Professional Documents

Culture Documents

Anchor and Base Plate Calculation

Uploaded by

selahattin_erturk06Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Anchor and Base Plate Calculation

Uploaded by

selahattin_erturk06Copyright:

Available Formats

p n A

gross

A

s

pitch

length

mm

# of

threads

mm

2

mm

2

Civata

ap

(mm)

ap

(mm)

Ds ap

(mm)

t(mm) W (gr)

1 12 12 1.75 DN 7990 0.57 113.10 83.3 10 11 21 8 15.8

2 16 16 2 DN 7990 0.50 201.06 155.1 12 14 24 8 18.7

3 20 20 2.5 DN 7990 0.40 314.16 242.3 16 18 30 8 28.4

4 22 22 2.5 DN 7990 0.40 380.13 300.6 20 22 37 8 43.7

5 24 24 3 DN 7990 0.33 452.39 348.9 22 24 39 8 46.6

6 27 27 3 DN 7990 0.33 572.56 455.3 24 26 44 8 62.1

7 30 30 3.5 DN 7990 0.29 706.86 555.3 27 30 50 8 78.9

8 33 33 3.5 DN 601 0.29 855.30 687.7 30 33 56 8 101.0

9 36 36 4 DN 601 0.29 855.30 834.2 33 36 60 8 113.6

10 39 39 4 DN 601 0.25 1194.59 967.8 36 39 66 8 139.8

10 42 42 4.5 DN 601 0.22 1385.44 1111.4 39 40 72 6 132.6

10 45 45 4.5 DN 601 0.22 1590.43 1295.7 42 43 78 7 182.8

10 48 48 5 DN 601 0.20 1809.56 1461.0 45 46 85 7 220.5

10 52 52 5 DN 601 0.20 2123.72 1744.6 48 50 92 8 294.2

52 54 98 8 329.9

Civata

ap

(mm)

W (gr) Item No Code QuaIity

9

U

(MPa)

shear

stress

9

U

(MPa)

breaking

stress

8 4.62 1 3,6 Gr 3.6 180 300

10 10.9 2 4,6 Gr 4.6 240 400

12 15.9 3 5,6 Gr 5.6 300 500

14 25 4 5,8 Gr 5.8 300 500

16 30.8 5 6,8 Gr 6.8 360 600

18 49.4 6 8,8 Gr 8.8 480 800

20 60.3 7 10,9 Gr 10.9 600 1000

22 80.2 8 7,8 Gr 7.8 420 700

24 103

27 154

30 216

33 271

36 369

39 472

42 610

45 750

48 924

52 1130

55 1350

60 1600

64 1880

Somun AgrIk Listesi (DIN 555'e gre) BOLT QUALITY (DIN)

BOLT CROSS-SECTION AREAS RondeIa AgrIk Listesi

tem No Bolt Diameter

Related

Standard

Related

Standard

DN 7989

DN 7989

DN 7989

DN 7989

DN 7989

DN 7989

DN 7989

DN 7989

DN 7989

DN 7989

DN 125

DN 125

DN 125

DN 125

DN 125

UItimate

f

yieId

stress

(MPa)

180

240

300

400

480

640

900

560

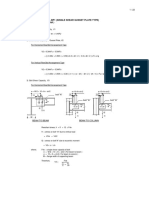

ANCHOR BOLT DESIGN OF MONOPOLES

A- Input Data: D- Check of Geometry:

= 24mm : Bolt Diameter Max Usage: 86.26% ==> OK, FaII>(FT)max

7: 5,8 : Bolt Quality .27% ==> OK, (As)req<(As)chosed = 222.7mm : Distance between anchor bolts

F.S= 1 : Factor of Safety d= 27mm : diameter of anchor hole

n= 16 : number of bolts 3d= 81mm :The distance between two holes tha

D

TUBE

= 1055mm : Bottom diameter of monopole

a= 1.6 : Increment factor for D

anc

D

= 1141.4mm : Diameter of Anchor Bolt Axes (assumed D

TUBE

+2*a*

D

BP

= 1227.8mm : Diameter of Base Plate (assumed D

ANC

+2*a* - Weight Calculation:

BP

= 86.4mm : Base Plate Width

-= 22.5 : Angle btw anchor bolts in degrees

ancho7

mm)= 24mm : ankraj ubugu api

ank7aj

mm)= 1248mm : ankraj ubugu uzunlug

- Foundation Reactions: n

ank7aj

= 16 : bir ayaktaki ankraj ade

Summary of Joint Support Reactions For All Loadcases:

ank7aj

= 4.43kg : bir ankraj ubugu agir

oad ase Joint abel

ong. Fo7ce

k)

T7an.

