Professional Documents

Culture Documents

SLR English Exe - Summary

Uploaded by

balaasenthilOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SLR English Exe - Summary

Uploaded by

balaasenthilCopyright:

Available Formats

Summary of the Final EIA Report

M/s Nirani Cements Pvt.Ltd

SUMMARY OF THE FINAL ENVIRONMENTAL IMPACT ASSESSMENT REPORT

Prepared for

PROPOSED PIG IRON COMPLEX

(33 m2 Sinter Plant, 262 m3 Pig Iron Plant and 6 MW Captive Power Plant)

at Sy Nos. 44, 632 to 652, Narayanadevevanakere Village, Hagaribommanahalli Taluk, Bellary District, Karnataka.

Prepared by

ENVIRONMENTAL HEALTH & SAFETY CONSULTANTS # 529, Shanthashree Nivaasa, 15th main, 1st stage, 3rd block, Manjunatha Nagar, Bangalore-560 010. Tele/Fax: 080 23226484

EHS Consultants, Bangalore.

Summary of the Final EIA Report

M/s SLR Metaliks Ltd

CHAPTER-1.0 PROJECT DESCRIPTION 1.1 Introduction M/s SLR Metaliks Ltd (SLR), incorporated on November 17, 2005 propose to set up a 33 m3 Sinter Plant, 262 m3 Blast Furnace with Waste gas based Captive Power Plant (CPP) of 6 MW capacity at Sy Nos. 44, 632 to 652, Narayanadevanakere Village, Hagaribommanahalli Taluk, Bellary District, Karnataka State. The other group companies of M/s SLR are M/s SLR Steels Ltd., A.R. Co-extruded Films Ltd., A.R. Plastics Pvt. Ltd., Raj Polypack Pvt. Ltd., Goel Polypack Pvt. Ltd., and INS Finance and Investment Pvt. Ltd. M/s SLR are already engaged in the business of manufacturing and selling of Pig Iron. Its plant at Parmenhally village, Hiriyur Taluk, Chitradurga District consists of 262 m3 mini Blast Furnace and related facilities including a Captive Power generation through the use of Blast Furnace gas.

EHS Consultants, Bangalore.

Summary of the Final EIA Report

M/s SLR Metaliks Ltd

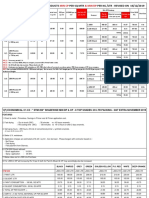

Table 1.1: Salient features of the proposed project and project site

Sl.No Features 1 Location

Particulars Sy Nos. 44, 632 to 652, Narayanadevanakere Village, Hagaribommanahalli Taluk, Bellary District, Karnataka State.

Objective of the Project

The proposed project is a Pig Iron Complex involves the production of Sinter, Pig Iron envisaging major

technological units such as Sinter Plant (1 X 33 m2), Blast Furnace (1X262 m3 useful volume), Pig Casting Machine (2X500 TPD) and Captive Power Plant (1X6 MW). 3 4 5 Promoters Total Investment Extent of land M/s SLR Metaliks Ltd. Estimated Capital Cost 146.77 Crores 90 Acres (35.43 Hectares) 6 Category of Project Schedule 3 (a), Category A of EIA Notification dated 1409-2006. 7 8 Man Power Raw Materials About 200 direct Employees Raw materials required are Iron Ore lump, Imported Coke, Quartzite, Lime Stone, Dolomite and Manganese ore. Iron Bearing waste materials like iron ore fines2,20,499 TPA from Waste from this plant, and also from Bagalkot, Sandur and Bellary region Iron Ore Lump - 10-40mm (BF Grade) 1,30,421 TPA to be procured from Sandur and BellaryHospet region, Karnataka. EHS Consultants, Bangalore. 2

Summary of the Final EIA Report

M/s SLR Metaliks Ltd

Limestone 10-40mm (BF Grade) 31,129 TPA to be procured from Bagalkot/Local sources,

Karnataka. Dolomite 10-40mm (BF Grade) 14,267 TPA to be procured from Bagalkot/Local sources,

Karnataka. Manganese Ore lump 10-40mm (BF Grade) to be procured from Sandur mines of Bellary region, Karnataka. Quartzite 10-40mm (BF Grade) to be procured from Saundatti, Karnataka. Manganese Ore lump and Quartzite used as additives-10,500 TPA Metallurgical Coke 20-60mm 128,333 TPA will be imported. 9 Water demand and Source 10 Power supply The estimated power requirement for the proposed plant is 4.2 MVA and Annual Energy consumption is 35 M kWH. It will be met from new 1 X 6 MW Captive Power Plant. Additionally, 1 X 1 MW D.G set is proposed to take care of emergency conditions. Also, connection will be taken from nearest 66kV grid substation through single circuit overhead line. 11 By products/ solid wastes Sinter fines and Fine dust Slag, Flue Dust and sludge Domestic Solid waste (Garbage/ Trash/ garden litters) EHS Consultants, Bangalore. 3 2220 KLD from Tungabhadra Reservoir

Summary of the Final EIA Report

M/s SLR Metaliks Ltd

12 13

Nearest Town Nearby Industry

Hospete 15 Km, NE Direction BMM Ispat Steel Ltd - Located at a distance of about 12

(with in 25 km radius) Kms from the proposed project site in the Eastern direction. Sandur Manganese and Iron Ore (closed Unit)- Located at about 17 Km from the proposed project site. 14 15 16 Latitude Longitude Altitude 150110.6.0 N 7601853.7 E 1180 feet above MSL

1.2 Raw Material Requirements Table 1.2 Estimated annual requirement of major raw materials Sl.No Gross Annual Source Requirement (TPA) Iron Bearing waste < 6 mm 220499 Waste from this plant, materials like iron ore Bagalkot, Sandur and Bellary fines region Flue Dust < 6 mm 3400 Waste from this plant, Bagalkot, Sandur and Bellary region Waste from this plant, Bagalkot, Sandur and Bellary region Blast Furnace Raw Material Size (mm)

1.

Coke Breeze

< 6 mm

15564

Return sinter

Blast

Furnace < 6 mm

38912

5 6 7

Iron Ore (BF Grade) Limestone (BF Grade) Dolomite (BF Grade)

10-40 10-40 10-40

130421 31129 14267

Sandur and Bellary-Hospet, Karnataka Bagalkot/Local sources, Karnataka Bagalkot/Local sources, Karnataka 4

EHS Consultants, Bangalore.

