Professional Documents

Culture Documents

SIMATICC

Uploaded by

Samir MujoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SIMATICC

Uploaded by

Samir MujoCopyright:

Available Formats

SIMATIC TP 270/OP 270 The "allrounders" for operator control and monitoring

SIMATIC TP 270

The Touch Panels SIMATIC TP 270

feature Color-STN touchscreens (analog/resistive) and are available with 5.7" or 10.4" displays. SIMATIC OP 270

The Operator Panels SIMATIC OP

Product Brief

270 are operated via a keypad and are also available with optional 5.7" or 10.4" Color-STN displays. Key features at a glance

Excellent value for money Robust and compact Backup/restore options via

Ethernet (TCP/IP), CF card, MPI or USB

Remote download/upload for

configuration and Firmware

All interfaces on board, e.g. MPI,

PROFIBUS-DP, USB; optional Ethernet connection

Sharp, clear 256-color displays Extensive HMI functionality Optimum performance Specific drivers can be loaded at

a later stage

The SIMATIC Touch Panels TP 270 and Operator Panels OP 270 have everything you could expect from an operator control and monitoring device. At the same time, these powerful high-performance panels manage to remain highly cost-effective.

Based on the Windows CE operating system, TP 270/OP 270 offer innovative operator control and monitoring functions combined with the known advantages of Operator Panels: robustness, stability and simplicity. The standard hardware/software interfaces guarantee increased flexibility and transparency, as well as access to the Office world.

New

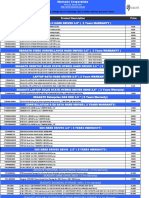

Summery of technical specifications

Display Size in inches / W x H in mm Resolution (pixels) / colors MTBF of backlighting (at 25C) Input medium Programmable function keys, optional labelling System keys Alpha / numerical input Keyboard, mouse, barcode reader Processor Operating system Memory for ProTool configuration Interfaces Serial CF card slot USB Printer Connection to controller Power supply Current consumption Clock Dimensions Front panel, W x H in mm Mounting dimensions, W x H x D in mm Weight Temperature Operation: vertical installation / tilted installation max. 35 Transport / storage Relative humidity Degree of protection, front/rear Certificates Functionality Variables Event/alarm messages Message buffer Process screens Graphic objects Dynamic objects Recipes Data sets per recipe Entries per recipe Archiving Types of archives Visual Basic Scripts Print functions Online languages Character sets PG functions (STATUS/CONTROL) Scheduler Password protection Configuration

1) Ethernet optional via NE 2000 compatible network cards

OP 270 6

C-STN liquid crystal display (LCD) 5.7 / 115 x 86 320 x 240 / 256 colors 40,000 h Membrane keyboard 24 (18 with LED), 14 of which as softkeys 36 (3 with LED) yes via USB

OP 270 10

C-STN liquid crystal display (LCD) 10.4 / 211 x 158 640 x 480 / 256 colors 60,000 h Membrane keyboard 36 (28 with LED), 20 of which as softkeys 38 (3 with LED) yes via USB

TP 270 6

C-STN liquid crystal display (LCD) 5.7 / 115 x 86 320 x 240/256 colors 40,000 h TouFK VFUeen (analog/resistive)

TP 270 10

C-STN liquid crystal display (LCD) 10.4 / 211 x 158 640 x 480 / 256 colors 60,000 h Touch screen (analog / resistive)

yes via USB 64-bit RISC CPU Microsoft Windows CE 3.0 Flash, integrated, 2 MByte

yes via USB

IF1A: RS 232; IF1B: RS 422 / RS 485; IF2: RS 232 CF-card memory cards (for archives, recipes, backup/restore) / NE 2000-compatible network card (e.g. Ethernet) Universal serial bus USB, serial (RS 232), network (Ethernet)1) SIMATIC S7 (MPI), SIMATIC 505 (NITP), Allen Bradley, Omron, GE Fanuc, Mitsubishi FX, Telemecanique Unitelway, AEG Modicon; via PROFIBUS-DP (integrated) to SIMATIC S7/S5/505 24 V DC (18 to 30 V) max. 0.6 A Hardware clock, with battery backup 308 x 204 282 x 178 x 59 approx. 1 kg 0 to +50C / 0 to +35C -20 to +60C 483 x 310 436 x 295 x 55 approx. 6 kg 0 to +50C / 0 to +40C -20 to +60C 212 x 156 198 x 142 x 59 approx. 1 kg 335 x 275 310 x 248 x 59 approx. 4.5 kg

