Professional Documents

Culture Documents

300 - FyD Head Design Tool Ver E4.01

Uploaded by

Siva KumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

300 - FyD Head Design Tool Ver E4.01

Uploaded by

Siva KumarCopyright:

Available Formats

1 2 3 4 5 6 7

Pressure Vessel Engineering Ltd.

Finite Element Analysis ASME Code Calculations Canadian Vessel Registration Vessel Modeling and Drafting

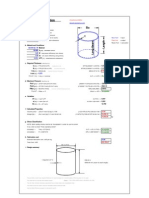

F&D Head Design Tool ver E4.01

F&D Head Description Dimensions: 24.000 24.000 1.440 0.188 0.159 0.010 2.000 Do [in] - outside diameter of head L [in] - inside crown radius (note 1) IKR [in] - inside knuckle radius (note 2) tb [in] - thickness before forming tf [in] - thickness after forming (note 3) Corr [in] - corrosion allowance Skirt [in] - straight skirt length

Page 1 of 1

8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49

Material and Conditions: SA-240 304 Material 20,000 S [psi] - allowable stress 0.85 E - head longitudinal efficiency 50.0 P [psi] - interior pressure Calculated Properties:

note 1:Suggested radius L per UG-32(j) note 2:Suggested radius IKR per UG-32(j) note 3:Suggested thickness after forming

24.00 1.440 0.1555

Approx. head weight based on steel, lbs = Approx. head volume including skirt, cuft =

38.53 1.12

Variables: nt [in] = tf-Corr ~~ thickness with corrosion allowance removed D [in] = Do-2*nt ~~ ID with corrosion allowance removed L/r = L/IKR M = 0.25*(3+sqrt(L/IKR)) Ro [in] = L+tb 0.159-0.01 = 24-2*0.149 = 24/1.44 = 0.25*(3+SQRT(24/1.44)) = 24+0.188 = 0.149 23.701 16.667 1.771 24.188

Required Thickness: App. 1-4(a), App. 1-4(d) App1-4(f) = tf/L 0.159/24 = 0.007 App1-4(f)Calc = if(AND(0.0005=<App1-4(f),App1-4(f)<0.002),"Calculation Required","Calculation not required") App. 1-4(f) Calculation Not Required Treq [in] = (P*L*M)/(2*S*E-0.2*P)+Corr ~~ required minimum thickness (50*24*1.771)/(2*20000*0.85-0.2*50)+0.01 = 0.073 CheckTreq = Treq<=tf 0.073<=0.159 = Acceptable Maximum Pressure: App. 1-4(a), App. 1-4(d) Pmax [psi] = (2*S*E*nt)/(L*M+0.2*nt) ~~ maximum allowed design pressure (2*20000*0.85*0.149)/(24*1.771+0.2*0.149) = 119.4 CheckPMax = Pmax >= P 119.4 >= 50 = Acceptable

App. 1-4(f) calculation is not included on this sheet Nozzles may be subject to a smaller required thickness depending on location in the head. Only the knuckle required thickness is calculated on this sheet Heads may be subject to stress relief if large elongation occurs - UCS-79(d), UNF-79(d), UG-37(a)(1) The UG-16(b) minimum thickness requirement has not been taken into consideration here. This sheet cannot be used to check for allowable exterior pressure loads. Use the Weld Efficiency program to calculate E This sheet is for educational use only - use at your own risk.

50 51 52 53

Pressure Vessel Engineering Ltd. 120 Randall Drive, Suite B Waterloo, Ontario, Canada, N2V 1C6 www.pveng.com (519) 880-9808

You might also like

- Acum#2 RoladoDocument1 pageAcum#2 RoladoJuan PabloNo ratings yet

- 299 Elliptical Head Design Tool Ver E4 01Document1 page299 Elliptical Head Design Tool Ver E4 01Noman Abu-FarhaNo ratings yet

- Elliptical Head Design Tool: Pressure Vessel Engineering LTDDocument1 pageElliptical Head Design Tool: Pressure Vessel Engineering LTDJaveed KhanNo ratings yet

- Elliptical Head Design ToolDocument1 pageElliptical Head Design ToolssierroNo ratings yet

