while their sharp edges acted as rotating edges, modeling the behaviour of roller supports. Reinforcement is modeled by 3-noded truss elements. For more detailed description of these elements, the reader is referred to DIANA Element Library3. Figure 2 illustrates the typical concrete FE mesh used together with the reinforcement FE meshes and their boundary conditions for the three series. Because of its computational convenience as well as its resemblance to reality, the smeared crack approach was used to model the cracking of concrete. The initiation of cracks was governed by a linear tension cut-off criterion. After cracking, Hordijk softening curve was incorporated to capture the effects of tension stiffening and softening. Two constitutive models only could be incorporated with the brick elements to model the

Samir M. O. Hassan Dirar and Chris T. Morley

Figure 2: Typical concrete FE mesh and reinforcement FE meshes for the three series

compressive behaviour of concrete under loading. Those were: (1) the constitutive models of plasticity, where Von-Mises criterion was chosen to specify yield, and (2) crack models based on total strain, where compressive behaviour was in general described by a nonlinear function between stress and strain in a certain direction. Shear was embodied by a constant shear retention model incorporating a value of about 0.1 for the shear retention factor ( ), after cracking, in most of the analyses. The loading plates, supporting plates, and reinforcing steel were modeled as elasticperfectly plastic materials. Von-Mises yield criterion was used again to model plasticity. 4 RESULTS AND DISCUSSION

A comparison between the experimental and predicted ultimate loads for the ten analyzed specimens is given in Figure 3. The peak load predictions were generally very close to the experimental results. The plasticity and total strain constitutive models gave approximately similar results with mean predicted to experimental ratios of 1.04 and 1.05, and standard deviations of 0.11 and 0.10 respectively.

800 Load (kN) 600 400 200 0 S1/95 S1/96 S1/97 S1/98 S2/95 S2/96 S3/95 S3/98 S3/99 S3/03

Beam Reference

Experimental Peak Loads

Plasticity Model Predictions

Total Strain Model Predictions

Figure 3: Comparison between FE predictions and experimental results

The experimental and analytical load-midspan deflection relationships for S1/96 and S3/98 are compared in Figure 4. These relationships could be divided into four stages. Throughout the first stage, the relationship was linear and the deflections developed at a relatively low level. After this initial stage, the flexural cracks reduced the beams stiffness significantly and the mid-span deflections increased markedly. The third stage marked the sudden appearance

Samir M. O. Hassan Dirar and Chris T. Morley.

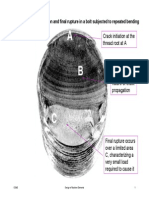

of diagonal cracks at the middle of the deep beams running between the loading plate and the central support. These diagonal cracks caused a sudden drop in the applied load, usually regained as displacement continued. During the last stages, the beams continued to lose their stiffness until they finally collapsed. Figure 5 shows the various stages of crack initiation and propagation in terms of crack strains, using a coloured scale of strain magnitude.

Loa d- De fle c t ion Cur ve (S 1/ 96) 600 500 Load (kN)

Loa d- De f le c t ion Cur ve ( S 3/ 98) 800 600 Load (kN) 400 200 0

400 300 200 100 0 0 0.5 1 1.5 De fle c t ion ( mm) P la st ic it y Mode l 2 2.5

0.5

1.5 De f le c t ion (mm) P la st ic it y Mode l

2.5

Expe r ime nt a l Cur ve

Tot a l S t ra in Mode l

Expe rime nt a l Cur ve

Tot a l S t r a in Mode l

Figure 4: Load-Deflection Curves

Figure 5: Cracks initiation and propagation

CONCLUSIONS The FE method was capable of modeling the behaviour of the RC deep beams. Shear retention factor was the only parameter varied during the analyses. Predictions of the ultimate load were within an accuracy region of 5%. The method also picked the mode of failure characterized by a diagonal shear crack.

