Professional Documents

Culture Documents

Aluminium Specification

Uploaded by

klhlOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aluminium Specification

Uploaded by

klhlCopyright:

Available Formats

www.limatherm.

com

TECHNICAL INFORMATION

ALUMINIUM SPECIFICATIONS

ALUMINIUM ALLOYS FOR CONNECTION HEADS

Aluminium connection heads are used in industry as rugged terminal junction boxes for building temperature sensors, pressure transmitter, level transmitter, electronic transmitter housing, etc.Aluminium enclosure are also often exposed to conditions which can cause corrosion and they must be protected again this.

ALUMINIUM CASTING METHOD

Limatherm uses to produce aluminium enclosure pressure die-casting method.

ALUMINIUM ALLOYS

Limatherm uses as a standard alloy

Comparable to the Polish Standard Germany Standard GD-AlSi9Cu3 No. 226 European Standard EN AC AlSi9Cu3 EN AC 46 000 1 Cost Factor

Polish Standard AK 93 lc

Limatherm can use on request alloy

Comparable to the Polish Standard Germany Standard GD-AlSi12(Cu) No. 231 EN AC AlSi12Cu1 EN AC - 47100 1.06 Cost Factor

Polish Standard AK 11 lc

Limatherm can use on request cooper free alloy

Comparable to the Polish Standard Germany Standard GD-AlSi12 No. 230 European Standard EN AC AlSi12 mod EN AC 44200 mod 1.32 Cost Factor

Polish Standard AK 11 B lc

mod modified, with increased content of Fe = 0,8 1,2

COPPER FREE ALUMINIUM

Limatherm can use also copper free alloy. The term Copper Free is used to describe aluminium alloys which contain less than 0,4% copper. The copper content for pressure die casting not exceed 0,05%. It is the reduction in the copper content which, increases the natural corrosion resistant properties of aluminium. Copper Free aluminium is particularly resistant to salt atmosphere, sulphur gases and ammonium nitrate. Above a level of 0,4 % copper the range of corrosion due to galvanic action within the structure of the metal increases rapidly.

449 Limatherm Sp. z o.o., ul. Tarnowska 1, 34-600 Limanowa, Poland, tel. +48 18 337 98 20, fax +48 18 337 98 25

www.limatherm.com

TECHNICAL INFORMATION

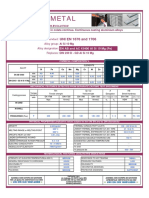

Standard aluminium alloy Standard ZN-86/MH-MN-260-14 DIN 1725 t 2:1986 EN 1706:1998 Alloy AK 93 lc GD-AlSi9Cu3 3.2163.05 Alloy No 226 EN AC-AlSi9Cu3 Si (%) 8 11 8 11 8 11 Fe (%) 1.2 1.2 1.3 Cu (%) Mn (%) Mg (%) 0.10.5 Ni (%) 0.3 0.3 Pb (%) 0.2 0.2 Sn (%) 0.1 0.1 Ti (%) 0.15 0.15 Zn (%) 1.2 1.2 1.2 AL

2 3.5 0.1 0.5

2 3.5 0.1 0,5 0.1 0,5 24 0.55

0.05 0.55 0.55 0.35 0.25 0.25

On request: aluminium alloy PN-76/H-88027 DIN 1725 t 2:1986 EN 1706:1998 AK 11 lc GD-AlSi12(Cu) 3.2982.05 Alloy No 231 10 13 10.513.5 1.4 1.2 1.3 0.8 1.2 0.71.2 0.5 0.10.5 0.55 0.3 0.10.5 0.35 0,5 0,2 0.3 0,2 0.1 0,1 0.2 0,15 0.2 0,3 Rest 0,5 0.55

EN AC-AlSi12Cu1 10.513.5

On request: Copper free aluminium alloy PN-76/H-88027 DIN 1725 t 2:1986 EN 1706:1998 AK 11B lc GD-AlSi12 3.2586 Alloy No 230 EN AC-AlSi12 10.513.5 0.81.2 10.513.5 10.513.5 1.0 0.55 0.05 0.10 0.05 0,5 0.10.5 0.35 0,3 0.4 0,5 0.2 0.2 0.1 0.15 0.15 0.3 0.5 0.1