0 to +50C / 0 to +35C 0 to +50C / 0 to +40C -20 to +60C -20 to +60C max. 90%; non-condensing IP 65 (available soon: NEMA 4x Indoor; NEMA12) / IP 20 CE (in preparation: cULus; FM Class I Div 2; Ex Zone 2/22; C-Tick) All specified values are maximum values. The total of all configured elements is limited by the size of the configuration memory. 2,048 4,000 (total) 512 entries 300 Vector graphics (line, polygon, rectangle, circle etc.), bitmaps 2,048 300 500 1,000 20 archives / 20 measuring points per project Cyclic and sequential archives for process values and messages 50 (max. 20 lines per script) Hard copy, message log, shift log 5 Windows fonts; true type and fixed pitch fonts: 16 colors with SIMATIC S5/S7 yes 9 levels SIMATIC ProTool or SIMATIC ProTool/Pro configuration software running under Windows 98SE/Me/NT/2000; to be ordered separately

SIMATIC TP 270/OP 270 Innovative operator control and monitoring systems

Standard interfaces for flexibility Thanks to the Windows CE environment, standard hardware and software interfaces are available for the SIMATIC TP 270/OP 270 devices. This opens up access to the Office world with new, forward-looking communication possibilities. It also means that the system can be upgraded with components from different manufacturers. CF card slot e.g. for memory upgrades in archives or storage devices, backup/restore or additional interfaces Optional Ethernet (TCP/IP) access via a network card for data exchange with higher-level computers and central data administration systems/ project administration systems Integrated USB interface for "Hot plug and play" of peripheral devices (keyboard, mouse, printer and barcode reader) during operation Standard Windows data storage format (CSV) for archives and storage devices for further processing with standard tools (e.g. Excel) Visual Basic Scripts or customer-specific ActiveX Controls for individual functional expansion/upgrades Robust and compact for applications close to the machine Windows CE offers the basic requirements for applications in close proximity to machinery, in harsh industrial conditions. This includes hard-drive operation with no cooling fan requirements, real-time capability and fast boot times. The TP 270 and OP 270 are extremely robust, with protection system IP 65 at the front, high EMC compatibility and the ability to withstand extreme vibrations. Thanks to their compact design with an installation depth of just 55 / 59 mm, there is always enough space for the TP 270/OP 270 system, even in the tightest conditions.

Extensive HMI functionality With an extensive range of available functions, the SIMATIC Panels TP 270/OP 270 enable innovative operation and monitoring for the most demanding machine visualization applications. They offer 256-color displays, archiving of process values and messages, user-friendly graph displays with scrolling and zoom functions, and many more features. Efficient configuration with SIMATIC ProTool The SIMATIC Panels TP 270/OP 270 are part of a coordinated and complete range of SIMATIC HMI Panels. All SIMATIC Panels, and therefore all of the TP 270 and OP 270, are configured with a software package which runs under Windows: SIMATIC ProTool. ProTool allows simple yet efficient configuration of the TP 270/OP 270: Configuration testing in PC-simulations even without the PLC and TP/OP The configuration can be zoomed in or out for different display resolutions Graphics can be created and modified quickly and easily with vector graphics Extensive libraries of graphics with pre-drawn picture objects Standard Windows fonts, animations, pixel-precise positioning, etc. An integral part of SIMATIC, but still open to devices from other manufacturers SIMATIC TP 270/OP 270 can of course also be used to take advantage of Totally Integrated Automation (TIA) systems in order to reduce the engineering costs. For example, the STEP 7 database is accessed during configuration to avoid multiple data entry. At the same time, the SIMATIC TP 270/OP 270 can still be linked up with control systems/devices from a variety of manufacturers. The necessary drivers are already included free of charge.

Reducing servicing and start-up costs The cost for servicing and start-ups can be reduced with TP 270/OP 270 and ProTool by: Downloading/uploading the configuration and firmware via RS 232 (serial), USB, MPI, PROFIBUS-DP optionally via modem, Ethernet (TCP/IP) Data security for the complete internal Flash memory via backup/restore with application, storage device and passwords via CF card, USB, MPI, PROFIBUS-DP, RS 232 (serial) optionally via Ethernet (TCP/IP) Specific drivers can be loaded at a later stage Switch between 5 languages online including Asian languages with pictorial characters choose from 32 languages already available online A standard keyboard and mouse can be easily connected via USB using "hot plug and play"

Further information on SIMATIC Panels can be found on the Internet at:

www.siemens.com/panels

All names marked with in this Product Brief are registered trademarks of Siemens AG.

Siemens Aktiengesellschaft Automation and Drives SIMATIC Human Machine Interfaces P.O. Box 4848, D-90327 Nuremberg, Germany www.siemens.com/simatichmi

Order no. 6ZB5370-1BH02-0BA0 Printed in Germany 09403/201137 SB 1201 5.

