Professional Documents

Culture Documents

Dynamic Systems Lab Report

Uploaded by

Sachee PereraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dynamic Systems Lab Report

Uploaded by

Sachee PereraCopyright:

Available Formats

CurtinUniversity of Technology

Department of Mechanical Engineering

Dynamic Systems 334

Natural Frequency and Damping of Single

Degree of Freedom Systems

Prepared by: SachithaPerera

Student ID No.: 13352079

Contents

Introduction__________________________________________________________1

Aims________________________________________________________________2

Apparatus & Equipments_______________________________________________3

Nomenclature________________________________________________________4

Theory______________________________________________________________6

A. Spring Stiffness________________________________________________________6

B. Natural Frequency______________________________________________________7

C. Viscous Damping______________________________________________________12

Procedure___________________________________________________________17

A. Spring Stiffness_______________________________________________________17

B. Natural Frequency_____________________________________________________17

C. Viscous Damping______________________________________________________18

Results_____________________________________________________________19

A. Spring Stiffness_______________________________________________________19

B. Natural Frequency_____________________________________________________20

C. Viscous Damping______________________________________________________22

Summary of Results__________________________________________________23

A. Spring Stiffness_______________________________________________________23

B. Natural Frequency_____________________________________________________23

C. Viscous Damping______________________________________________________24

Calculations_________________________________________________________25

A. Spring Stiffness_______________________________________________________25

B. Natural Frequency_____________________________________________________25

C. Viscous Damping______________________________________________________25

Discussion__________________________________________________________28

A. Spring Stiffness_______________________________________________________28

B. Natural Frequency_____________________________________________________30

C. Viscous Damping______________________________________________________30

Conclusion__________________________________________________________33

References__________________________________________________________34

Appendix A: Graphs__________________________________________________35

Appendix C: Maple Calculations for Error Analysis of Damping Coefficient_____38

Appendix C: Maple Calculations for Error Analysis of Damping

Coefficient

Introduction

Mechanical vibration is a phenomenon which exists within every object or

structure any mechanical engineer will need to take into consideration. This is mainly

due to the fact that minute vibration amplitudes are capable of causing considerable

cyclic stresses which ultimately result in failure of the component or structure because

of fatigue.

In order for a system to vibrate, the system must possess both properties of

inertia and elasticity. The co-existence of both properties in simultaneous effect

within the system creates the potential for ongoing and repeated interchange of a

quantity of energy between kinetic energy and gravitational potential energy.

(Entwistle 2011)

The type of vibration investigated in this experiment was natural vibration.

Generally, energy is initially imparted into the system and allowed to vibrate freely in

its natural frequency afterwards. It should be noted that there is energy dissipation

within the system called damping which eventually stops the vibration motion.

Furthermore, this experiment was restricted to only single degree systems such as a

spring oscillating vertically.

1

Aims

The main aims of the experiment are as follows:

1. Accurately determine the stiffness, k of a Hookeanhelical spring supplied by a

static deflection test.

2. Investigate the effect and the significance of mass of spring on the natural

frequency of the vibrating system.

3. Determine experimentally and calculate the damping coefficient of a dashpot

filled with oil.

4. Investigate the effect of viscous damping on the frequency and motion of free

oscillations.

5. Compare the accuracy in which a model describes the performance of a real

system dynamics via comparing calculated values from derived equations and

experimental values.

1

Apparatus &Equipments

1. Tecequipment universal vibration apparatus

2. Digital counter

3. Stop watches

4. Electronic digital weighing scale

5. Vernier linear Scale

6. Metric Ruler

1

Nomenclature

Independent variables:

i. m

i

= Total suspended mass (kg)

ii. m

i

=Total mass of weights on hanger (kg)

iii. N =Number of Cycles (unitless)

Dependant variables:

i. F

i

= m

i

g = Total force (N)

ii.

i

=Scale reading (mm)

iii.

i

o

=Deflection (m)

iv. t =Time for N oscillations (sec)

v.

t

=Mean time (sec)

vi.

N

t

T

=Period of oscillation (sec)

vii. k =Spring stiffness (N/m)

viii.

T

f

N

1

=Natural frequency (Hz)

ix. 2y

n

, = peak-to-peak value of the cycle (m)

x. I

O

=Moment of inertia about pivot O (kgm

2

)

xi. q =Damping coefficient (N/(ms

-1

))

xii. f

q

=Frequency of damped free oscillations (Hz)

xiii.

2

4 2

4

1

c kI

a q

O

=Radical (unitless)

Controlled variables:

i. m

s

=Mass of the spring (kg)

ii. m

h

=Mass of the hanger, (kg)

iii.

h i

m m +

= square root of total mass on hanger and mass of hanger (kg)

1

iv.

3

s

h i

m

m m + +

= square root of total mass on hanger, hanger mass and spring

mass (kg)

v. a = Distance from point O to the dashpot (m)

vi. c = Distance from point O to the linear spring (m)

vii. Theoretical value of T (sec)

Constants:

i. g = gravity acceleration = 9.81 ms

-2

1

Theory

A. Spring Stiffness

Figure 1.1: Suspended Hookean Spring-Mass System. (Simanek 2004)

To determine the spring stiffness, Hookes law has been employ.An object

with elastic property will deform by compression or tension when a force is applied to

it Hookes law states that the displacement of the deformation is directly proportional

to the deforming force.(Encyclopedia Britannica Online n.d.) Hence, when a force is

applied to a spring, the force exerted on the spring is proportional to the displacement

of the spring from equilibrium. In mathematical form:

kx F

(Eqn.1.1)

Where

F

= force exerted on spring (N)

k

= spring constant or stiffness of spring (N/m)

x

= displacement of the spring from equilibrium (m)

1

Figure 1.2: Typical force versus extension graph.(Deformation of Solids n.d.)

However, Hookes Law is only valid within the materials elastic range below

the limit of proportionality. Beyond the proportional limit, the linear proportionality

between the stress and strain ceases.(DiracDelta Science & Engineering Encyclopedia

n.d.)