Summary of the Final EIA Report

M/s SLR Metaliks Ltd

8 9 10

Manganese ore lump (BF Grade) Quartzite (BF Grade) Metallurgical Coke

10-40 10,500 10-40 20-60 133,900

Sandur Mines of region, Karnataka Saundatti, Karnataka Import

Bellary

1.3 Technology & Manufacturing Process 1.3.1 SINTER PLANT Sintering is a technology for agglomeration of iron ore fines into useful Blast Furnace burden material. The raw materials used in sinter plant are - Iron ore fines (-10 mm), coke breeze (-3 mm), Lime stone & dolomite fines (-3mm) and other metallurgical wastes. The proportioned raw materials are mixed and moistened in a mixing drum. The mix is loaded on sinter machine. The top surface of the mix is ignited through stationary burners at approximately 1200 0C. Sinter is produced as a combined result of locally limited melting, grain boundary diffusion and recrystallisation of iron oxides. On the completion of sintering process, finished sinter cake is crushed and cooled.

1.3.2 BLAST FURNACE The blast furnace shop will comprise one furnace of 262 m3 useful volume and two single strand pig casting machine of around 500 t/d each strand capacity The blast furnace is envisaged to operate with sized lump iron ore, coke, fluxes and additives. The hot metal produced will be casted in pig casting machine to produce cold pigs. The liquid slag will be granulated at cast house granulation unit. The BF top gas will be cleaned in dust catcher and gas cleaning system and distributed to the stoves, burners for runner drying, boilers for process and process steam

EHS Consultants, Bangalore.

Summary of the Final EIA Report

M/s SLR Metaliks Ltd

supply. The excess BF gas will be supplied to 1X 6 MW power plant for power generation.

1.3.4 Pig casting machine For casting the hot metal into cold pigs a double strand pig casting machine of capacity 500 t/d per strand has been envisaged. The pig casting machine will be equipped with lime milk spray system, water spray for pigs cooling etc. The pigs will be discharged to pig storage yard. Hydraulic tilting arrangement has been envisaged for pouring of hot metal in to Pig casting machine for efficient operation.

1.3.5 CAPTIVE POWER PLANT Based on the above requirements, following facilities have been envisaged for power plant. Captive Power Plant mainly consists of 1 X 40 TPH blast furnace gas fired boiler and auxiliaries 1X 6 MW turbo-generators and auxiliaries Deaerators Boiler feed pumps Electrics and Instrumentation & controls

EHS Consultants, Bangalore.

Summary of the Final EIA Report

M/s SLR Metaliks Ltd

CHAPTER-2.0 DESCRIPTION OF THE ENVIRONMENT The proposed site for the pig iron complex comprising of Sinter plant, Mini Blast Furnace, Pig Casting Machine and Captive Power Plant is located at Sy Nos. 44, 632 to 652, Narayanadevevanakere Village, Hagaribommanahalli Taluk, Bellary District, Karnataka. The site is bounded by Tunga Bhadra back waters and villages like Lokappana hola village, Venkatapuram Colony at a distance of around 2-5 kms from the proposed pig iron complex. Hospete Harihar State Highway is located at a distance of about 5 kms in the Southern direction; NH13 is located at a distance of about 6 kms from the proposed project site in Eastern Direction. The plant is located at around 85 kms from Bellary town, which is proximate to rich deposits of Iron ore at Bellary, Hospet & Sandur area to provide an assured and continuous supply of raw materials. Well known fact that Karnataka is the richest in terms of mineral potential in the country, with large deposit of Iron ore. Considering the demand for steel and steel products, the company proposes to encash the opportunity and therefore has proposed to set up a pig iron complex consisting of 33 m2 Sinter Plant, 262 m3 Blast Furnace with waste gas based 6MW Captive Power Plant.

The location is very well connected by Road & Rail. Moreover, the unit will further add to the Economy of the state and provide additional employment to the people of neighboring villages.

EHS Consultants, Bangalore.

Summary of the Final EIA Report

M/s SLR Metaliks Ltd

Table 2.1: Environmental Settings around the proposed project site (Within 10 Kms Radius) Sl.No Description Details 1 Nearest Water body Tungabhadra backwater at 2 Kms from the proposed plant site towards Northern Direction. Dhayanakana kere at 7.5 Kms from the proposed plant site towards south. 2 Nearest Railway line South Central Railway Line (Vyasanakere Railway station) - 9.3 Kms in North East Direction 3 Nearest Heritage site Hampi World heritage site Located at a distance of about 30 Kms from the proposed project site. 4 Nearest National park / Reserved Forest Gunda Reserved Forest - Located at a distance of about 8.0 Kms from the proposed project site in the North Eastern direction. Nandi Banda Reserved Forest- Located at a distance of about 8.5 Kms from the proposed project site in the Southern direction. Ramgad Reserved Forest- Located at a distance of about 9.5 Kms from the proposed project site in the Eastern direction. 5 6 7 8 Nearest Biosphere Reserve Nearest Wildlife Sanctuary Nearest Defense Installation Nearest Highway Nil Nil Nil SH-25 : Hospet Harihar State Highway Located at a distance of about 5 Kms from the proposed project site in Southern direction. NH-13 -Located at a distance of about 8 Kms from the proposed project site in Eastern direction. EHS Consultants, Bangalore. 8

Summary of the Final EIA Report

M/s SLR Metaliks Ltd

10

Nearest densely populated place

Hosapet 15 Kms in North Eastern direction.

12

Nearest Village

Lokappanahola village - Located at a distance of about 2.0 Kms from the proposed project site.

EHS Consultants, Bangalore.

Summary of the Final EIA Report

M/s SLR Metaliks Ltd

CHAPTER - 3.0 ANTICIPATED ENVIRONMENTAL IMPACTS & MITIGATION MEASURES

Table 3.1: EMP for Construction Phase Impacts "Site Clearing" Environmental Impacts Soil erosion Extent of vegetation removal Implementation shall be minimized to prevent responsibility: extent of soil erosion. Vegetative cover shall be Contractor M/s SLR Metaliks Ltd. Mitigation Remarks

reprojected /rehabilitated at the earliest practicable time to minimize duration & extent of soil erosion. Noise generation

Selection of equipment with Implementation less noise generation to be responsibility: used. Contractor M/s SLR Metaliks Ltd.