MECHANICAL PROPERTIES Alloy Tensile strength Rm ( min ) AK 93 lc Value 240 310 140 240 0.5 3 80 120 2.65 Good Adequate Good Inadequate Unit MPa MPa % HB G/mm

2

AK 11 lc Value 220 280 140 200 14 60 80 2.65 Unit MPa MPa % HB G/mm Very Good Adequate Adequate Inadequate

2

AK 11B lc Value 170 80 6 55 95 2.65 Unit MPa MPa % HB G/mm2 Very Good Bad Adequate Very Good

0,2 % Proof stress Rp0.2 (min ) Elongation A5 Brinell Hardness Density Castability Polishability Machinability Weldability ( min )

ELECTRICAL AND THERMAL PROPERTIES Electrical Conductivity Thermal Conductivity Heat Resistance Cold Resistance CHEMICAL PROPERTIES Corrosion resistance Bad Adequate Good 13 17 110 120 MS/m W/m K 15 20 120 150 MS/m W/m K 1724 140 170 MS/m W/m K

+ 300C - 100C

450 Limatherm Sp. z o.o., ul. Tarnowska 1, 34-600 Limanowa, Poland, tel. +48 18 337 98 20, fax +48 18 337 98 25

You might also like

- SS 578 2012 Portable Fire Extinguishers (Formerly CP55)Document45 pagesSS 578 2012 Portable Fire Extinguishers (Formerly CP55)Andreas Indrakusuma100% (1)

- Din 1732-3-2007Document5 pagesDin 1732-3-2007Luis PaletoNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Perkins 2800 Series WorkshopmanualDocument10 pagesPerkins 2800 Series Workshopmanualmarylee100% (41)

- Aluminium SpecificationDocument2 pagesAluminium SpecificationkmrsekharNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Anshuman RoyNo ratings yet

- Alloy 5556 Weld Data Sheet: Typical ApplicationsDocument2 pagesAlloy 5556 Weld Data Sheet: Typical Applicationsvishal bailurNo ratings yet

- Non-Ferrous Metals and AlloysDocument58 pagesNon-Ferrous Metals and AlloysPradeep Kumar BagadiNo ratings yet

- EN 1706 Grade AC-42100 T6: Matmatch Is Trusted by 2 Million+ Engineers and Product Developers Each YearDocument4 pagesEN 1706 Grade AC-42100 T6: Matmatch Is Trusted by 2 Million+ Engineers and Product Developers Each Yearmelvin ekboteNo ratings yet

- Elettrodo Per Alluminio e Sue Leghe AWS A5.3 - E4043 (Selectarc - Eurosald Mod. AL105)Document1 pageElettrodo Per Alluminio e Sue Leghe AWS A5.3 - E4043 (Selectarc - Eurosald Mod. AL105)Eraldo MigliavaccaNo ratings yet

- Matmatch Is Trusted by 2 Million+ Engineers and Product Developers Each YearDocument3 pagesMatmatch Is Trusted by 2 Million+ Engineers and Product Developers Each Yearhardeep SinghNo ratings yet

- 22%Cr DUPLEX STAINLESS STEEL WELDING CONSUMABLESDocument7 pages22%Cr DUPLEX STAINLESS STEEL WELDING CONSUMABLESNguyen Anh TuanNo ratings yet

- FSH TigDocument105 pagesFSH TigChee WeiNo ratings yet

- Technical data sheet for rutile flux cored welding wireDocument1 pageTechnical data sheet for rutile flux cored welding wireawNo ratings yet

- B Bã-Hler Nibas 70 20-Fd Fcaw 02Document1 pageB Bã-Hler Nibas 70 20-Fd Fcaw 02kamals55No ratings yet

- Westermann Tables Materials Classification and PropertiesDocument86 pagesWestermann Tables Materials Classification and PropertiesDipak88% (17)

- C 18150Document2 pagesC 1815003sri03No ratings yet

- Tetra S 316L-G: Technical Data Sheet Cored Welding WireDocument1 pageTetra S 316L-G: Technical Data Sheet Cored Welding WirePeter TvardzíkNo ratings yet

- Material Cross Reference TableDocument3 pagesMaterial Cross Reference TableLuis Pol SistiNo ratings yet