B. Natural Frequency

Deriving differential equations for simple harmonic motion

Figure 1.2: Representation of a simple harmonic motion by a phasor. (Entwistle

2011)

Simple harmonic motion is the underlying component of most vibratory

motions. Simple harmonic motion is a reciprocating motion and can be represented

geometrically as a phasor as shown in Figure 1.3. (Entwistle2011) The orthogonal

1

projection of P on horizontal line passing O, which is point Q executes simple

harmonic. Stated mathematically by circular functions:

cos( ) x A t +

(Eqn.1.2)

Where

x

= displacement of point Q from O

A

= maximum value of

| | x

known as the amplitude

= constant angular velocity of phasor or circular frequency

t

= time

= phase angle

Differentiating Equation 1.2 twice will give the differential equations that

describe simple harmonic motion:

sin( )

dx

x A t

dt

+ &

(Eqn. 1.3)

2

2 2

2

cos( )

d x

x A t x

dt

+ &&

(Eqn. 1.4)

Thus, for simple harmonic motion, the acceleration is proportional but

opposite in direction to the displacement. The standard form is given by:

2

0 x x + &&

(Eqn. 1.5)

The period, T is the time taken to complete one full revolution of OP or one

cycle. In mathematical form:

2 T

(Eqn. 1.6)

2

T

(Eqn. 1.7)

2

The frequency,

f

is the number of cycles completed in a unit time. In

mathematical form:

1

2

f

T

(Eqn. 1.8)

Deriving differential equations of motion for a one-degree-of-freedom system

executing simple harmonic motion

Since the experiment resembles a one-degree-of-freedom system executing

simple harmonic motion, a lump parameter model approach is applied. Several

assumptions are made in this approach to simplify the model, yet maintaining the core

nature of dynamics:

Mass is concentrated mainly in stiff components such as hanger and weights,

while flexibility is located mainly in the spring. Hence, a rigid mass and a

massless spring system.A rigid support frame

Motion of the system is restricted only to vertical direction, hence a one-

degree-of-freedom system. Without any rotation, moments of inertia of the

mass become irrelevant in the sense that any moments tending to cause

rotation are countered by equal and opposite support reactions, allowing the

mass to be treated as a point mass. (Entwistle2011)

The spring obeys Hookes law, therefore having a directly proportional linear

force-displacement relationship, with spring stiffness being the proportionality

constant.

The spring adheres to similar properties in tension and compression.Small

displacements are assumed, as large extensions will result in the failure of the

linear Hookean relationship, whereas large compressions will buckle the coils.

The air offers no resistance to the motion.

A positive sense downwards is selected for displacement, velocity,

acceleration and applied forces. The initial system is assumed to have a positive

displacement, velocity and acceleration at the instant.

3

Figure 1.3: Free body diagram of one-degree-of-freedom system. (Entwistle2011)

Where Point A = end of unloaded spring

Point B = end of spring loaded with mass m

Point C = end of spring with mass at some instant during vibration

Based on Newtons 2

nd

Law, the differential equation of motion can be written

as:

y m F

y

y m ky k mg

static

, where

mg k

static

0 + y

m

k

y

(Eqn. 1.9)

With reference to Eqn. 1.9, the one-degree-of-freedom system is shown to be

executing simple harmonic motion. Comparing Eqn. 1.5 and Eqn. 1.9 yields:

m

k

(Eqn. 1.10)

Substituting Eqn. 1.10 into Eqn. 1.7 results in:

The natural period,

k

m

T

2

2

(Eqn. 1.11)

1

The natural frequency,

m

k

f

2

1

(Eqn. 1.12)

Note that gravity has no effect on the dynamics of the vibration but altered the

static equilibrium position of the system.

Spring mass correction for a heavy spring

As mentioned before, one assumption made was that the spring was

massless, having little effect on the dynamics of the system.If the spring mass is

significant, spring mass will need to be taken into consideration in the lump parameter

model.

An equivalent one-degree of freedom model utilising an equivalent mass,

eq

m

and a massless spring with the same spring stiffness needs to be derived.

(Entwistle2011) In order to apply Rayleighs Energy method, assumptions are made:

i. The motion is a simple harmonic motion with a natural vibration mode, which

is valid in the case of an undamped linear system executing free vibration.

ii. The maximum kinetic energy of the system equals the maximum strain energy

of the system.

iii. Mode shape is assumed.

Figure 1.4: One-degree-of-freedom model with a heavy spring. (Entwistle2011)

3

Initially, the model is at the instance of passing through the equilibrium

position. Hence,

C

is the free length of the heavy spring and strain energy in the

spring becomes zero.Therefore, the total energy of the system is equal to the

maximum kinetic energy of the system.

The equivalence to assuming a mode shape is assuming that the variation of

local velocity along the spring is linear. (Entwistle2011)

Kinetic energy of mass =

2

2

1

mV

Kinetic energy of spring element dc =

2

2

1

v

C

dc

m

s

,

`

.

|

Using similar triangles,

2

2

,

`

.

|

C

cV

v

C

V

c

v

Hence, Kinetic energy of entire spring =

2

0

2 2

3

3 2

1

2

1

V

m

dc c V

C

m

C

s s

Total maximum kinetic energy of system = kinetic energy of mass + kinetic energy of

entire spring

=

2

3 2

1

V

m

m

s

,

`

.

|

+

(Eqn. 1.13)

At the instant the mass reaches maximum displacement,

X

. The total

maximum kinetic energy of the system would be completely converted into maximum

strain energy of the system. Hence, the maximum strain energy equals to the total

energy of the system while there is no kinetic energy. As the model is assumed to

execute simple harmonic motion,

( ) + t X x sin

, with maximum amplitude

X

.

3

Maximum Strain Energy =

2

2

1

kX

(Eqn. 1.14)

Total energy of system = total maximum kinetic energy of system = maximum strain

energy of system

2 2

2

1

3 2

1

kX V

m

m

s

,

`

.

|

+

, where maximum velocity

X x V | |

( )

2 2

2

1

3 2

1

kX X

m

m

s

,

`

.

|

+

(Eqn. 1.15)

eq

s

m

k

m

m

k

(Eqn. 1.16)

Hence,

3

s

eq

m

m m +

(Eqn. 1.17)

Therefore, the equivalent mass can be obtained via addition of a third of spring

mass to body mass which is a good approximation for relatively short spring

oscillating at low frequencies, but at higher frequencies, the natural vibration modes

of the spring are excites causing the linear velocity mode to break down.