The earth moving equipment shall be periodically checked and maintained for noise

levels. Since the site is more or less even use of these earthmoving equipments may not be necessary. The workers shall be provided with adequate PPE such as earplugs to reduce impact of high noise levels. Dust The site cleared shall be Implementation 10

EHS Consultants, Bangalore.

Summary of the Final EIA Report

M/s SLR Metaliks Ltd

generation

periodically watered to reduce responsibility: emission of dust particles. The workers shall be provided with PPE such as nose masks and goggles to reduce impact on health. Contractor M/s SLR Metaliks Ltd.

Table 3.2: EMP for Construction Phase Impacts "Transportation of Construction Materials Environmental Impacts Noise generation

Mitigation

Remarks Implementation

Periodic maintenance of responsibility: vehicles is required Contractor M/s SLR

Metaliks Ltd. Dust generation Construction shall be materials Implementation with responsibility: Contractor M/s SLR

covered

tarpaulin sheets to prevent the material from being air borne. The vehicle speed shall be regulated. The workers transporting materials shall be

Metaliks Ltd.

provided with PPE such as nose asks to reduce impact

EHS Consultants, Bangalore.

11

Summary of the Final EIA Report

M/s SLR Metaliks Ltd

of air borne dust on their health Vehicular emissions Periodic emission check Implementation for vehicles is required. Clean fuel shall be used for vehicles. responsibility: Contractor M/s SLR

Metaliks Ltd.

Table 3.3: EMP for Construction Phase Impacts "Construction Activities Environmental Impacts Noise generation Mitigation Remarks

Personnel Protective Equipment Implementation (PPE) such as ear plugs and responsibility: helmets shall be provided for construction workers. shall be Contractor M/s SLR

The

working

hours

Metaliks Ltd.

imposed on construction workers. Dust generation PPE in the form of nose masks Implementation shall be provided for construction responsibility: workers. Use of water sprays to prevent the dust Contractor from being air borne. Air Emissions from construction machinery Periodic check of and regular Implementation Contractor M/s SLR

Metaliks Ltd.

maintenance

construction responsibility: used in Contractor M/s SLR

machinery for emissions Clean fuel shall be

equipments

Metaliks Ltd.

EHS Consultants, Bangalore.

12

Summary of the Final EIA Report

M/s SLR Metaliks Ltd

Table 3.4 Characteristics of Environmental Impacts from Construction Activities Environmental Attributes Air Quality (SPM and RSPM) Impact characteristics Cause Nature Direct Negative Direct Negative Direct Negative Direct Negative Durat ion Shortterm ShortTerm Long Term Long Term

Reversibility

Activity

Significance Low, if Personnel Protective Equipment (PPE) are used

Dislodging of particles from the ground Noise generation from

Reversible

Site clearing

Noise levels

earth excavating equipment

Reversible

Low, if PPE are used by workers

Land Use

Industrial land use Removal of vegetation

Irreversible

Low.

Ecology

and loss of flora and fauna

Reversible

Low. No cutting of trees.

Transpor tation of construct ion materials Noise levels Air Quality (SPM, SO2, NOx, CO)

Transport of construction material in trucks & Exhaust emission from vehicles Noise generation from vehicles Direct Negative ShortTerm Reversible Low if regular vehicle maintenance is done. Direct Negative ShortTerm Reversible Medium if regular emission checks are performed

EHS Consultants, Bangalore.

13

Summary of the Final EIA Report

M/s SLR Metaliks Ltd

Risk

Risk of accidents during transit Operation of

Direct Negative

Long Term

Irreversible

Low, if safety measures are taken to prevent accidents

Air Quality (SPM, Construc tion activities / Laying of roads Noise levels SO2, NOx, CO)

construction machinery, welding activities and others Noise generation from use of machinery Setting up of Project

Direct Negative

ShortTerm

Reversible

Low, if PPE are used by workers

Direct Negative Direct Negative Direct Negative

ShortTerm Long Term Long Term

Reversible Irreversibl e Reversible

Low, if PPE are used by workers The area is designated as Industrial area Low. No cutting of trees and green belt development is envisaged

Land use

Ecology

Loss of vegetation

EHS Consultants, Bangalore.

14

Summary of the Final EIA Report

M/s SLR Metaliks Ltd

Table 3.5 : Sources and types of Environmental Pollutants released due to the proposed project during operational phase Section Feed materials and fuels Raw material handling iron ore , imported coke, limestone, dolomite Sinter plant Iron Bearing waste materials like iron ore fines, coke fines, mill scale, quick lime, limestone, dolomite, GCP gas Blast Furnace Plant Coke, iron ore, sinter, fluxes and BF gas Smelting of iron oxide Heat, dusts SO2, NOx Noise Air Work zone Noise Pollution Captive Power Plant Flue gas Steam raising and power generation Noise Work zone Noise Pollution Heat, CO2 Air Air Pollution Air Air Pollution Sintering at an elevated temperature Noise Air Work zone Noise pollution Heat, dust, SO2, NOx Air Air Pollution Runoff/ leachates Drain Water pollution Storage Dust Air Air pollution Operation Pollutants Recipient Form of pollution

EHS Consultants, Bangalore.

15

Summary of the Final EIA Report

M/s Nirani Cements Pvt.Ltd

Table 3.6 Characteristics of Environmental Impacts from Operational Phase Environmental Attributes Ecology

Impact characteristics

Activity

Cause Nature Planting of trees Direct Positive

Duratio Reversibili n Long Term ty Reversible

Significance High positive impact

Afforestation / Green belt development Emissions from various unit processes and Vehicular traffic

Air Quality (SPM, SO2, NOx, CO, HC)

Unit operations Vehicle operation and fuel combustion

Direct Negative

Long Term

Reversible

Low as Ambient and Stack Monitoring, vehicle maintenance will be performed.

Noise levels

Noise generation from Direct vehicles Negative Direct Positive

Shortterm Long Term

Reversible

Low, with periodical maintenance of vehicles

Socio- economic

Employment generation

Direct and indirect employment

Reversible

High, new opportunities of steady income for many families

Quality of life

In-flow of funds the region/nation

in Direct Positive Direct

Long Term Short-

Reversible

High, the project will generate employment

Solid waste disposal Land and soil

Generation of solid

Reversible

Low, proper collection and

EHS Consultants, Bangalore.

