Professional Documents

Culture Documents

DoD 4160.21-H Defense Scrap Yard Handbookmetalspotidentif

Uploaded by

Ray ArrowoodOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DoD 4160.21-H Defense Scrap Yard Handbookmetalspotidentif

Uploaded by

Ray ArrowoodCopyright:

Available Formats

Ezl DOD-HDBK-249A( SH)

.26 December 1984 SUPERSEDING DOD-HDBK-2fI 9 ( SH) 7 October 1977

MILITARY .JIANDBOOK

METALS AND ALLOYS , IDENTIFICATION (RECOMMENDED PROCEDURS TESTING AND ASSOCIATED ALLOY MRTAL PHYSICAL RAPID OF FOR CHEMICAL TESTS SPOT TO VERIFY ON-SITE

CLASSIFICATION)

(METRIC)

FSC

95GP

Source: http://www.assistdocs.com -- Downloaded: 2008-05-06T21:12Z Check the source to verify that this is the current version before use.

DoD-HDBK-249A( 26 December

SH) 1984

DEPARTMENT NAVAL SEA

OF THE NAVY COlOIAND

SYSTEMS

Washington,

DC 20362

DOD-HDBK-249A(

SH)

Metals and Alloys, Sapid On-Site Identification Chemical Spot Testing and Associated Physical Classification) (Metric)

1. This

of (Recommended Procedure Tests to Verify Metal Alloy

for

Ikefense

2. inclusion 3. on-cite

in

standardization accordance with

publication the military

handbook established

waa approved

was developed procedure.

on 26 Dacember

by the

Department

of

This in This

1984

for

printing

and

standardization provides of metala basic and and alloys

handbook fundamental which

series. information include both on chemical the rapid spot

document

identification

testing and associated physical teste to identify lhe handbook ia not intended to be referenced in for informational purposes, nor shall it supersede 4. pertinent to: Washington, Improvement letter. Beneficial data which DC 20362 Propnsal comments may be by (DD using Form (reconnnendations, use in improving Command, self-addressed appearing at the 1426)

metal alloy classification. purchase specifications except any specification requirements. and any be addressed the Navy, or by

of

additions, deletions) this document should Department end of this of Standardization the

Commander,

Nava 1 Sea

Systeme

SEA 5523,

Document document

Source: http://www.assistdocs.com -- Downloaded: 2008-05-06T21:12Z Check the source to verify that this is the current version before use.

ii

. ,,.

DOD=3DBK-249A :26 December

( SH) 1984

FOKEWOKD

The similar procedures spectrographic testing methods purpose methods are of for or this handbook only. analytical be applicable may is of to provide and chemical coatings or by one reeults the purpoee. spot on should or testing metal. be more and These obtained special test by

identification chemical

metals procedures for

qualitative which

Quantitative

Source: http://www.assistdocs.com -- Downloaded: 2008-05-06T21:12Z Check the source to verify that this is the current version before use.

iii

DOD-HDBK-249A( 26 December

SH) 1984

.. ,. .,.,

CONTENTS

Paragraph

1. 2.

SCOPE. ---------------------------------------------------REFERENCED GENERAL Intended Testing Safety DOCUMENTS -.------.------------------

1 1

3 ---------- ---------- ------ --------- 3 3 4 4 - -------------- -------- -------- -- --------------5 6 8 8 9 15 , ,.

3. 3.1 3.2 3.3 4.

5.

REQUIREMENTS ------use conditions precautions

------------------------------. ----------------- ---------------------- -----

EQUIPMENT RSAGENTS TEST

---------------------------------------- - ------------------- ------------- -- ------ procedures

6.

7. 7.1 7.2 7.3

STANDARDS

PROCEDURE Step-by-step Miscellaneous

------procedures auxiliary

Ce ne ra 1 ---------------------------

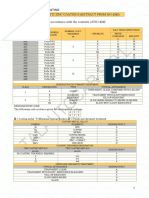

FIGURSS Figure 1. 2. 3. 4. Identification Identification Identification Identification scheme scheme scheme scheme outline out Iine outline outline --------- (continued (continued (continued from from from ---------figure figure figure 1) --2)--- 1) --16 17 18 19

TABLE Table I. Significant alloy content of common steels -------------11

Source: http://www.assistdocs.com -- Downloaded: 2008-05-06T21:12Z Check the source to verify that this is the current version before use.

iv

DOD-HDBK-249A( 26 ~., 1. 1. I site for SCOPE ~i~ handbook. -~scribes metals and chemical the the equipment December

SH) 1984

and

procedures are but of

for not will metals

rapid provide and

Ona alloys.

identification of use when quantitative means 2. 2.1 of

alloys. analysis most

These is

procedures required,

intended

reliable

identifying DOCUMENTS documents.

common

categories

REFERENCED Isauee of extent

The

following

for

documents,

proposal,

.of the

form

issue

of

in

ef feet

on date

handbook

of

to

invitation

the

for

bids

or

request herein.

a part

this

specified

SPECIFICATIONS FEDERAL QQ-B-626 Brass, Leaded and Nonleaded: with Wire, Finished shapes, Edges (Bar, (Plate, Rod, Wd, shapes, Edges ( Bar Forgings, and and Wire, Sheet, Strip, Sections. . CopperFlat and qnd Flat and Flat Strip) . QQ-B-637 Brass, Products Strip) . QQ-B-639 QQ-B-750 Brass, Strip). Bronze, Wire, QQ-C-390 QQ-C-591 Copper Products Rod,

Naval: with

Forgings, Flat Bar, Sheet, Shaped Cast Bar) and Shapes,

Finished Flat

Naval: Phosphor; and Alloy

Products Bar, Plate, and ( Including Rod,

Structural Casting, Alloys:

Special

Copper-Silicon, Nickel-Silicon

Copper-Zinc-Silicon, Wire,

QQ-N-281

QQ-N-286 QQ-S-763 QQ-W-390 MILITARY MIL-S-870 MIL-S-872 MIL-S-1222 MIL-N-7786 MIL-N-8550 MIL-S-16216 MIL-T-16420

Forging$, and Flat Products (Flat Wire, Strip, Sheet, Bar, and Plate). Nickel-Copper Alloy Bar, ~d, Plate, Sheet, Strip, Wire, Forgings, and Structural and Special Shaped sections. Nickel-Copper-Aluminum Al 10Y, Wrought. Stee 1 Bars, Wire, Shapes, and Forginga, CorrosionResisting. Wire, Nicke l-Chromium-Iron Alloy.