REFERENCES

[1] S.M.O. Hasan, Nonlinear Finite Element Analysis of Reinforced Concrete Deep Beams, MPhil Thesis, University of Cambridge, Department of Engineering, (2004). [2] I.M. May, C.T. Morley and C.T. Chen, Benchmarking of nonlinear finite element analyses for reinforced concrete deep beams, Comp. Modelg. of Conc. Struc., 751-758, (2003). [3] TNO Building and Construction Research, DIANA Users Manual, Element Library, Delft, The Netherlands, (1998).

You might also like

- Dynamic Damage and FragmentationFrom EverandDynamic Damage and FragmentationDavid Edward LambertNo ratings yet

- p10 PDFDocument4 pagesp10 PDFakash kumarNo ratings yet

- Ecentric LoadDocument4 pagesEcentric LoadArun NesamNo ratings yet

- Tang, ZS, Rao, NSVK, and Jodin Makinda-Full PaperDocument8 pagesTang, ZS, Rao, NSVK, and Jodin Makinda-Full PaperZisheng TangNo ratings yet

- The Effect of Hole Shape On Fatigue LifeDocument4 pagesThe Effect of Hole Shape On Fatigue LifeLukita Wahyu PermadiNo ratings yet

- Evaluation of The Tensile Strength of SFRC As Derived From Inverse Analysis of Notched Bending TestsDocument9 pagesEvaluation of The Tensile Strength of SFRC As Derived From Inverse Analysis of Notched Bending TestsJakob FiskerNo ratings yet

- Fracture Mechanism of A Coarse-Grained Magnesium Alloy During Fracture Toughness TestingDocument10 pagesFracture Mechanism of A Coarse-Grained Magnesium Alloy During Fracture Toughness TestingSwagat Kumar PaniNo ratings yet

- Three Point Bending Test 1Document18 pagesThree Point Bending Test 1dinesh ramratanNo ratings yet

- Corrugated Web BeamDocument4 pagesCorrugated Web BeamNegin MalekiNo ratings yet

- Performance Criteria For Dissipative Steel Plate Shear Walls StructuresDocument8 pagesPerformance Criteria For Dissipative Steel Plate Shear Walls StructuresgiorgosantzelidisNo ratings yet

- Characteristic Withdrawal Capacity and Stiffness of Threaded RodsDocument13 pagesCharacteristic Withdrawal Capacity and Stiffness of Threaded RodsAndrej SørensenNo ratings yet

- Parametric Studies of Steel Cold-Formed Section Beam To Column Moment Connections With Self-Drilling ScrewsDocument11 pagesParametric Studies of Steel Cold-Formed Section Beam To Column Moment Connections With Self-Drilling ScrewsAhmed SalehNo ratings yet

- 2.13 Nonlinear Finite Element Analysis of Unbonded Post-Tensioned Concrete BeamsDocument6 pages2.13 Nonlinear Finite Element Analysis of Unbonded Post-Tensioned Concrete Beamsfoufou2003No ratings yet

- Amr 1013 242Document8 pagesAmr 1013 242Ibrahim HasanNo ratings yet

- 2012 Influence of Blank Holding Force On The Forming Limits of DP590 SteelDocument6 pages2012 Influence of Blank Holding Force On The Forming Limits of DP590 SteelJhon DonNo ratings yet

- Finite Element Analysis of The Effects of Clearance On Single-Shear, Composite Bolted JointsDocument11 pagesFinite Element Analysis of The Effects of Clearance On Single-Shear, Composite Bolted JointsVatambeti YugandharNo ratings yet

- Characterization of The Toughness of FRC Using Load CMOD ResponseDocument14 pagesCharacterization of The Toughness of FRC Using Load CMOD ResponseourebooksNo ratings yet

- Michels Et Al SMAR2013Document9 pagesMichels Et Al SMAR2013Rodrigo LameirasNo ratings yet

- Experimental Study of The Effect of Triaxiality RatioDocument4 pagesExperimental Study of The Effect of Triaxiality RatioEl Ehsan Abinya FatihNo ratings yet

