Professional Documents

Culture Documents

Anesthesia Machines

Uploaded by

Emilio CánepaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Anesthesia Machines

Uploaded by

Emilio CánepaCopyright:

Available Formats

Equipment Specifications for Anesthesia Machines

UNSPSC Code: 42272501 ECRI Code: 10-134 1 Description of Function Sl 1.1 Name Anaesthesia Machine is used for delivering anaesthesia agents to the patients during surgery. The complete unit also monitors the vital signs and ventilates the patients.

2 Operational Requirements Sl 2.1 Name 1) Anaesthesia machine complete and integrated with Anaesthesia gas delivery system; Circle absorber system; Precision vaporizer for halothane, isoflurane/ Sevoflurane; Anaesthesia ventilator. Monitoring system to monitor Anaesthetic gases, ECG, EtCO2, FiO2 (Online O2 Analyzer), Pulse Oximeter and airway pressure, NIBP, IBP (No as required), rectal/&skin temperature. 2) Essential accessories to make the system complete and compatible with the existing system of gas outlets. Demonstration of the equipment as per specifications is a must.

2.2

3 Technical Specifications Sl 3.1 Name Anaesthesia gas delivery system. 1. Should have provision for delivery of oxygen, nitrous oxide and medical air with pressure gauges. 2. Should have independent attachments for connecting central gas supply and pin indexed cylinders. Should have provision for attaching 1 cylinder each for O2 and N2O (Total 2 cylinders). 3. Flow Meter Cascade type of flow meter 2 for O2, 2 for N2O and 1 for Medical Air 4. Oxygen and Nitrous oxide should be linked either mechanically or pneumatically to ensure a minimum of 25% oxygen delivery at all times to avoid delivery of hypoxic mixture. 5. Should have audio-visual oxygen Failure warning System with Nitrous oxide cut off. 6. Should have back bar which is ISO pin type to attach vaporizer easily. 7. Should be supplied with necessary reusable and disposable breathing circuits (Bains, Jackson-Rees and closed circuit etc.,) 8. Should have top shelf to keep monitors and a tabletop to keep anaesthetic drugs, equipments etc. 9. The machine should possess battery back up for electrical components 10. Castor wheels should be durable and moisture resistant & Smooth. 11. The Anaesthesia machine frame should be made of rust proof material/Stainless steel. 12. Silicone cushion high quality, adult and Pediatrics face mask of four different sizes 2 each size

3.2

Standard Circle Absorber System - Should have adjustable pressure limiting valve, breathing circuit pressure measuring device. - Should have a bag/ventilator selecting valve integrated onto the absorber. - Should be suitable to use low flow techniques - Facility to attach oxygen sensor. Should have CO2 absorbent chamber canister Precision Vaporizers (Temperature, pressure and flow compensated) for Halothane, Isoflurane and Sevoflurane. - Should be easy to mount and dismount from the back bar. - Vaporizers should have ISO pin type (Selectatec) mounting and vaporizer interlocking facility. - Should have a standard filling port with keyed filling device. - Should be designed for transport with liquid in vaporizer chamber with protection against tipping and shaking -Maintenance free vaporizer Ventilator (Integrated) - Should be a bag in bottle anaesthesia ventilator with standing (ascending/Piston) bellows. - Should be supplied with adult and pediatric bellows. - Should be able to set tidal volume, respiratory rate and I:E ratio - Ventilator should have audible alarms for ventilator failure, low oxygen supply pressure, inadequate volume delivery, disconnection alarm, and power supply failure. - Should have battery backup for min 30min Integrated Monitoring system Should provide facility to monitor a) Oxygen and Nitrous oxide and anaesthetic agent in the inspired mixture b) Inspired and end tidal carbon dioxide through side stream c) Oxygen saturation of the blood with both adult, paediatric/ neonates, probes & sensors (Reusable) d) Monitoring of ECG (5 leads), NIBP (inclusive of adult, paediatric & neonatal NIBP cuffs), IBP and CVP should be present Pressure transducers and necessary accessories as per requirement (preferably four reusable transducers with bracket and holder and 100nos disposable domes with pressure lines per monitor) e) Airway Pressure monitoring should be present f) Temperature Monitoring with 2 probes oesophageal / rectal and skin probe. g) Glare free TFT/LCD color monitors with large screen for easy visibility. h) Monitor should be accurate, precise and standard monitoring modes in modular type