(Entwistle2011)

C. Viscous Damping

Every dynamics system will be subjected to damping causing the amplitude to

decay with time, and eventually brought to a halt. Therefore, some energy is lost to

other forms of energy besides the interchanging kinetic and strain energies.

5

Figure 1.5: Model of mass experiencing viscous drag. (Entwistle2011)

In the case of this experiment, viscous damping will be used. A simple model

of a mass affected by viscous drag is shown in Figure 1.5. This viscous drag is

proportional to velocity under laminar fluid flow conditions. This viscous damping is

stated mathematically as:

x q F

, for translational systems

q T

, for torsional systems

Where, q = damping coefficient(N/(ms

-1

)) or (Nm/(rad.s

-1

))

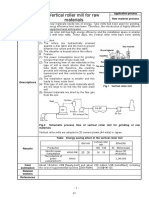

Firstly, the vibration apparatus set up will resemble the schematic diagram in

Figure 1.6.

Figure 1.6: Schematic diagram of vibration apparatus configuration.

1

The arm is allowed to oscillate freely by pivoting at O with a moment of

inertia of

O

I

about O. A linear dashpot acts tangentially at a distance

a

from O,

while a linear spring acts tangentially at a distance

c

from O. Displacing the arm

from its equilibrium position and allowing it to vibrate freely will result in the

execution of a damped oscillation, as shown in Figure 1.7.

Figure 1.7: Typical time history for a viscously damped oscillation.

Figure 1.8:Vibration apparatus with arm rotated through small angle about O.

In order to attain the rotational spring stiffness,

k

about O, at radius

c

, the

following approach is taken. The arm is rotated through small angle .

3

Therefore, at point where linear spring is tangentially attached, the arm will have

deflection,

c

Thus, incremental tension in spring =

kc

The moment generated by the tension about O,

c kc M

Hence, the equivalent torsional stiffness of the configuration,

2

kc

M

Likewise, torsional damping coefficient,

2

qa

M

Newton II is applied about O:

O O

I M

O

I qa kc

2 2

0

2 2

+ +

O O

I

kc

I

qa

(Eqn. 1.18)

Compare Eqn. 1.18 with the standard form,

0 2

2

+ +

N N

:

2 4

2

2

4

O

q a

c I k

(Eqn. 1.19)

O

N

I

kc

2

(Eqn. 1.20)

The frequency of damped vibration will be,

3

,

`

.

|

2

4 2 2

2

4

1

2

1

1

c kI

a q

I

kc

f f

O O

undamped damped

(Eqn. 1.21)

Recalling the logarithmic decrement,

1

1

2

2

2

ln

1

2

,

`

.

|

n

o

y

y

n

Solve for

,

( )

2

1

2

1

ln 2 / 2

o n

n

y y

]

+

]

]

(Eqn. 1.22)

Substitute Eqn. 1.22 into Eqn. 1.19,

( )

k I c

a q

y y

n O

n o

2

4 2

2

4

1

2 / 2 ln

2

1

+

]

]

]

( )

1

2 / 2 ln

2

2

2 2

+

]

]

]

n o

O

y y

n

kI

a

c

q

(Eqn. 1.23)

Where

o

y 2

and

n

y 2

are measured from a record of the damped oscillation taken at a

convenient position along the arm in tangential direction, as shown in Figure 1.6.

If

0 q

, Eqn. 1.22 becomes,

O

N

I

k c

f

2

(Eqn. 1.24)

k

f

c

I

N

O

2

2

,

`

.

|

(Eqn. 1.25)

Substitute Eqn. 1.25 into Eqn. 1.23,

3

( )

2

2

2

1

ln 2 / 2

N

o n

k c

f a

q

n

y y

| `

. ,

]

+

]

]

(Eqn. 1.26)

5

Procedure

A. Spring Stiffness

1. The mass of the10 weights were measured on an electronic digital weighing

scale and recorded in the measured order. The mass displayed was in grams

(g) and was converted to kilograms (kg) during recording.

2. An appropriate mass increment of approximately 0.4 kg and a number of 10

increments has been selected.

3. For the spring in an initial state, the initial length,

o

, of the unloaded spring

was measured with a Vernier Linear Scaleand recorded in millimetres (mm).

4. The first weight measured was loaded onto the spring and the consequent

length,

i

, of the spring was measured with a Vernier Linear Scaleand recorded

in millimetres (mm). The difference between the consequent length and initial

length,

i

-

o

, will give the deflection of the spring.

5. Subsequent 9 weights corresponding to the measured order was loaded onto

the spring incrementally, while measuring the consequent length between

loadings in similar manner.

6. The recorded data was tabulated and an accurate graph of total force versus

deflection was plotted.

B. Natural Frequency

1. The mass of the spring, m

s

, and the mass of the hanger, m

h

, were measured on

an electronic digital weighing scale and recorded.The mass displayed was in

grams (g) and was converted to kilograms (kg) during recording.

2. The load hanger guide was removed and the digital counter was set up.

3. The first weight measured was loaded onto the spring.

4. Vertical oscillations were induced with amplitude of about 10 mm and the

corresponding 120 cyclesspecifiedin Table 2.2was timed.

5. This method is repeated 6 more times with incrementing weights and the

corresponding number of cycles as stipulated in Table 2.2.

6. The recorded data was tabulated and three sets of data were plotted on the

same axis for a graph of T versus

m

with appropriate scales to have clear

visual of any differences between lines:

1

a. The theoretical relationship which is given by

m

k

T

,

`

.

|

2

. Using

the spring stiffness, k determined from part A, the slope

,

`

.

|

k

2

can be

determined. Therefore, the accurate value of T for every value of

m

is known. A continuous line was plotted for the Theoretical Line.

b. The experimental data points, T versus

h i

m m +

was plotted as

Experimental Line 1.

c. The experimental data points, T versus

3

s

h i

m

m m + +

was plotted as

Experimental Line 2.

C. Viscous Damping

1. The vibration apparatus was set up as shown schematically in Figure 1.6 with

oil filled in the dashpot.