- The Use of Symmetric Taylor Impact To Validate Constitutive Models For An FCC Metal (Copper) and A BCC Alloy (RHA Steel)Document6 pagesThe Use of Symmetric Taylor Impact To Validate Constitutive Models For An FCC Metal (Copper) and A BCC Alloy (RHA Steel)michaelpj5No ratings yet

- Combe and Hartig 2006Document10 pagesCombe and Hartig 2006Komathi MuruganNo ratings yet

- Fragmentation Study of Interfacial Shear Strength of Single Sic Fiber Reinforced Al After FatigueDocument8 pagesFragmentation Study of Interfacial Shear Strength of Single Sic Fiber Reinforced Al After FatigueSai SaiNo ratings yet

- Effect of Beam Dimensions On Structural Performance of Wide Beam-Column JointsDocument7 pagesEffect of Beam Dimensions On Structural Performance of Wide Beam-Column JointsRafa SouzaNo ratings yet

- Torsional Deformation and Fatigue Behaviour of 6061 Aluminium AlloyDocument12 pagesTorsional Deformation and Fatigue Behaviour of 6061 Aluminium Alloyvahid66466No ratings yet

- Bond Between CFRP Sheets and ConcreteDocument8 pagesBond Between CFRP Sheets and ConcreteDamini ThakurNo ratings yet

- OgBayrak - Response Prediction by Plastic Hinge AnalysisDocument6 pagesOgBayrak - Response Prediction by Plastic Hinge AnalysisRui CbNo ratings yet

- Variation of Failure Mechanisms of Slopes in Jointed Rock Masses With Changing ScaleDocument8 pagesVariation of Failure Mechanisms of Slopes in Jointed Rock Masses With Changing ScaleUniMinasNo ratings yet

- The Behaviour of A Self-Piercing Riveted Connection Under Quasi-Static Loading ConditionsDocument22 pagesThe Behaviour of A Self-Piercing Riveted Connection Under Quasi-Static Loading ConditionsShreehari HaridasanNo ratings yet

- Numerical Analysis of Load Test On Bored Pile (Wehnert & Veermer) PDFDocument6 pagesNumerical Analysis of Load Test On Bored Pile (Wehnert & Veermer) PDFAnonymous BuFjdLNo ratings yet

- 4.1. Modelling Confinement in Concrete Columns and Bridge Piers Through 3D Nonlinear Finite Element AnalysisDocument8 pages4.1. Modelling Confinement in Concrete Columns and Bridge Piers Through 3D Nonlinear Finite Element AnalysisFaraaz FaisalNo ratings yet

- N. A. Alang, N. A. Razak, K.A.Safie', and A. SulaimanDocument9 pagesN. A. Alang, N. A. Razak, K.A.Safie', and A. SulaimanOskar CorderoNo ratings yet

- Lauke 1994Document5 pagesLauke 1994lami75No ratings yet

- Average Stress Strain Relations For ConcDocument10 pagesAverage Stress Strain Relations For ConcKorrapati Pratyusha 19PHD0497No ratings yet

- 03 JTE Astm Tensile Stress ConcentrationDocument6 pages03 JTE Astm Tensile Stress ConcentrationTanu RdNo ratings yet

- AM1.6 - Mechanical Testing (Tensile)Document6 pagesAM1.6 - Mechanical Testing (Tensile)Flying ThinNo ratings yet

- Composite Substructures With Partial Shear Connection: Low Cycle Fatigue Behaviour and Analysis IssuesDocument8 pagesComposite Substructures With Partial Shear Connection: Low Cycle Fatigue Behaviour and Analysis IssuesCaesarAbdullahNo ratings yet

- Three-Dimensional Finite Element Analysis of Single-Bolt Single-Lap Composite Bolted Joints Part IIDocument17 pagesThree-Dimensional Finite Element Analysis of Single-Bolt Single-Lap Composite Bolted Joints Part IIJungseok KimNo ratings yet

- Mechanism of Mechanical Failure of Sapphire at High TemperatureDocument10 pagesMechanism of Mechanical Failure of Sapphire at High TemperatureChristian MavarezNo ratings yet