Fo7ce

k)

Ve7t. Fo7ce

k)

Shea7

Fo7ce k)

ong.

Moment

k.m)

T7an.

Moment

k.m)

Ve7t.

Moment

k.m)

Bending

Moment

k.m)

somun

= 0.103kg : bir somun agirligi

Des,oice 0 29.49 -37.23 29.49 556.25 0 0 556.25 n

somun

= 3 : her ankraj ubugunda

Des,ce

7ondela

= 0.062kg : bir rondela agirligi

Op,oice n

7ondela

= 1 : her ankraj ubugunda

Op,ce

ancho7-set

= 4.80kg : Ankraj seti agirligi(ank

ote:

ayak

= 76.85kg : bir ayaktaki ankraj set

- Foundation Reactions above are results of EIA solution of monopole design n

ayak

= 1 : bir direkteki ayak aded

%

= 76.85kg : bir direkteki ankraj set

- "-" vertical force is compression

F- ase Plate Calculation:

Factored Support Reactions For All Loadcases:

oad ase Joint abel

ong. Fo7ce

k)

T7an.

Fo7ce

k)

Ve7t. Fo7ce

k)

Shea7

Fo7ce k)

ong.

Moment

k.m)

T7an.

Moment

k.m)

Ve7t.

Moment

k.m)

Bending

Moment

k.m)

Diamete7

of Base

Plate

Diamete7

of Bolt

xes

Botton

Diamete7 of

Pole

umbe7

of bolts

Effective

B.ine

length

Des,oice 0 0 29.49 -37.23 29.49 556.25 0 0 556.25 1228mm 1141mm 1055mm 16 211.0

Des,ce 0 0 0 0 0 0 0 0 0

Op,oice 0 0 0 0 0 0 0 0 0

Op,ce 0 0 0 0 0 0 0 0 0 S 235 : Base Plate Quality

ote:

- Foundation reactions are multiplied by factor of safety as the support reactions above are EIA results 26.0mm : Thickness of Base Plate

(M

long

max

= 63.23kg. : Weight of Base Plate (with waste

(M

trans

max

=

V

max

=

H

max

=

C- Calculation: -= 0.0 -= 22.5 -=

Coordinates of Anchor Bolts: Forces in Anchor Bolts: (- : compression, + : tension os-= 1 os-= 0.92388 os-=

F7om

ong.

F7om

T7ans.

F7om

Ve7t.

Total

Fo7ce

F

i

k) F

i

k) F

i

k)