Siemens AG 2001 Subject to change without prior notice

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- LiveOptics 1928653 PERF 11 29 2022Document39 pagesLiveOptics 1928653 PERF 11 29 2022Rajesh KNo ratings yet

- Veritas VXVM - TshootDocument106 pagesVeritas VXVM - Tshootsushant_sarkarNo ratings yet

- Grade 12 ICT 3rd Term 2021 Paper 1Document9 pagesGrade 12 ICT 3rd Term 2021 Paper 1Thulmin Damsilu JayawardenaNo ratings yet

- Rsa Authentication Manager 8.2 SP1 Setup Config GuideDocument126 pagesRsa Authentication Manager 8.2 SP1 Setup Config GuidecdrbcNo ratings yet

- Chapter 10Document10 pagesChapter 10vikasmumbai0% (1)

- Taking Your Hyperion Upgrade To The Next LevelDocument41 pagesTaking Your Hyperion Upgrade To The Next Levelsen2natNo ratings yet

- CDS SET-1 - MergedDocument175 pagesCDS SET-1 - MergedPAVAN kumarNo ratings yet

- Merit Badges RankDocument35 pagesMerit Badges RankMahathirNo ratings yet

- CSC 101 LECTURE NOTES - 09 - 05 - 2023 CompleteDocument43 pagesCSC 101 LECTURE NOTES - 09 - 05 - 2023 Completedavidoluwadimu28No ratings yet

- OSY-Microproject V VDocument20 pagesOSY-Microproject V VComputer ActivityNo ratings yet

- Csi 104Document102 pagesCsi 104vietanh hoangNo ratings yet

- Android Porting To BeagleboardDocument14 pagesAndroid Porting To BeagleboardPratik MahajanNo ratings yet

- Summative2 CSS3RDDocument3 pagesSummative2 CSS3RDmyrnaNo ratings yet

- Marsons Price List JAN-2016Document6 pagesMarsons Price List JAN-2016adnanNo ratings yet

- Dip Unit 1Document75 pagesDip Unit 1sheikdavoodNo ratings yet

- Technical White Paper For Data Compass 2011Document10 pagesTechnical White Paper For Data Compass 2011edisonhsiunNo ratings yet

- Lesson 3 Digital Literacy: Discovering Computers: Chapter 1Document37 pagesLesson 3 Digital Literacy: Discovering Computers: Chapter 1Karyl Hann SarenNo ratings yet

- Computer Operations and Fundamentals: Learning ObjectivesDocument17 pagesComputer Operations and Fundamentals: Learning ObjectivesReem RezkNo ratings yet

- Satellite A105 Series Detailed Product Specification: Model Name Description Part Number UPCDocument11 pagesSatellite A105 Series Detailed Product Specification: Model Name Description Part Number UPChaldoromarNo ratings yet

- Western Digital SSD Dashboard: User ManualDocument32 pagesWestern Digital SSD Dashboard: User ManualLaxman ThapaNo ratings yet

- Frsky 2.4Ghz Accst Taranis Q X7 Manual Frsky 2.4Ghz Accst Taranis Q X7 ManualDocument2 pagesFrsky 2.4Ghz Accst Taranis Q X7 Manual Frsky 2.4Ghz Accst Taranis Q X7 ManualAni NurhayatiNo ratings yet

- CSS 11 - Q1 DIAGNOSTIC TEST - No AnswerDocument4 pagesCSS 11 - Q1 DIAGNOSTIC TEST - No AnswerJanelkris PlazaNo ratings yet

- Dataram RAMDisk Users ManualDocument20 pagesDataram RAMDisk Users ManualBabis ArbiliosNo ratings yet

- 70-740: Installation, Storage, and Compute With Windows Server 2016Document113 pages70-740: Installation, Storage, and Compute With Windows Server 2016Roberto Tébar EspuigNo ratings yet

- 8086 MPDocument89 pages8086 MPBindu Handa MahandruNo ratings yet

- VU-Advanced Computer Architecture Lecture 1-Introduction 1Document40 pagesVU-Advanced Computer Architecture Lecture 1-Introduction 1Awais FarooqNo ratings yet

- Chapter 12Document45 pagesChapter 12ManalAmerNo ratings yet

- Netbackup Interview QuestionsDocument15 pagesNetbackup Interview QuestionsVasudev50% (2)

- Ficha Técnica Disk On ChipDocument21 pagesFicha Técnica Disk On ChipCAGERIGONo ratings yet

- Page Replacement and SegmentationDocument33 pagesPage Replacement and Segmentationkritika ravishankarNo ratings yet