Steel Steel Studs,

Castings, Bars, Bolts,

Molybdenum Billets, Al 10Y. Hex Cap Screws, and

Alloy. Forgings and and Carbon-

Molybdenum Nickel-Chromium Age-flardenable Nickel Steel ( HY-80 Tube, (Copper A11oY, Plate, and Operating

Wuts. Strip, 1200 to Yield and 1500 F

Alloy, Sheet Annealed. Bars Alloy, HY-1OO). 1 Alloy, Numbers 715 and Forgings, Structural, Temperatures.

High Saamless and 706). Strength

Copper-Nicke A11oY

Welded

Source: http://www.assistdocs.com -- Downloaded: 2008-05-06T21:12Z 1 Check the source to verify that this is the current version before use.

DOD-HDBK-249A( 26 December

SH) 1984

,..

MILITARY ( cent inued ) Steel Bars, Billets, Blooms or . Surfacing. Forgings ChromiumSteel, and Slabs, Carbon and Alloy (For Reforging Before Heet Treatment) MIL-R-17131 MIL-S-1841O MIL-T-20155 MIL-T-20157 MIL-C-20159 MIL-s-22698 MIL-S-23192 MIL-T-23227 MIL-N-23228 MIL-N-23229 MIL-T-24107 MIL-N-24114 MIL-I-24137 Rods Steel Tube and Powdere, Billets, Alloy. Pipe, (ASI14 Carbon-Molybdenum A-335 -55T, Grade Alloy P-1). : Castings. Strength Bare, and and Other operations MIL-S-16974

Welding,

Mnlybdenum Seamlese

Tube and Pipe, Carbon Steel, Copper -Nicke 1 Alloy ( 70-30 Steel and Iron Tube Plate Righer and Shapee, Strength:

Seamleee. and 90-10)

Weldable ordinary Hull Strength.

Springe,

Helical,

Age-Hardenable Nickel-Chromium-Iron

Nickel-ChromiumAlloy. Sheet and and Strip,

Alloy. and Pipe,

Nicke l-Chromium-Iron Alloy Plate, Air Melted or Vacuum Remelted. Nicke Tube, 108, Rods, Iron, and l-Chromium-Iron Copper 120, ( Seamless) 122, and 142). Age-Hardenable Graphitic (Corrosion Alloy Bars (Copper

Forgings. 102, 103,

numbere

Nickel-Chromium-Iron

Al 10Y (Ductile Kasisting,

Bare, Iron)

and Forgings. Castings, Nodular Nodular Graphitic Low Magnetic Application).

Austenitic, Shipboard MIL-C-24252 MIL-B-24480 MIL-N-24492 Tungsten Bronze, service.

Permeability) and

(For Cobalt-ChromiumSeawater le Forging and

...

Cobalt-Chromium-Tungs Alloy Bars, Nickel-Aluminum

ten-Nickel Hods and Castings, lumbimm Reforging Steel istant Alloy,

Forgings. For

Ni cke l-Chromium-Iron-Co Alloy Bars, Rode, (A11oY 718). Chromium-Nickel Forginge, Hardening) .

Age-Nardenab Stock, Bars, and Sc.de,

MIL-C-24527

Al 10Y, Corrosion-Ree

(Precipitation Age Hardenable, Bars

MIL-N-24549

Nickel-Copper-Aluminum and Rods.

STANDARD FEDERAL FED-S2D-66 (Copies specific or 2.2 book effect to of specifications acquisition. as directed publications. specified invitation by Steel: Chemical standards should Composition required obtained ) form a part of this handin and Hardenability.

with activity

and functione the

be

by contractors in connection from the contracting

contracting The following

of ficer.

Other

documents

the extent on date of

herein. for bids

Onless otherwise or request for

indicated,. the issue proposal shall apply.

Source: http://www.assistdocs.com -- Downloaded: 2008-05-06T21:12Z 2 Check the source to verify that this is the current version before use.

DOD-HDBK-249A( 26 December

SH) 1984

ASTM A48 A 217 Gray Iron CastinSs, Standard Steel Parts Specification for. for Nartensitic Stainless Pressure-Containing and Alloy Steel Castings Suitable for High-Temperature for. lumbium A11oY for. A11OYS Alloy ( UNS N06625) ( UNS N06625) Pipe Wd

B 160 B 443 B 444 B 446 B 637

Service. Nickel Sod and Bar, Specification Nicke l-Chromium-Molybdenum-Co Sheet, and Strip, Nickel-Chromium-Mo and Nickel Tube,

( UNS N06625)

Plate,

Specification lybdenum-Columbium for.

Specification

-Chromium-Molybdenum-Columbium

and Bar, Specification Precipitation-Hardening

Forging Stock should for

for. , Nickel

High-Temperature

Alloy

Bars,

service,

Forgings,

Specification

and

for.

(Application

for

copies

be

addressed

to

ASTN,

1916

Sate

Street,

Philadelphia, (Technical

are among 3. 3.1 3.1.1 metallic This of metal weld welding, general ly technical

PA 19103. society

available groups

)

and for and technical reference using Federal association from libraries. agencies. ) apecificationa They are and alao standards distributed

GENEKAL Intended Tnis materials alloy sorting overlaya,

KBQUIRBNSNTS uae. procedure is by category claaaification of scrap, locating or lead plating, intended for or subcategory, procedure weld shielding. as a substitute determine whether procedure a metal metal. only confirm that the unknown is only which is for quantitative or not a metal use can beads when it ia i.e. , alloy be or used for overlays, desired to identification. identification and insuring identify for removal

3.1.2 ~ia chemical analyais. specification which meet may behave 3.1.3 the 3.2 3.2.1 temperatures ature (z5 +

procedure is It cannot

not intended be used to

meets

chemical specification in this

requirements. requirements aa this of

This since

valid for metals off specification

procedure

a different

reacts

Ihe same Testing

procedure of as a standard conditions. spot teats

handbook will known chemistry.

Chemical

should

be ( C) and

performed or the above test

on 7C. cauae

materials Normal variances must

that ambient in be at

are reaction the

at tempersame

below 60 degrees Celsius 5C) is best. Temperature Both the unknown

variation

time and i=tensity. temperature.

standard

Source: http://www.assistdocs.com -- Downloaded: 2008-05-06T21:12Z 3 Check the source to verify that this is the current version before use.

DOD-HDBK-249A( SH) 26 December 1984

3.2.2

reaction testing flashlight lighting

TO assure

the provide

accurate

best possible Unfiltered the shall be

determination

and comparisons

of

be

colors

and in each of a case, standard.

rates, situation. may conditions

lighting conditions shall daylight would be preferable. acceptable came for both light the intensity. unknown

provided The case In any teet the

loweet the

and

3.3. 3.3.1

regarding in thie

Safety .Ueera

safety, procedure.

precautione. of this procedure

and disposal

shall

comply with

with

all to the

local

regulations. involved

storage,

respect

reagents

3.3.2 precautions be observed.

when not in

Most of the reagents are acida or corrosive chemicala. Normal (ace 4.l(f)) to avoid contact with clothing, ekin, and eyee should be tightly closed Plastic containers shall be used and should

use to avoid spills. Adequata ventilation should be provided.