16

Summary of the Final EIA Report

M/s SLR Metaliks Ltd

wastes Wastewater discharge DG set, operation Air quality Water quality Generation of waste water Exhaust emissions

Negative Direct Negative Direct Negative

term Shortterm Shortterm Shortterm Reversible Reversible Reversible

disposal. Low, as Septic Tank and soak pit will be provided Medium (DG set is only a standby). Low due to noise protection measures (enclosures, PPE etc.)

Noise levels

Noise generation

Direct Negative

EHS Consultants, Bangalore.

17

Summary of the Final EIA Report CHAPTER - 4.0

M/s Nirani Cements Pvt.Ltd

ENVIRONMENTAL MONITORING PROGRAMME 4.1 Environmental Monitoring Plan: Regular monitoring in a systematic and standardized manner helps in assessment of current environment and provides information on operational performance of installed pollution control facilities.

4.2 Following are the Environmental aspects will be strictly considered in conducting routine Environmental Monitoring: Monitoring of Stack emissions for Temperature, Velocity, SPM, SO2, NOx and CO. This will be carried out once in a month. Monitoring of fugitive emissions will be carried out once in a month. Monitoring of Ambient Air Quality at plant boundary for fugitive emissions for SPM, RSPM, SO2 and NOX. This will be carried out once in a month. Work Zone Air Quality Monitoring will be carried out in areas like Cooler Discharge, pig casting unit, Ore charging place near Hopper, Coke Handling Plant and Product House, granulation yard. This will be carried out once in a month. Monitoring of ground water quality of surrounding area of dump yard for pH, conductivity, total solids, suspended solids and oil and grease. This will carried out once before monsoon and after monsoon. Recirculation water after Cooling will be analyzed for pH, TSS, TDS, COD, Iron and Oil and Grease. Ambient Noise Level Monitoring near the Blast furnace, Product House, pig casting machine, Cooler discharge, Near boiler, Compressor Room, Stock House and plant boundary. This will be carried out once in a month. Monitoring of solid wastes quantity and utilization potential (Slag, sinter fines, flue dust, sludge, etc.).

EHS Consultants, Bangalore.

18

Summary of the Final EIA Report

M/s SLR Metaliks Ltd

Table 4.1: Monitoring Schedule for Environmental Parameters for mitigation of anticipated Environmental Impacts Sl. No. I 1 Monitoring frequency Duration of monitoring Important parameters for monitoring

Particulars

Air Quality Ambient Air Quality Once within month in a Grab, 24 hrly SPM, sample NOx. RSPM, SO2,

Monitoring premises 2 Stack/Chimney Monitoring 3 Fugitive monitoring II 1 Water Quality

Once month

in

a Grab

Temperature, Velocity, SO2, SPM, NOx, HC, CO

emissions Once month

in

a Grab

SPM

Ground Water Analysis

Once month

in

a Grab

As

per

KSPCB

requirements

III 1

Soil Quality Soil Quality Analysis Pre monsoon Grab and monsoon post Colour, Class, Infiltration Moisture capacity, matter, Textural pH, C, rate, retention Organic Na,

K,P,Pb,Cu,Zn,Cd,Fe IV Ecological preservation Seasonal and up gradation V Noise Quality Visual observations Survival rate

EHS Consultants, Bangalore.

19

Summary of the Final EIA Report

M/s SLR Metaliks Ltd

Once in Main Gate/Boundary Month Power Plant D.G Set Room Crushing Areas Vibrators Compressor Loading and Unloading Others as notices

a 24Hrs Monitoring

Noise levels in dB(A)

EHS Consultants, Bangalore.

20

Summary of the Final EIA Report

M/s SLR Metaliks Ltd

CHAPTER 5.0 ADDITIONAL STUDIES

Following are the additional studies taken up with respect to the proposed project: Land use pattern of the proposed expansion project surrounding area determined through using Satellite Imagery for a radius of 10 Kms which was procured from the Karnataka State Remote Sensing and Technology Utilization Centre, Bangalore. Air Quality Dispersion Modeling studies.

EHS Consultants, Bangalore.

21

Summary of the Final EIA Report

M/s SLR Metaliks Ltd

CHAPTER 6.0 PROJECT BENEFITS 6.1 Following are the benefits from the proposed project: PIG IRON is raw iron in an ingot form. It is the immediate product of smelting iron ore with coke and limestone in a blast furnace. Traditionally pig iron would be worked into wrought iron in finery forges, and later puddling furnaces, more recently into steel. Based on the assessment of steel market (considering the boom in construction sector and industrial applications) and the resources available to the promoters, it is recommended to set up a 2.0 Mt/yr pig iron plant. It provides employment opportunities directly for about 200 people & indirectly about 300 people. Socio economic status of the proposed project region will improve.

EHS Consultants, Bangalore.

22

Summary of the Final EIA Report

M/s SLR Metaliks Ltd

CHAPTER 7.0 ENVIRONMENTAL MANAGEMENT PLAN 7.1 Environmental Management during Construction Stage i) During excavation and transportation on roads at the plant site, there is a scope for local fugitive dust emissions. Frequent water sprinkling in the vicinity of the construction activity will be done. ii) There is a likelihood of fugitive dust from the construction activity and material handling from the truck movement in the premises of the proposed plant. The industry will take up tree plantation program around the plant site. iii) It will be ensured that construction vehicle are properly maintained. The vehicle maintenance area will be located in such a manner, so as to prevent contamination of water sources by accidental spillage of oil. iv) Proper care will be taken for storage of LSD etc. Location will be identified for the storage of such flammable liquids, away from the main plant. The storage will be as per institutional safety standards. v) The construction workers will be provided with sufficient and suitable toilet facilities to allow proper standards of hygiene. vi) Onsite workers using high noise equipment will adopt noise protection devices. Noise prone activities will be restricted to daytime hours only. vii) viii) Hazardous material will be stored in proper areas. After completion of construction activities, the rubbish will be cleared and disposed to nearby authorized sites. 7.2 Environmental Management during Operation Stage 7.2.1 Air Environment: Following are the arrangements made for control of pollution are considered: The mitigation measures needs to be adopted during the operation stage to control the negative impacts on air environment of the surrounding of the project area given below: EHS Consultants, Bangalore. 23

Summary of the Final EIA Report

M/s SLR Metaliks Ltd

The air pollution control equipment like Bag filters and other dedusting equipments shall be operated continuously and provision shall be made for backup power supply for these.

