Professional Documents

Culture Documents

H2 Embrittlement

Uploaded by

rodneyrlrOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

H2 Embrittlement

Uploaded by

rodneyrlrCopyright:

Available Formats

1

January 2005

HYDROGEN EMBRITTLEMENT OF

PIPELINE STEELS: CAUSES AND

REMEDIATION

P. Sofronis, I. Robertson, D. Johnson

University of Illinois at Urbana-Champaign

Hydrogen Pipeline R&D Project Review Meeting

Oak Ridge National Laboratory, Oak Ridge TN

January 5-6, 2005

2

January 2005

Hydrogen Embrittlement: Long History

M.L. Cailletet (1868) in Comptes Rendus, 68, 847-850

W. H. Johnson (1875) On some remarkable changes

produced in iron and steels by the action of hydrogen acids.

Proc. R. Soc. 23, 168-175.

D. E. Hughes (1880) Note on some effects produced by the

immersion of steel and iron wires in acidulated water,

Scientific American Supplement, Vol. X, No 237, pp. 3778-

3779.

Literature is voluminous

3

January 2005

Hydrogen Embrittlement: Long History

Proc. R. Soc. 23, 168-175, 1875

4

January 2005

Hydrogen Embrittlement: Long History

Proc. R. Soc. 23, 168-175, 1875

5

January 2005

Hydrogen Embrittlement: Definition

Material degradation caused by the presence of hydrogen

under load. It is manifested in

z Strain hardening rate

z Tensile strength

z Reduction in area

z Fracture toughness

z Elongation to failure

z Crack propagation rate

Degraded material often fail prematurely and sometimes

catastrophically after many years of service

Degradation is influenced by

z Microstructure and operating conditions

6

January 2005

Hydrogen-Induced Crack Propagation in IN903

a b c

d e f

0 s 17s 21s

29s 32 s 39s

Static crack in vacuum. Hydrogen gas introduced

thinning

thinning

main

crack

main

crack

Micro-crack

formed

Crack

linkage

7

January 2005

Deformation band

hole

Direction

of crack

advance

Crack Propagation in IN 903 Due to Hydrogen

8

January 2005

Hydrogen Embrittlement Mechanisms

Several candidate mechanisms have evolved each of which is

supported by a set of experimental observations and strong

personal views

Viable mechanisms of embrittlement

z Stress induced hydride formation and cleavage

Metals with stable hydrides (Group Vb metals, Ti, Mg, Zr and their

alloys)

Supported by experimental observations

z Hydrogen enhanced localized plasticity (HELP)

Increased dislocation mobility, failure by plastic deformation

mechanisms

Supported by experimental observations

z Hydrogen induced decohesion

Direct evidence is lacking

Supported by First Principles Calculations (DFT)

Degradation is often due to the synergistic action of mechanisms

9

January 2005

Hydrogen Enhanced Localized Plasticity

(HELP)

Failure is by localized shear processes occurring along slip

planes: shear localization

Transgranular fracture surfaces are highly deformed despite the

fact macroscopic ductility is reduced (localized shear processes

occurring along slip planes)

Intergranular fracture occurs by localized ductility in the region

adjacent to the grain boundaries

Applicable to all systems

z Non-hydride forming systems (Fe, Ni, Al, 304, 310, 316 stainless steel,

Ti

3

Al, Ni

3

Al)

z Hydride forming systems -Ti, -Ti

z Alloy and high purity systems

z Bcc,fcc, hcp

Underlying principle is the hydrogen-induced shielding of the

Interactions between microstructural defects

10

January 2005

Features on Intergranular Surfaces of a

0.28pct C Steel Fractured in Hydrogen

Decrease in the density and

size of ductile features (tear

ridges) as a function of crack

length.

Observations such as these

led Beachem to conclude

that hydrogen impacts

plastic processes.

C. D. Beachem, Met. Trans. 3,437, (1972)

11

January 2005

0

10

20

30

0.00 0.10 0.20 0.30

Hydrogen concentration (H/M)

P

l

a

s

t

i

c

e

l

o

n

g

a

t

i

o

n

(

%

)

Fracture Surface of a Beta 21S Alloy in Absence

of Macroscopic Ductility (Brittle Failure)

12

January 2005

Slip Lines on Brittle Intergranular Facets

310s stainless steel, 5.3 at% H 310s stainless steel, 5.3 at% H

Ulmer and Altstetter, in Hydrogen Effects on Materials Behavior Moody and Thompson, p. 421

13

January 2005

Instrumentation: Controlled Environment

Transmission Electron Microscope

JEOL 4000 Environmental

cell TEM

Objective Lens Pole-piece

D. K. Dewald, T. C. Lee, J. A. Eades, I. M. Robertson and H. K. Birnbaum Review of Scientific Instruments, 62, 1438, 1991.