3.3.3 At the completion of teeting, the water followed by the use of. moist, absorbent and the work shall be dried reaction producte

3.4. sticker information: (a) (b) (c) (d) (e) 4. Reagent Preparation Expiration Special Signature name and the identifying Labelin&. affixed. Seagents The label should shall be include, labeled as

epecimens should clothe or paper

to prevent and have further

be rineed with to wiPe Off

chemical attack.

a hazardous the following

material

a minimum,

paragraph

number.

date. date. safety of precautions. preparer.

EQUIPMENT

4.1

l%e equipment

(a) (b) (c) (d) (e) Seagents Plastic &he Cleaning

to

be used

is

ae

followe:

as specified milliliters herein. (mL) capacity

and distilled dropping bottles

water 50

for paper. into

storing

reagents. materials euch aa a fine paper, Whatman No. 3 paper 2.5 and or centimeters because shades of (cm) lighting color in (l-inch) is both often alloy file or abraeive or equivalent, wide. poor and under reaction testing condiare products skin as from by glovee, cut strips

Filter

about tions

A flashlight difficult Rubber contact local safety

(f)

to judge without plaetic gloves or and Beco eye nails. case for

an adequate finger cots other safety

light source. (to protect equipment include plastic

with reagents) regulations. glasses, uncoated and stael

required

,.mended iteme ~ash bottle.

(g) (h) (i) (j)

Clean,

Small magnet. A suitable carrying standards. A stopwatch or

equipment, device.

reagents,

and

test

equivalent

timing

Source: http://www.assistdocs.com -- Downloaded: 2008-05-06T21:12Z 4 Check the source to verify that this is the current version before use.

DOD-HDBK-249A( 26 December

SH) 1984

,. --., ,,, ,...;

. . ..

5.

KEAGENTS

of

Fifty 5.1 concentrated

of 5.2 distilled Five me In shelf view

percent

nitric water. percent is 1 gram life of the

nitric

acid,

acid.

Fifty

percent

nitric

acid 1.42,

is added

one to

volume one

volume

with a specific The shelf life acid

gravity of is 6 months. solution. Five

chromotropic of is very chromotropic 8 hours. brief

percent in

chrrmotropic 20 mL distilled

acid water. NOTS : powder, distilled be

solution

acid

powder

dissolved

shelf

life

of

chromotropic in

acid

solution, with should

the

which has a 3-year shelf water, only as needed with the date of

life, shall be mixed for use within 8 hours. to avoid accidental

proper amounts The container use of

marked

preparation

deteriorated

reagent. 5.3 Silver nitrate. Silver water. from The nitrate reagent the acid. life is 1 gram of silver bottle should be solution. The is specific indefinite. Ten in percent 100 potasaium distilled ferricyanide water. l%e nitrate wrapped shelf of life the dissolved with opaque is 6 months.

in 100 mL of distilled tape to prevent sunlight 5.4 bvdrochloric 5.5 ( /-- ..., :,.: ., is The 10 grams shelf 5.6 grams life of is 5.7 of shelf life 5.8 (paper) distilled and The allow by shelf 5.9 trated acid 5.10 soaking fil:er dimethylglyoxime by dissolving hydroxide. , .:, ,. . of to glacial air dry is Concentrated acid is Ten of life Forty sodium 6 months. l%enty is p ercent sulfuric 6 months. percent. potasaium is

degrading

hydrochloric 1.18. Ihe potassium ferric

gravity

concentrated

shelf

ferricyanide. yanide dissolved

mL of

6 months. percent sodium hydroxide. .in 100 Forty mL of percent distilled sodium water. hydroxide The shelf is 40

k.;,;

hydroxide dissolved

sulfuric acid elowly

acid. added

Tventy to 80

percent mL of

sulfuric distilled

acid water.

is

20 The

mL

concentrated

Potaaaium 10 water. grams

ethyl of Eoak

xanthogenate potassium whole pieces ethyl of

(paper) filter cut .

Potassium dissolved in in the an into strips

ethyl in solution,

xanthogenate 100 mL of remove, 0.6 container.

xanthogenate paper Store

cm wide

to dry completely. 5 cm long ( l/4-inch life Ten of the paper nitric 90 mL of ia

After drying, by 2 inches) 6 months. Ten

approximately air tight

percent to

acid. distilled (paper) .

percent water.

nitric The shelf

acid life paper

is

10 is

UIL of

concen-

added

6 months. by grama of

Dimethylglyoxime paper in a in powder

Dimethylglyoxime as alcohol. follows: ethyl

is

prepared 0.4

solution 40 mL of

prepared

dissolve

5 grams of ammonium acetate Combine the two solutions and acetic acid. thoroughly. cm wide by The shelf After The 5 cm life soaking is for then paper

Prepare a second solution in 15 mL of concentrated ammonium mix well. Add this solution to 30 1 minute, cut into. remove strips the paper in an and approxiair measuring Store

mL allow

mately 0.6 container.

long (1/4-inch of the paper

by 2-inches). is 6 months.

tight

Source: http://www.assistdocs.com -- Downloaded: 2008-05-06T21:12Z Check the source to verify that 5 this is the current version before use.

DOD-IfDBK-249A( 26 December

SH) 1984

volume water.

5.11 of

percent Fifty concentrated shelf life percent hydroxide

sulfuric sulfuric is 6 months.

acid. acid slowly

Fifty

percent added to

sulfuric one volume

acid of

is distilled

one

The 5.12 of

grams is

Five sodium

sodium

hydroxide. in 100

Five mL of

percent distilled

sodium water.

hydroxide The

is shelf

5 life

dissolved

6 months. 5.13 Five percent diseolved sodium in 100 sulfide. mL of Five dietilled acid. acid percent water. Fifty added percent to 50 sodium The sulfide shelf life is 5 grams is. of

sodium

sulfide

6 monthe. is

hydrochloric 5.14 Fifty p ercent 50 mL of concentrated hydrochloric water. The shelf life is 6 months. 5.15 dissolved dietilled 5.16 thiocyanate 6. 6.1 required. tested shall for have Stannous chloride. in 20 mL of 50 percent water. Ammonium diseolved TEST A set thiocyanate. in 100 mL of

hydrochloric mL of dietilled

acid

S1OW1Y

Stannous

chloride acid

is

35 and

hydrochloric

grams diluted

of

etannous chloride to 100 mL with

Ammonium distilled

thiocyanate water.

is

100

grams

of

ammonium

STANDARDS of standard test shall color, cm2 examples a white specimens be tested chemical (1 square of of known chemical composition is

These standards comparison of an area of 6.25 provides Materials

concurrently with tests, and magnetic inch) or which more. can The be

the materials being Specimens teats. following for this luster. many available are as list of used procedure.

specifications 6.2 6.2.1 AISI or

standards or silvery,

Iiaving

steel-like from alloy any steel. one

metallic of the

as

Carbon or SAE grades in MIL-S-16974 Caat Ouctile 300 series 300 series 17-4 steel, 400 iron.