Monitoring of stack emissions and emissions from the dedusting equipments shall be carried out regularly to ascertain the performance of the air pollution control equipments.

Arrangements are made for periodical monitoring of stack gas and ambient air quality. The sampling points are located based on meteorological conditions of the region.

Ladder, port hole, power supply points are provided to the boiler and Blast furnace stacks for monitoring of emissions.

Gas Cleaning Plant and de-dusting equipments are operated continuously. Provision are made for back-up power for this equipment.

Water spraying shall be adopted at loading and unloading points, storage yards and near solid waste dumping yards which will reduce fugitive emissions due to movement of truck.

All the internal roads shall be asphalted to reduce the fugitive dust due to truck movement.

Green belt cover shall be provided. For this, the project has proposed to have green belt cover to an extent of 30 acres (33%) of the total site area.

Cabins for shovel and dumpers and dust masks to workmen A good house keeping and proper maintenance will be practiced in the industry, which helps in controlling pollution.

Proper maintenance air pollution control equipment

Regular maintenance of vehicles and machinerys in order to control emissions.

Table 7.1 Plant wise air pollution control system to control gaseous and fugitive emissions Sl.No Particulars of Plant in Proposed Pig Iron Air Complex Project 1 Pig Iron Plant Pollution Control

Equipments proposed Dust catcher Venturi Scrubber 24

EHS Consultants, Bangalore.

Summary of the Final EIA Report

M/s SLR Metaliks Ltd

Dry

fog

dust

suppression systems Stack/Chimneys (>30 m) 2 Captive Power Plant Stack/Chimneys (>30 m) 3 Sinter Plant ESP

To reduce fugitive emissions of particulate matter during handling of materials, the following prevention and control techniques will be followed: Using indoor or covered stockpiles or, when open-air stockpiles are unavoidable, use of water spray system, dust suppressants, windbreaks, and other stockpile management techniques; Designing a simple, linear layout for material handling operations to reduce the need for multiple transfer points (trucks and tippers) Maximizing the use of enclosed silos to store bulk powder; Enclose conveyer transfer points with dust-controls; Cleaning the return belts in the conveyor belt systems to remove loose dust; Implementing routine plant maintenance and good housekeeping to keep small leaks and spills to a minimum; Implementation of correct loading and unloading practices.

7.2.2 Water Environment Water requirement of 2220 KLD for the proposed project will be met from Tungabhadra River. The water will be used majorly for cooling purposes. Water pollution mainly comprises of inorganic solids, oil, grease, etc. in suspension, solution and emulsion. The pollutants present in the waste water will be reduced to acceptable levels by adoption of the following schemes.

Re-circulating water in the process whereby discharged volume is considerably reduced

EHS Consultants, Bangalore.

25

Summary of the Final EIA Report

M/s SLR Metaliks Ltd

Close circuit cooling wherever feasible. Clarifier and sludge pond for removal of suspended solids Neutralization of acidic water by lime Removal of oil and grease from the contaminated water by means of oil traps and skimming devices

No Water is drawn from the river during lean seasons. During rainy season water is drawn and collected in the storage reservoir. The quantity of sewage generated from canteen & office activities will be treated in the Septic Tank and Soak pits. 7.2.3 Noise Environment Personnel working near noisy areas shall be provided with adequate personal protective equipment such as earplugs and earmuffs, use of which will be strictly enforced. Sophisticated and low noise generating equipments will be selected. Proper mounting of equipments and providing noise insulating enclosures or paddling where practicable. The equipments will be maintained at all times to ensure permissible noise levels. Appropriate advanced silencers, acoustic barriers; vibration-reducing pads will be provided for all noise generating equipments. The sources of continuous noise generating equipment such as compressors, pumps etc will be designed to have noise level not exceeding 85-90dB(A). It would be ensured that there would not be any operator near the noise generating equipments on continuous basis. Boundary walls and dense green belt will be erected to act as acoustic barriers. Adequate and appropriate type of green belt would be developed in and around the proposed project site for noise mitigation in the area. Shock absorbing techniques will be adopted to reduce noise level.

EHS Consultants, Bangalore.

26

Summary of the Final EIA Report

M/s SLR Metaliks Ltd

Acoustical walls and roofs are provided to buildings where such machineries are installed.

Proper maintenance of machineries especially oiling and greasing of bearing and gears etc.

Use of personnel protective to persons working near noise creating locations. Plantation of green trees around the factory building and premises to control the intensity of noise to the surrounding area.

33 % land area around the factory is covered with green belt. It includes green belt of 6 to 10 m width around storage yards.

Trees are planted on either side of the roads with in the factory premise and with in the vicnity around the factory.

Trees species are selected as per guidelines of CPCB.

7.2.4 Solid Waste and Hazardous Waste generation Sl.No A 1 Item Sinter Plant Sinter Fines (< 5mm) Fine Dust Description After screening from MBF Dust from Filter/ESP Quantity 10% of Sinter Production Pollution Control

To be charged back as blend mix for sinter production. Bag 0.5 Kg/T of To be charged back Sinter & Pellet as blend mix for production sinter production. 320 Kg/T of HM 10 Kg/T of HM 0.5 Kg/T of HM To be granulated and sold to Cement Plants To be charged back as blend mix for sinter production. Solidified sludge from the Thickener to be charged back as blend mix for sinter production. Stored in Garbage collection Pits and disposed to nearby Municipality.

B 1

Mini Blast Furnace (MBF) Slag From the process

Flue Dust

Sludge

Dust from Primary Dust Catcher From Gas Cleaning Plant

C 1

Domestic Solid Waste Garbage/Trash/ From the entire Garden litters Industry

60 Kgs/day

EHS Consultants, Bangalore.

27

Summary of the Final EIA Report

M/s SLR Metaliks Ltd

7.2.5 Greenbelt Development An area of about 35 acres of land (38% of total site area) in the plant premises is proposed for greenbelt development. The species selected for greenbelt development shall fulfill the following specific requirements of the area: Tolerate to specific conditions. Shall have rapid growth rate. They shall rich canopy and shielding property. Large bio-mass and leaves to provide fodder and fuel. Ability to improve wastelands/barren areas. As for as possible shall be native in nature.