3.3

3.4

3.5

4 System Configuration Accessories, spares and consumables Sl 4.1 4.2 4.3 4.4 Name Anaesthesia Gas Delivery system -01 Circle absorber 01 Ventilator 01 Monitor 01

4.5 4.6 4.7 4.8 4.9

Vaporiser Halothane -01 Vaporiser Savoflurane -01 Vaporiser Isoflurane -01 Accessories for above- 02 sets Should be supplied with negative pressure leak test equipment

5 Environmental factors Sl 5.1 5.2 5.3 5.4 Name The unit shall be capable of operating continuously in ambient temperature of 100C - 400C and relative humidity of 15-90% The unit shall be capable of being stored continuously in ambient temperature of 00C - 500C and relative humidity of 15-90% Shall meet IEC-60601-1-2: 2001(Or Equivalent BIS) General Requirements of Safety for Electromagnetic Compatibility. Safe disposal system/port of waste anesthetic gases (AGSS Anesthetic Gas Scavenging System/Port) should be in place. Supplier will be held responsible if this is not ensured at the time of installation

6 Power Supply Sl 6.1 6.2 6.3 6.4 Name Power input to be 220-240VAC, 50Hz fitted with Indian plug Resettable over current breaker shall be fitted for protection Suitable Servo controlled Stabilizer/CVT UPS of suitable rating shall be supplied for minimum 1 hour backup for the entire system

7 Standards, Safety and Training Sl 7.1 7.2 7.3 7.4 Name Should be FDA or CE approved product Electrical safety conforms to standards for electrical safety IEC60601 / IS-13450 Manufacturer should have ISO certification for quality standards. Certified to be compliant with IEC 60601-2-13-Medical Electrical Equipments part 2-13:Particular requirements for the safety of Anaesthesia Workstations Should have local service facility .The service provider should have the necessary equipments recommended by the manufacturer to carry out preventive maintenance test as per guidelines provided in the service/maintenance manual. Comprehensive warranty for 5 years and provision of AMC for next 5 years.

7.5

7.6

8 Documentation Sl 8.1 8.2 8.3 8.4 8.5 Name User manual in English Service manual in English List of important spare parts and accessories with their part number and costing. Certificate of calibration and inspection from factory. Log book with instruction for daily, weekly, monthly and quarterly maintenance checklist. The job description of the hospital technician and company service engineer should be clearly spelt out List of Equipments available for providing calibration and routine maintenance support as per manufacturer documentation in service / technical manual. Compliance Report to be submitted in a tabulated and point wise manner clearly mentioning the page/Para number of original catalogue/data sheet. Any point, if not substantiated with authenticated catalogue/manual, will not be considered. Must submit user list and performance report within last 5 years from major hospitals.

8.6

8.7

8.8

You might also like

- Anaesthetic MachineDocument8 pagesAnaesthetic MachineRaja AntonyNo ratings yet

- Modern Anaesthesia Machines: Upgrading and SafetyDocument24 pagesModern Anaesthesia Machines: Upgrading and SafetyShiva Kumar P SNo ratings yet

- Anesthesia Considerations for Microlaryngoscopy and Direct LaryngoscopyDocument6 pagesAnesthesia Considerations for Microlaryngoscopy and Direct LaryngoscopyRubén Darío HerediaNo ratings yet

- Inj. Ergometrine MaleatDocument17 pagesInj. Ergometrine MaleatAarti RajputNo ratings yet

- Tracheobronchial TreeDocument51 pagesTracheobronchial TreeravishNo ratings yet

- Anaesthesia Breathing SystemsDocument22 pagesAnaesthesia Breathing SystemsKaveya BharathiNo ratings yet