A specimen alloy steel. of carbon steel or low and Any FED-STD-66. of the be gray in cast

Canpositions

specified 6.2.2 ASTM A 48. 6.2.3 the

irons with

shall

be

in

accordance class series A. CSES

with

iron

shall

accordance steel QQ-S-763.

MIL-I-24137, 300

one

of

corrosion classes

resietant listed in

(CRES).

ie

any

6.2.4 stainless 6.2.5 clasaes 6.2.6

PH CRSS. type I or series CSBS. in QQ-S-763.. %opper.

17-4 PH CRBS is II of MIL-C-24527. 400 series

precipitation

hardening

17-4

PH

CRSS

is

any

one

of

the

400

series

listed

Nickel

Nickel-copper

is

class

A ( UNS N04400) is

of

QQ-N-281-. of .

6.2.7 QQ-N-286 or

Nicke l-copper-aluminum. MIL-N-24549.

Nickel-copper-aluminum

UNS N05500

Source: http://www.assistdocs.com -- Downloaded: 2008-05-06T21:12Z 6 Check the source to verify that this is the current version before use.

DOD-HDBK-249A( 26 ,/--,>. ,.:. . .. December

Sli) 1984

6.2.8 6.2.9 6.2.9.1 (d (b) (c) (d) 6.2.9.2 (a) (b) (c) 6.2.9.3 141L-N-24492. 6.2.9.4 (d (b)

Copper~ickel. Nickel-chromium-iron. UNs N06600. Bars, , Plate, Pipe Wire rods sheet and shall tube be

Copper-nickel

is

70/30

Cu-Ni

of

MIL-T-16420.

UNS N06600 and forginge strip be shall in

is

as

follows: be be with in in accordance accordance with QQ-W-390. with with MIL-T-23227. MIL-N-23229. MIL-N-23228.

shall ehall in

and

accordance

accordance ie shall shall be in shall as

UNS N06625. Sod Plate, Pipe and and

UNS N06625 forging stock and shall strip

follows: be be in in accordance accordance with accordance ASTN with with ASTM B 446. ASTM B 443.

sheet tube

accordance be in

B 444. with ASTN B 637 or

UNS N07718.

UNS N07718

UNS N07750.. Bars, rode, MIL-S-23192 Plate, sheet

UNS N07750 and or and f~rginga MIL-N-241 strip ten

is

as shall 14.

follows: be be shall in in accordance with with MIL-N-8550, MIL-N-7786. with

shall alloy

accordance be in

~. .. ...

6.2.10 MIL-R-1 7131 Cobalt-chromium-tunge or MIL-C-24252. ten-nickel alloy shall be in accordance with accordance

6.2.11 MI L-C-24252. 6.2.12 6.2.13 leaat 70

Cobalt-chromium-tungs

Nickel. Titanium. percent

Nickel

200

shall shall

be be

in pure

accordance titanium

with or

ASTM B 160. alloy of at

Titanium

any

titanium. shall be pure aluminum or any alloy of at

leaat

6.2.14 Aluminum. Aluminum 70 percent aluminum. 6.2.15 Magnesium.. percent Zinc. magnesium. Zinc shall be Negneaium

shall

be

pure

magnesium

or

any

alloy

of

at

least

70 6.2.16

pure

zinc

or

any

alloy

of

at

least

70

percent

zinc. 6.3 color. Meteriala having reddish, red-brown, dark yellow, or light yellow

,,. . ..,,,

\:...

6.3.1

Pure

copper.

Copper

tubing

shall

be

in

accordance

with

MIL-T-24107.

Source: http://www.assistdocs.com -- Downloaded: 2008-05-06T21:12Z Check the source to verify that this is the current version before use.

DOD-HDBK-249A( 26 December

SH) 1984

. .

6.3.2 (a) (b) 6.3.3

Cbpper-ickel.

Copper-nickel

is

as

follows:

~pe II, 90/10 Cu-Ni shall be in accordance with MIL-C-20159. 90/ 10 Cu-Ni tubing shall be in accordance with MIL-T-16420. bronze. Aluminum alloy bronze are as bronze is aa follows:

Aluminum (a) (b)

Aluminum bronze, Nickel-aluminum Braaaes. Braaaea

952 shall be in accordance with QQ-C-390. shall be in accordance with MIL-B-24480. follows:

6.3.4 (a) (b) (c)

Leaded brass, composition 360 shall be in accordance with QQ-B-626. mval brasa, alloy 464 shall be in accordance with QQ-B-639.. High-p trength yellOw braes (manganeae brOnze), allOYs 864 and 865 shall be in accordance with QQ-C-390. Other bronzes. Other bronzes are aa follows:

6.3.5 (a) (b) (c) (d) (e) (f)

7.

Silicon bronze, alloy 655 sliall be in accordance with QQ-C-591. Valve bronze ( !4), alloy 922 shall be in accordance with QQ-C-390.. Gun bronze (G) , alloy 903 shall be in accordance with QQ-C-390. Phosphor bronze, composition A shall be in accordance with QQ-B-750. Manganese bronze, alloy 863 shall be in accordance with QQ-C-390. be in accordance with QQ-C-390. Manganese bronze, alloy 861 shall

PROCEDURS

7.1

General.

7.1.1 lhis handbook providea a procedure for metal alloy identification or claaaification of an unknown metallic material into the categories or subcategories of section 6. he further separation of metala and alloya within the groups ia as specific as poaaible within practical limits, i.e. , a reasonable number of chemicala and no complex apparatus. 7.1.2 The following are examplee of use of this procedure:

scrap used with in the yard, to tentatively. the unknown

foundry, identify and

7.1.2.1 If the sample is completely unknown, such as or forge shop, then the entire procedure shall be the unknown. The procedure should then be repeated standard If the for comparison. ia expected the the of or suspected to be

a known 7.1.2.2

unknovn

some

specific

materia 1, then and run through 7.1.2.3 either reaction of

a known standard the procedure III the typical

of with example, steel, percent stainless

desired unknown submarine

material shall be acquisitioned for positive identification. air flack heads, which can be

UNS N04400 or stainless of the unknown to 50 alloy and a

all that ia nitric acid steel.

required with that

is to compare the of known standards

nickel-copper

Source: http://www.assistdocs.com -- Downloaded: 2008-05-06T21:12Z Check the source to verify that this is the current version before use.