7.2.6 Ecological Aspects The following measures proposed will have minimum impact on ecology of the project area: Zero discharge of wastewater from the proposed project in the operation stage. Continuing greening efforts in and around the project site. An area of about 30 acres of land (33% of total site area) in the plant premises is proposed for greenbelt development. 7.2.7 Aesthetics Aspects Plant species of aesthetic value, fodder value, fruit bearing, and birds attracting tree will be planted. Hence it would be converted into a possible park for the nearby villages and project staff for recreation. 7.2.8 Socio Economic Aspects The project is not going to cause significant damage to the existing agricultural situation. Instead, it is likely to provide the farmers with supplementary income. The project has very strong positive employment and income effects. There is a great possibility of industrialization in the vicinity of the proposed plant. This is likely to bring dramatic changes by transforming this backward area into an industrially developed one. EHS Consultants, Bangalore. 28

Summary of the Final EIA Report

M/s SLR Metaliks Ltd

The project has very strong positive impact, which is likely to result in the improvement of economic situation of Hospet As an impact of identification of the project, small-scale industrial economy is likely to flourish in the surrounding area. The small-scale industrial units are expected to get financial supports from the financial institutions and banks. In this way, an overall development may take place in this area. The process of development will have maximum impact on the lifestyle of the local people. The project and the consequent peripheral industrial economy will generate income to the local and migrated people which will increase the aggregate demand. This demand will get realized in the market and finally, lead to the market in the locality of the project. Market expansion supported by expected infrastructural developments like roads, electricity, water supply etc. will result in improving the economic development in the entire region. 7.2.9 Storm Water Management Storm water gutters will be constructed in the premises. Garland channels will be provided to the storage yards.

Storm water storage capacity will be provided for about 30% of the annual storm

water collected from the factory premises. The rain water thus collected is used for greenery development in the factory. Also, part of storm water thus collected can also be used as a source of water for the industry. Storm water drains will be provided within the premises of the industry to avoid mixing with affluent. Storm water drains will be provided on both sides of the roads. Rectangular drains will be provided based on the quantity of storm water to be conveyed and depth limitations. 40 recharge pits are provided for the purpose of ground water recharge.

7.2.10 Post Project Environmental Monitoring M/s SLR Metaliks Ltd. will implement various productivity management programs in the plant to improve the work environment, effective house keeping and environment EHS Consultants, Bangalore. 29

Summary of the Final EIA Report

M/s SLR Metaliks Ltd

quality. All the necessary steps shall be taken in the plant to meet standards prescribed by the Karnataka State Pollution Control Board and Department of Ecology and Environment, Government of Karnataka.

EHS Consultants, Bangalore.

30

You might also like

- Ferrous Alloys Metallurgy ReviewDocument80 pagesFerrous Alloys Metallurgy ReviewAlvin Garcia PalancaNo ratings yet

- Great KilnDocument8 pagesGreat Kilnmbamarketing54No ratings yet

- Grease Cross ReferenceDocument1 pageGrease Cross ReferenceJuan Perez100% (3)

- Iron and Steel Making ProcessDocument22 pagesIron and Steel Making Processmaghfira100% (1)

- Vizag Steel PlantDocument27 pagesVizag Steel Plantpramod_k67% (6)

- Materials For JointsDocument25 pagesMaterials For Jointshariharanoilgas100% (1)

- Indian Ferro Alloy Industry: A Review of its Development, Current Status, and Future OutlookDocument18 pagesIndian Ferro Alloy Industry: A Review of its Development, Current Status, and Future OutlookGourav ChoudhuriNo ratings yet

- CURRENT DEVELOPMENT OF SLAG VALORISATION IN ChinaDocument13 pagesCURRENT DEVELOPMENT OF SLAG VALORISATION IN ChinaHung LeNo ratings yet

- The Indian Cold Rolling IndustryDocument5 pagesThe Indian Cold Rolling IndustrymalevolentNo ratings yet

- Belgaum Foundry ClusterDocument19 pagesBelgaum Foundry ClusterVinay Vasant Mangale0% (1)

- Ibac - Matrix Iron Foundry: Benori Knowledge SolutionsDocument28 pagesIbac - Matrix Iron Foundry: Benori Knowledge SolutionsKanika1908No ratings yet

- Lubrication Table FOK 4x en-GB - 11Document22 pagesLubrication Table FOK 4x en-GB - 11balaasenthil0% (1)

- Steel Industries in IndiaDocument28 pagesSteel Industries in IndiaVivek NesaNo ratings yet

- Mini Steel Plant 790699Document57 pagesMini Steel Plant 790699Eyock PierreNo ratings yet

- JSW Steel InfoDocument3 pagesJSW Steel InfoHiren PatelNo ratings yet

- Coal Mines in India-2014Document3 pagesCoal Mines in India-2014iData InsightsNo ratings yet

- MSPL Final ReportDocument53 pagesMSPL Final ReportKiran RawalNo ratings yet

- BCCL Project ReportDocument42 pagesBCCL Project ReportChandan Kumar Singh100% (1)

- State Investment Promotion Board List of MoU's Updated ProjectsDocument24 pagesState Investment Promotion Board List of MoU's Updated ProjectsPraveen Kumar SriragghavanNo ratings yet

- MoU's for Chhattisgarh Investment PromotionDocument30 pagesMoU's for Chhattisgarh Investment Promotionsuraj pandeyNo ratings yet

- Steel: The Indian Steel IndustryDocument43 pagesSteel: The Indian Steel IndustrySylvia GraceNo ratings yet

- New Projects in Karnataka 2013-14Document6 pagesNew Projects in Karnataka 2013-14IndScan Report StoreNo ratings yet

- Steel PlantDocument21 pagesSteel PlantKaran Sagar KathuriaNo ratings yet

- Major customers of state electricity boards and core industries in IndiaDocument30 pagesMajor customers of state electricity boards and core industries in IndiaankitimtNo ratings yet

- Masters in Business Administration: Bhilai Steel Plant (Sail)Document62 pagesMasters in Business Administration: Bhilai Steel Plant (Sail)संदीप द्विवेदीNo ratings yet

- List of MoUsDocument24 pagesList of MoUsSrinivasa Rao VenkumahanthiNo ratings yet

- Major Steel and Power Projects by POSCO E&C in IndiaDocument8 pagesMajor Steel and Power Projects by POSCO E&C in IndiaRam GuptaNo ratings yet

- SAIL IISCO Marketing Project PDFDocument74 pagesSAIL IISCO Marketing Project PDFABCDNo ratings yet