%F

i

k) y1= 43.2mm

1 570.70 0.00 0.00 0.00 -2.33 -2.33 124.16 y2= -0.24mm

2 527.26 218.40 46.62 0.00 -2.33 44.30 114.8878 y3= -124mm

3 403.55 403.55 86.15 0.00 -2.33 83.82 88.47725 y4= -309mm

4 218.40 527.26 112.56 0.00 -2.33 110.23 48.95112

5 0.00 570.70 121.84 0.00 -2.33 119.51

6 -218.40 527.26 112.56 0.00 -2.33 110.23

7 -403.55 403.55 86.15 0.00 -2.33 83.82

8 -527.26 218.40 46.62 0.00 -2.33 44.30 43.20 124.16 5363.79

9 -570.70 0.00 0.00 0.00 -2.33 -2.33 0 114.89 0.00

10 -527.26 -218.40 -46.62 0.00 -2.33 -48.95 0 88.48 0.00

11 -403.55 -403.55 -86.15 0.00 -2.33 -88.48 0 48.95 0.00

12 -218.40 -527.26 -112.56 0.00 -2.33 -114.89 0 124.16 0.00

13 0.00 -570.70 -121.84 0.00 -2.33 -124.16 0 114.89 0.00

14 218.40 -527.26 -112.56 0.00 -2.33 -114.89 0 88.48 0.00

15 403.55 -403.55 -86.15 0.00 -2.33 -88.48 0 48.95 0.00

16 527.26 -218.40 -46.62 0.00 -2.33 -48.95

- - - - - - - S 235

- - - - - - -

- - - - - - -

- - - - - - -

- - - - - - -

- - - - - - -

- - - - - - -

- - - - - - -

Space

between

hole and

B.ine mm)

Fo7cek)

Moment

k.mm)

- The places of of the column headers for Long. and Trans. moments are different than PLS-POLE output. They are

changed in between. Because their direction are wrong according to the direction of Long. and Trans. forces

556.25k.m

0.00k.m

ote: n case long., t7ans. moment and ve7tical fo7ce datas exist at the same

time then take ca7e to the 7esults chosen fo7 max. hen one is max then the

othe7s should be chosen f7om the same load case.

- Results of long. Force, trans. and vertical forces should be multiplied by -1 after they are copied from PLS-Pole

output

BoIt No X

i

(mm) Y

i

(mm)

-37.23k

29.49k

- - - - - - -

- - - - - - -

- - - - - - -

- - - - - - -

- - - - - - -

- - - - - - -

- - - - - - -

- - - - - - -

- - - - - - -

- - - - - - -

- - - - - - -

- - - - - - -

- - - - - - -

- - - - - - -

- - - - - - -

- - - - - - -

- - - - - - -

- - - - - - -

- - - - - - -

- - - - - - -

- - - - - - -

- - - - - - -

- - - - - - -

- - - - - - -

%X

i

=

Max Compression Force: (F

C

max

=

%

i

=

Max Tension Force: (F

T

max

= 119.51k

Design Checks:

d

b

= 21.570mm

s

= 349mm : stress area through the threads (A

s

= 6 *d

b

2

/4

d= 21mm : diameter of anchor rod

= 346mm : rod cross-section area

Bolt Grade: 7 5.8

9

y

=

400MPa : Yield stress

F

all

= 138.54k

: Maximum allowable force for anchor bolt [F

all

= 9

y

*min(A

s

;A/1000]

==> OK, FaII>(FT)max

Max Usage: 86.26% 100%

H

i

= 3.69k : Shear force on each bolt (H

i

=2*H

max

/n

When anchor bolts are subjected to uplift and shear loads, required steel area:

3 =

0.55 : coefficient of friction (0.9, 0.55 or 0.55 acc to fig 9.3 in ASCE Manual No: 52

s

)

7eq

= 318mm

: (A

s

req

=(F

T

max

/ 9

y

+H

i

/( 3 *0.85* 9

y

When anchor bolts are subjected to downward and shear loads, required steel area:

s

)

7eq

= 219mm

: (A

s

req

=[H

i

-0.3*(F

c

max

] /( 3 *0.85* 9

y

==> OK, (As)req<(As)chosed

Max Usage: .27% 100%

: diameter at threaded part (d

b

=d-0.974/n; where n=no of

threads per unit length and it is acc to DIN601

-124.16k 2,605,587.92mm

2,605,587.92mm

X ong. Di7.)

T7ans. Di7.)

ncho7 Bolt o:1 is always

placed x,0) coo7dinate

X ong. Di7.)

T7ans. Di7.)

D

BP

D

TUBE

BP

M

long

M

t7ans

F

long

F

t7ans

X ong. Di7.)

T7ans. Di7.)

SIGN CONVENTION

V: Upward is positive

Sum.

Moment

k.mm)

ancho7

bolts in

deg7ees

nc7ement

facto7 fo7

Danc

5363.8 22.5 1.6

45.0

-=

67.5

0.707107

os-=

0.382684

43.20

0

211

T 25.48mm

Beff. mm)

Sum.