DOD-HDBK-249A( 26 ,,---.:,,:, ,, ..... , will December

SH) 1984

7.1.2.4 eliminate possibilities.

In

many

other

cases,

the

form,

shape,

or

usage

of

the

unknown three materials.

many Tne

possible unknown

metals and can then be

thus narrow the search compared with standards

to two or of these

7.1.3 difficult

reagents so In for that less

The procedure specified herein has been developed with the most The technique of applying field (or shipboard) condition in mind.

and observing can the on the with his as Although to as spot Test and is be situations same metal known reagents surface standards. is for not intended example, for Ni-Cu alloy set should forth not be use weld on weld metals. will provide Such the use can same reactions done even in in on which and rather filter vertical a flat, in reactions than paper is presented or but surface can paper, be wherever piping is available in in observed always feasible systems. surfaces horizontal prevail the filter overhead

testing rigorous

testing,

droplets comparison 7. 1.4 provide color

handbook results,

erroneous reaction 7.1.5

metal

nickel-copper-aluminum the tests, procedures they

provides. in test this which handbook with utilizes the are Arid commonly Spot

referred Absorption analysis 7.1.6 ,, -.,, .. ::,, herein, be used

confused

(ASAT), a more not covered by

quantitative this handbook. the 4)

spectrographic

flow only

To facilitate charts (figures with the aid

visualizing 1. through of the

spot are

test procedures package necessarily abbreviated procedures as specified

presented and shall in 7.2.

step-by-step

,...,, ; ,f

.7.2

Step-by-step

procedures. the metal or file to metallic or otherwise

Prior to testing, clean a spot of at least 6.25 cm2 on 7.2.1 surface with a decreasing solvent, abrasive wheel, abrasive cloth, remove dirt, greaae, corrosion products, oxide or temper films, or When testing for coating identity, do not use abrasivea coatings. remove coating prior to testing.

7.2.2 Examine the clean surface and classify on the basis of color two groups, the first group having white or silvery, steel-like metallic luster and the second group having reddish, red-brown, dark yellow, or yellow color. Figures 7.2.3 the unknown materials steel-like metallic sequentially on this

7.2.3.1 screening tests. saparate

into light

1,

2, and 3 comprise a schematic flow chart for identifying that are color identified as having white or ailvery, luster. The following procedures shall be performed group of metals aa specified by the flow charts.

aluminum, magnesium, or zinc alloys by the following

7.2.3.1.1

abraded Aluminum .; ~.~..<, heavy aa

These

metals

are

always

nonmagnetic

surface therefore

and extremely

is dull light, gray while

soft

when as

or filed; and and magnesium common steels.

the normal air-oxidized are low density and,

or white. zinc is

Source: http://www.assistdocs.com -- Downloaded: 2008-05-06T21:12Z Check the source to verify that this is the current version before use. 9

DOD-HDBK-249A( 26 December

SH)

1984 . .. . ..

7.2.3.1.2 goes (see a vigorous 5.6) 7.2.3. is 1.3

Aluminum, white applied to

exclusive when spot. zinc a clean and

of

all

other o f 40

white percent

or

silvery sodium

metals, hydroxide

underreagent

reaction

a drop

Fiagnesitun

can

be

screened reagent spot on two (see than metala 5.11) 15

from (see the

other 5.3) metal be to

white on a when separated spot. the

or

silvery

metals by placing a drop lhe drop will turn black product a drop of is absorbed in

of silver and leave filter paper. acid

nitrate a black The reagent less

clean spot. reactant by spot applying Tne spot zinc

can

50

percent becomes gray in After

sulfuric chalky about eliminating

a clean and

on magnesium s lowly turns. 7.2.3.2 aPPIY paper,

white in 1 minute. the nitric for at

seconds

on

possibility acid least the

of

the

white

metals strip

as

above, of filter

two drops press on 7.2.3 17-4

of 50 percent a clean spot

reagent (see 5 .1) to a 2 minutes, and remove. filter alloy, paper indicates

CKSS, cobalt

No visible color on .2.1 PH CHES, nickel-chromium-iron ungsten-nicke A vigorous. indicates An paper 1 alloy,

300/400

series alloy,

chromium-tungsten-cobalt

-chromium-t 7.2.3.2.2 or black 7.2.3 .2.3

or

titanium. paper iron. coloration .. . on alloy, indicates add one to the indicates the or filter pure paper nickel. alloy, filter to or

brown

reaction which turns both metal and filter plain carbon steel, low alloy steel, or cast reaction copper-nickel and a green and a bluish-green 70/30. coloration (turquoise)

immediate. indicates

on

the

filter 7.2.3.2.4

A slower

reaction alloy,

indicates

nickel-copper the

nickel-copper-aluminum of 7.2.3 .2.4 pure nickel, (see 5.2) coloration

7.2.3.3. If nickel-copper-aluminum chromotropic paper. alloy. greater An acid

green color alloy, or reagent to scarlet red

nickel-copper drop of 5 percent spot on the

solution

green

immediate

nickel-copper-aluminum ie equal paper.

The red color in absorbency

is most visible when the than Whatman No. 3--double

filter paper thickness

7.2.3.4 drops of 50 hydrochloric If, plated nail after on the indicates

Nickel-copper percent nitric acid reagent a clean nail, pure Ihe or that

alloy and nickel can be separated by applying two acid reagent (see 5.1) and one drop of concentrated (see 5.4) cm a clean spot and reacting for 1 minute. steel nail alloy in the is reactants present. for Absence 1 minute, of copper copper on is the

rubbing

riickel-copper nickel. carbon black steels, reaction tubing,

vigorous and

7.2.3.5 brown (bars,

alloy steels, of 7.2.3 .2.2 and forgings) of

and cast encompass with an uriknown iron the

irons identified by so many specifications overlapping is not If it family surface. iron. are chemical possible. relatively is necessary of steels, The drop simple

the

forms

cast tests limited iron,

inga, for or

compositions However, spot and provide a identify one will cast drop of remain

positive

identification

nickel, basis for to otherwise

molybdenum and cast further classification. separate it from

to add

silver clear

nitrate on steels

reagent (see 5.3) to the metal and turn black or gray on cast

Source: http://www.assistdocs.com -- Downloaded: 2008-05-06T21:12Z Check the source to verify that this10 the current version before use. is

DOD-HDBK-249A( 26 December

SH) 1984

,<,-.,, ,,, ,.,

!