2. The distance of

a

and

c

, as shown in Figure1.6 were measured to the nearest

mm using a metric ruler.

3. Oil from the dashpot was drained and the free end of the oscillating arm was

disturbed from the equilibrium position and four stopwatches were used to

measure the time taken for 40 oscillations and 3 of the best times were used

for averaging.

4. The recorded data was tabulated and natural frequency was calculated.

5. Moment of inertia about pivot O,

O

I

was calculated from Eqn. 1.25, using

values for undamped system for 40 cycles.

1

6. The dashpot is refilled and the end of the arm disturbed again about 35mm

from equilibrium and released. A time trace of this oscillation where the

amplitude y verses time for 20 cycles is taken.

7. Damping coefficient, q was calculated from Eqn. 1.26, using values for

damped system for 20 cycles.

15 n

was used for good accuracy.

8. The frequency of the damped free oscillations, f

q

was determined using the

values of k, I

O

, and q.

1

Results

A. Spring Stiffness

i

Total

suspende

d mass,

m

i

(kg)

Total

force, F

i

= m

i

g

(N)

Scale

reading

,

i

(mm)

Deflection

,

Incremen

t in

deflectio

n

i

o

(mm)

mm

0 0 0 25.37 0 0

1 0.39886

3.91281

7

25.47 0.1 0.1

2 0.39728

3.89730

6

25.56 0.19 0.09

3 0.3976

3.90042

9

25.66 0.29 0.1

4 0.40316

3.95497

6

25.76 0.39 0.1

5 0.40281

3.95159

7

25.85 0.48 0.09

6 0.40503

3.97337

2

25.95 0.58 0.1

7 0.40041

3.92797

3

26.05 0.68 0.1

8 0.4014

3.93773

8

26.14 0.77 0.09

9 0.40008

3.92479

9

26.24 0.87 0.1

1

0

0.39963

3.92037

1

26.34 0.97 0.1

Table 2.1:Results for effect of total increment loading of suspended mass on spring

deflection.

Figure 2.1: Plot of force versus deflection. (Refer to Appendix A)

B. Natural Frequency

Total mass of

weights on

hanger, m

i

(kg)

Number of

Cycles, N

Mean time, Period of Oscillation

1

(sec)

0 120 9.5150 0.0793

0.4 90 8.9400 0.0993

0.8 80 9.2275 0.1153

1.2 70 9.2525 0.1322

1.6 60 8.6525 0.1442

2.0 55 8.6325 0.1570

2.4 50 8.3525 0.1671

Table 2.2:Results of time and period for the corresponding masses and cycles.

Mass of the

spring, m

s

(kg)

Mass of the

hanger, m

h

(kg)

k determined in

stiffness test

(N/m)

0.37775 0.47648 4064.41

Total mass of

weights on

hanger, m

i

(kg)

Number of

Cycles, N

Theoretical value

of T (sec)

h i

m m +

(kg)

3

s

h i

m

m m + +

(kg)

0 120 0.0000 0.690 0.776

0.4 90 0.0623 0.936 1.001

0.8 80 0.0882 1.130 1.184

1.2 70 0.1080 1.295 1.343

1.6 60 0.1247 1.441 1.484

2.0 55 0.1394 1.574 1.613

2.4 50 0.1527 1.696 1.733

Table 2.3:Results ofrecorded masses, theoretical values of T and lumped masses for

corresponding values of masses and cycles.

Total mass

of weights

on hanger,

m

i

(kg)

Number

of

Cycles,

N

Period of

oscillation,

N

t

T

(sec)

Theoretical

value of T

(sec)

h i

m m +

(kg)

3

s

h i

m

m m + +

(kg)

0 120 0.0793 0.0000 0.690 0.776

0.4 90 0.0993 0.0623 0.936 1.001

0.8 80 0.1153 0.0882 1.130 1.184

1

(sec)

1.2 70 0.1322 0.1080 1.295 1.343

1.6 60 0.1442 0.1247 1.441 1.484

2.0 55 0.1570 0.1394

1.574 1.613

2.4 50 0.1671 0.1527

1.696 1.733

Table 2.4:Relevant calculated results derived from recorded results.

Figure 2.2: Plot of T versus m. (Refer to Appendix A)

C. Viscous Damping

Number

of

Cycles,

N

Time frequency

, (Hz)

Undampe

d system

40 7.96s 7.796

Damped

System

40 7.

Table 2.5:Results of time, period and frequency for corresponding cycles for damped

and undamped systems.

a (m) c (m)

0.234 0.651

2y

n

(m)

2y0 0.036

2y6 0.011

Table 2.6:Measured distances and maximum & minimum amplitude with

corresponding peak to peak values for cycles along the time trace.

1

Summary of Results

A. Spring Stiffness

By observing the tabulated data in Table 2.1, an obvious trend can be noticed.

The deflection of the spring, (

i

o

) increases as the total suspended mass, m

i

was

incremented.

Furthermore, based on Eqn. 1.1 and the data distribution on the graph, the plot

of force versus deflection, shown in Figure 2.1, reveals that the deflection of the

spring, (

i

o

) is directly proportional to the force applied by the total suspended

mass, F

i

. The slope of the plot is the spring stiffness, k.

B. Natural Frequency

The mean time,

t

is seen to be decreasing as the total mass of weights on

hanger increases and the number of cycles decreases. However, the mean time,

t

for

the first row of data is less than the following mean time,

t

. This is probably due to

the effect of the combination of the total mass of weights on hanger and number of

cycles selected.

From Table 2.2, the period for one complete oscillation, T increases as the

total mass of weights on hanger, m

i

increases. From Table 2.3, the theoretical period

for one oscillation, T increases with increasing total mass of weights on hanger, m

i

as

well.

The last two columns of Table 2.3 depicts the square root of the equivalent

mass for the relevant apparatuses, so it can be applied to Eqn. 1.11 which is derived

from a lump parameter model analysis. This allows the graph of T against

m

to be

plotted based on the theoretical relationship,

m

k

T

,

`

.

|

2

which is Eqn. 1.11.

1

Table 2.4 is the tabulation of all relevant calculated results obtained from

Table 2.2 and Table 2.3 required for the analysis and discussion for the experiment.