Aperture

cones

Pumping

port

Specimen

axis

JEOL 4000 Controlled

Environment Transmission

Electron Microscope

CELL

14

January 2005

Instrumentation: Stages and Samples

Single-tilt straining stage Double-tilt straining stage

Single-tilt, low T straining Single-tilt, high T straining

Double-tilt stage Double-tilt, high T stage

15

January 2005

Influence of Hydrogen on Dislocation Mobility

(Fe under constant Load and Increasing H Pressure)

16

January 2005

Dislocation Motion in Fe due to Introduction

of Hydrogen Gas

14:60 14:77 18:50 18:90

20:71 20:60 30:40 30:64

36:41 36:16 38:41 41:21

Increasing hydrogen gas pressure

17

January 2005

Hydrogen Effect on Dislocation Mobility in Ti

18

January 2005

Hydrogen-Deformation Interactions

Solute hydrogen atoms interact with an applied stress field

z Hydrogen-induced local volume dilatation (2cm

3

/mole in Fe)

z Hydrogen-induced local elastic moduli changes (measurements

in Nb)

Solute hydrogen diffuses through normal interstitial lattice

sites (NILS) toward regions of lower chemical potential, i.e.

z Tensile hydrostatic stress

z Softened elastic moduli

19

January 2005

Iso-concentration Contours of Normalized Hydrogen Concentration

around two Edge Dislocations in Niobium as the Separation

Distance Between the Dislocations Decreases

20

January 2005

Effect of Hydrogen Atmospheres around the Two Dislocations:

Shear Stress on Dislocation 2 vs Separation along the Slip Plane

Hydrogen reduces the interaction between dislocations

21

January 2005

Reversibility of Hydrogen Effect on Adding

and Removing Hydrogen

Pressure increase from 15 to 75 torr

Pressure increase from 15 to 75 torr

Pressure decrease from 75 to 9 torr

Material: high-purity Al

black - initial position

white - final position

22

January 2005

Influence of Hydrogen on Dislocation

Separation in a Pile-up (310S Stainless Steel)

23

January 2005

Iso-concentration

countours of normalized

hydrogen concentration

around an edge

dislocation and a carbon

atom with a tetragonal

axis [100]

Carbon atom is modeled

as a stress center with a

tetragonal distortion

Hydrogen-Carbon Interaction

24

January 2005

Shielding of Interaction Between Edge

Dislocation and Carbon Atom

25

January 2005

Hydrogen Effect on Dislocation Cross Slip in Aluminum

An Alternative Explanation of Increasing Slip Localization

Comparison images

Increasing hydrogen pressure constant hydrogen pressure decreasing hydrogen pressure.

Change in line

direction in (c)

indicates cross-slip

process has

initiated.

Cross-slip process

halted due to

hydrogen, (c) and

(d).

Cross slip process

resumes as

hydrogen pressure

reduced (f).

Cross-slip in progress.

Cross-slip process halted.

Cross slip process resumes

26

January 2005

HELP: Conclusions

Hydrogen enhances the mobility of dislocations and

decreases the separation distance between dislocations in

a pile-up

Hydrogen restricts cross-slip by stabilizing edge character

dislocations.

Hydrogen enhances crack propagation rates

Hydrogen reduces the stacking-fault energy of 310S

stainless steel by 20%

27

January 2005

HELP and Hydrogen Embrittlement

5 1

10 s

>

0

/ exp( / )

B

C C W KT =

T>473K

High temperatures

No atmposphere

No hydrogen effect

Ni is not embrittled

B

KT W >

Low temperatures

or high strain rates

Atmosphere lags behind

Both Ni and pure Fe

hardened by hydrogen at

Ni is hardened by

hydrogen at

Pure Fe is hardened at

200K T <

100K T <

Intermediate temperatures

or low strain rates

Atmosphere moves with

dislocation

Shielding Embrittlement

Fe 77 400K T < <

6

1

Ni 200 300K; 10 s T

< < <

At higher strain rates atmosphere

moves but lags behind hardening

Increasing the temperature

gives serrated yielding

473K T >

28

January 2005

Critical Issues for the HELP Mechanism

How does the hydrogen effect on the microscale affect the

mechanical behavior on the macroscale?

How does hydrogen enhance slip localization?

What are the synergistic effects of other solutes on HELP

type fracture, particularly at grain boundaries?

What is the actual mechanism by which the enhanced

plasticity leads to fracture?

z Localized microvoid coalescence (seen in situ TEM)?

z Stroh crack due to compressed pile-ups?

29

January 2005

MODELING OF HELP

Connecting

the microscopic to the

macroscopic

30

January 2005

Initially

homogeneous

deformation

localizes into

a band of

intense shear

Initially

homogeneous

deformation

localizes into

a narrow neck

Modeling of Hydrogen-Induced Instabilities

in Plane Strain Tension

How does hydrogen affect these instabilities?

Important note

Shear band bifurcation or shear

localization is a precursor to

material failure.

Multiplicity of solutions

31

January 2005

Lattice hydrogen

Equilibrium theory

Hydrogen in Equilibrium with Local Stress

and Plastic Strain

Dilatational strain

Flow stress reduction

Elastoplasticity

Problem

is

fully coupled

Solution incremental in time (load)

Stress-Plastic strain

,

0 L kk

C C

| |

|

\ .