- Elliptical Head Design ToolDocument1 pageElliptical Head Design ToolSudjono BroNo ratings yet

- Working Principle of Shell and Tube Heat ExchangerDocument8 pagesWorking Principle of Shell and Tube Heat ExchangersanjayNo ratings yet

- VERIFICATIONDocument3 pagesVERIFICATIONshaishavNo ratings yet

- Stress RelievingDocument1 pageStress RelievingCruz Gabriel Rosetti100% (1)

- 10inch Inlet DiffuserDocument1 page10inch Inlet DiffuserJulian Vega DiazNo ratings yet

- ES-20.14 Waste Heat PTT Public Co., LTD Recovery Units Engineering Standard REV: 02Document10 pagesES-20.14 Waste Heat PTT Public Co., LTD Recovery Units Engineering Standard REV: 02Nikki RobertsNo ratings yet

- Pipe Wall Thickness Calculations: Burnex Burner HeadDocument16 pagesPipe Wall Thickness Calculations: Burnex Burner Headpramodptvpm_65797156No ratings yet

- UHX - Osweiller - WhitePaper PDFDocument20 pagesUHX - Osweiller - WhitePaper PDFMichael BasaNo ratings yet

- Typical Specification For Steam Surface Condensers Appendix ADocument5 pagesTypical Specification For Steam Surface Condensers Appendix Ahappale2002No ratings yet

- Pvelite OutputDocument44 pagesPvelite OutputRam MurtyNo ratings yet

- Design of Pressure Vessel by Group 4Document46 pagesDesign of Pressure Vessel by Group 4anteneh tesfayeNo ratings yet

- Flat Ends With A Relief GrooveDocument11 pagesFlat Ends With A Relief GrooveEng-CalculationsNo ratings yet

- Sample4 SpreadsheetDocument21 pagesSample4 SpreadsheetTrishul Nath Pallay100% (1)

- Asme Tubesheet (Heater 10m2)Document23 pagesAsme Tubesheet (Heater 10m2)Omil Rastogi100% (1)

- Final Energy Balance-Vizag DT 9-6-18Document6 pagesFinal Energy Balance-Vizag DT 9-6-18SUBHOMOYNo ratings yet

- Exchanger Tube Min ThicknessDocument2 pagesExchanger Tube Min ThicknessMohamed ElshehnyNo ratings yet

- PC-01 - Process Column Design Calculations Using CademPVD SoftwareDocument127 pagesPC-01 - Process Column Design Calculations Using CademPVD SoftwareCADEM SoftwaresNo ratings yet

- Asme Viii Uhx Tubesheet CalcsDocument3 pagesAsme Viii Uhx Tubesheet CalcsjdfdfererNo ratings yet

- Design Check List Viii-1 Rev1Document2 pagesDesign Check List Viii-1 Rev1nirmalNo ratings yet

- Deaera DesignDocument13 pagesDeaera DesignBhanu K PrakashNo ratings yet

- Design of Partition PlateDocument5 pagesDesign of Partition Platepippo2378793No ratings yet

- Tailing Lifting Lug Design 57 V 202 r2Document10 pagesTailing Lifting Lug Design 57 V 202 r2Dinesh KhaparkarNo ratings yet

- ASME Section VIII, Division 2: Pressure Vessel Stress and Fatigue AnalysisDocument17 pagesASME Section VIII, Division 2: Pressure Vessel Stress and Fatigue AnalysisBernacleboy IDNo ratings yet

- Pipe Shell Design ToolDocument1 pagePipe Shell Design Toolep_alfiNo ratings yet

- Bulk Air Eliminator R1Document1 pageBulk Air Eliminator R1hydrothermsNo ratings yet

- What Is Design Interpretation?Document17 pagesWhat Is Design Interpretation?Qaisir MehmoodNo ratings yet

- WI06-0260 Calculations For Obround Nozzle ConnectionsDocument4 pagesWI06-0260 Calculations For Obround Nozzle ConnectionskumarNo ratings yet

- Design of Pressure Vessel by Using ASME Sec-VIII Div-1Document6 pagesDesign of Pressure Vessel by Using ASME Sec-VIII Div-1jhaamit4No ratings yet

- Tema Tubesheet Calculation SheetDocument1 pageTema Tubesheet Calculation SheetSanjeev KachharaNo ratings yet

