Professional Documents

Culture Documents

Hydrogen Sensor

Uploaded by

vivek daveOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hydrogen Sensor

Uploaded by

vivek daveCopyright:

Available Formats

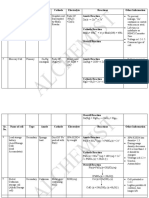

A COMPARITIVE STUDY OF DIFFERENT HYDROGEN SENSORS

Niobium sensors

Iron sensors

Optimized iron sensors

Tritium sensing and processing technologies in leadlithium-A. Ciampichetti, M. Utili, A. Aiello ENEA UTIS C.R. Brasimone

Iron-palladium sensors

Tritium sensing and processing technologies in lead-lithium-A. Ciampichetti, M. Utili, A. Aiello ENEA UTIS C.R. Brasimone

Sc-doped CaZrO3 hydrogen sensor for liquid blanket system

Sc-doped CaZrO3 hydrogen sensor for liquid blanket system --Masatoshi Kondo,Takeo Muroga, Koji Katahira Tomoko Oshima

REFERENCE

Materials selection and design of a hydrogen measurement device in Pb17Li A. Ciampichetti, I. Ricapito, G. Benamati, M. Zucchetti

Materials selection and design of a hydrogen measurement device in Pb17Li A. Ciampichetti, I. Ricapito, G. Benamati, M. Zucchetti

STRUCTURE

OPERATING PRINCIPLE

A hydrogen permeation sensor is a hollow capsule immersed in a liquid metal where hydrogen is dissolved at a certain concentration CL in equilibrium with a pressure Peq. The capsule is connected, through a small tube, to a vacuum pumping system, depending on its mode of operation. The measurement of the hydrogen isotopes partial pressure in the capsule or hydrogen permeation flux through the capsule walls has to be correlated with the Hydrogen concentration CL in the liquid metal.

A hydrogen permeation sensor is a hollow capsule immersed in a liquid metal where hydrogen is dissolved at a certain concentration CL in equilibrium with a pressure Peq. The capsule is connected, through a small tube, to a vacuum pumping system, depending on its mode of operation. The measurement of the hydrogen isotopes partial pressure in the capsule or hydrogen permeation flux through the capsule walls has to be correlated with the Hydrogen concentration CL in the liquid metal.

A hydrogen permeation sensor is a hollow capsule immersed in a liquid metal where hydrogen is dissolved at a certain concentration CL in equilibrium with a pressure Peq. The capsule is connected, through a small tube, to a vacuum pumping system, depending on its mode of operation. The measurement of the hydrogen isotopes partial pressure in the capsule or hydrogen permeation flux through the capsule walls has to be correlated with the Hydrogen concentration CL in the liquid metal.

A hydrogen permeation sensor is a hollow capsule immersed in a liquid metal where hydrogen is dissolved at a certain concentration CL in equilibrium with a pressure Peq. The capsule is connected, through a small tube, to a vacuum pumping system, depending on its mode of operation. The measurement of the hydrogen isotopes partial pressure in the capsule or hydrogen permeation flux through the capsule walls has to be correlated with the Hydrogen concentration CL in the liquid metal.

The sensor cell is placed in the melt which contained hydrogen of the designed concentration. Hydrogen comes to the gas compartment from the melt. After equilibrium, the hydrogen concentration S is derived by the partial pressure of the hydrogen in the gas compartment as PH(1) according to the Sieverts law. In the sensor cell, reference gas is continuously supplied and the hydrogen partial pressure is Regulated at PH(2).

RANGE

tested at 450 0C a high hydrogen testing pressure (range 12 bar)

Tested at temperature range 350550 0C, with a hydrogen partial pressure between 200 and 1100 mbar. capsule external diameter: 1.3 cm capsule thickness: 1 mm capsule height: 3 cm tube height: 30 cm tube external diameter: 1.3 cm tube thickness: 1.5 mm.

Tested at 400-450- 500 C in the range 10-100 mbar both in equilibrium and dynamic mode

Tested at 350-400-450500 C in the range 1100 mbar both in equilibrium and dynamic mode. .

Test temperature was 700 C. The reference gas and measurement gas were continuously injected at the flow rate of 50 and 100 cm3/min, respectively. Proton conducting ceramics of CaZr0.95O3aSc0.05 (better corrosion resistance ) The surface of the sensor cell was covered by Pt which works as electrode. Pt was plated over the surface of the sensor. The sensor performance and validity was investigated by means of performance test in ArH2 gas atmosphere at 700 C. The obtained electromotive force of the sensor was agreed well with the theoretical value. The sensor exhibited stable

DESIGN

capsule external diameter: 1.3 cm capsule thickness: 1 mm capsule height: 3 cm tube height: 30 cm tube external diameter: 1.3 cm tube thickness: 1.5 mm.