Hydrogen trapped

at dislocations

,

p

T L

C C

| |

|

\ .

L T

C C +

0

C

Plastic response assumptions:

Material rate independent

von Mises yielding

Hardens isotropically

H-induced softening

H-induced lattice dilatation

32

January 2005

Condition for Shear Banding Bifurcation

Dependence of the critical and

tangent modulus on the

macroscopic strain for initial

hydrogen concentrations of H/M =

0.1, 0.3, 0.5

h

cr

h

h =

1

3

Y

p

+

Y

c

c

p

|

\

|

.

|

|

( )

( )

( )

( )

( )( )

2

2

2

2

2

0

1 1

2 3

9 1

4 3 1

sin2

24 3 1

cr

II

II

e e

h

N

G

N

O

G G

u

u

| |

|

|

\ .

| |

|

| |

\ .

|

|

\ .

+ + +

= +

+

+ +

equals

0 200 400 600 800

-0.001

0

0.001

0.002

h

h

cr

c

0

=0.1

c

0

=0.3

c

0

=0.5

bifurcation points

22 0

,

cr

h h

III

I

=

22

22

33

January 2005

Critical Strain for Shear Banding Bifurcation

in Plane-Strain Tension

6

28

1

1.88

10.852 10

5.55 10

3.3

29.2

300

3

3

3

cm /mole

=0.174

m /mole

Nbatoms/m

kJ/mole

H

M

L

o

B

V

V

N

a A

W

T K

= =

=

=

=

=

=

=

10 16

0

10 , 2.0 10

0.1

= =

=

0

115 , 0.34

400 , 10

E GPa

MPa n

= =

= =

Present work Rudnicki and Rice(1975)

1

3

( )

3

3

Y Y

p p

p

Y

kk

c

h

c

c c

c

c

K K

u

| |

+

|

\ .

Hydrogen triggers shear localization which could never

happen in the absence of hydrogen in a work hardening

material in plane strain uni-axial tension

Niobium

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7

0

200

400

600

800

1000

22

1

2

shear band

n

22

0

b

0

c

III

I

=

22

22

34

January 2005

x

2

x

1

c

0

c

0

+c

u

2

l

/2 l

s

s

0

x

1

x

2

c

0

c

0

+ c

0

Hydrogen Perturbation and Plastic Instability

Motivation: Hydrogen concentration at grain boundaries

larger than concentration in the bulk of the grain

It has been estimated that in nickel at 253K there is a 70nm grain

boundary zone in which . In this zone high resolution TEM

showed that fracture is a highly localized ductile process

230

zone

bulk

C C =

35

January 2005

Perturbation in H Concentration to Model

Necking Bifurcation in Plane-Strain Tension

1.6000

1.5000

1.4000

1.3000

1.2000

1.1000

1.0000

0 20 40 60

0.0

0.5

1.0

1.5

normalized true stress

normalized force F

2

/(2 w)

0

22

/

0

homogeneous case

c

0

=0.3

c

0

=0.3

c

0

=0.003

22

.

22

.

F

2

c

0

+ c

0

c

0

elastic unloading point

22

=37.2

0

b

1.0200

1.0167

1.0133

1.0100

1.0067

1.0033

1.0000

22 0

/ 29.40 =

22 0

/ 42.92 =

0

0.3 / c H M =

0 0

0.01 c c =

Local flow stress depends

on the local hydrogen concentration

Load attains its maximum at

22 0

28.4 =

36

January 2005

0 0.1 0.2 0.3 0.4 0.5 0.6

32

34

36

38

40

42

with concentration perturbation

with geometric imperfection

Hydrogen Effect on Necking Bifurcation in

Uniaxial Tension

22

0

b

Hydrogen reduces the macroscopic strain at which

necking bifurcation commences

( )

0

/ c H M

37

January 2005

Hydrogen-Induced Decohesion

V,

surface energy

cohesive

r

B =

2

V r

2

H

V r

V

cohesive

Basic premise: hydrogen reduces

the local bond strength which

results in the maximum force

per unit area required to

separate two half solids being

reduced.

Problem: magnitude of the

reduction is not known,

especially under dynamic

fracture conditions.