- Anesthesia MachineDocument37 pagesAnesthesia MachineDakshNo ratings yet

- Bronchial AsthmaDocument25 pagesBronchial AsthmaKamil HannaNo ratings yet

- Pacu Tylenol PresentationDocument10 pagesPacu Tylenol PresentationStanford AnesthesiaNo ratings yet

- General Anesthetics: General Anesthesia - Characteristics Balanced AnesthesiaDocument7 pagesGeneral Anesthetics: General Anesthesia - Characteristics Balanced AnesthesiarisanataliasiburianNo ratings yet

- Supraglottic Airway Devices A Review in A New Era of Airway Management 2155 6148 1000647Document9 pagesSupraglottic Airway Devices A Review in A New Era of Airway Management 2155 6148 1000647Riris SihotangNo ratings yet

- 1095 Preoperative Risk Stratification and OptimizationDocument99 pages1095 Preoperative Risk Stratification and OptimizationHening Tirta KusumawardaniNo ratings yet

- Conscious sedation techniques and risksDocument84 pagesConscious sedation techniques and risksKhaled GharaibehNo ratings yet

- Ultrasound-Guided Regional Anesthesia TechniquesDocument59 pagesUltrasound-Guided Regional Anesthesia TechniquesAdi Nugroho Melyana100% (1)

- Ivc FilterDocument15 pagesIvc FilterashishNo ratings yet

- Patient Controlled AnalgesiaDocument129 pagesPatient Controlled AnalgesiamehranerezvaniNo ratings yet

- Mechanical Ventilation and Intracranial PressureDocument30 pagesMechanical Ventilation and Intracranial PressureFlavius AnghelNo ratings yet

- Regional AnesthesiaDocument54 pagesRegional AnesthesiaIdza Fariha AfriNo ratings yet

- Abg AnalysisDocument43 pagesAbg AnalysisHakuna MatataNo ratings yet

- Principles of AnesthesiaDocument60 pagesPrinciples of AnesthesiaTakale BuloNo ratings yet

- King Airway: Norcal Ems Training ModuleDocument13 pagesKing Airway: Norcal Ems Training Moduleandrew22No ratings yet

- Anaesthesia VaporisersDocument4 pagesAnaesthesia VaporisersTAMAR HEALTHCARENo ratings yet

- Local Anesthesia I LectureDocument44 pagesLocal Anesthesia I LectureMavisNo ratings yet

- Breathing System: Assembly and Functional Analysis: DR Ashutosh Verma Moderator-Dr ChetnaDocument79 pagesBreathing System: Assembly and Functional Analysis: DR Ashutosh Verma Moderator-Dr Chetnaaahutosh vermaNo ratings yet

- Premedication: by Alif Moderator: Dr. JasmineDocument45 pagesPremedication: by Alif Moderator: Dr. JasmineAlef AminNo ratings yet

- The Preoperative EvaluationDocument25 pagesThe Preoperative Evaluationnormie littlemonsterNo ratings yet

- Intravenous Anesthetic Agents: by Miss Maidah MehtabDocument49 pagesIntravenous Anesthetic Agents: by Miss Maidah MehtabLuqman QadirNo ratings yet

- Uptake and Distribution of Volatile AnestheticsDocument22 pagesUptake and Distribution of Volatile AnestheticsSuresh Kumar100% (3)

- GeneralAnesthetics and Stages of AnesthesiaDocument27 pagesGeneralAnesthetics and Stages of AnesthesiaNaghman Zuberi100% (1)

- Anaesthesia MachineDocument57 pagesAnaesthesia MachineAli AftabNo ratings yet

- Head TraumaDocument22 pagesHead TraumaEllsay AliceNo ratings yet

- ps52 2015 Guidelines For Transport of Critically Ill Patients PDFDocument12 pagesps52 2015 Guidelines For Transport of Critically Ill Patients PDFPalwasha MalikNo ratings yet