- Fracture Toughness of Cast Aluminium Alloys: Bulletin of Materials Science March 1982Document8 pagesFracture Toughness of Cast Aluminium Alloys: Bulletin of Materials Science March 1982Aung Khant KyawNo ratings yet

- Stringer Panel Method. A Discrete Model To Project Structural Reinforced Concrete ElementsDocument7 pagesStringer Panel Method. A Discrete Model To Project Structural Reinforced Concrete ElementsJose Maria GedaNo ratings yet

- (2005) Zhou, Allameh, Soboyejo - Microscale Testing of The Strut in Open Cell Aluminum FoamsDocument11 pages(2005) Zhou, Allameh, Soboyejo - Microscale Testing of The Strut in Open Cell Aluminum Foamsandrogyny0wed8No ratings yet

- A Constitutive Model For Jointed Rock MassDocument7 pagesA Constitutive Model For Jointed Rock MassHồ Xuân NamNo ratings yet

- Material Mass (KG/M) Portland Cement Water Fly Ash (Unclassified) 19 MM Stone (Granite) 13 MM Stone (Granite) Crusher Sand (Granite) Filler SandDocument24 pagesMaterial Mass (KG/M) Portland Cement Water Fly Ash (Unclassified) 19 MM Stone (Granite) 13 MM Stone (Granite) Crusher Sand (Granite) Filler Sanddisha847No ratings yet

- 2.2 Strengthening The T Elements With Carbon Fiber Reinforced Polymer PlatesDocument11 pages2.2 Strengthening The T Elements With Carbon Fiber Reinforced Polymer PlatesdhruvgokuNo ratings yet

- My PaperDocument9 pagesMy PaperBelal HyariNo ratings yet

- Non Linear Analysis of Bolted Extended End Plate Steel Beam To Column ConnectionDocument9 pagesNon Linear Analysis of Bolted Extended End Plate Steel Beam To Column ConnectionmirosekNo ratings yet

- Inter2018 - Modelling The Variation of MechanicalDocument16 pagesInter2018 - Modelling The Variation of MechanicalCristopherNo ratings yet

- Paper 7Document9 pagesPaper 7RakeshconclaveNo ratings yet

- A New Method For Predicting Forming Limit Curves From Mechanical Properties PDFDocument11 pagesA New Method For Predicting Forming Limit Curves From Mechanical Properties PDFJoselo HR0% (1)

- Bending Test (Report) eDocument14 pagesBending Test (Report) eWesam Maleh100% (1)

- Tutorial Notchedbeam103 PDFDocument43 pagesTutorial Notchedbeam103 PDFxxxNo ratings yet

- Bending and Axial Compression With RestraintsDocument8 pagesBending and Axial Compression With RestraintsszalaijaNo ratings yet

- Effect of Reinforcement On The Failure Load of RC Beams: Osama Salem, Arafa El-HellotyDocument16 pagesEffect of Reinforcement On The Failure Load of RC Beams: Osama Salem, Arafa El-HellotyHesham EdressNo ratings yet

- QST000286Document2 pagesQST000286Malik AtikNo ratings yet

- Effects of Confined Concrete Models On Simulating RCDocument7 pagesEffects of Confined Concrete Models On Simulating RCKhalid WaziraNo ratings yet

- Cold-Formed Steel MembersDocument19 pagesCold-Formed Steel MembersLiviu IonNo ratings yet

- Effects of Opening On The Behavior of Reinforced Concrete Beam I011275261Document10 pagesEffects of Opening On The Behavior of Reinforced Concrete Beam I01127526101010No ratings yet

- Axial Compression Tests of RC Columns Confined by Aramid Fiber Belt PrestressingDocument6 pagesAxial Compression Tests of RC Columns Confined by Aramid Fiber Belt Prestressingx620No ratings yet

- Journal of Crystal Growth: S. Dhanuskodi, T.C. Sabari GirisunDocument6 pagesJournal of Crystal Growth: S. Dhanuskodi, T.C. Sabari GirisunRama GaurNo ratings yet

