Professional Documents

Culture Documents

Lec 01

Uploaded by

nixrateOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lec 01

Uploaded by

nixrateCopyright:

Available Formats

Safety and Risk Management

I. Introduction

1.3 Accident and Loss Statistics

Are important measures of effectiveness of safety programs

(1)

3 systems are considered (all report No of accidents and or fatalities for a fixed No of workers during specified period):

-

Occupational Safety and Health Administration (OSHA) incident rate Fatal accident rate (FAR) Fatality rate, or deaths per person per year

1.3 Accident and Loss Statistics

OSHA Incident Rate (USA) based on cases per 100 worker yrs 1 worker yr = 2000 hours (50 weeks/yr x 40 h/week)

(2)

Applicability can also be based on lost workdays (instead of injuries and illnesses) provides information on all types of work-related injuries and illnesses (including fatalities) Better representation of workers accidents Fatality can not be extracted from OSHA inc. rate without additional information

1.3 Accident and Loss Statistics

FAR (UK) No of fatalities based on 1000 employees working their entire lifetime (50 yrs) Can be converted (if you know No exposed hours)

(3)

Fatality Rate (per person per yr) Independent of No of hours actually worked Useful for performing calculation on the general population (exposed hours poorly defined)

1.3 Accident and Loss Statistics

(4)

Glossary of Terms Used by OSHA and Industry to Represent Work-Related Losses Incident Rate- No of occupational injuries and/or illnesses or lost work-days/100 full time employees. Lost workdays- No of days (consecutives or not) after but not including the day of injury or illness which the employee would have worked but couldnt do so. Occupational injury- Any injury (cut, sprain, burn, etc) that results from a work accident. Occupational illness- Any abnormal condition or disorder caused by exposure to environmental factors associated with employment. Etc (see Crowl, D. and Louvar, J., 2002, p.6)

1.3 Accident and Loss Statistics

Tab 1.2: Accident Statistics for Selected Industries OSHA incident rate (days away and deaths) Industry Chemicals and allied products Motor vehicles Steel Paper Coal mining All manufacturing

Source: Crowl, D. and Louvar, J., 2002, p 8

(5)

FAR (deaths) 1986 4 1.3 8 40 7.3 1.2 1990 1.2 0.6

1985 0.49 1.08 1.54 2.06 2.22

1998 0.35 6.07 1.28 0.81 0.26 1.68

1.3 Accident and Loss Statistics

Tab 1.3: Fatality Statistics for Common Non-industrial Activities FAR Activity Staying at home Travelling by: Car Bicycle Voluntary Air Motorcycle Canoeing Rock climbing Smoking (20 cigarettes/day) Struck by meteorite Involuntary Struck by lightning (U.K.) Fire (U.K.) Run over by vehicle

Source: Crowl, D. and Louvar, J., 2002, p 9

(6)

Fatality rate

(deaths/E8 hours) 3 57 96 240 660 1000 4000

(deaths per person per year)

17xE(-5)

4xE(-5) 500xE(-5) 6xE(-11) 1xE(-7) 150xE(-7) 600xE(-7)

1.3 Accident and Loss Statistics

(8)

Ex 1.1 A process has a reported Far of 2. If an employee works a standard 8 hr shift 300 days per year, compute the deaths per person per year Ex 1.2 If twice as many people used motorcycles for the same average amount of time each, what will happen to (a) the OSHA incident rate, (b) the fatality rate, (c) the FAR, and (d) the total number of fatalities? Ex 1.3 If all riders used their motorcycles twice as much, what will happen to (a) the OSHA incident rate, (b) the FAR, (c) the fatality rate, and (d) the total number of fatalities? Ex 1.4 A friend states that more rock climbers are killed traveling by automobile than are killed rock climbing. Is this statement supported by the accident statistics?