From Figure 2.2, based on Eqn. 1.11, the theoretical and both experimental

data distribution exhibit a linear relationship, with the period of oscillation, T varying

in a directly proportional manner to square root of equivalent mass,

m

.

The slopes for all three trend lines seemalmost comparable. However,

Experimental Line 2 better reflects the theoretical relationship, which deviates

fromthat of the Theoretical Line by0.41%. The slope of Experimental Line 1 has a

larger deviation from the Theoretical Line of 3.73%.

C. Viscous Damping

The damping coefficient, q is found to be 25.06N/(ms

-1

). The moment of

inertia has been calculated as 1.72 kgm

2

, while the calculation of the value of the

damping ratio, is 0.00029.

Theradical

2

4 2

4

1

c kI

a q

O

yields a value almost equal to 1, further proving the

similarities between the damped and undamped frequencies.

3

Calculations

A. Spring Stiffness

Example calculations using data when i = 5,

From Table 2.1,m

5

= 1.99811 kg

mm 7 . 253

0

,

mm 5 . 258

5

.

Calculate,

i. Total force: F

5

= m

5

g = 1.9981 x 9.81 = 19.60N

ii. Deflection:

m mm 0048 . 0 8 . 4

0 5

B. Natural Frequency

Example calculations using data when m =1.2 and N = 70,

Table 2.3,

kg m

s

37775 . 0

,

kg m

h

47648 . 0

,

m N k / 041 . 4064

.

Calculate,

i. Period of oscillation:

sec 1322 . 0

70

2525 . 9

N

t

T

ii. Theoretical value of T:

T=2km=24064.0411.2 =0.10797sec

iii. mi+mh=1.2+0.47648=1.295 kg1/2

iv. mi+mh+ ms=1.2+0.47648 +0.37775 =1.433 kg1/2

C. Viscous Damping

Example calculations using data for undampedsystem when N = 40,

1

i. Period of oscillation:

sec 1972 . 0

40

8875 . 7

N

t

T

ii. Frequency: fq = 1T= 10.1972=5.071 hz

Example calculations using data for damped system when N = 40,

i. Period of oscillation:

sec 199 . 0

40

96 . 7

N

t

T

ii. Frequency: fN = 1T= 10.199=5.025 hz

Moment of inertia about pivot O:

Io= c2fn2k=0.65125.02524064.041=1.72 kgm2

Calculating q from Eqn. 1.26, using values for damped system when N = 20 and make

15 n

,

From Table 2.3,

m N k / 041 . 4064

.

From Table 2.5, f

N

= 5.025

From Table 2.6, a = 0.234 m,

c = 0.651 m,

2y

0

= 0.036 m,

2y

15

= 0.011 m.

Damping coefficient:

q=kfNca22nlm(2y02y15)2+1=4064.0145.0250.6510.2342215lm(0.0360.011)

2+1=25.064 N/(ms-1)

Calculating

q

f

from Eqn. 1.21, using values for undamped system when N = 40,

From Table 2.3,

m N k / 041 . 4064

.

1

From previous calculations, Io=1.72kgm2

q=25.064 N/(ms-1

From Table 2.6, a = 0.234 m,

c = 0.651 m.

Evaluating the damping ratio,

=q2a44kIOc2=25.06420.234444064.0411.720.6512=0.00029

fqfN=1-q2a44kIOc2=1-2=1-0.000292=0.999

fqfN= 5.0715.025=1.00910.999

3

Discussion

A. Spring Stiffness

When a mass was loaded onto the spring, a constant static force was applied

due to the effects of gravity. The stress due to this force caused the spring to

experience strain by deflecting from its free length to a new static equilibrium

position. Similar to the relationship between stress and strain, the relationship

between force and deflection is linear and directly proportional.

As the total suspended mass was incremented, the force increases, hence

deflecting the spring further. Based on Eqn. 1.1, the linear and directly proportional

relationship is shown in the plot and the equation of the trend line.

From the graph plotted as shown in Figure 2.1, the spring obeys Hookes Law

throughout the course of the loading and thus, was not loaded beyond the limit of

proportionality, where the relationship between force and deflection will no longer be

linear and proportional. Therefore, the spring had not exceeded the elastic limit and

will not be permanently deformed.

A slope of best fit will be obtained via the method of least square from the set

of tabulated data from Table 2.1. For a straight line

c Mx y +

, the slope M can be

obtained with the following expression:

( ) ( )( )

( )

2

2

x x n

y x xy n

M

Where, x = Deflection,

i

o

(m)

y = Total force, F

i

= m

i

g (N)

x y xy x

2

(10

-5

)

0 0 0 0

0.001 3.912817 0.003913 0.000001

0.0019 7.806209 0.014832 3.61E-06

0.0029 11.70274 0.033938 8.41E-06

0.0039 15.65382 0.06105 1.52E-05

0.0048 19.60146 0.094087 2.3E-05

0.0058 23.57088 0.136711 3.36E-05

0.0068 27.49488 0.186965 4.62E-05

0.0077 31.42869 0.242001 5.93E-05

0.0087 35.34955 0.307541 7.57E-05

0.0097 39.266 0.38088 9.41E-05

sum 0.0532 215.787 1.461918 0.00036

Table 3.1: Summation of x, y, xy, and x

2

.

1

Substitute appropriate values into the expression to find M:

( ) ( ) ( )

m N M / 08 . 4073

) 0532 . 0 ( 00036 . 0 * 11

787 . 215 * 0532 . 0 461918 . 1 * 11

2

The value calculated is relatively close to the one obtained by plotting on Excel,

4064.4. Hence, it is safe to say that the slope from Excel is reliable as it just deviates

as much as 0.23% from the calculated slope, M. In addition, the least square method

does not take into account the zero y-intercept as described by Hookes Law.

According to Eqn. 1.14, larger spring stiffness means a larger capacity to store

strain energy compared to smaller spring stiffness for the same displacement. Based

on Eqn. 1.12, larger spring stiffness contributes to an increase in the frequency of the

system.

It should be noted that although the masses have been measured individually,

there is actually another preferable technique in recording the masses. The masses

could have been lumped together incrementally on the electronic digital weighing

scale in order to reduce the collective error of the individual mass during addition.