Moment

k.mm)

5363.79 211.00

You might also like

- As Combined Stress Ratio Is Below 1 So Anchor Bolt Is OKDocument1 pageAs Combined Stress Ratio Is Below 1 So Anchor Bolt Is OKNaresh KumarNo ratings yet

- Anchor Bolt Design As Per American CodeDocument1 pageAnchor Bolt Design As Per American CodeS A K ClostreNo ratings yet

- Manual: Engineering Calculation TemplateDocument8 pagesManual: Engineering Calculation TemplateHamiNo ratings yet

- Mathcad - C06-C8 PDFDocument7 pagesMathcad - C06-C8 PDFKrish ChandNo ratings yet

- Glass Balustrade StaadDocument6 pagesGlass Balustrade StaadArya GopakumarNo ratings yet

- Mat Foundation Reinforcement DesignDocument1,094 pagesMat Foundation Reinforcement DesignRajveer SinghNo ratings yet

- Fillet Weld Connection DesignDocument1 pageFillet Weld Connection Designbalaji gmscNo ratings yet

- Computation: Reinforced Concrete Slab DesignDocument4 pagesComputation: Reinforced Concrete Slab DesignARSENo ratings yet

- Concrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part2-Breakout Strength in TensionDocument6 pagesConcrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part2-Breakout Strength in TensionVenu GopalNo ratings yet

- Rev G Connection-Double AngleDocument12 pagesRev G Connection-Double AnglePankaj_Taneja_9684No ratings yet

- Caisson Design Based On 2018 IBC & 2016 CBCDocument2 pagesCaisson Design Based On 2018 IBC & 2016 CBCIsprotec IngenieriaNo ratings yet

- Computation: Reinforced Concrete Rectangular Pad Footing DesignDocument5 pagesComputation: Reinforced Concrete Rectangular Pad Footing DesignJamil AlhamatyNo ratings yet

- ACI Shrinkage CalculationDocument15 pagesACI Shrinkage CalculationHussein BeqaiNo ratings yet

- Star AngleDocument1 pageStar AngleDebasish MondalNo ratings yet

- Source: Aisc Shapes Database V14.0 American Hot Rolled Bars & Sections Per Aisc StandardDocument4 pagesSource: Aisc Shapes Database V14.0 American Hot Rolled Bars & Sections Per Aisc StandardAldin AlicNo ratings yet

- Sample Shear ConnectionDocument1 pageSample Shear ConnectionmaheshbandhamNo ratings yet

- Daniel T. Li: Capacity of Bolts in Bearing Connection Based On AISC-ASD 9th Edition FDocument2 pagesDaniel T. Li: Capacity of Bolts in Bearing Connection Based On AISC-ASD 9th Edition FvtalexNo ratings yet

- Anchor Calculation - Case 2Document10 pagesAnchor Calculation - Case 2MdShahbazAhmedNo ratings yet

- BasedhorDocument18 pagesBasedhorSurya FahmiNo ratings yet

- RCFootingDesignWebDocument3 pagesRCFootingDesignWebjudeNo ratings yet

- Fin Plate G3Document3 pagesFin Plate G3jiun yee chinNo ratings yet

- Prying Action Analysis Per AISC 9th Edition (ASD)Document5 pagesPrying Action Analysis Per AISC 9th Edition (ASD)Anonymous w5SJiLsNo ratings yet

- Weld Group Under Shear and BendingDocument4 pagesWeld Group Under Shear and Bendingangelica abanesNo ratings yet

- Ms TowerDocument2 pagesMs TowerishacoNo ratings yet

- Beam - Section Classification Is 800-2007Document6 pagesBeam - Section Classification Is 800-2007ranjitNo ratings yet

- Angkur BaseplateDocument54 pagesAngkur BaseplateDS IchaqueNo ratings yet

- Foundation BoltsDocument1 pageFoundation BoltsShuvam SarkarNo ratings yet

- Circular Section Crack Width Under Tension Plus MomentDocument2 pagesCircular Section Crack Width Under Tension Plus MomentAbinash ModakNo ratings yet