1.4 The Nature of The Accident Process

Tab 1.6: Definitions for Case Histories Term Accident Hazard Incident Consequence Likelihood Risk

(Crowl and Louvar, p. 21)

(6)

Definition Occurrence of a seq. of events unintended injury, death or property damage Chem/phys cond. with potential for damage (people, property or environ) Loss of containment of material or energy Measure of expected effects of the result of an accident Measure of expected probability/frequency of an event Measure of human injury, envir. damage or econ. loss (in terms of accident likelihood and its magnitude) Quant. estimative of risk (engineering evaluation and math techniques, for combining estimative of incident consequences and frequencies) Using results of risk analysis to make decisions (either through a relative raking of risk reduction strategies or through comparison with risk targets) Description of events that in an accident or incident (with enough information to define the root causes)

Risk analysis

Risk assessment

Scenario

1.4 The Nature of The Accident Process

(7)

Ex 1.6 Failure of a threaded 1 drain connection on a rich oil line at the base of an absorber tower in a large (1.35 MCF/D) gas producing plant allowed the release of rich oil and gas at 850 psi and -40F. The resulting vapor cloud is probably ignited from the ignition system of engine-driven recompressors. The 75 high x 10 diameter absorber tower eventually collapsed across the pipe rack and on the two exchangers trains. Breaking pipelines added more fuel to the fire. Severe flame impingement on an 11,000 horsepower gas turbinedriven compressor, waste heat recovery and super-heater train resulted in its near total destruction. Identify the initiation, propagation, and termination steps for this accident.

10

1.6 Four Significant Disasters

Tab 1.7: Four Significant Disasters Flixborough Where When Product England Jun-74 Caprolactam Failure improvised Causes b-passrelease 30t cicl-hexvap cloud ignexpl Plant+offic destroyed Conseq 28 casualties 36 work+53 civ enjur 10 days fire Safety review Prevent on desig/inst b-pass Standard modific inventory hazardous No workers injuried No equip damaged 2000 civ died 20,000 injuried Proper work of safety system (scrubber and flare) inventory interm MIC Rainsoil contamin 250 cases chloracne 600 people evacuated Stll adj area fenced Proper oper procedur Proper containment systems (HAZOP) Bhopal India Dec-84 Pesticides Serie oper failures release 25t MIC tox cloud spread town Seveso Italy Jul-76 Bactericides Reactor failure2kg TCDD(dioxin) release white cloud

(1)

Pasadena Texas-USA Oct-89 Polyethylene SOP failure release 85 kpounds flamm mixture massive explosion 23 fatalities 314 injuries $715 million cap loss SOP approp followed Proper HAZOP Proper lay-out of equip and facilities

11

would be

You might also like

- Topic One: An Introduction To Health & Safety in IndustryDocument19 pagesTopic One: An Introduction To Health & Safety in IndustrysrkamNo ratings yet

- Introduction To Health & Safety in Industry: Lecture NotesDocument11 pagesIntroduction To Health & Safety in Industry: Lecture NotesNiel NisperosNo ratings yet

- Chemical Process Safety: ProblemsDocument34 pagesChemical Process Safety: ProblemsganeshNo ratings yet

- Topic 1 - Introduction To H&s in IndustryDocument21 pagesTopic 1 - Introduction To H&s in IndustryMunachi IbokoNo ratings yet

- QRA DraftDocument38 pagesQRA DraftKishore Reddy100% (1)

- Industrial Accidents Triggered by Earthquakes, Floods and Lightning: Lessons Learned From A Database AnalysisDocument16 pagesIndustrial Accidents Triggered by Earthquakes, Floods and Lightning: Lessons Learned From A Database AnalysismaheshNo ratings yet

- Industrial Organisation Class Notes Uottawa MCG 5171BDocument66 pagesIndustrial Organisation Class Notes Uottawa MCG 5171BRatandeep PandeyNo ratings yet

- Environmental Impacts of Newark Liberty International AirportDocument12 pagesEnvironmental Impacts of Newark Liberty International AirportKarolis JokubaitisNo ratings yet

- Chemical Process Safety NotesDocument49 pagesChemical Process Safety NotesSujathaKs100% (2)

- Accident and Loss Statistics - FormulasDocument7 pagesAccident and Loss Statistics - FormulasmymdbNo ratings yet

- Unit 1 and 2Document57 pagesUnit 1 and 2AKNo ratings yet

- Overview of Disasters in The Chemical Engineering Regime B Nikhil Rohan 2Document21 pagesOverview of Disasters in The Chemical Engineering Regime B Nikhil Rohan 2chandanjoy15No ratings yet