7.2.3.5.1 Test nitric acid solution (see 5.14) on a clean

four drops of the of .5.2 a red strip color stannous thiocyanate color in intensity 7.2.3 nitric inserting Pink to ability higher acid reagent

for molybdenum in reagent (see 5.1)

Absorb the spot. chloride reagent (see 5. 16) on the

steels by dropping one drop and 50 percent hydrochloric

reactant (see filter 5.15). paper percent, to by spot, product on A drop will filter or two

of 50 percent acid reagent

paper and add of ammonium Or red The

develOp

a pink molybdenum. content. of 10 into of to

presence of approximately 0.2 color development is proportional Test of on for (see nickel 5.9) on in steels

or greater the molybdenum one for (see lower drop

dropping reacting

percent and the drOp. detectred at

reagent

a clean

1 minute, 5.10) limit

dimethylglyoxime the paper indicates nickel and the

(paper) reagent The nickel. pink color is

is 0.05 percent nickel contents. 7.2.3.5.3 lhe have for nickel content Two above nickel or in

intensified

tests and if

are

not

sufficiently contents or is steels are found. are specified less

sensitive than The 0.15 limits shipboard

to

identify but require nickel and and

alloys are stee 1s

which useful with

molybdenum receipt and shipboard none

percent, of

rejection

inspection

verification

molybdenum typical of proven

molybdenum guidance. 7.2.3.5.3.2.

specified

in

in

7.2.3

table

.5.3.1

I fOr

examples

utility

TABLE

I.

Significant

alloy

content

of

common

steels.

Alloy

and

specification

Alloy percent Ni

content ; minlmax Ma

Carbon (1) (2) (3) Alloy C-tie (1) (2) (3) (4). (5)

steels AISI Grade Tube steels steels Tube and pipe of MIL-T-20155 .25 .25 --- 1030 and of pipe MIL-S-16974 of of MIL-S-22698 MIL-T-20157

D plate

-------

----1.25 ntax

--max max

.441 .40/.60

.65

Bar or Castings Grade

forgings of MIL-S-872 of MIL-S-870 4 nuts of Gr. MIL-S-1222 WC1 castings

.40/.60 .20 min .45/ .65

ASTM A 217,

< ... ..

Source: http://www.assistdocs.com -- Downloaded: 2008-05-06T21:12Z Check the source to verify that this 11 the current version before use. is

DOD-HDBK-249A( SH) 26 December 1984

TABLE

I.

Significant

alloy

content

of

common steels.

- Continued

Alloy

and

specification

Alioy percent; Ni

content minlmax Ma

Cr-MO (1) (2) (3) (4) (5) (6) (7) Ni-Cr-Mo (1) (2) (3) (4)

steels 1-1/2 2-1/2 AISI B-14 B-16 Cr-1/2 Cr-1 4140 bar bar of and and MO of MO of studs studs Gr. Gr. MIL-s-1841O --. --- MIL-S-1222 MIL-S-1222 --- ----.45/ .65

MIL-S-1841O of of

MIL-S-16974

.90/1 .10 .15/.25 .28/.42 .42/.68 .45/.65 .90/1 .20

I

7.2.3 indicates steels of red color

7.2.3

ASTM A 217, ASTM A 217, steels kISI AISI Grade Grade 4340 8630 of of

WC6 castings WC9 castings

MIL-S-16974 MIL-S-16974 of MIL-S-16216 of MIL-S-16216

L.65/2.00 .40/ .70 2.00/3.25 2.25/3.50

.20/ .15/ .20/ .20/.60

.30 .25 .60

HY-80 plate HY-1OO plate

In steel pipe or tube materials, absence of molybdenum .5.3.1 carbon stee 1. Carbon -olybdenum steel and the chromium-molybdenum MIL-S-1841O are distinguishable by comparison of the intensity of with known standards.

.5.3.2 spot Submarine nlate Absence of lack series of alloy, reaction CRSS, 17-4 cobalt steels Ni and to of HY-80 or HY-1OO shall have positive Mo may indicate grade D of MILLS-22698. 50 percent nitric acid reagent alloy, (see alloy,, or fully CRES or 5.1)

MO and

Ni

tests. If

7.2.3.6 indicates 300

the 400

or

PH CRES,

nickel-chromium-iron If the sample is either 400 series

chromium-tungsten-cobalt titanium alloys, ferromagnetic, 17-4 CRES PH CRES. standard

-chromium-tungsten-nickel of the standard, sample. it is

check the in comparison Samples will be alloy, with

magnetism with a less

300

series

than the full ferromagnetism CRES, nickel-chromium-iron alloy,

of a 400 series allOY, chromiumor titanium alloys.

tungsten-cobalt

cobalt

-chromium-tungsten-nickel

5.4) and

7.2.3 .6.1 Apply two drops of concentrated hydrochloric acid reagent (see to a strip of filter paper, apply to a clean spot, react for 30 seconds, remove. Then apply one drop of 10 percent potassium ferric yanide reagent A yellow ring with a green paper. CRES and a plain yellow ring indicates cobalt -rhromium-tungs ten-nickel then be placed back onto the center the same ,,:. : then removed. If nickel-chromium-iron a purplish-black residue or is indicated. with a

(see 5.5) onto the reactants on the filter or blue-green center indicates 300 series nickel-chromium-iron, chromium-tungsten-cobalt, alloy, spot spot If on on the or the the residual titanium. metal, metal The yellow spot shall and over, held for 2 minutes, is bluish-green all spot on the metal

contains

Source: http://www.assistdocs.com -- Downloaded: 2008-05-06T21:12Z Check the source to verify that this is the current version before use.

12

DOD-HDBK-249A( 26 December

SH) 1984

bluish-green spot is gray tungsten-nickel alloy is

fringe, or black alloy

chromium-tungsten-cobalt in ie the center indicated.

alloy

is

indicated. fringe, on the

If

the

residual

with a bluish-green If no spot remains

cobalt-chromiummetal, a titanium

indicated.

If it is desired to separate the various 7.2.3.6.2 alloys specified in 6.2.9, place two drops of 50 percent and one drop of concentrated hydrochloric acid (see 5.1)

a clean of green spot, react for 3 or. on known etandards. 4 minutes, and compare with

nickel-chromium-iron nitric acid reagent

reagent (see the distinctive 5.4) On shades

7.2.3.6.3 17-4

(see clean these indicate PH can 5.1) epot d.. be

After

separated

the

of for

identification

by applying twn concentrated 1 minute. copper ie

of

an unknnwn

nf 50 acid rubbing on the

as 400

series

nitric (ace steel

or

acid

17-4

PH,

drops

percent

reagents on a in

and one drop and reacting for

hydrochloric If, after plated

reagent a clean 17-4

5.4) nail is

reactanta

1 minute,

nail,

PH CRSS

7.2.3.7 identification 7.2.3 400 aeriee .7.1

A magnet schame. Carbon are

ia

a very

ueeful

tool

for

confirming

the

chemical

steels,

low-alloy strongly

steels,

nickel,

17-4

PH CHES,

and

CSES

always

magnetic. nickel-copper-aluminum, -chromium-tungs ten-nicke nickel-chromium1, and titanium

irom, alloys

7.2.3 .7.2 70/30 copper-nickel, chromium-tungsten-cnbalt, are 7.2.3 alwaye .7.3 lhe nonmagnetic.. other metals

cobalt

in

this

group

exhibit

magnetic

variancee

aa

followe: 7.2.3 .7.3.1 Molybdenum-bearing nonmagnetic, or cnld-worked l%e other but can 300 eeries CSES euch aa 316, 316L, 317, m

and 319 are usually either the annealed 7.2.3 .7.3.2 annealed condition, after cold 7.2.3 strongly working. .7.3.3 magnetic. In follows: always a lwaya usually as

but

can sometmes condition.