B. Natural Frequency

According to Eqn. 1.11, if the equivalent rigid mass, m is increased, the period

of oscillation, T increases as well as shown in Table 2.2, wherethe period of

oscillation, T was increasing with incrementing total mass on hanger. Likewise the

linear relationship from Eqn. 1.11 is reflected in the graph in Figure 2.2 as well.

Mass of the spring has been measured to be almost as large as the mass of the

hanger. Hence, the mass of the spring was significant and the spring can be

considered to be heavy.From the graph in Figure 2.2, by visually analysing the lines

plotted and by comparing the value of the slope, it can be deduced that Experimental

Line 2 which possess the spring mass correction is quite similar compared to the

Theoretical Line.

It is obvious that the spring mass correction skews the plotted line towards a

more favourable result. Therefore, it is imperative that the mass of a heavy spring

should be taken into account in order to obtain a more precise lump parameter model,

which better represents the system dynamics. However, the spring mass correction is

only a viable approximation for a relatively short spring undergoing low frequency

oscillations. (Entwistle2011)

3

The experimental value of T is a good approximation relative to the theoretical

values of T with the largest as can be seen from the results. To improve the

experimental readings taken for time for N oscillations, an electronic digital timer can

be connected to the digital counter to start and stop at an instant,instead of using stop

watches.

During the experiment, the spring performed slight rotations and slight

horizontal oscillations, although a device was installed into the apparatus set up to

limit the degrees of freedom to just vertical oscillations. Hence, not all the energy

initially imparted into the spring was conveyed to the vertical oscillations but some of

the energy was given to produce these other motions. The system is therefore not

restricted to a one-degree-of-freedom. However, the results show that the assumption

of a one-degree-of-freedom model does not affect the overall result much compared to

the spring mass.

C. Viscous Damping

The damping coefficient supplied by the viscosity of the dashpot is 25.06N/

(ms

-1

).

This implies that the damping ratio, is smaller than 1, which was verified by

the calculation as 0.00029.

An error analysis was performed on the damping coefficient, q. Firstly, the

measured quantities and the corresponding uncertainties are listed:

i. m= 0.00001kg

ii. i-o= 0.0002m

iii. t = 0.0005 sec

iv.

m c 001 . 0 651 . 0 t

v.

m a 001 . 0 234 . 0 t

vi.

m y 0001 . 0 036 . 0 2

0

t

vii.

m y 0001 . 0 0011 . 0 2

15

t

3

From the list above, the second (ii.), third (iii.), sixth (vi.) and seventh (vii.)

quantities have undergone their respective additions of uncertainties. For the fourth

(iv.) and fifth (v.) quantities, usually, the uncertainty is taken to half of the smallest

reading on the scale, but due to measuring circumstances, it is safer to assume a larger

uncertainty.

Other values taken into account are:

viii.

2

81 . 9

ms g

ix. N= 40

x.

15 n

The general form to determine the error is written:

'

'

t

) 2 (

) 2 (

) 2 (

) 2 (

) (

) (

15

15

0

0

y d

y

q

y d

y

q

da

a

q

dc

c

q

t d

t

q

d

q

dm

m

q

dq

o i

o i

Performing the differentiations and calculations on maple outputs a result of 3.90N/

(ms

-1

). Hence,

1

) /( N 90 . 3 06 . 25

t ms q

.This is a rather large error of 15.5%.

Improvement could be done to increase the accuracy of theexperiment and

decrease the uncertainty associated with the measured quantities such as measuring

the mass by lumps instead of individually and using an electronic digital timer.

Also, viscosity of the oil in the dashpot might be slightly affected by the

energy received from the oscillating system, which will heat it up slightly, and lower

the viscosity. It is also possible that the spring was undergoing hysteretic damping due

to the internal friction when strained. This means that energy was lost as heat for

every oscillating cycle.

It should be noted that although the motion for the damped system was

oscillatory, it was not periodic due to changing amplitudes. The frequency of the

3

damped system was reduced by a factor

2

1

due to the viscous damping effect

provided by the dashpot.

2

Conclusion

Through the implementation of a static deflection test while keeping within

the limit of proportionality of the Hookean helical spring, the spring stiffness, k given

by the slope of the plot in Figure 2.1 was established to be 4064.41 N/m. Through

further utilisation of the method of least square, it can be confirmed that that the

spring stiffness obtained is of valid accuracy.

The mass of the spring in this experiment was relatively heavy when. Hence,

the spring mass should be taken into consideration when modelling a vibrating system

with a heavy spring, using the spring mass correction. This spring mass correction

skews the period of oscillation or frequency attained towards a more precise

description of the real system dynamics.

The damping coefficient, q of the dashpot filled with oil was determined as

25.06N/(ms

-1

) with a uncertainty of 3.15N/(ms

-1

). The dashpot provided a light

damping effect to the vibrating system, decreasing the amplitude of the motion over a

period of time until the motion stops completely. This implies that the damping ratio,

is smaller than 1, which was verified by the calculation as 0.00029.

The viscous damping of the dashpot has virtually insignificant effects on the

frequency of free oscillations. Hence, if the damping effects on frequency is ignored

when modelling a vibrating system, a relatively reliable result will still be obtained.

However, damping will affect the motion of the oscillation and is important in

controlling resonance peak.

In conclusion, the experiment has shown that the theoretical equations derived

from modelling gives a decent idea of the behaviour of the operating dynamics within

a certain system. Moreover, this shows that the assumptions made during modelling

did not compromise the dynamic nature of the system, but simplified the analysis, as

well as producing straightforward and comprehensible equations.

1

References

Deformation of Solids n.d. Retrieved April 4, 2011 from http://www.ngfl-

cymru.org.uk/vtc/ngfl/science/58/solids_under_stress/hookes_law.doc

DiracDelta Science & Engineering Encyclopedian.d. Retrieved April2, 2011 from

http://www.diracdelta.co.uk/science/source/p/r/proportional%20limit/source.html

Encyclopedia Britannica Online n.d.Retireved April3, 2011 from

http://www.britannica.com/eb/article-9040985/Hookes-law

Least-Squares Line, Efunda: Engineering Fundamentals n.d. Retrieved from April 01,

2011 from http://www.efunda.com/math/leastsquares/lstsqr1dcurve.cfm

Dynamic Systems, Entwistle 2011.RetrievedApril2, 2011 from

http://lms.curtin.edu.au/

M-6 Hookes Law, Simanek 2004. Retrieved April4, 2011 from

http://www.lhup.edu/~dsimanek/scenario/labman1/h ooke.htm

1

1

Appendix A: Graphs

Figure 3.1: Plot of force versus deflection.