- PUS Unit IV Safety and ToxicologyDocument34 pagesPUS Unit IV Safety and ToxicologySumit GaudNo ratings yet

- PCSM Lecture Intro of SafetyDocument21 pagesPCSM Lecture Intro of SafetyDHRUV SONAGARANo ratings yet

- Guidelines for Determining the Probability of Ignition of a Released Flammable MassFrom EverandGuidelines for Determining the Probability of Ignition of a Released Flammable MassNo ratings yet

- Fault Tree Analysis - FTADocument6 pagesFault Tree Analysis - FTAmark_vyzNo ratings yet

- Estimation of Average Hazardous-Event-Frequency For Allocation of Safety-Integrity LevelsDocument10 pagesEstimation of Average Hazardous-Event-Frequency For Allocation of Safety-Integrity Levelsyka1358No ratings yet

- Human Failure Capitulo 1Document21 pagesHuman Failure Capitulo 1Fernando Alberto Sanguino ArellanoNo ratings yet

- A Risk Reduction Worth Index For Sensitivity Analysis of Motor Protection System ComponentsDocument7 pagesA Risk Reduction Worth Index For Sensitivity Analysis of Motor Protection System ComponentsMohamed KarakacheNo ratings yet

- Safety Class Note - LatestDocument98 pagesSafety Class Note - LatestAshutosh TiwariNo ratings yet

- Safety Hazards Associated With Oil and Gas Extraction ActivitiesDocument5 pagesSafety Hazards Associated With Oil and Gas Extraction ActivitiesNaiduSatyanarayanaNaiduNo ratings yet

- Industrial SafetyDocument19 pagesIndustrial Safety1realestabassNo ratings yet

- Topic One: An Introduction To Health & Safety in IndustryDocument19 pagesTopic One: An Introduction To Health & Safety in IndustrytuNo ratings yet

- 01 02 IntroductionDocument20 pages01 02 IntroductionHendra D'Light WinnerNo ratings yet

- Accident Analysis 2022Document31 pagesAccident Analysis 2022sandaru malindaNo ratings yet

- HSE - Loss Prevention in The Petrochemical and Chemical-Process High-Tech Industries in TaiwanDocument8 pagesHSE - Loss Prevention in The Petrochemical and Chemical-Process High-Tech Industries in TaiwanLandryNo ratings yet

- Chemical Process Safety: ProblemsDocument19 pagesChemical Process Safety: ProblemsBala SubramanianNo ratings yet

- Chapter 1-IntoductionDocument39 pagesChapter 1-IntoductionSatvik SaxenaNo ratings yet

- Introduction To Safety ProcessesDocument5 pagesIntroduction To Safety ProcessesGerry LouNo ratings yet

- Domino Effects in the Process Industries: Modelling, Prevention and ManagingFrom EverandDomino Effects in the Process Industries: Modelling, Prevention and ManagingRating: 3 out of 5 stars3/5 (1)

- Safety Management: University of The East College of EngineeringDocument8 pagesSafety Management: University of The East College of EngineeringAries MalicdemNo ratings yet

- Process Safety and Enviromental Quality CA-Exams1-Exam 2Document13 pagesProcess Safety and Enviromental Quality CA-Exams1-Exam 2Abdoul RahimNo ratings yet

- Applications of 3D QRA Technique To The Fire-Explosion Simulation and Hazard Mitigation Within A Naphtha-Cracking PlantDocument10 pagesApplications of 3D QRA Technique To The Fire-Explosion Simulation and Hazard Mitigation Within A Naphtha-Cracking PlantypzoNo ratings yet

- Chemical Process Safety NotesDocument59 pagesChemical Process Safety NotesRishikesh AwaleNo ratings yet

- Notes98 105Document9 pagesNotes98 105peach5No ratings yet

- CH 4037D Safety in Chemical IndustriesDocument12 pagesCH 4037D Safety in Chemical Industriesfaisal dilshadNo ratings yet

- Guidelines For Quantitative Risk Assessment (Qra) StudyDocument12 pagesGuidelines For Quantitative Risk Assessment (Qra) StudyYanka IlarionovaNo ratings yet

- Process Safety OverviewDocument110 pagesProcess Safety Overview03038100% (1)