- Breathing SystemDocument29 pagesBreathing SystemOkvi KurniatiNo ratings yet

- Adams ValveDocument5 pagesAdams ValveSuresh KumarNo ratings yet

- Laryngeal SprayDocument19 pagesLaryngeal SprayKavya JNo ratings yet

- Dexmedetomidine Reduces Tourniquet Pain in IVRADocument88 pagesDexmedetomidine Reduces Tourniquet Pain in IVRAJacob OrtizNo ratings yet

- Purchasing and Commissioning of AutoclaveDocument28 pagesPurchasing and Commissioning of Autoclavenorhafizahstoh89100% (2)

- Patient Monitoring1370Document53 pagesPatient Monitoring1370Ridha Surya NugrahaNo ratings yet

- Poisoning DecontaminationDocument14 pagesPoisoning DecontaminationadystiNo ratings yet

- Opioid Analgesics & Antagonists: Dr. Hayder B Sahib Ph.D. PharmacologyDocument47 pagesOpioid Analgesics & Antagonists: Dr. Hayder B Sahib Ph.D. Pharmacologyarham pirachaNo ratings yet

- One Lung Ventilation: Llalando L. Austin Ii, MHSC, Aa-C, RRT Nova Southeastern UniversityDocument47 pagesOne Lung Ventilation: Llalando L. Austin Ii, MHSC, Aa-C, RRT Nova Southeastern UniversityZulkarnainBustamam100% (1)

- General anesthesia procedure, indications, and comparison to local anesthesiaDocument9 pagesGeneral anesthesia procedure, indications, and comparison to local anesthesiaRavi PatelNo ratings yet

- Acbt and AdDocument20 pagesAcbt and AdYusrah Sani100% (1)

- IV Induction Agents UMAIDDocument63 pagesIV Induction Agents UMAIDUmaid Mirza100% (1)

- Management of Post-Operative Nausea and Vomiting in Adults - The Pharmaceutical JournalDocument18 pagesManagement of Post-Operative Nausea and Vomiting in Adults - The Pharmaceutical JournalResti DwiuNo ratings yet

- Maples OnDocument20 pagesMaples OnanugerahNo ratings yet

- Useful Formulas for Fluid Therapy CalculationsDocument2 pagesUseful Formulas for Fluid Therapy CalculationsPrabhakar KumarNo ratings yet

- Preoperative Preparation of Patient For SurgeryDocument23 pagesPreoperative Preparation of Patient For SurgeryFauzi SebunyaNo ratings yet

- Types of Anesthesia and Their Purpose and RisksDocument8 pagesTypes of Anesthesia and Their Purpose and RisksAshlene Kate BagsiyaoNo ratings yet

- Obesity & Anaesthesia: Co-Ordinator - Dr. Chavi Sethi (MD) Speaker - Dr. Uday Pratap SinghDocument56 pagesObesity & Anaesthesia: Co-Ordinator - Dr. Chavi Sethi (MD) Speaker - Dr. Uday Pratap SinghRafi ramdhanNo ratings yet

- Management of Intraoperative Bronchospasm: Dr. ImranDocument49 pagesManagement of Intraoperative Bronchospasm: Dr. ImranhellodrvigneshwarNo ratings yet

- Pediatric Anesthesia For StudentsDocument4 pagesPediatric Anesthesia For StudentsMarco TolentinoNo ratings yet

- Interpretation of Blood Gas Reports - Made Easy: Dr. A K Sethi's EORCAPS-2010, DelhiDocument0 pagesInterpretation of Blood Gas Reports - Made Easy: Dr. A K Sethi's EORCAPS-2010, DelhiPrabhakar KumarNo ratings yet

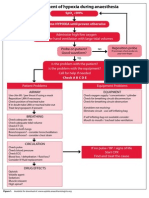

- Management of Hypoxia During AnaesthesiaDocument5 pagesManagement of Hypoxia During AnaesthesiaNurhafizahImfista100% (1)

- ICU TriageDocument27 pagesICU TriageAkmal FahrezzyNo ratings yet

- Mechanisms of Drug Toxicity: Proceedings of the Third International Pharmacological MeetingFrom EverandMechanisms of Drug Toxicity: Proceedings of the Third International Pharmacological MeetingH. RaškováNo ratings yet