Figure 3.2: Plot of T versus m.

2

3

Appendix C: Maple Calculations for Error Analysis of Damping

Coefficient

>

4

You might also like

- Hazmat Transportation Training RequirementsDocument12 pagesHazmat Transportation Training RequirementsSafety IezzproNo ratings yet

- Design of Foundations For Dynamic LoadsDocument446 pagesDesign of Foundations For Dynamic LoadsJose Luis Velasco Cadavid100% (49)

- Solid Waste ManagementDocument12 pagesSolid Waste ManagementAmiteshAwasthiNo ratings yet

- Steam Power Plant1BoilerDocument21 pagesSteam Power Plant1BoilerJay Mark Cayonte100% (1)

- Lecture Notes - Linear Elasticity TheoryDocument43 pagesLecture Notes - Linear Elasticity Theoryzcapg17No ratings yet

- Mechanical VibrationDocument72 pagesMechanical VibrationMuhammadNasir100% (1)

- Computation of TR Line Parameters & ModellingDocument18 pagesComputation of TR Line Parameters & ModellingVibin NivasNo ratings yet

- Measurement of Vibration Using Piezoelectric SensorDocument7 pagesMeasurement of Vibration Using Piezoelectric SensorAnand RajNo ratings yet

- Power System Operation Guide: Load Curves, Forecasting & CommitmentDocument14 pagesPower System Operation Guide: Load Curves, Forecasting & Commitmentindhu.cs75% (4)

- Vertical Roller Mill For Raw MaterialsDocument63 pagesVertical Roller Mill For Raw Materialssajjad100% (1)

- Gasifier Thesis PDFDocument164 pagesGasifier Thesis PDFJohn Taulo100% (1)

- Mechanical Vibrations Week 1Document57 pagesMechanical Vibrations Week 1mrb87No ratings yet

- Study and Implementation of Object Detection and Visual TrackingDocument32 pagesStudy and Implementation of Object Detection and Visual TrackingBharat GiddwaniNo ratings yet

- Energy Audit Notes FinalDocument64 pagesEnergy Audit Notes FinalNaga Ananth100% (6)

- Text Editor Data Structure ComparisonDocument91 pagesText Editor Data Structure ComparisonglobalhodmechNo ratings yet

- Lab ReportDocument7 pagesLab Reportlesh allanoNo ratings yet

- Experiment 4: Design Comparator CircuitsDocument10 pagesExperiment 4: Design Comparator CircuitsNeekita ChamaneNo ratings yet

- Cisco CSS Basic Configuration GuideDocument484 pagesCisco CSS Basic Configuration GuideKumar Mukherjee-BiltuNo ratings yet

- Thevenin's Theorem Lab: Voltage, VDocument3 pagesThevenin's Theorem Lab: Voltage, VMd Johurul IslamNo ratings yet

- Mass Spring SystemDocument25 pagesMass Spring SystemKhoironSyamdatuNo ratings yet

- 9 Thevenin & Norton CircuitsDocument11 pages9 Thevenin & Norton CircuitsKhalidSa23No ratings yet

- Full Paper A PRAGMATIC ANALYSIS OF SPEECH ACTS IN MARGARET OGOLA'S THE RIVERDocument9 pagesFull Paper A PRAGMATIC ANALYSIS OF SPEECH ACTS IN MARGARET OGOLA'S THE RIVERBenita NicholasNo ratings yet

- Text EditorsDocument26 pagesText EditorsSachin VeerashettyNo ratings yet

- Smartening Up With Artificial Intelligence PDFDocument52 pagesSmartening Up With Artificial Intelligence PDFHWANG INBUMNo ratings yet

- RS579 - Computer Engineering Curriculum 2073 PDFDocument80 pagesRS579 - Computer Engineering Curriculum 2073 PDFreema yadav75% (8)

- Bitstream Group7Document6 pagesBitstream Group7Naina DasouniNo ratings yet

- Artificial Intelligence, Blockchain, and Internet of Medical Things: New Technologies in Detecting, Preventing, and Controlling of Emergent DiseasesDocument27 pagesArtificial Intelligence, Blockchain, and Internet of Medical Things: New Technologies in Detecting, Preventing, and Controlling of Emergent DiseasesVania V. EstrelaNo ratings yet

- PHY1331 Assignment 1 Solutions PDFDocument2 pagesPHY1331 Assignment 1 Solutions PDFLarissa83% (6)

- (Mass Spring System) : Department Course Name SemesterDocument9 pages(Mass Spring System) : Department Course Name SemesterMohammad AlshourbajeNo ratings yet

- Lecture On Fuzzy Logic ControlDocument87 pagesLecture On Fuzzy Logic ControlHEMANT KUMARNo ratings yet

- Research Paper On Basic of Artificial Neural NetworkDocument5 pagesResearch Paper On Basic of Artificial Neural NetworkEditor IJRITCCNo ratings yet

- (FINAL) Gas Leakage Detection With Buzzer System Using AtmegaDocument3 pages(FINAL) Gas Leakage Detection With Buzzer System Using AtmegaYash Kapure100% (2)

- Domino Effect AnalysisDocument16 pagesDomino Effect Analysisapi-270822363No ratings yet

- Promoting Safety Culture in Romanian Organizations As A Pillar of Occupational Health and Safety ManagementDocument8 pagesPromoting Safety Culture in Romanian Organizations As A Pillar of Occupational Health and Safety ManagementSEP-PublisherNo ratings yet

- Week 1 Vibration IntroductionDocument22 pagesWeek 1 Vibration IntroductionSaya SantornoNo ratings yet