- Acid StorageDocument1 pageAcid StorageChelsea SkinnerNo ratings yet

- Flat Face Flanges With Metal-To-metal Contact Outside The Bolt Circle For Class 1 Flange Assembly (Identical Flange Pairs)Document15 pagesFlat Face Flanges With Metal-To-metal Contact Outside The Bolt Circle For Class 1 Flange Assembly (Identical Flange Pairs)Eng-CalculationsNo ratings yet

- Tailing LugDocument2 pagesTailing Lugjagannadha varmaNo ratings yet

- SQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21Document4 pagesSQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21SRINo ratings yet

- Mechanical Design For Pressure VesselDocument26 pagesMechanical Design For Pressure VesselibicengNo ratings yet

- STHE Design (Training Material)Document37 pagesSTHE Design (Training Material)Herman_ms2000No ratings yet

- Vessel Heat LossDocument2 pagesVessel Heat LossakisdassasNo ratings yet

- Heat Exchanger - Preliminary Data SheetDocument4 pagesHeat Exchanger - Preliminary Data SheetgksakthiNo ratings yet

- Steam-Water Two-Phase Flow in Large Diameter Vertical PipingDocument11 pagesSteam-Water Two-Phase Flow in Large Diameter Vertical Pipingfujiman35No ratings yet

- Shell Thickness CalcDocument1 pageShell Thickness CalcDidi KurniadiNo ratings yet

- 3000 Litre Transcube Fuel TankDocument1 page3000 Litre Transcube Fuel Tankyulianus_srNo ratings yet

- Electric Heater Datasheet: Duty Bundle (@nom Voltage) Duty Heater (@nom Voltage)Document3 pagesElectric Heater Datasheet: Duty Bundle (@nom Voltage) Duty Heater (@nom Voltage)SonNguyenNo ratings yet

- Stirred Tank Heat ExchangerDocument4 pagesStirred Tank Heat ExchangerMiguel OjedaNo ratings yet

- Sa-516 70 TDCDocument2 pagesSa-516 70 TDCshazan100% (1)

- Vessel With Large Opening: PVE SamplesDocument25 pagesVessel With Large Opening: PVE SamplesSivateja NallamothuNo ratings yet

- F.O.B Cost Estimation of Shell and Tube Heat Exchangers: Surface Area Per ShellDocument9 pagesF.O.B Cost Estimation of Shell and Tube Heat Exchangers: Surface Area Per ShellVINOD KAMBLENo ratings yet

- Flange DesignDocument12 pagesFlange DesignSantoshNo ratings yet

- Elliptical Head Design ToolDocument1 pageElliptical Head Design ToolMohammad Kamal HabbabaNo ratings yet

- Elliptical Head DesignDocument1 pageElliptical Head Designrodriguez.gaytanNo ratings yet

- 299 - Elliptical Head Design Tool Ver E4.01Document1 page299 - Elliptical Head Design Tool Ver E4.01Pankaj SinglaNo ratings yet

- Diseño de Cabeza ElípticaDocument1 pageDiseño de Cabeza ElípticapedroluischoqueNo ratings yet

- 299 - Elliptical Head Design Tool Ver E4.01Document1 page299 - Elliptical Head Design Tool Ver E4.01mohamed faragNo ratings yet

- 299 - Elliptical Head Design Tool Ver E4.01Document1 page299 - Elliptical Head Design Tool Ver E4.01BAHADIRNo ratings yet

- Elliptical Head Design ToolDocument1 pageElliptical Head Design Toolbai tap hoa vo coNo ratings yet

- Elliptical Head Design ToolDocument1 pageElliptical Head Design Toolnaveen_86No ratings yet

- Elliptical Head Design ToolDocument1 pageElliptical Head Design ToolJaveed KhanNo ratings yet

- 300 - F&D Head Design Tool Ver E4.01Document1 page300 - F&D Head Design Tool Ver E4.01Mo ZeroNo ratings yet

- PPP Prospectus 8 12 19 1Document18 pagesPPP Prospectus 8 12 19 1Honey Tiwari100% (1)

- SAUDI-EDB Rank World Bank PDFDocument1 pageSAUDI-EDB Rank World Bank PDFHoney TiwariNo ratings yet