38

January 2005

Hydrogen-Induced Decohesion

Experimental evidence

z Cohesive energy: Unaffected by H in NbH fracture energy

compared to Nb

z Surface energy: Ni+300ppm H has equal surface free energy to

pure Ni

z Cohesive stress (not measured)

z Phonon frequencies and force constant: Increased by H in Vb

metals

z Bulk modulus: Increased by H in Vb metals

Ab-initio calculations

z Based on equilibrium fracture considerations hydrogen was

found to be a grain boundary embrittler at Ni Sigma 5 (210) GB

z Ideal fracture energy of Fe (110) decreases linearly with H

coverage

39

January 2005

Hydrogen-Induced Fracture of beta-Titanium

as a Function of H Content

P

l

a

s

t

i

c

e

l

o

n

g

a

t

i

o

n

(

%

)

0

10

20

30

0.00 0.10 0.20 0.30

Hydrogen concentration (H/M)

Ductile microvoid

coalescence

Transgranular cleavage

40

January 2005

In situ TEM Deformation of beta-Titanium

No New Hydrides at Crack Tip or Along Flanks

H/M=0.29

41

January 2005

Hydrogen-Induced Fracture of beta-Titanium

No hydrides

No HELP

Sharp decrease in the fracture load

with increasing hydrogen concentration

is consistent with a decohesion

mechanism at the observed

high H/M values

Jokl, Vitek, McMahon

c

K

H

c

K

Ideal work of brittle fracture 7.5

p

p

d

d

n n

= =

A small reduction in brings about a dramatic

reduction of the plastic work for fracture

42

January 2005

Pipeline Steels

Hydrogen Embrittlement

under

High-pressure Gaseous

Hydrogen Environment

43

January 2005

Embrittlement Issues and Phenomenology

Mild steels with yield strength less than 700 MPa and large

fracture toughness

z Hydrogen pressure of at least 14 Mpa for cost equity with natural gas

z Fatigue due to cyclic loading from in-line compressors

z There are no studies of embrittlement under these conditions

Safety design does not allow hoop stress to exceed 80% of yield

stress (plastic collapse approach)

z Cracks propagate before plastic collapse

z Need for an approach based on Elastoplastic Fracture Mechanics

Residual stresses at girth and longitudinal welds

z A weld cannot be efficiently protected by coatings

z Little is known on the interaction between hydrogen solutes and

elastoplasticity in the heat affected zone. Especially in the presence

of hard spots of martensite upon cooling

Stronger steels X-80 and X-100 recently suggested to reduce

thickness and diameter are more susceptible to embrittlement

44

January 2005

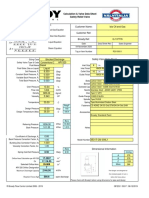

Embrittlement Issues and Phenomenology

No difference in fracture response

between burst and J

IC

testing (Robinson

and Stoltz at A516-70 and A106-B)

z Less cumbersome and less expensive

J

IC

testing

z Hydrogen reduces J

IC

for crack initiation

Critical flaw size may be reduced from

cm in natural gas to mm in high pressure

hydrogen

z Dramatic tenfold loss of crack growth

resistance dJ

IC

/da

Slope dJ

IC

/da was found independent of

hydrogen pressure

Hence supply of hydrogen is fast and not

the rate limiting process

It is the plastic work that controls

hydrogen degradation

z Crack growth resistance dJ

IC

/da impacts

the stability of crack advance

z Fracture behavior needs to be

investigated

2

2

2

2

Air

3.45 MPa H

6.90 MPa H

20.7 MPa H

34.5 MPa H

D

,

+

,

Robinson and Stoltz

Hydrogen Effects in Metals, 1981, pp-987-995

IC

2

J

in lb

in

| |

|

\ .

( )

a in

1500

1250

1000

750

500

250

0.01 0.02 0.03 0.04 0.05

45

January 2005

Embrittlement Issues and Phenomenology

Fractographic evidence suggests

z Hydrogen-assisted transgranular fracture by void or

microcrack initiation through decohesion at second phase

particles (precipitate/inclusion) ahead of a crack or notch

accompanied by shear localization (HELP) leading to the

linking of the void/microcrack with the tip of crack

z Intergranular cracking in welds by hydrogen-induced lowering

of grain boundary or matrix/carbide interfacial cohesion in the

HAZ

Our contention, which needs to be verified through experiment, is

that embrittlement is a result of the synergistic action of the HELP

and decohesion mechanisms

46

January 2005

Identify mechanisms of failure

z Transgranular vs intergranular

z Role of inclusions and precipitates

z Fatigue or static loading conditions

Explore for optimum microstructure

z Tempered bainite or tempered martensite superior to pearlitic or

pearlite-ferrite steels with speroidized in between

z C: increasing H content gives higher strength but higher H

susceptibility

z Mn : ferrite strengthener but reduces fracture toughness in H

z Si: potent ferrite strengthener, neutral to H, problems with formability

and weldability

z Ti and Ni: alloying additions may help

z Morphology and volume fraction of inclusions is controlled by S

levels

z Silicon steel rather than manganese with fine spheroidized

carbides may be a promising system to explore

Objectives

47

January 2005

Objectives (Contd)

Model the failure processes

Provide an insight to the critical flaw size and its stability

Device a fracture criterion with predictive capabilities for the

incubation period in subcritical crack growth and remnat life of the

pipeline

Study the viability of using high strength steels

z H incompatibilty increases with strength

48

January 2005

Objectives (Contd)

Mitigate hydrogen embrittlement by adding water vapor in the

transported hydrogen

z Water vapor is cheap

z Water vapor is separated easily at final destination stations through

cooling

z Water vapor lowers crack growth rates (Robinson, Wei)