Thickness of the permeable walls: 0.125 mm Manufacturing: welded with a laser technique Filling: cylinder of Al Gas tight

Membrane: pure iron, thickness 50/125 m Coating: 2 m of palladium in the internal side Coating technology: magnetron sputtering Welding technology: micro-laser

RESULTS

Equilibrium mode: The observed low permeation fluxes show the impossibility of operating the Nbsensor in equilibrium Mode Dynamic mode: The differences obtained performing tests in the same conditions prove the

Equilibrium mode: The operation of the iron sensor in equilibrium mode is not feasible, because of the very long time (several hours) necessary to reach the hydrogen pressure equilibrium. Dynamic mode: The Fe-sensor

Equilibrium mode: the order of magnitude of the response time is around 1 hour

Dynamic mode:

response time of few seconds but the behavior of the sensor over the time is not completely reliable

Equilibrium mode: the time necessary to reach the equilibrium pressure is around 8 h (higher permeation flux but reduced permeation surface with respect the cylindrical sensor). Dynamic mode: the response time is very short and the reliability is better than the pure

impossibility of operating the sensor in dynamic mode.

quickly reaches the steady state condition of the permeating flux (a few seconds are necessary) and, therefore, if operated in dynamic mode.

iron sensor. Reproducible results in terms of permeation fluxes have been obtained in the different operating conditions.

output in the varied hydrogen partial pressure. The sensor responded well with the change of hydrogen concentration in the gas atmosphere. The sensor showed good reproducibility.

ADVANTAGE

simplest design and mechanism of operation

shows fast response in dynamic mode Fe sensor is more advanced compare to Nb sensors simplest design and mechanism of operation

Act in both equilibrium and dynamic mode

In the dynamic mode response time is very short and it is more reliable than pure iron and niobium sensors.

sensor was constructed using proton conducting ceramics of CaZr0.95O3aSc0.05 which was expected to show better corrosion Resistance than others. Stable output Sensor showed good response due to the change of hydrogen concentration in the melt.

DISADVANTAGE

low permeation fluxes shows that it can be operated in equilibrium as well as in dynamic mode

Cannot be operated in equilibrium mode because time require to reach equilibrium is very long.

the behavior of the sensor over the time is not completely reliable in dynamic mode

In equilibrium mode time require to reach equilibrium time taken is very high compare to others

You might also like

- Preparation of Alkyl HalideDocument1 pagePreparation of Alkyl Halidevivek daveNo ratings yet

- (Section A) - Answer The Following For 1 Mark.Document6 pages(Section A) - Answer The Following For 1 Mark.vivek daveNo ratings yet

- SilicatesDocument7 pagesSilicatesvivek daveNo ratings yet

- Chemical KineticsDocument3 pagesChemical Kineticsvivek daveNo ratings yet

- Topic-0 Development of ChemistryDocument2 pagesTopic-0 Development of Chemistryvivek daveNo ratings yet

- Topic Faraday's Law and Electrolytic CellsDocument7 pagesTopic Faraday's Law and Electrolytic Cellsvivek daveNo ratings yet

- Solid State NotesDocument15 pagesSolid State Notesvivek daveNo ratings yet

- Topic Faraday's Law and Electrolytic CellsDocument7 pagesTopic Faraday's Law and Electrolytic Cellsvivek daveNo ratings yet

- Chapter 3 Electrochemistry Topic 1 Electrochemical Cell, Electrodes and E.M.F. SeriesDocument8 pagesChapter 3 Electrochemistry Topic 1 Electrochemical Cell, Electrodes and E.M.F. Seriesvivek daveNo ratings yet

- Topic Different Types of CellsDocument2 pagesTopic Different Types of Cellsvivek daveNo ratings yet

- Chapter 3 Electrochemistry Topic ElectrochemistryDocument16 pagesChapter 3 Electrochemistry Topic Electrochemistryvivek daveNo ratings yet

- TOPIC Products Obtained by ElectrolysisDocument2 pagesTOPIC Products Obtained by Electrolysisvivek daveNo ratings yet

- Topic Nernst Equation and Concentration CellDocument6 pagesTopic Nernst Equation and Concentration Cellvivek daveNo ratings yet

- Topic Different Types of CellsDocument2 pagesTopic Different Types of Cellsvivek daveNo ratings yet