- Anesthesia Complications in the Dental OfficeFrom EverandAnesthesia Complications in the Dental OfficeRobert C. BosackNo ratings yet

- Necessity of A Bed-Sensor in A Smart Digital HomeDocument5 pagesNecessity of A Bed-Sensor in A Smart Digital HomeEmilio CánepaNo ratings yet

- Analog Front End Design of A Digital Blood Pressure Meter IJERTV4IS050866Document5 pagesAnalog Front End Design of A Digital Blood Pressure Meter IJERTV4IS050866Emilio CánepaNo ratings yet

- Type-2 Fuzzy Classification of Blood Pressure paraDocument7 pagesType-2 Fuzzy Classification of Blood Pressure paraEmilio CánepaNo ratings yet

- Volume-Pressure Curves During Mechanical VentilationDocument6 pagesVolume-Pressure Curves During Mechanical VentilationEmilio CánepaNo ratings yet

- Mobile Operating Tables Alphaclassic ProDocument16 pagesMobile Operating Tables Alphaclassic ProEmilio CánepaNo ratings yet

- Microcontroller Based Telephone Intercom System Circuit DiagramDocument5 pagesMicrocontroller Based Telephone Intercom System Circuit DiagramEmilio CánepaNo ratings yet

- Weaning From Mechanical Ventilation-What Have We LearnedDocument15 pagesWeaning From Mechanical Ventilation-What Have We LearnedEmilio CánepaNo ratings yet

- Volume Guarantee New Approaches in Volume Controlled Vent...Document77 pagesVolume Guarantee New Approaches in Volume Controlled Vent...Emilio CánepaNo ratings yet

- Wave Form AnalysisDocument14 pagesWave Form AnalysisEmilio CánepaNo ratings yet

- Weaning of The Patient With ARDSDocument7 pagesWeaning of The Patient With ARDSEmilio CánepaNo ratings yet

- EDAN SE-3 Service Manual PDFDocument47 pagesEDAN SE-3 Service Manual PDFEmilio CánepaNo ratings yet

- Basic Care 305 & 405 Service ManualDocument176 pagesBasic Care 305 & 405 Service ManualRicardo Carrillo50% (2)

- Electrocardiògrafo Fukuda FCP-7101 FX7102Document170 pagesElectrocardiògrafo Fukuda FCP-7101 FX7102Marce CastroNo ratings yet

- Design and Construction The Low Cost Defibrillator AnalyzerDocument4 pagesDesign and Construction The Low Cost Defibrillator AnalyzerEmilio CánepaNo ratings yet

- Detector de Paciente en CamaDocument9 pagesDetector de Paciente en CamaEmilio CánepaNo ratings yet

- A New Family of Sensors For Pulse OximetryDocument22 pagesA New Family of Sensors For Pulse OximetryEmilio CánepaNo ratings yet

- EDAN SE-3 Service Manual PDFDocument47 pagesEDAN SE-3 Service Manual PDFEmilio Cánepa91% (11)

- HD11 Reference ManualDocument546 pagesHD11 Reference ManualEmilio Cánepa83% (12)

- AN ABCs of ADCDocument64 pagesAN ABCs of ADCkiran445No ratings yet

- Heart Rate Detection from BallistocardiogramDocument5 pagesHeart Rate Detection from BallistocardiogramEmilio Cánepa100% (1)

- HD11 Reference ManualDocument546 pagesHD11 Reference ManualEmilio Cánepa83% (12)

- Treatment and Management of AstrocytomaDocument2 pagesTreatment and Management of AstrocytomaAqila MumtazNo ratings yet

- Fio Guia InQwire Merit PDFDocument4 pagesFio Guia InQwire Merit PDFbiomedical_com_brNo ratings yet

- Clinical Abstract (2nd Sem 1st Rotation)Document3 pagesClinical Abstract (2nd Sem 1st Rotation)Michael Gino SarenasNo ratings yet