be

strongly

magnetic

300 aeriaa CRES range to strongly

claeses are magnetic,

nonmagnetic in if not annealed

the

Nickel-copper

alloy

is

usually

nonmagnetic,

but

can

range

to

7.2.3.7.4 specified as

figures

1 through

4,

these

magnetic

characteriatica

are

SM NM nm -

strongly

magnet

ic but subject to variances

nonmagnetic nonmagnetic, above reaaon, the

specified for any

:

(,,,:

,,

not ful,

7.2.3.8 agree, submit

If,

chemical chemical chemical

reaction reactions analysis.

and

magnetic or magnetism

response are

do dnubt -

or interpretations the unknown to

of either quantitative

Source: http://www.assistdocs.com -- Downloaded: 2008-05-06T21:12Z Check the source to verify that this is the current version before use.

13

DOD-HDBK-249A( SH) 26 December 1984

7.2.4 the unknown color. the yellow following

Figures materiale flow By

1 and that charts. comparison

4 coneist of reddieh, have procedures

schematic red-brown, are to be

flow chart for dark yellow, performed

identifying or light by

Lhe following

sequentially

7.2.4.1 eeparate the copper alloys. 7.2.4.2 silver bronze. or in gray 6.3.2 nitrate development

with

a known pure copper

standard from

of the

pure dark

copper, yellow

vieually or light yellow

reddish,

red-brown

For of A rapid a

classifying (eea coloration reaction to 15 bronzes 3 gray black in

the 5.3)

balance tO in a clean indicatee 2 secoods indicatee in can

of

thesa sPOt.

materials, No reaction bronze indicates copper-nickal or

apply or the

one

drop

of

reagent

e low

aluminum or the 6.3.5. be less

nickel-aluminum A black brase. alloys specified

reaction or the

seconds specified bronze eilver eurface

other

7.2.4.2.1 Apply one drop for 30 seconds, turquoise indicates can be

Nickel-aluminum of 50 either percent. ae a

separated

from (see 5.1) paper. or of in

aluminum

bronze. spot of reaction bronze

nitrate drop or

reagent in filter

to a clean A reaction dirty 7.2.3.5.2. in as 7.2.4.2 follows. lhe .3.1 green

color indicatee nickel-aluminum confirmed by

aluminum bronze. the

A gray bronze. The identification nickel within test tha

-grean

nickel-aluminum

conducting separation

specified identified in figure

be

7.2.4.2.2 made using 7.2.4.3

Further the Apply of magnetic

groups 4. and of in

can

responses to confirm of metals

specified the are

magnet this

classification as specified

metals. 7.2.4

magnetic

.,.,

characteristic 7.2.4.3.4. 7.2.4.3.1 (b) ) are 7.2.4.3.2 copper-nickel of about 1.50

group

through

and

Fure copper (eee always nonmagnetic. 90/10 (see percent. The bronzee copper-nickel can

6.3.1),

leaded

and

naval

braases

(see

6.3.4(a)

tubing be faintly

is

nonmagnetic as a

but result

the

caat of iron

90/10 content

6.3.2(a))

magnetic

the

7.2.4.3.3 manganeee

aluminum bronze (see 6.3.4(c) due to iron

and nickel-aluminum bronza (see 6.3.5(f), and 6.3.5(g)) exhibit of about 2.0 in ae percent 6.3.5 are bronze, minimum. alwaye are

6.3.3) faint

and tO

moderate 7.2..4 NOTE : de-alloying

magnetism .3.4 of type

content alloys alloys in

The. remaining, the of copper-baae corrosion

specified such

nonmagnetic. subject to a

Some

aluminum

seawater

service.

not normally react react strongly if unknown materials with but caution. can be Tha detected

to the application they have suffered are suspected of da-alloyed by the

of silver de-alloying this condition,

Copper-base nitrate reagent corrosion in spot testing

alloys (see service. ehall

that do 5.3) may When be used

---

condition eddy-current

is not readily determined visually, type of nondestructive testing.

... ,.

14

Source: http://www.assistdocs.com -- Downloaded: 2008-05-06T21:12Z Check the source to verify that this is the current version before use.

DOD-HDBK-249A(

SH) 1984

,<.-., ... ,..:

the the 7.2.5 unknown tentative After shall and ly

26

December

tentative lY identifying be c leaned again and ehall be identified meteria 1.

the

the unknown observations and compared

by of

the preceding procedures, color, chemical a known standard of

raactione,

magnetiam

repeated

to

7.3 7.3.1 infeasible.

tests in siver the shall joints, nitrate sil-braze 7.3.2 easantial

Miscellaneous

auxiliary

procedures. of silver brazing alloya is

Spot testing for Whare possible,

be this secured. shall raagent deposit. be (see If

identification

suitable etching

samples to permit analytical chemistry is done to detect residual sil-braze metal by Instant is swabbing black required. stainless steel ramoved prior to piping welding systems, of the it the coloration joint with will 50 occur percent only on

accomplished 5.1). No standard

is

In the repair that the lead

of lead-ehielded ba completely

stainlesa steel. To check for complete by 5 percent sodium hydroxide reagent hold there for sodium sulfide paper turna rotating, a 7.3.3 faateners, If of the metal tioned cadmium adequate a rapid hold If ia occurs, acid. metal 1 minute.. Ihen remove reagent (see 5.13) on A standard in a lathe

laad remova 1, wrap filter ( see 5. 12) around the wald the paper the filter test prasa or and place dropa paper. Lead is be manufactured smearing lead on acid the items reagent

paper wetted prep area and of 5 percent if the by surface. present locally onto its

brown. CKSS bar

for this or drill tin, percent the nail in occurs

shall and

{,:. .:. I

\..;.

To separate cadmium, apply one drop of 50 reaction a clean rapid cadmium. Faatenars up locally takea gas place, uncoated evolution If

zinc coatings hydrochloric is the zinc. interface with

such as (see 5.14)

coating contact at

If no surface of

obvious reaction beneath the drop the nail and acid,

is tin. or made

no obvious coated with for use aa

gas evolution cadmium, tin, standards for are

of this nature occurs, the and zinc shall be acquisi this test. Caution: Positive time and ensure

identification ventilation

avolvea toxic gaaea. when cadmium coatinge

Minimize testing suspected.