Reaction Fe+O FeO is 10

8

faster than Fe+H

2

O FeO+H

2

O (inhibitor of crack growth) and H (promoter of crack growth)

compete for adsorption sites on the metal surface

z At high transport pressures it is expected that the surface reactions

will not be the controlling step. Embrittlement depends on the

transport of hydrogen

z Effects of water vapor or O need to be carefully explored in particular

at high pressures

49

January 2005

Objectives (Contd)

Understand the hydrogen or water vapor effects on interfacial

cohesion by

z studying the fracture of a thin film attached to a substrate or

z through using hour-glass radiused uniaxial tension specimens

50

January 2005

OUTLINE OF AN EXAMPLE

STUDY

Transgranular Cracking

Initiation - Propagation

51

January 2005

Modeling of Ductile Transgranular Fracture: Initiation

Hydrogen concentration

set by the adsorption

surface reactions

X

1

X

2

Crack tip

Crack face

Crack tip

T

i

=

K

I

2R

f

ij

( )n

i

n

Hydrogen flux to the

fracture process zone

J

H

R

C = C

0

C = C

0

J

H

= 0 X

1

X

2

Boundary concentration

of hydrogen

X

2

X

1

J

H

J

H

r

MACRO

MESO

MICRO

Hydrogen mixed with

water vapor

Surface reactions

that release

hydrogen and oxygen

inclusion

Hydrogen

atmosphere

Zone of intense shear

Decohesion at inclusion

Void formation

Linking with crack through shear banding

Fracture mechanisms assisted by

transient hydrogen adsorption and diffusion

52

January 2005

Modeling of Ductile Transgranular Fracture: Initiation

Address the role of significant parameters, such as

z Material flow characteristics

z Material trapping characteristics (type of traps, trap density, and binding energy)

z Hydrostatic stress

z Plastic strain

z Hydrogen concentration

z Loading rate

z Loading in terms of the applied J-integral

z Adsorption kinetics (ab-initio modeling)

z Cohesive properties of the inclusion/matrix interface (ab initio)

z Lattice cohesion in a direction perpendicular to the slip band (ab-initio)

z Effect of water vapor or other crack growth inhibitors

Hydrogen boundary conditions on the crack face are set by the local

adsorption kinetics

z Assumption of first order kinetics leads to hydrogen coverage

( ) ( )

1

1

h h o o o h h

k p k p

+ = +

53

January 2005

Modeling of Ductile Transgranular Fracture: Propagation

X

-1 0 1 2

0

0.5

1

1.5

2

K

I

(disp.)

R=2m

Hierarchical Modeling

200umx200um

Crack tip:

Fracture Process zone

X

0 0.5 1

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

Cohesive elements characterized by

a traction-separation law based on the void

cell model

54

January 2005

Modeling of Ductile Transgranular Fracture: Propagation

X

Y

0 0.5 1

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

1.1

1.2

X

0 0.5 1

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

1.1

X

Y

0 0.5 1

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

1.1

X

0 0.5 1

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

1.1

X

0 0.5 1

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

X

0 0.5 1

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

1.1

1.2

X

0 0.5 1

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

1.1

Initial void volume fraction f

0

=0.001, Triaxiality=3

X

0 0.5 1

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

X

0 0.5 1

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

X

0 0.5 1

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

1.1

No hydrogen

With hydrogen

/ 3

initial ref

L L

c c =

E

e

=2.5% E

e

=5.0% E

e

=7.5% E

e

=10% E

e

=15%

EP

2

1.8

1.6

1.4

1.2

1

0.8

0.6

0.4

0.2

0

Material Data for A533B Pressure Vessel Steel

55

January 2005

Modeling of Ductile Transgranular Fracture: Propagation

0.0

1.0

2.0

3.0

4.0

5.0

0 0.5 1 1.5

U

33

/D

3

3

/

0

No hydrogen

T=1.0

T=1.5

T=2.0

T=2.5

T=3.0

T=3.5

T=4.0

f

0

=0.001

11 22 33 33 11

/ , ( ) / 3,

m e m e

T = = + + =

33 33

, U

11 11

, U

Axisymmetric

Model

Void shape at high T

Void shape at low T

Peak stress controls initiation

J

IC

Area underneath controls R-Curve

dJ

IC

/da

Material Data for A533B Pressure Vessel Steel

56

January 2005

Modeling of Ductile Transgranular Fracture: Propagation

0

1

2

3

4

5

0 0.1 0.2 0.3 0.4

u33

3

3

/

y

No hydrogen

Smin=0.9Sy

Smin=0.7Sy

Smin=0.5Sy 0

0 0

0

0

[ ] ,

( 1) 1 1

[ ]

1

y

N

y

N

if softening effect then

c

c

else

softening effect

| |

= + +

|

\ .

<

| |

= +

|

\ .