- Aluminium 2014 t6 2014 t651Document3 pagesAluminium 2014 t6 2014 t651Agung Sapto AjiNo ratings yet

- DS482Document3 pagesDS482mariomatoNo ratings yet

- Esab DublexDocument8 pagesEsab DublexSuphi YükselNo ratings yet

- URB25Document4 pagesURB25malika_00No ratings yet

- This documentDocument44 pagesThis documentTran Thanh HaoNo ratings yet

- Metrode E2209 (B-60) ElectrodeDocument6 pagesMetrode E2209 (B-60) ElectrodeClaudia MmsNo ratings yet

- 31102015000000B - Boehler E 308 H PW-FD - CWDocument1 page31102015000000B - Boehler E 308 H PW-FD - CWKARLNo ratings yet

- AUTROD 316LSiDocument2 pagesAUTROD 316LSijoao guilhermeNo ratings yet

- Material Table AluminiumDocument1 pageMaterial Table AluminiumfeltofsnakeNo ratings yet

- Met 05 Nonferrous WeldingDocument16 pagesMet 05 Nonferrous WeldingRaghu vamshiNo ratings yet

- PetroCor BrochureDocument14 pagesPetroCor BrochuredediodedNo ratings yet

- Copper Casting Alloys - Foundry TechnologyDocument16 pagesCopper Casting Alloys - Foundry TechnologyOnilio Firmino de MedeirosNo ratings yet

- 29102015000000B - Boehler DCMS-IG - SWDocument1 page29102015000000B - Boehler DCMS-IG - SWErdinc BayatNo ratings yet

- 29102015000000B - Boehler DCMS-IG - SWDocument1 page29102015000000B - Boehler DCMS-IG - SWErdinc BayatNo ratings yet

- Aluminum Alloy EvolutionDocument2 pagesAluminum Alloy Evolutionc4pp3ll410_m4tt0No ratings yet

- Böhler Eas 2 PW-FDDocument1 pageBöhler Eas 2 PW-FDHAKANNo ratings yet

- AAMRADocument50 pagesAAMRARona Khairol Pratama100% (1)

- En 43400Document2 pagesEn 43400shivendrakumarNo ratings yet

- MME Group Anode - BookletDocument137 pagesMME Group Anode - BookletvtechelectricNo ratings yet

- ASM Material Data SheetDocument2 pagesASM Material Data SheetShankar PranavNo ratings yet

- GMAW Solid Wire for High Temperature Steel WeldingDocument1 pageGMAW Solid Wire for High Temperature Steel Weldingदिनेश कुशवाहाNo ratings yet

- Master AlloysDocument8 pagesMaster AlloysAsif AliNo ratings yet

- Aluminium Uses in Electrical EngineeringDocument7 pagesAluminium Uses in Electrical EngineeringTigrilloNo ratings yet

- Aluminium Electrode With 5%si: Size (MM) 2,5x350 3,2x350 4,0x350 Packets/Carton Kg/Packet Kg/CartonDocument1 pageAluminium Electrode With 5%si: Size (MM) 2,5x350 3,2x350 4,0x350 Packets/Carton Kg/Packet Kg/CartonAdel AbduoNo ratings yet

- MIG 80SB2: ClassificationDocument1 pageMIG 80SB2: ClassificationElMacheteDelHuesoNo ratings yet

- Material AlSiDocument2 pagesMaterial AlSidoanthanh88No ratings yet

- 27 AprvdGmaDocument68 pages27 AprvdGmacereferNo ratings yet

- Mechanical PropertiesDocument39 pagesMechanical Properties42030237No ratings yet

- Boehler CN 23 12 PW-FDDocument1 pageBoehler CN 23 12 PW-FDbrayanNo ratings yet

- Welding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesFrom EverandWelding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- High-Temperature Brazing in Controlled Atmospheres: The Pergamon Materials Engineering Practice SeriesFrom EverandHigh-Temperature Brazing in Controlled Atmospheres: The Pergamon Materials Engineering Practice SeriesNo ratings yet

- The Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 40 to EN 363From EverandThe Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 40 to EN 363No ratings yet

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- 436 - 1 - 1 - Sampling of CoalDocument24 pages436 - 1 - 1 - Sampling of CoalSudhanshu DashNo ratings yet