- Ferro AlloysDocument13 pagesFerro Alloysvjkumar7378397No ratings yet

- InsightsDocument72 pagesInsightsArunkumar DurairajNo ratings yet

- Coke Oven New1Document6 pagesCoke Oven New1abhishekgarg98No ratings yet

- Gujarat NRE Coke Strategy AnalysisDocument20 pagesGujarat NRE Coke Strategy AnalysisMangesh GulkotwarNo ratings yet

- Pig Iron Production GuideDocument120 pagesPig Iron Production Guidesaurabh100% (1)

- Kirloskar FerrorsI Ndustries LTD (Project)Document53 pagesKirloskar FerrorsI Ndustries LTD (Project)rameshmba100% (6)

- Coal Directory PDFDocument203 pagesCoal Directory PDFJEFY JEAN ANo ratings yet

- CMR Jan 13Document7 pagesCMR Jan 13James WarrenNo ratings yet

- JBL Sinter PlantDocument77 pagesJBL Sinter PlantShashi Kant Tiwari100% (2)

- Steel Industries and Six SigmaDocument8 pagesSteel Industries and Six SigmaNaveen RajhaNo ratings yet

- Heat & Mass Balance For Blast Furnace - Report Rev 1Document19 pagesHeat & Mass Balance For Blast Furnace - Report Rev 1Fikan Mubarok RohimsyahNo ratings yet

- Coal For Metallurgical Coke Production PDFDocument24 pagesCoal For Metallurgical Coke Production PDFS SITAPATI100% (1)

- An Industrial Vist Report On Durgapur Steel PlantDocument34 pagesAn Industrial Vist Report On Durgapur Steel PlantChandarshekar Swaminathan50% (2)

- Iron & Steel IndustryDocument21 pagesIron & Steel IndustryShejal SharmaNo ratings yet

- 07092014130558IMYB-2012-Iron & Steel and ScrapDocument27 pages07092014130558IMYB-2012-Iron & Steel and ScrapPriyamNo ratings yet

- DIUPL Project TextDocument29 pagesDIUPL Project Textca_akr0% (1)

- Navbharat Steel Re-Rolling MillDocument74 pagesNavbharat Steel Re-Rolling MillChintan Pavsiya100% (1)

- Vocational Training: Durgapur Steel PlantDocument28 pagesVocational Training: Durgapur Steel PlantBaptu Roy100% (1)

- Hos Pet Steels LimitedDocument116 pagesHos Pet Steels LimitedArvind GargNo ratings yet

- Iron & Steel Manufacturers in NepalDocument3 pagesIron & Steel Manufacturers in NepalMishal LimbuNo ratings yet

- Status of Sponge Iron Units in OrissaDocument14 pagesStatus of Sponge Iron Units in OrissamaheswarreddyNo ratings yet

- Aby CumiDocument75 pagesAby CumiAby VargheseNo ratings yet

- Ferroalloys 1Document20 pagesFerroalloys 1akki018No ratings yet

- Industry Statistics: Major Industrial Areas/ Zones in OrissaDocument17 pagesIndustry Statistics: Major Industrial Areas/ Zones in OrissaBhavani PrasadNo ratings yet

- Hospet Steels Limited, KoppalDocument21 pagesHospet Steels Limited, KoppalSagar GNo ratings yet

- Siding Type and Good ShedDocument11 pagesSiding Type and Good ShedPooja SamadhiyaNo ratings yet

- AttachmentDocument3 pagesAttachmentKaushik Kumar AushNo ratings yet

- With Reference ToDocument45 pagesWith Reference ToSIRIGIREDDY SWETHANo ratings yet

- Iron and Steel Industries in IndiaDocument13 pagesIron and Steel Industries in IndiaShyam AbhishekNo ratings yet

- RSP: A Brief History of Rourkela Steel PlantDocument20 pagesRSP: A Brief History of Rourkela Steel PlantkathirNo ratings yet

- Organization StudyDocument48 pagesOrganization StudyVinay Vatsa50% (4)

- Anantapur Industry ListDocument4 pagesAnantapur Industry ListM.Venkata Siva ReddyNo ratings yet

- NameDocument18 pagesNameDharamNo ratings yet

- Jayaswal Neco PDFDocument117 pagesJayaswal Neco PDFSUKHSAGAR1969No ratings yet

- JSWDocument41 pagesJSWsushantmishra85100% (1)

- Company AnalysisDocument9 pagesCompany AnalysisNaveen KumarNo ratings yet

- Mining Sector in IndiaDocument6 pagesMining Sector in IndiaSAMAYAM KALYAN KUMARNo ratings yet

- Existing Mineral Based Industries: Iron & Steel PlantDocument4 pagesExisting Mineral Based Industries: Iron & Steel PlantAshokNo ratings yet

- PROJECT REPORT ON STEELDocument9 pagesPROJECT REPORT ON STEELChander ShekharNo ratings yet

- GM Tata SteelDocument32 pagesGM Tata SteelAniket AutkarNo ratings yet

- Sip Project SailDocument68 pagesSip Project SailRavi Kant RajNo ratings yet

- Jindal Saw Process FlowDocument2 pagesJindal Saw Process Flowvikalp shriNo ratings yet

- Pankaj Final Industrial Training Report 1234Document36 pagesPankaj Final Industrial Training Report 1234pankaj madhheshiyaNo ratings yet

- Portrait of an Industrial City: 'Clanging Belfast' 1750-1914From EverandPortrait of an Industrial City: 'Clanging Belfast' 1750-1914No ratings yet

- STATE-WISE QUARANTINE NORMSDocument41 pagesSTATE-WISE QUARANTINE NORMSbalaasenthilNo ratings yet

- Information From Client (ETO)Document11 pagesInformation From Client (ETO)balaasenthilNo ratings yet

- Ductile Iron Versus Steel PDFDocument1 pageDuctile Iron Versus Steel PDFbalaasenthilNo ratings yet

- 0.0 3rer.0 3rer!attachment!a3Document8 pages0.0 3rer.0 3rer!attachment!a3balaasenthilNo ratings yet

- Chennai Aero Park Land Application FormDocument11 pagesChennai Aero Park Land Application FormbalaasenthilNo ratings yet

- Comparative ratings of 650/1100V PVC and XLPE cablesDocument1 pageComparative ratings of 650/1100V PVC and XLPE cablesbalaasenthil100% (1)