Preparing Navy (Project SH

activity: 95 GP-NO07)

,.. :

$,.

,.,

<4.. ..,

Source: http://www.assistdocs.com -- Downloaded: 2008-05-06T21:12Z Check the source to verify that this is the current version before use.

15

DOD-EDBK-249A( SH) 26 December 1984

~

u h.

In

.,. .

Source: http://www.assistdocs.com -- Downloaded: 2008-05-06T21:12Z Check the source to verify that this is the current version before use.

16

DOD-BDBK-249A( SH) 26 December 1984

,...- . . ,/, . .

Q..)

Source: http://www.assistdocs.com -- Downloaded: 2008-05-06T21:12Z Check the source to verify that this is the 17 current version before use.

DOD-8DBK-249A( SE) 26 December 1984

Source: http://www.assistdocs.com -- Downloaded: 2008-05-06T21:12Z Check the source to verify that this 18 the current version before use. is

DOD-HDBK-249A( SH) 26 December 1984

,.<;,. ::. . . ... .. .,,.

Source: http://www.assistdocs.com -- Downloaded: 2008-05-06T21:12Z Checkus. G0VKRNM6.NT .mINT, MGis the current s-s. s-03. /2.. s. * the source to verify that this OFFICE: ,9. version before use.

19

WANDARDIZATION

DOCUMENT

IMPROVEMENT

PROPOSAL

(.% Insnudms 00CUWENTNUUOER

DOD-HDBK-249A(SH) 12. 00CUMCN7TITLE

- Rewrs? SkIt)

I . MAME OF SU6W1T?lNOoROAN1ZATION

TYPE OF ORGANIZATION WA

u u

-)

VaMDo

u u

Pm08LEW AREAS .

P..waph

U8en

MA,ACTRS OTHER (xrw,

N.mbor md

Wordlw

,..

e. Rbon/ndOMl.

f.

m-

-1.:

REMA14K9

I. NAMEOFSU9MITTER(&I. Plmt, Ml) - Ootlalld MAILINGAOO17ESS (9imt, t.3ty.sam, ZIP cods, - O@nnd

b. WI&l

T=

PLLIMS8M (-A.

a OATS OF SUBMISSION (YYMMDDJ

Source: http://www.assistdocs.com -- Downloaded: 2008-05-06T21:12Z Check the source to verify that this is the current version before use.

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- SB 111-SB 111MDocument14 pagesSB 111-SB 111MRoberto Faustino FaustinoNo ratings yet

- Applicable Codes and StandardsDocument48 pagesApplicable Codes and Standardskiki270977No ratings yet

- Material SelectionDocument58 pagesMaterial SelectionSivareddy InduriNo ratings yet

- Defence Standard 02-313 (NES 313)Document100 pagesDefence Standard 02-313 (NES 313)devajjisNo ratings yet

- POSI12124580L BrocDocument352 pagesPOSI12124580L BrocJuan Carlos SoHeNo ratings yet

- The Rotating Cylinder Electrode PDFDocument11 pagesThe Rotating Cylinder Electrode PDFbuvanseaNo ratings yet

- Parker SizeTempratureApplicationMediaPressureDocument40 pagesParker SizeTempratureApplicationMediaPressuretrilemmaNo ratings yet

- MSS SP-117 (1996) PDFDocument11 pagesMSS SP-117 (1996) PDFadprim100% (1)

- SB 111Document14 pagesSB 111patelr123No ratings yet

- SWO - Water-Oil-Coolers-EMDC - HY10-6011Document8 pagesSWO - Water-Oil-Coolers-EMDC - HY10-6011766 HINo ratings yet

- Rules For Pipes P1Document10 pagesRules For Pipes P1asif712No ratings yet

- Cu - Ni Alloy - Electrodeposition and Powder Metallurgy MethodsDocument8 pagesCu - Ni Alloy - Electrodeposition and Powder Metallurgy MethodsyascheNo ratings yet

- Chemistry Project On Coin AnalysisDocument19 pagesChemistry Project On Coin AnalysisVidit YadavNo ratings yet

- Astm B283-20Document16 pagesAstm B283-20Gregory Alan Francisco IINo ratings yet

- Report Final Kiran Sir InternDocument25 pagesReport Final Kiran Sir InternSandeep ReddyNo ratings yet

- Marine Seawater ValvesDocument8 pagesMarine Seawater ValvesPhornlert WanaNo ratings yet

- Nes 771Document50 pagesNes 771jra9090No ratings yet

- Copper-Nickel Welding and FabricationDocument1 pageCopper-Nickel Welding and FabricationsatnamNo ratings yet

- Temperature Effect On Seawater Immersion Corrosion of 90-10 Copper-Nickel AlloyDocument12 pagesTemperature Effect On Seawater Immersion Corrosion of 90-10 Copper-Nickel Alloyyw_oulalaNo ratings yet

- Copper Tubes SfCu F25Document1 pageCopper Tubes SfCu F25mohsen_267No ratings yet

- ISO 4020 ExtractDocument2 pagesISO 4020 ExtractBartek HajaNo ratings yet

- Application of Cu-Ni Alloys For Sea Water ServicesDocument14 pagesApplication of Cu-Ni Alloys For Sea Water ServiceskarunaNo ratings yet

- CEN 13388 - 2013 - Cuivre Et Alliages - Recueil Des Compo Cuivre - ENGDocument61 pagesCEN 13388 - 2013 - Cuivre Et Alliages - Recueil Des Compo Cuivre - ENGmauriceNo ratings yet

- JyotiDocument67 pagesJyotigulatisrishti15No ratings yet

- OSNA10 Sheathing MTL Group EN 2019Document6 pagesOSNA10 Sheathing MTL Group EN 2019David RobsonNo ratings yet

- Copper and Its Alloys PresentationDocument50 pagesCopper and Its Alloys PresentationIranthaShalindaJayawardanaNo ratings yet

- SEA CURE Technical BrochureDocument12 pagesSEA CURE Technical BrochurekulilistrikNo ratings yet

- Home Appliance - S Ka026 B Eng - LRDocument98 pagesHome Appliance - S Ka026 B Eng - LRwillwNo ratings yet

- Pub 157 Preventing Bio Fouling With Copper NickelDocument4 pagesPub 157 Preventing Bio Fouling With Copper NickelBiyong SantocildesNo ratings yet

- Electrolytic Zinc Coatings (Extract From Iso 4042)Document2 pagesElectrolytic Zinc Coatings (Extract From Iso 4042)Abhishek DhawanNo ratings yet