- Lecture 2b - Accident ConceptDocument36 pagesLecture 2b - Accident ConceptDivyashini MohanNo ratings yet

- Utm NOTE SAFETY PDFDocument59 pagesUtm NOTE SAFETY PDFFiqa SuccessNo ratings yet

- 2.3.2.3 Hazard Assessment NotesDocument6 pages2.3.2.3 Hazard Assessment Noteskit_mak_5No ratings yet

- UK HSE Plant Ageing Study Ref - No. RR823Document199 pagesUK HSE Plant Ageing Study Ref - No. RR823kzlpNo ratings yet

- Occupational Safety by Zeeshan AhmedDocument68 pagesOccupational Safety by Zeeshan AhmedMazharNo ratings yet

- Guidelines On Quantitative Risk Assessments (Qra) PDFDocument12 pagesGuidelines On Quantitative Risk Assessments (Qra) PDFamandadianNo ratings yet

- Handbook of International Electrical Safety PracticesFrom EverandHandbook of International Electrical Safety PracticesNo ratings yet

- Potential Occupational Health Hazards in The Microelectronics IndustryDocument5 pagesPotential Occupational Health Hazards in The Microelectronics IndustryPhan Thanh HoaNo ratings yet

- Introduction To Chemical Process Safety: Instructor: Dr. Tamaghna Chakraborti Ph. No.: +91 9892770980Document44 pagesIntroduction To Chemical Process Safety: Instructor: Dr. Tamaghna Chakraborti Ph. No.: +91 9892770980Ishaat HussainNo ratings yet

- Glossary of HSE TermsDocument15 pagesGlossary of HSE TermskarunaNo ratings yet

- Toluene Acc First Chemical Corporation (FCC)Document80 pagesToluene Acc First Chemical Corporation (FCC)Ali AbbasovNo ratings yet

- Analysis of 801 Work-Related Incidents in The Oil and Gas Industry That Occurred Between 2014 and 2016 in 6 RegionsDocument16 pagesAnalysis of 801 Work-Related Incidents in The Oil and Gas Industry That Occurred Between 2014 and 2016 in 6 RegionsArun MozhiNo ratings yet

- Prognosis BasicsDocument13 pagesPrognosis BasicsElladaNo ratings yet

- The Safety Critical Systems Handbook: A Straightforward Guide to Functional Safety: IEC 61508 (2010 Edition), IEC 61511 (2015 Edition) and Related GuidanceFrom EverandThe Safety Critical Systems Handbook: A Straightforward Guide to Functional Safety: IEC 61508 (2010 Edition), IEC 61511 (2015 Edition) and Related GuidanceRating: 5 out of 5 stars5/5 (1)

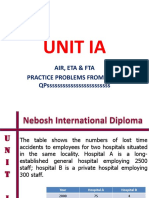

- Unit Ia - Solved ProblemsssssssssssDocument36 pagesUnit Ia - Solved ProblemsssssssssssShabin ShabiNo ratings yet

- Bosh 3-4Document67 pagesBosh 3-4alvin cruzNo ratings yet

- The Bhopal Gas Tragedy..Document4 pagesThe Bhopal Gas Tragedy..Oluwaseun GodsonNo ratings yet

- Reliability Assessment of Offshore Oil WDocument28 pagesReliability Assessment of Offshore Oil WJerome LIKIBINo ratings yet

- Event Tree AnalysisDocument9 pagesEvent Tree AnalysisAmitSinhaNo ratings yet

- Fire Safety Journal Volume 43 issue 8 2008 (doi 10.1016 - j.firesaf.2008.01.002) Mercedes GГіmez-Mares; Luis ZГЎrate; Joaquim Casal - Jet fires aDocument6 pagesFire Safety Journal Volume 43 issue 8 2008 (doi 10.1016 - j.firesaf.2008.01.002) Mercedes GГіmez-Mares; Luis ZГЎrate; Joaquim Casal - Jet fires aigor VladimirovichNo ratings yet

- Recognizing Catastrophic Incident Warning Signs in the Process IndustriesFrom EverandRecognizing Catastrophic Incident Warning Signs in the Process IndustriesNo ratings yet

- Removing Gallstones NaturallyDocument113 pagesRemoving Gallstones NaturallyCorinne Cinco-Cadavis0% (1)