Softening model

f

0

=0.001, T=3, HCon=3

2

max 0 0

2

max 0 0

2

max 0 0

2

max 0 0

: / 4.32, 58.2 kJ/m ( 200 )

( 0.9) : / 3.91, 51.3 kJ/m (88%)

( 0.7) : / 3.81, 36.8 kJ/m (63%)

( 0.5) : / 3.77, 27.4 kJ/m (

without softening D m

with softening

with softening

with softening

u

= = =

= = =

= = =

= = = 47%)

Material Data for A533B Pressure Vessel Steel

Peak stress controls initiation

J

IC

Area underneath controls R-Curve

dJ

IC

/da

57

January 2005

SUMMARY AND CONCLUSIONS

Hydrogen Embrittlement

z Direct experimental evidence and solid mechanics finite element

calculations support the hydrogen enhanced localized plasticity

mechanism as a viable mechanism for hydrogen embrittlement

z Indirect experimental evidence, thermodynamic considerations,

and ab-initio calculations indicate that hydrogen-induced

decohesion can also be a viable mechanism of hydrogen

embrittlement

Pipelines

z It appears that do have the capability of assessing whether

existing structural material systems can be used for hydrogen

transport

z Advanced knowledge and technology are available for the design

of new structural materials with hydrogen compatibility

You might also like

- Sa 420Document10 pagesSa 420Widya widyaNo ratings yet

- File - 4houldcroft Weldability Test of Aluminium Alloy EN AW 6082 T6 7 - Part - 254-1Document8 pagesFile - 4houldcroft Weldability Test of Aluminium Alloy EN AW 6082 T6 7 - Part - 254-1Corey DodsonNo ratings yet

- Case Study - Knockout DrumDocument2 pagesCase Study - Knockout DrumAshfaq AnwerNo ratings yet

- Miter Bend Calculation: E W S D T' BDocument4 pagesMiter Bend Calculation: E W S D T' BSong TaoNo ratings yet

- Typical Specification For Steam Surface Condensers Appendix ADocument5 pagesTypical Specification For Steam Surface Condensers Appendix Ahappale2002No ratings yet

- Pressure Drop Via The Karman MethodDocument2 pagesPressure Drop Via The Karman MethodAtul kumar KushwahaNo ratings yet

- Anodes in Cooling Water Exchangers PDFDocument12 pagesAnodes in Cooling Water Exchangers PDFcbrittaivNo ratings yet

- Thread Data ChartsDocument4 pagesThread Data Chartsrasinv100% (1)

- IMIOrton MV SeriesDocument4 pagesIMIOrton MV SeriesFelipe Gamboa GálvezNo ratings yet

- Material Data Sheet en Aw 6082 Almgsi1Document1 pageMaterial Data Sheet en Aw 6082 Almgsi1pankajrs.mechengineer4502No ratings yet

- Design Requirements For Pressure Safety Relief ValvesDocument5 pagesDesign Requirements For Pressure Safety Relief Valvesvela vanNo ratings yet

- Pipe Wall Thickness Calculations: Burnex Burner HeadDocument16 pagesPipe Wall Thickness Calculations: Burnex Burner Headpramodptvpm_65797156No ratings yet

- Sizing CalcDocument1 pageSizing CalcHilary AbaratuNo ratings yet

- Material Information Sheet For Plates: Erndtebrücker EisenwerkDocument2 pagesMaterial Information Sheet For Plates: Erndtebrücker EisenwerkAhmad KamilNo ratings yet

- Control Valve Technical Specification Sheet Globe Service: GasDocument1 pageControl Valve Technical Specification Sheet Globe Service: Gassiddhesh_guessNo ratings yet

- ATEC Cyclone Datasheet EnglDocument1 pageATEC Cyclone Datasheet EnglDilnesa EjiguNo ratings yet

- Bulk Air Eliminator R1Document1 pageBulk Air Eliminator R1hydrothermsNo ratings yet

- WHRB-265!08!00 Front and Rear Mirrors, Shell CalculationDocument2 pagesWHRB-265!08!00 Front and Rear Mirrors, Shell CalculationmehmacarNo ratings yet

- Aluminium en AW 6082Document3 pagesAluminium en AW 6082doshi78No ratings yet

- Vetrolux Din 11851Document1 pageVetrolux Din 11851uptc1985No ratings yet

- Butterfly Torque Selection GuideDocument3 pagesButterfly Torque Selection Guidedragon2065No ratings yet

- Filter Design Data (24 Oct20)Document2 pagesFilter Design Data (24 Oct20)Hedi Ben MohamedNo ratings yet

- Tube Bundle DrawingDocument1 pageTube Bundle DrawingVeera ManiNo ratings yet

- BZ 8009372 PDFDocument22 pagesBZ 8009372 PDFizia_2No ratings yet

- What Is An ASME Appendix 2 Flange Design PDFDocument1 pageWhat Is An ASME Appendix 2 Flange Design PDFMangesh BanaleNo ratings yet