- Referral Letter - Pre-EclampsiaDocument3 pagesReferral Letter - Pre-EclampsiaChristafar RajNo ratings yet

- Tattoo Consent Form MinorDocument1 pageTattoo Consent Form MinorafkjdkfjslkfjdklNo ratings yet

- Uterine atony treatment and preventionDocument1 pageUterine atony treatment and preventionYakumaNo ratings yet

- About VaginaDocument13 pagesAbout VaginaRazend Muhd0% (1)

- National Board Dental ExaminationDocument2 pagesNational Board Dental Examinationjyoti rawatNo ratings yet

- Partial Thromboplastin Time Principle and ProcedureDocument5 pagesPartial Thromboplastin Time Principle and ProcedurealxxndraromeroNo ratings yet

- DEVELOPMENT OF PIG EMBRYODocument4 pagesDEVELOPMENT OF PIG EMBRYOAstrid AmadorNo ratings yet

- CPD Providers As of Feb 6, 2020Document733 pagesCPD Providers As of Feb 6, 2020John Mark ArcillaNo ratings yet

- Hospital Liable Under Doctrine of Apparent AuthorityDocument3 pagesHospital Liable Under Doctrine of Apparent AuthorityJohn Louie LontocNo ratings yet

- S O C R A T E S: History TakingDocument5 pagesS O C R A T E S: History Takingsnanan100% (1)

- People v. VenturaDocument1 pagePeople v. VenturaAphrNo ratings yet

- Hyperemesis Gravidarum: A Current Review: Rami Eliakim, M.D., Ovadia Abulafia, M.D., and David M. Sherer, M.DDocument12 pagesHyperemesis Gravidarum: A Current Review: Rami Eliakim, M.D., Ovadia Abulafia, M.D., and David M. Sherer, M.DTitis Retno Sawitri SawitriNo ratings yet

- William J. Harrington Medical Training Programs for Latin America and CaribbeanDocument16 pagesWilliam J. Harrington Medical Training Programs for Latin America and CaribbeansusyqarmonNo ratings yet

- Jurnal Polip EndometriumDocument4 pagesJurnal Polip EndometriumNamira AmmarinNo ratings yet

- Doctors MaputoDocument6 pagesDoctors Maputosaisridhar99No ratings yet

- General Introduction of NeonateDocument42 pagesGeneral Introduction of Neonateapi-19916399No ratings yet

- Nicu Checklist Bundles Infection Control 1Document60 pagesNicu Checklist Bundles Infection Control 1Mithlesh Dewangan92% (13)

- Court upholds damages against doctor for missed procedureDocument25 pagesCourt upholds damages against doctor for missed procedureanalynNo ratings yet

- Krok2 - Medicine - 2014Document24 pagesKrok2 - Medicine - 2014ashighaNo ratings yet

- Instructions for Ministry of Health Officials on Statement of Need LettersDocument1 pageInstructions for Ministry of Health Officials on Statement of Need LetterssurenvishvaNo ratings yet

- With 650 Bed-Capacity: Staff Nurse Progressive Care Unit-PulmonaryDocument3 pagesWith 650 Bed-Capacity: Staff Nurse Progressive Care Unit-PulmonaryMersalynNo ratings yet

- Useful Websites For Listening OETDocument2 pagesUseful Websites For Listening OETJHON MARTINEZNo ratings yet

- Avascular NecrosisDocument3 pagesAvascular Necrosishendra wibawaNo ratings yet

- African Adventure: by Margaret Iggulden Streamline Graded Readers Level 3 1000 HeadwordsDocument8 pagesAfrican Adventure: by Margaret Iggulden Streamline Graded Readers Level 3 1000 Headwordsjluis1980No ratings yet

- Oxytocin, Dinoprostone, Cefuroxime Drug StudyDocument3 pagesOxytocin, Dinoprostone, Cefuroxime Drug StudyMary Shane MoraldeNo ratings yet

- Ambulatory Care Pharmacy Group 18Document10 pagesAmbulatory Care Pharmacy Group 18Precious ParkNo ratings yet