- Amendment Notificaiton - List of Parties and Symbols English Dated 01.04.2019Document5 pagesAmendment Notificaiton - List of Parties and Symbols English Dated 01.04.2019balaasenthilNo ratings yet

- TNHB Fire TenderDocument5 pagesTNHB Fire TenderbalaasenthilNo ratings yet

- Project Report of Infotech Hospitality Hospital PDFDocument21 pagesProject Report of Infotech Hospitality Hospital PDFbalaasenthilNo ratings yet

- Vicflex Sprinkler Fittings Series Ah2-300 and Ah2-Cc-300 Braided Flexible Hose AssembliesDocument20 pagesVicflex Sprinkler Fittings Series Ah2-300 and Ah2-Cc-300 Braided Flexible Hose AssembliesbalaasenthilNo ratings yet

- Comparative ratings of 650/1100V PVC and XLPE cablesDocument1 pageComparative ratings of 650/1100V PVC and XLPE cablesbalaasenthil100% (1)

- 11 Vesda-E Veu Tds A4 Ie LoresDocument2 pages11 Vesda-E Veu Tds A4 Ie LoresRicardo MercadoNo ratings yet

- Measuring Fire Loads and Calculating SeverityDocument14 pagesMeasuring Fire Loads and Calculating Severitykermech21607No ratings yet

- Sanyal Steel - MonnetDocument13 pagesSanyal Steel - MonnetbalaasenthilNo ratings yet

- Panic Hardware Owner's GuideDocument2 pagesPanic Hardware Owner's GuidebalaasenthilNo ratings yet

- Annual Planner 10-01-2014Document2 pagesAnnual Planner 10-01-2014Venkat RamananNo ratings yet

- Measuring Fire Loads and Calculating SeverityDocument14 pagesMeasuring Fire Loads and Calculating Severitykermech21607No ratings yet

- Technical Note Pellet PlantDocument4 pagesTechnical Note Pellet PlantbalaasenthilNo ratings yet

- Una Kostela Hydro ProjectDocument1 pageUna Kostela Hydro ProjectbalaasenthilNo ratings yet

- New Iron Making TechnologiesDocument2 pagesNew Iron Making TechnologiesMarcWorldNo ratings yet

- Chhattisgarh Steel Conclave-BrochureDocument2 pagesChhattisgarh Steel Conclave-BrochurebalaasenthilNo ratings yet

- Itmk3 Process: Shoichi Kikuchi, Shuzo Ito, Dr. Isao Kobayashi, Osamu Tsuge, Koji TokudaDocument8 pagesItmk3 Process: Shoichi Kikuchi, Shuzo Ito, Dr. Isao Kobayashi, Osamu Tsuge, Koji TokudabalaasenthilNo ratings yet

- Una Kostela Hydro ProjectDocument1 pageUna Kostela Hydro ProjectbalaasenthilNo ratings yet

- 20111014082849Document8 pages20111014082849balaasenthilNo ratings yet

- New Iron Making TechnologiesDocument2 pagesNew Iron Making TechnologiesMarcWorldNo ratings yet

- ABB Contact South AfricaDocument32 pagesABB Contact South AfricaCONTACTABBNo ratings yet

- Energy Recovery from Municipal Solid WasteDocument48 pagesEnergy Recovery from Municipal Solid WastebalaasenthilNo ratings yet

- Strategic Management, Jindal SteelDocument12 pagesStrategic Management, Jindal Steellino67% (3)

- VT-SAIL Abhishek ShrivastavaDocument105 pagesVT-SAIL Abhishek ShrivastavaCHINMAYA BHURE0% (1)

- Rashtriya Ispat Nigam Limited Visakhapatnam Steel Plant: A Study On"Industrial Relations"Document102 pagesRashtriya Ispat Nigam Limited Visakhapatnam Steel Plant: A Study On"Industrial Relations"Sateesh KumarNo ratings yet

- Modelarea Proceselor Din FurnalDocument4 pagesModelarea Proceselor Din Furnalmihai_1983No ratings yet

- TsDocument9 pagesTsdeepu1009No ratings yet

- Environmental control in metallurgical industry blast furnacesDocument55 pagesEnvironmental control in metallurgical industry blast furnacesChandra Shekar EmaniNo ratings yet

- Investigation of High-Rate and Pre-Heated Natural Gas Injection in The Blast FurnaceDocument16 pagesInvestigation of High-Rate and Pre-Heated Natural Gas Injection in The Blast FurnaceJJNo ratings yet

- Energy Conservation Measures in Pusher-Type Reheating Furnace Through Modifications and ModernizationDocument7 pagesEnergy Conservation Measures in Pusher-Type Reheating Furnace Through Modifications and ModernizationNoman AliNo ratings yet

- CDQDocument2 pagesCDQKalai SelvanNo ratings yet

- The Finex® ProcessDocument16 pagesThe Finex® ProcessNavin Kumar BinitNo ratings yet

- Process Simulation of Blast Furnace Operation With BiomassDocument4 pagesProcess Simulation of Blast Furnace Operation With BiomasskronafNo ratings yet

- CoalDocument5 pagesCoalPooja DhawanNo ratings yet

- JASE-W Japanese Smart Energy Dry Electrostatic PrecipitatorsDocument2 pagesJASE-W Japanese Smart Energy Dry Electrostatic Precipitatorsgautamcool100% (1)

- Management of Solid Waste For Sustainability of Steel IndustryDocument7 pagesManagement of Solid Waste For Sustainability of Steel IndustryAtika syafawiNo ratings yet

- The New Hot Stove Technology by NSENGIDocument11 pagesThe New Hot Stove Technology by NSENGIsmelt_928471401No ratings yet

- 41724Document60 pages41724SocarisNo ratings yet

- Ibrahim Ahmadzai Syn CorrectedDocument10 pagesIbrahim Ahmadzai Syn CorrectedzahidNo ratings yet

- Notes For 3rd Exam (Ferrous Metallurgy)Document2 pagesNotes For 3rd Exam (Ferrous Metallurgy)Fabie BarcenalNo ratings yet

- Tata SteelDocument4 pagesTata SteelMohammad MamunNo ratings yet

- Pig IronDocument42 pagesPig IronWajih HaiderNo ratings yet

- Bhushan Steels Or.Document189 pagesBhushan Steels Or.Naveen SinghNo ratings yet