- Side Mounted HandwheelDocument20 pagesSide Mounted HandwheelaaaNo ratings yet

- Load On Vessel Calculation: Distance From Base Line To Center of VesselDocument6 pagesLoad On Vessel Calculation: Distance From Base Line To Center of Vesselทนงศักดิ์ วิไลพันธ์No ratings yet

- FDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Document15 pagesFDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Gisela ViskaNo ratings yet

- Spec No / Name Unsno/ Numeric Norm Form Class Condition: Material Database ReportDocument16 pagesSpec No / Name Unsno/ Numeric Norm Form Class Condition: Material Database ReportRafeek ShaikhNo ratings yet

- Norma Pipe Connections DIN-11864Document17 pagesNorma Pipe Connections DIN-11864bioNo ratings yet

- A571 PDFDocument6 pagesA571 PDFMahendra PatilNo ratings yet

- Gas Processors Suppliers Association GPSA Eng (Bookos - Org) - 701-821!1!60!1!20Document20 pagesGas Processors Suppliers Association GPSA Eng (Bookos - Org) - 701-821!1!60!1!20Karen Vl100% (1)

- En10028 2Document12 pagesEn10028 2Patilea Daniela100% (1)

- Pig Trap End Closure105671465 PDFDocument24 pagesPig Trap End Closure105671465 PDFashishNo ratings yet

- TAYLOR FORGE - SIF CALCS - ES 3.9.2 r0, Design & Forming of Extruded OutletsDocument6 pagesTAYLOR FORGE - SIF CALCS - ES 3.9.2 r0, Design & Forming of Extruded OutletsDDNo ratings yet

- Normal Design: Depressurize From Design Pressure To 50% in 15 MinutesDocument2 pagesNormal Design: Depressurize From Design Pressure To 50% in 15 Minutesmatteo2009No ratings yet

- Why Stainless Steel Rust - Corrosion - Part 2 - Other CorrosionDocument12 pagesWhy Stainless Steel Rust - Corrosion - Part 2 - Other CorrosionViệt Đặng XuânNo ratings yet

- Tema StandardsDocument1 pageTema Standardsjose_alberto2No ratings yet

- Corrosion Resistance Chart: Metal Non-Metal Gasket/Seal MaterialDocument6 pagesCorrosion Resistance Chart: Metal Non-Metal Gasket/Seal MaterialFreddyPerazaNo ratings yet

- Material STDDocument36 pagesMaterial STDmagarmat1980No ratings yet

- Flow and CV Calculation ToolDocument3 pagesFlow and CV Calculation Toolmohan babuNo ratings yet

- 4 2500 (F347H)Document2 pages4 2500 (F347H)siddhesh_guessNo ratings yet

- AS-Interface: The Simple System SolutionDocument25 pagesAS-Interface: The Simple System SolutionJoaquín PérezNo ratings yet

- Materials Comparison DIN / EN / ASTM: Finished PartsDocument6 pagesMaterials Comparison DIN / EN / ASTM: Finished PartsBittuNo ratings yet

- Face-To-Face Valve Dimensions - EN-558-1: DN Basic SeriessDocument3 pagesFace-To-Face Valve Dimensions - EN-558-1: DN Basic Seriessdona_001No ratings yet

- Product Date Sheet - Swagelok BrocureDocument6 pagesProduct Date Sheet - Swagelok BrocurejulianpirahNo ratings yet

- Iso 15552 2004 en PDFDocument8 pagesIso 15552 2004 en PDFashokkumarNo ratings yet

- CalcvesselDocument11 pagesCalcvesselHami Keserci100% (1)

- MS 01 168Document12 pagesMS 01 168Rawn BushNo ratings yet

- Nozzle Development For AerosolsDocument38 pagesNozzle Development For Aerosolsemre sönmezNo ratings yet

- Flame Arrester - Technical DetailsDocument16 pagesFlame Arrester - Technical DetailsAnonymous 3DHogINo ratings yet

- Sagging of The Pipe (F) Between 2 Pipe Clamps (1/"?") X LDocument7 pagesSagging of The Pipe (F) Between 2 Pipe Clamps (1/"?") X LEdwardhutaurukNo ratings yet

- Thermal Degassing Fundamentals R4i1 enDocument6 pagesThermal Degassing Fundamentals R4i1 enAnonymous v5uipHNo ratings yet

- Volum Water HydrotestDocument2 pagesVolum Water HydrotestFerinoviardi100% (1)

- API 650 RF Pad Calculation PDFDocument1 pageAPI 650 RF Pad Calculation PDFBimal DeyNo ratings yet

- Heat Exchanger Gaskets 1 PDFDocument2 pagesHeat Exchanger Gaskets 1 PDFMuhammad Aftab AhmedNo ratings yet

- Api 5l Test PressrureDocument2 pagesApi 5l Test PressrureSıddık SarıcalarNo ratings yet

- Kennell - 2008 - CS - A Critical Crevice Solution and IR Drop Crevice Corrosion ModelDocument10 pagesKennell - 2008 - CS - A Critical Crevice Solution and IR Drop Crevice Corrosion ModelKassia Cristina Kafer EscherNo ratings yet