- Factors Affecting SolubilityDocument5 pagesFactors Affecting Solubilityvivek daveNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Chapter 1 Exercises PDFDocument8 pagesChapter 1 Exercises PDFGeorges SalloumNo ratings yet

- Suzuki GSXS 1000 Manual Servicio Tecnico PDFDocument86 pagesSuzuki GSXS 1000 Manual Servicio Tecnico PDFRoberto Nicolás Mera Velásquez75% (8)

- Crude TBP Country Nigeria Distillation: Akpo BlendDocument2 pagesCrude TBP Country Nigeria Distillation: Akpo Blendeke23No ratings yet

- Thyristor: Semi-Conductor DeviceDocument11 pagesThyristor: Semi-Conductor DeviceAmit RastogiNo ratings yet

- Transformer Interview Questions & Answers: Search For Jobs..Document29 pagesTransformer Interview Questions & Answers: Search For Jobs..shamshadNo ratings yet

- RMIPA Port Master PlanDocument362 pagesRMIPA Port Master Planjoncpasierb100% (6)

- OCTG Piping Inspection MethodsDocument26 pagesOCTG Piping Inspection MethodsAli HashimNo ratings yet

- Commissioning NotesDocument13 pagesCommissioning NotesÇınar İnalNo ratings yet

- Pcm120 Brochure PDFDocument2 pagesPcm120 Brochure PDFshyroro2010No ratings yet

- Electrical Disturbances in LV Networks Due To Energization of MV NetworksDocument5 pagesElectrical Disturbances in LV Networks Due To Energization of MV NetworksAlejandro Solis GomezNo ratings yet

- On CryogenicsDocument15 pagesOn Cryogenicsaswinchand50No ratings yet

- 42NQV050 060 SVMDocument102 pages42NQV050 060 SVMRob KoopmanNo ratings yet

- Wa900 8R - Cen00855 00Document20 pagesWa900 8R - Cen00855 00Ahmad Badawi100% (1)

- C 13Document5 pagesC 13مصطفي الغنيمى0% (1)

- Quick Exhaust Solenoid Valves: NC NODocument4 pagesQuick Exhaust Solenoid Valves: NC NOMuhammad AsadNo ratings yet

- Quasi Turbine EngineDocument18 pagesQuasi Turbine EngineKailas Sree Chandran100% (2)

- Simulation and Performance Analysis of Dielectric Modulated Dual Source Trench Gate TFET BiosensorDocument9 pagesSimulation and Performance Analysis of Dielectric Modulated Dual Source Trench Gate TFET BiosensoramitNo ratings yet

- DC01 (STAT Table) DA01 (Reagent Refrigerator) GA01: Heat ExchangerDocument2 pagesDC01 (STAT Table) DA01 (Reagent Refrigerator) GA01: Heat ExchangerQuốc CườngNo ratings yet

- Dekomposisi AnaerobikDocument31 pagesDekomposisi AnaerobikRahma PratiwiNo ratings yet

- Windbox M 2000 ADocument2 pagesWindbox M 2000 ADU A NENo ratings yet

- Parts Catalogue: '19 ER300 AKF/AKFA (CL) (Z300)Document87 pagesParts Catalogue: '19 ER300 AKF/AKFA (CL) (Z300)Yeison Cartagena BedoyaNo ratings yet

- Chapter LV Presenting and Analysis of DataDocument8 pagesChapter LV Presenting and Analysis of DataKimberly HipolitoNo ratings yet

- Full ReportDocument44 pagesFull ReportCes ShengNo ratings yet

- Documentary EvidenceDocument15 pagesDocumentary EvidenceDharuna PNo ratings yet

- TYH - TYA-Inverter Ducted PAC - CatalogueDocument4 pagesTYH - TYA-Inverter Ducted PAC - CatalogueNguyễn Thành ChungNo ratings yet

- Spectrasyn Plus™ 5: Advanced Polyalphaolefin (Pao) FluidDocument2 pagesSpectrasyn Plus™ 5: Advanced Polyalphaolefin (Pao) FluidMaram YasserNo ratings yet

- Bombardier¿ and Challenger¿ Are Trademarks of Bombardier, IncDocument5 pagesBombardier¿ and Challenger¿ Are Trademarks of Bombardier, IncMiguel Andres Esparragoza CeballosNo ratings yet

- Electric PV PPT New3Document32 pagesElectric PV PPT New3Anushka PagalNo ratings yet

- Hirarki Detail Engineering Design (DED)Document1 pageHirarki Detail Engineering Design (DED)Agus SusantoNo ratings yet

- 4 - AppendicesDocument27 pages4 - AppendicesDin Flores MacawiliNo ratings yet