- Morocco Noor AF Project Paper P164288 May17 Clean 05212018 PDFDocument87 pagesMorocco Noor AF Project Paper P164288 May17 Clean 05212018 PDFHoney TiwariNo ratings yet

- PRESS RELEASE Round3 RFQ PDFDocument2 pagesPRESS RELEASE Round3 RFQ PDFHoney TiwariNo ratings yet

- Editorial Board - 2018 - Technological Forecasting and Social Change PDFDocument1 pageEditorial Board - 2018 - Technological Forecasting and Social Change PDFHoney TiwariNo ratings yet

- Graphs RE Source Platform PDFDocument7 pagesGraphs RE Source Platform PDFHoney TiwariNo ratings yet

- Air Cooled Heat Exchanger SUMMARYDocument1 pageAir Cooled Heat Exchanger SUMMARYHoney TiwariNo ratings yet

- PEC Fund Cook IslandsDocument3 pagesPEC Fund Cook IslandsHoney TiwariNo ratings yet

- ACCIONA, A Pioneer in The Hybridization of Solar Panels With Wind Power TowersDocument3 pagesACCIONA, A Pioneer in The Hybridization of Solar Panels With Wind Power TowersHoney TiwariNo ratings yet

- Air Cooled HX Data SheetDocument1 pageAir Cooled HX Data SheetHoney TiwariNo ratings yet

- As On 31.01.2014 Target For 31.03.2017: 1. Facts & FiguresDocument2 pagesAs On 31.01.2014 Target For 31.03.2017: 1. Facts & FiguresHoney TiwariNo ratings yet

- CPCB DG Set Noise Emission NormsDocument6 pagesCPCB DG Set Noise Emission NormsRSNo ratings yet

- Eleccostsum PDFDocument4 pagesEleccostsum PDFHoney TiwariNo ratings yet

- Fluor Daniel India Private LimitedDocument1 pageFluor Daniel India Private LimitedHoney Tiwari100% (1)

- Heat Load CalculationsDocument6 pagesHeat Load CalculationsHoney Tiwari0% (1)

- Cable Laying SpecificationDocument16 pagesCable Laying SpecificationdavidgarciavazquezNo ratings yet

- Sizing of SeparatorDocument2 pagesSizing of SeparatorHoney TiwariNo ratings yet

- Compressor Capacity CalculationDocument4 pagesCompressor Capacity CalculationHoney Tiwari100% (1)

- Engineering Unit Conversion PDFDocument5 pagesEngineering Unit Conversion PDFBarcepandoNo ratings yet

- Seal Gas Conditioning Skid To Solar Tie-In DWG No. 3P961-149446 / SHEET 8 OF 20 Rev BDocument1 pageSeal Gas Conditioning Skid To Solar Tie-In DWG No. 3P961-149446 / SHEET 8 OF 20 Rev BHoney TiwariNo ratings yet

- Rules of Thumb PDFDocument2 pagesRules of Thumb PDFHoney Tiwari100% (1)

- Coulson& Richardson - Cap.10 Gas-Liquid Separation PDFDocument6 pagesCoulson& Richardson - Cap.10 Gas-Liquid Separation PDFHoney TiwariNo ratings yet

- Plant NitrogenDocument4 pagesPlant NitrogenyogacruiseNo ratings yet

- Design Certification Offshore FRPDocument10 pagesDesign Certification Offshore FRPHoney TiwariNo ratings yet

- Ventilation Calculation For Inverter RoomDocument1 pageVentilation Calculation For Inverter RoomHoney TiwariNo ratings yet

- Separator CalcsDocument20 pagesSeparator CalcsHoney Tiwari100% (3)

- Stack SpecDocument10 pagesStack SpecHoney TiwariNo ratings yet

- Emission Standards Diesel Engin Upto 800 PDFDocument4 pagesEmission Standards Diesel Engin Upto 800 PDFHoney TiwariNo ratings yet

- Pump Seal PlanDocument25 pagesPump Seal PlanHoney TiwariNo ratings yet

- CPCB DG Set Noise Emission NormsDocument6 pagesCPCB DG Set Noise Emission NormsRSNo ratings yet