- Paper RPCMOD2007Document10 pagesPaper RPCMOD2007Jorge_UFCGNo ratings yet

- The Effect of Nickel Content On The Environmental in Low Alloy SteelDocument37 pagesThe Effect of Nickel Content On The Environmental in Low Alloy Steelmohit madaviNo ratings yet

- Ferro CementDocument236 pagesFerro Cementpbharadwaj545No ratings yet

- Sae Ams 4353-2014Document5 pagesSae Ams 4353-2014Hani YilmazNo ratings yet

- "Failure: Another Iteration" by Ander MonsonDocument8 pages"Failure: Another Iteration" by Ander Monsonalex647No ratings yet

- Leak Off TestDocument80 pagesLeak Off Testb4rfNo ratings yet

- Review of Design Code Provisions On Externally Strengthened Concrete Structures With FRP LaminatesDocument11 pagesReview of Design Code Provisions On Externally Strengthened Concrete Structures With FRP LaminatesRishika DixitNo ratings yet

- Rilem TC 162-Tdf: Test and Design Methods For Steel Fibre Reinforced ConcreteDocument17 pagesRilem TC 162-Tdf: Test and Design Methods For Steel Fibre Reinforced ConcreteJaniele MoreiraNo ratings yet

- Abaqus Output Variable IdentifierDocument215 pagesAbaqus Output Variable Identifiermithun5v5v5No ratings yet

- 7064 - M J Maqina - Research ProjectDocument23 pages7064 - M J Maqina - Research ProjectMlungisi Thekiso Ka-MaqinaNo ratings yet

- Aci 533r-93-Precast Wall PDFDocument56 pagesAci 533r-93-Precast Wall PDFSubashini JaganathanNo ratings yet

- Polyurea EbookDocument39 pagesPolyurea EbookJesus De la Rosa100% (1)

- Post Weld Heat TreatmentDocument1 pagePost Weld Heat TreatmentvijayachiduNo ratings yet

- Charpy Impact TestDocument6 pagesCharpy Impact Testanil chejara83% (6)

- Introduction To Offshore Structures-PART-3Document22 pagesIntroduction To Offshore Structures-PART-3RUDHRA DHANASEKAR100% (1)

- ISRM Suggested MethodsDocument4 pagesISRM Suggested MethodsSankar Cdm100% (2)

- Gorash Y Mackenzie D Pure Safe Structural Design For Fatigue and Creep Using Cyclic Yield Strength May 2014Document12 pagesGorash Y Mackenzie D Pure Safe Structural Design For Fatigue and Creep Using Cyclic Yield Strength May 2014sezgin bayramNo ratings yet

- German Atv StandardsDocument16 pagesGerman Atv StandardsMehmet Emre Bastopcu0% (1)

- STP 1576-2015Document268 pagesSTP 1576-2015HieuHTNo ratings yet

- FRP Reinforced Spun Concrete Poles Flexure Jan 15 3Document11 pagesFRP Reinforced Spun Concrete Poles Flexure Jan 15 3luchyl100% (1)

- Approval Standard For Explosion Venting SystemsDocument15 pagesApproval Standard For Explosion Venting Systemsrafael1978No ratings yet

- National Transportation Safety BoardDocument3 pagesNational Transportation Safety BoardDita FebrianaNo ratings yet

- 7.4. Plasticity Modeling: Softening Behavior 383Document1 page7.4. Plasticity Modeling: Softening Behavior 383ahmed shakerNo ratings yet

- Chapter 8: Failure: Issues To Address..Document27 pagesChapter 8: Failure: Issues To Address..Rowen PratherNo ratings yet

- Toughness of Old Mild SteelDocument8 pagesToughness of Old Mild SteelArya Scout Bilspensam JambudNo ratings yet

- Phmsa Final Summary Erw Seam Failures 1Document98 pagesPhmsa Final Summary Erw Seam Failures 1deogmozyxNo ratings yet

- Example j.7 Base Plate Bearing On ConcreteDocument19 pagesExample j.7 Base Plate Bearing On ConcreteBachtiar MahardikaNo ratings yet

- Tavares Kona 2022Document23 pagesTavares Kona 2022Vicente RodriguezNo ratings yet

- Design Standards For Railway Structures and Commentary (Concrete Structures) 2007-03 (OCR)Document25 pagesDesign Standards For Railway Structures and Commentary (Concrete Structures) 2007-03 (OCR)Huan Nguyen100% (3)

- Materials: Parametric Formula For Stress Concentration Factor of Fillet Weld Joints With Spline Bead ProfileDocument19 pagesMaterials: Parametric Formula For Stress Concentration Factor of Fillet Weld Joints With Spline Bead ProfilevincemugnaioNo ratings yet

- Strut-and-Tie Models Using MulDocument16 pagesStrut-and-Tie Models Using MulwambuigraduationphotosNo ratings yet

- An Overview of The API Section 10Document18 pagesAn Overview of The API Section 10api-3855165100% (1)