- Section PropertiesDocument8 pagesSection Propertiesrahulmenon995030No ratings yet

- 11stiffened Seat ConnectionDocument5 pages11stiffened Seat ConnectionAjit SinghNo ratings yet

- Z Section PropertiesDocument2 pagesZ Section PropertiesmaheshbandhamNo ratings yet

- Design of Chequered Plate DesignDocument2 pagesDesign of Chequered Plate DesignadihindNo ratings yet

- AMICO - Grating Stair Tread SectionDocument12 pagesAMICO - Grating Stair Tread SectionwijayanataNo ratings yet

- PF2Document4 pagesPF2nhulugallaNo ratings yet

- Bsep SMFDocument6 pagesBsep SMFamirgholami1100% (1)

- Gusset Plate Connection DesignDocument3 pagesGusset Plate Connection DesignMin Khant KyawNo ratings yet

- Corbel DesignDocument4 pagesCorbel DesignnonameNo ratings yet

- Frame For Area 7-8Document173 pagesFrame For Area 7-8Saurabh GuptaNo ratings yet

- RCC31R Rigorous One-Way SlabsDocument148 pagesRCC31R Rigorous One-Way SlabsMohammad Twaha JaumbocusNo ratings yet

- Water Tank DesignDocument34 pagesWater Tank Designmadasamya20No ratings yet

- Webe Lpo 24 PL MD 02 2tc 2t AnaDocument37 pagesWebe Lpo 24 PL MD 02 2tc 2t AnaRN Builder IpohNo ratings yet

- Check of Shear Plate Bolted Connection According AISC360-05 (LRFD)Document12 pagesCheck of Shear Plate Bolted Connection According AISC360-05 (LRFD)cataiceNo ratings yet

- Steel ConnectionsDocument83 pagesSteel ConnectionsMEPNo ratings yet

- Djoni S. - Special Moment FrameDocument14 pagesDjoni S. - Special Moment FrameRatihYustinaputriNo ratings yet

- Sample Bolt CalculationDocument8 pagesSample Bolt CalculationEdmond ChowNo ratings yet

- JassimDocument29 pagesJassimZain Communication0% (1)

- Calculation of Base Plate ThicknessDocument1 pageCalculation of Base Plate Thicknessusmanm1983No ratings yet

- Column LRFDshear (SI)Document12 pagesColumn LRFDshear (SI)donnybtampubolonNo ratings yet

- Monopole DesignDocument25 pagesMonopole DesignKang'ethe GeoffreyNo ratings yet

- BEAM ImperialDocument6 pagesBEAM ImperialPohn Myint HanNo ratings yet

- Design of Base Plate by EurocodeDocument13 pagesDesign of Base Plate by EurocodeBharati MajlekarNo ratings yet

- Composite Filled Composite Circular Column DesignDocument1 pageComposite Filled Composite Circular Column DesignAli SamaniNo ratings yet

- Bridge Design For Prestressed Concrete Box Section Based On AASHTO 17th Edition & ACI 318-19Document5 pagesBridge Design For Prestressed Concrete Box Section Based On AASHTO 17th Edition & ACI 318-19Luis Alfredo Atencia VillarealNo ratings yet

- RCC Design Based in Indian CodesDocument43 pagesRCC Design Based in Indian Codeschaos_atulNo ratings yet

- RCC Design Programmed by OthersDocument43 pagesRCC Design Programmed by OthersJessie Radaza TutorNo ratings yet

- Splice Connection - Full CapacityDocument14 pagesSplice Connection - Full Capacitykalpanaadhi75% (4)

- Job Information: Engineer Checked Approved Name: DateDocument17 pagesJob Information: Engineer Checked Approved Name: DateZitheeq UmarNo ratings yet

- Splice Design - LRFDDocument22 pagesSplice Design - LRFDkalpanaadhiNo ratings yet

- Cladiri Inalte ModelDocument42 pagesCladiri Inalte ModelBogdan BîngăNo ratings yet

- TCC63 Core Wall DesignDocument12 pagesTCC63 Core Wall DesignMario Sajulga Dela Cuadra100% (1)