- Project 610530 Epp 1 2019 1 FR Eppka1 JMD MobDocument2 pagesProject 610530 Epp 1 2019 1 FR Eppka1 JMD MobBrew-sam ABNo ratings yet

- SkiMaskDuets - Newsletter Email #6Document3 pagesSkiMaskDuets - Newsletter Email #6afonsovindo22No ratings yet

- Article: Vitamin B12 Deficiency: Case Report and Review of LiteratureDocument6 pagesArticle: Vitamin B12 Deficiency: Case Report and Review of LiteratureSilvia Emy RarasNo ratings yet

- Julie Matthews Practical Nutrition Steps To Better Health Learning BehaviorDocument10 pagesJulie Matthews Practical Nutrition Steps To Better Health Learning BehaviorAlina MilitaruNo ratings yet

- Coronavirus Disease (COVID-19Document1 pageCoronavirus Disease (COVID-19NakamiNo ratings yet

- The Effects of COVID-19 On Cancer Care Provision: A Systematic ReviewDocument29 pagesThe Effects of COVID-19 On Cancer Care Provision: A Systematic ReviewGabriela Araya MedranoNo ratings yet

- Tumor Necrosis Factor Inhibitors in Patients With Takayasu Arteritis: Experience From A Referral Center With Long-Term FollowupDocument5 pagesTumor Necrosis Factor Inhibitors in Patients With Takayasu Arteritis: Experience From A Referral Center With Long-Term FollowupMikhail PisarevNo ratings yet

- Dokumen PDF InggrisDocument14 pagesDokumen PDF Inggris07 Balqis SolekhahNo ratings yet

- Dispensing 1 MCQ 2BDocument22 pagesDispensing 1 MCQ 2Bsybyl formentera100% (1)

- 1Document50 pages1Sujit BhushanNo ratings yet

- Theory of Chronic SorrowDocument13 pagesTheory of Chronic Sorrowrusni rockabilly0% (1)

- Trends in Midwifry and ObstetricsDocument8 pagesTrends in Midwifry and ObstetricsVarna MohanNo ratings yet

- Signs of Vitamin b12 DeficiencyDocument9 pagesSigns of Vitamin b12 DeficiencyMark JonesNo ratings yet

- Fundamentals of NursingDocument21 pagesFundamentals of Nursingjaelrian jaelrianNo ratings yet

- Science: ObjectiveDocument3 pagesScience: ObjectiveOnguene Syntia100% (1)

- Grade 3 DLL Mapeh 3 q1 Week 3Document3 pagesGrade 3 DLL Mapeh 3 q1 Week 3Edza Formentera SasaritaNo ratings yet

- Drink Up To The Juics of LifeDocument1 pageDrink Up To The Juics of LifeErika Schwartz, MDNo ratings yet

- MuetDocument2 pagesMuetcheeNo ratings yet

- Pre EclampsiaDocument17 pagesPre Eclampsiachristeenangela0% (1)

- Evaluation and Management of GlossectomyDocument54 pagesEvaluation and Management of GlossectomyKUNNAMPALLIL GEJO JOHNNo ratings yet

- The Ailing Planet Notes PDFDocument7 pagesThe Ailing Planet Notes PDFMariappan NatarajanNo ratings yet

- Pharmacological Review of AnticoagulantsDocument16 pagesPharmacological Review of AnticoagulantsDiplomski Seminarski RadoviNo ratings yet

- ScabiesDocument6 pagesScabiesJayson ShieldsNo ratings yet

- Health Screenig ServicesDocument36 pagesHealth Screenig ServicesTarachand LalwaniNo ratings yet

- Chronic PainDocument269 pagesChronic PainAdrian Anca100% (4)

- Michelle MDocument4 pagesMichelle MHarlyn MagsinoNo ratings yet

- Literature Review Template DownloadDocument4 pagesLiterature Review Template Downloadaflsigfek100% (1)

- SAG - Emergency Medical Services NC II (Amended 2013)Document5 pagesSAG - Emergency Medical Services NC II (Amended 2013)Jaypz DelNo ratings yet

- Health (Las) - Consumer HealthDocument3 pagesHealth (Las) - Consumer HealthRainier DoctoleroNo ratings yet