- EMS430U Exam Practice Questions HSG - 2021 - 2022FINALQMDocument5 pagesEMS430U Exam Practice Questions HSG - 2021 - 2022FINALQMrasedaNo ratings yet

- ReviewDocument24 pagesReviewhunters eNo ratings yet

- Rock Engineering and Design (Papers)Document196 pagesRock Engineering and Design (Papers)danialalishahNo ratings yet

- Engineering Properties of RocksDocument77 pagesEngineering Properties of RocksTariq NiazNo ratings yet

- New Microsoft Word DocumentDocument14 pagesNew Microsoft Word Documentniraj jaiswalNo ratings yet

- EAS 326-03 M E: Ave 98/150, S.D. 21Document7 pagesEAS 326-03 M E: Ave 98/150, S.D. 21arief_7No ratings yet

- 3D2013 2 ReferenceDocument364 pages3D2013 2 ReferenceDiana Alice SugunanNo ratings yet

- CH 06Document34 pagesCH 06Firas Abu talebNo ratings yet

- ME Viva Copy PasteDocument3 pagesME Viva Copy PastesaveNo ratings yet

- Barlat - Et - Al - 1997 - JMPS - YIELD FUNCTION DEVELOPMENT FOR ALUMINUMDocument37 pagesBarlat - Et - Al - 1997 - JMPS - YIELD FUNCTION DEVELOPMENT FOR ALUMINUMYasser BouktirNo ratings yet

- Material Properties: (ESE - 1992) (ESE - 1992)Document121 pagesMaterial Properties: (ESE - 1992) (ESE - 1992)Sanket ManeNo ratings yet

- Solidworks FEA Model Type: Linear & NonlinearDocument16 pagesSolidworks FEA Model Type: Linear & NonlinearKuen WongNo ratings yet

- STD Iso 27956 Load Restraint System PDFDocument12 pagesSTD Iso 27956 Load Restraint System PDFAnonymous O0T8aZZNo ratings yet

- Design of Portal Frame - 3Document38 pagesDesign of Portal Frame - 3afn3178No ratings yet

- Fatigue FailureDocument47 pagesFatigue FailureOmar KhanNo ratings yet

- Shot PeeningDocument19 pagesShot PeeningchandruNo ratings yet

- Yield LocusDocument36 pagesYield Locusshanthakumar100% (1)

- Report On Tensile, Impact and Hardness Testing of Mild SteelDocument12 pagesReport On Tensile, Impact and Hardness Testing of Mild SteelEngr.Hamid Ismail CheemaNo ratings yet

- ME 603 RefresherDocument74 pagesME 603 RefresherArgielJohn LlagasNo ratings yet

- IRC 112 2011 Concrete Road Bridges PDFDocument289 pagesIRC 112 2011 Concrete Road Bridges PDFShanmuga Sundaram100% (2)

- SME4133 Module 4 Mechanisms FailureDocument14 pagesSME4133 Module 4 Mechanisms FailureyapzihwaNo ratings yet

- Structural Engineering & ConstructionDocument13 pagesStructural Engineering & ConstructionREX AMPONGANNo ratings yet

- Rolling Friction FundamentalsDocument19 pagesRolling Friction FundamentalsMuhammad AliNo ratings yet

- Burst Pressure Prediction of Pressure Vessel Using FEADocument6 pagesBurst Pressure Prediction of Pressure Vessel Using FEAMario TirabassiNo ratings yet

- Lecture 09 Rheology PDFDocument29 pagesLecture 09 Rheology PDFsukebadorNo ratings yet

- Mirzaei FractureMechanicsLecture PDFDocument61 pagesMirzaei FractureMechanicsLecture PDFkoohestani_afshinNo ratings yet

- PreDocument16 pagesPreJohn Eduard Felix BetuinNo ratings yet

- Blue Basic Concepts On Structure of SolidsDocument22 pagesBlue Basic Concepts On Structure of SolidsME011Mohsin BilalNo ratings yet

- Electro-Magnetic Breaking-Black BookDocument48 pagesElectro-Magnetic Breaking-Black BookAnjali BiramaneNo ratings yet