- Republic of The Philippines: Battery - 1Document8 pagesRepublic of The Philippines: Battery - 1Aileen AntipoloNo ratings yet

- BP1 Bolt Connection CapacityDocument22 pagesBP1 Bolt Connection CapacityballisnothingNo ratings yet

- Rayleigh Line FlowsDocument14 pagesRayleigh Line FlowsKantharaj ChinnappaNo ratings yet

- Analysis of The Free Surface Instabilities in Extrusion and Coextrusion Flows For Metallocene Based PolyolefinsDocument12 pagesAnalysis of The Free Surface Instabilities in Extrusion and Coextrusion Flows For Metallocene Based PolyolefinsDenisTarasNo ratings yet

- 1992 Ochoa & Reddy - Finite Element Analysis of Composite LaminatesDocument111 pages1992 Ochoa & Reddy - Finite Element Analysis of Composite Laminatessofianekha204243100% (7)

- Pressuremeter Tests in Municipal Solid Waste Measurement of Shear Stiffness - DixonDocument14 pagesPressuremeter Tests in Municipal Solid Waste Measurement of Shear Stiffness - DixonSen HuNo ratings yet

- Equations of HydrodynamicsDocument18 pagesEquations of HydrodynamicsAryce_No ratings yet

- Note 4Document21 pagesNote 4Serdar BilgeNo ratings yet

- 2 - Fredrickson Et Bird (1958)Document6 pages2 - Fredrickson Et Bird (1958)Hicham HichamNo ratings yet

- Knowles 1991Document16 pagesKnowles 1991cmkoh100% (1)

- Bearing Design MethodDocument38 pagesBearing Design MethodTeguh FahrezaNo ratings yet

- Mechanic of Fibrous Composites-DatooDocument649 pagesMechanic of Fibrous Composites-Datoorahman10191871100% (5)

- CH 14Document59 pagesCH 14Muhammad Tayyab Madni100% (1)

- MMK Bab 5Document96 pagesMMK Bab 5MaulitaNo ratings yet

- 3.1 Analysis Definition: Step 1 of 5Document51 pages3.1 Analysis Definition: Step 1 of 5sebastian gajardoNo ratings yet

- Concepts Rev 3 - 32 GuptaDocument106 pagesConcepts Rev 3 - 32 GuptaSorabh Gupta100% (1)

- Advanced Fluid Mechanics - Chapter 01 - IntroductionDocument26 pagesAdvanced Fluid Mechanics - Chapter 01 - Introductionhari sNo ratings yet

- ComentDocument100 pagesComentRajanNo ratings yet

- An Experimental Analysis of The Transport of Drilled ParticlesDocument10 pagesAn Experimental Analysis of The Transport of Drilled ParticlesAlvian IacoccaNo ratings yet

- Why Perform A Torsion TestDocument13 pagesWhy Perform A Torsion Testschoffil100% (1)

- Unit 1 Basic Concepts: StructureDocument45 pagesUnit 1 Basic Concepts: StructureMir Mustafa AliNo ratings yet

- Rheology of Suspensions and EmulsionsDocument17 pagesRheology of Suspensions and EmulsionsHaroon Rahim100% (3)

- MAE311 Test 1 SolutionsDocument9 pagesMAE311 Test 1 SolutionsStephenNo ratings yet

- Sand Control FluidsDocument110 pagesSand Control FluidsRichard Manguta100% (1)

- S A Final PDFDocument58 pagesS A Final PDFraghav VarmaNo ratings yet

- Aircraft Design Project-Ii Supersonic Interceptor FighterDocument5 pagesAircraft Design Project-Ii Supersonic Interceptor FighterJana AeroNo ratings yet

- Drag Coefficient and Reynolds NumberDocument2 pagesDrag Coefficient and Reynolds NumberdivNo ratings yet

- Fluid Mechanics&Machines Q&A PDFDocument307 pagesFluid Mechanics&Machines Q&A PDFUmesh ShresthaNo ratings yet

- Moving Loads Influence Lines DiagramDocument19 pagesMoving Loads Influence Lines DiagramchanakyaNo ratings yet