- Wires The Politics of Climate Change in India Narratives of Equity and Co-Benefits Dubash PDFDocument11 pagesWires The Politics of Climate Change in India Narratives of Equity and Co-Benefits Dubash PDFShubham Kumar JhaNo ratings yet

- Komatsu Hydraulic Excavator Pc850se 8 Shop ManualDocument20 pagesKomatsu Hydraulic Excavator Pc850se 8 Shop Manualleon100% (41)

- Calculate Specific Heat of MetalDocument2 pagesCalculate Specific Heat of MetalIsabelNo ratings yet

- Heat Exchanger (Oil To Water) Installation Information: Description: Power RequirementsDocument4 pagesHeat Exchanger (Oil To Water) Installation Information: Description: Power Requirements413666436qq.comNo ratings yet

- 0401544-Hydraulic StructuresDocument38 pages0401544-Hydraulic StructuresEfremWakjiraHodeNo ratings yet

- Electrical Machines DemystifiedDocument6 pagesElectrical Machines DemystifiedRishiSunariya50% (2)

- 64 Meeting January 7-8, 2013Document42 pages64 Meeting January 7-8, 2013ymadhukumarNo ratings yet

- 1104C Torque Specs PERKINS-1104-11-15-2018-657Document11 pages1104C Torque Specs PERKINS-1104-11-15-2018-657Jose Ricardo Gomez CardenasNo ratings yet

- 793 F Air SystemDocument9 pages793 F Air SystemWilson ClaveriaNo ratings yet

- Chapter 6 Current and Voltage Relations On A Transmission LineDocument22 pagesChapter 6 Current and Voltage Relations On A Transmission LineNaomie2 KoguemNo ratings yet

- Dynamis MaxxDocument14 pagesDynamis MaxxJas SumNo ratings yet

- Classification of Thyristor Commutation TechniquesDocument11 pagesClassification of Thyristor Commutation TechniquesUmar MurtazaNo ratings yet

- Auxiliary Blower Fans TYPE DM-51-76B: Technical ManualDocument11 pagesAuxiliary Blower Fans TYPE DM-51-76B: Technical ManualDragonta GontaNo ratings yet

- Master Plumber Review Material 2Document4 pagesMaster Plumber Review Material 2Marvin KalnganNo ratings yet

- AP TSS General Safety Course For 2019cycleDocument141 pagesAP TSS General Safety Course For 2019cycleFebry Dwi TranspuriNo ratings yet

- Myanmar Oil Field Info SummaryDocument19 pagesMyanmar Oil Field Info SummaryhtutsweNo ratings yet

- List LI FKK EH220 - EH221 - EH222 JUdsvdxvxcvxcLY SEPT 2015 As 180815Document194 pagesList LI FKK EH220 - EH221 - EH222 JUdsvdxvxcvxcLY SEPT 2015 As 180815Fikrie MuhdNo ratings yet

- Home Automation and Surveillance: A ReviewDocument4 pagesHome Automation and Surveillance: A ReviewATSNo ratings yet

- Thin-Film Solar CellDocument72 pagesThin-Film Solar CellPraveen KumarNo ratings yet

- Cylinder Head GasketsDocument2 pagesCylinder Head GasketsAdi_DCE0% (1)

- Monbat 12V200AhDocument1 pageMonbat 12V200AhMaria MuresanNo ratings yet

- Chemical Equations & ReactionsDocument78 pagesChemical Equations & ReactionsDelsie FalculanNo ratings yet

- How Do Electric Cars Work - Electric Engines Explained - EDFDocument2 pagesHow Do Electric Cars Work - Electric Engines Explained - EDFrainceder100No ratings yet

- A Methodology To Determine Transient Recovery Voltage in Short-Line FaultDocument7 pagesA Methodology To Determine Transient Recovery Voltage in Short-Line FaultLeonardo CamargoNo ratings yet

- Robert T. Knowlton JR.: Local Address: 301 S. Pugh ST, Apt. 409, State College, Pa 16801 Permanent Address: ObjectiveDocument1 pageRobert T. Knowlton JR.: Local Address: 301 S. Pugh ST, Apt. 409, State College, Pa 16801 Permanent Address: Objectivertk5025No ratings yet

- Winddevil ProductDocument2 pagesWinddevil Productavalladolid05No ratings yet