- Formal Report Lab 1Document11 pagesFormal Report Lab 1Mohan RyanNo ratings yet

- NPTEL - Mechanical Engineering - Vibration ControlDocument10 pagesNPTEL - Mechanical Engineering - Vibration Control8104772799No ratings yet

- AccelerometersDocument4 pagesAccelerometersఅయ్యలసోమయాజుల సాయి శివ100% (1)

- PPS Project ReportDocument7 pagesPPS Project ReportRITIK JAINNo ratings yet

- Experiment 1Document11 pagesExperiment 1Nurul Anati ZulkifliNo ratings yet

- Advanced Dynamics: Donald T. GreenwoodDocument24 pagesAdvanced Dynamics: Donald T. GreenwoodSasidhar JannuNo ratings yet

- Control 1 NotesDocument14 pagesControl 1 NotesGatheru NjorogeNo ratings yet

- Vibration Dynamics PDFDocument41 pagesVibration Dynamics PDFvbhvmht09No ratings yet

- Longitudinal Vibration BarsDocument83 pagesLongitudinal Vibration BarsGerson Cordoba Barco75% (4)

- DS - Lec 1Document7 pagesDS - Lec 1Sherif SaidNo ratings yet

- Measuring Spring Stiffness and Natural FrequencyDocument60 pagesMeasuring Spring Stiffness and Natural FrequencyRobert Lau Yik SiangNo ratings yet

- Discussion of The Improved Methods For Analyzing ADocument16 pagesDiscussion of The Improved Methods For Analyzing ASudheer Reddy TenaliNo ratings yet

- Simple Pedulum Motion: General Physics Quastion SheetsDocument8 pagesSimple Pedulum Motion: General Physics Quastion SheetsShiun TungNo ratings yet

- Axioms of Quantum MechanicsDocument7 pagesAxioms of Quantum MechanicsAZIZ ALBAR ROFI'UDDAROJADNo ratings yet

- Mechanics of Rigid BodyDocument21 pagesMechanics of Rigid Bodyhenzel espinaNo ratings yet

- Mathematical Modeling of Control System Assignment NewDocument8 pagesMathematical Modeling of Control System Assignment NewJawad SandhuNo ratings yet

- Equations of MotionDocument6 pagesEquations of MotionDharshan KofiNo ratings yet

- Oscillations TheoryDocument10 pagesOscillations TheoryJoanna PanayiNo ratings yet

- PDF Dynamic Analysis of StructuresDocument43 pagesPDF Dynamic Analysis of StructuresChegue BureNo ratings yet

- Sample Physics Lab ReportDocument8 pagesSample Physics Lab ReportAnonymous zF7oT5GrNo ratings yet

- Vibrations of Multi-Degree of Freedom Systems: Simple Harmonic Motion That Passes Through Their Equilibrium PositionsDocument15 pagesVibrations of Multi-Degree of Freedom Systems: Simple Harmonic Motion That Passes Through Their Equilibrium PositionsMï XavierNo ratings yet

- Lab 4 Mass-Spring System - v3Document13 pagesLab 4 Mass-Spring System - v3sairafiNo ratings yet

- Basic Concepts On StaticsDocument6 pagesBasic Concepts On Staticsmzairun100% (2)

- Motion and Dynamics: 3.1 Making Sense of Dynamic EquilibriumDocument6 pagesMotion and Dynamics: 3.1 Making Sense of Dynamic EquilibriumnasirfahimNo ratings yet

- Physics 11 Word.Document23 pagesPhysics 11 Word.Michael John C UrpianoNo ratings yet

- Dynamics CourseworkDocument9 pagesDynamics CourseworkRodney MensahNo ratings yet

- Static's Lecture 1-5 2Document121 pagesStatic's Lecture 1-5 2HaadS.AbbasiNo ratings yet

- Angular Momentum Course HandoutDocument29 pagesAngular Momentum Course HandoutAtif ImamNo ratings yet

- Linear Impulse and Momentum PrinciplesDocument17 pagesLinear Impulse and Momentum PrinciplesVinot EsanNo ratings yet

- Experiment 104 Torque: 2 Condition of Equilibrium: PhysicsDocument4 pagesExperiment 104 Torque: 2 Condition of Equilibrium: PhysicsJag MasterNo ratings yet

- SEEX1016 L T P Credits Total Marks 3 0 0 3 100: (Common To EEE and E&C)Document132 pagesSEEX1016 L T P Credits Total Marks 3 0 0 3 100: (Common To EEE and E&C)Suman MajumderNo ratings yet

- Model: ZR72KCE-TFD: Technical DataDocument9 pagesModel: ZR72KCE-TFD: Technical DataZakiFroidNo ratings yet

- GENERATING ELECTRICITYDocument34 pagesGENERATING ELECTRICITYAdeniji OlusegunNo ratings yet

- Faizan ResumeDocument3 pagesFaizan ResumeFaizanNo ratings yet

- SD 0100CT1502 Sec-06Document18 pagesSD 0100CT1502 Sec-06royvindasNo ratings yet

- BP Holstein Field & Platform TopsidesDocument2 pagesBP Holstein Field & Platform Topsidesbayboy75No ratings yet

- Fuel Cells On AerospaceDocument4 pagesFuel Cells On Aerospacevvtarun50% (2)

- Technical and Economic Impacts of Distributed Generation On Distribution SystemDocument5 pagesTechnical and Economic Impacts of Distributed Generation On Distribution Systemआश्विन मरहट्टाNo ratings yet

- Breaking The Myths of Nuclear Energy:Dr.D.N.Sharma, Member, NDMADocument3 pagesBreaking The Myths of Nuclear Energy:Dr.D.N.Sharma, Member, NDMANdma IndiaNo ratings yet

- ATB - GROUP BROCHURE RENEWABLES Small - WindDocument8 pagesATB - GROUP BROCHURE RENEWABLES Small - WindT Tryhard FnNo ratings yet

- Heliarc 250 Ac/Dc Power Sources For 230/460/575 VOLT SERVICEDocument4 pagesHeliarc 250 Ac/Dc Power Sources For 230/460/575 VOLT SERVICEDeepan MNo ratings yet

- Lab ManualDocument6 pagesLab ManualAnshikha NautiyalNo ratings yet

- How To Make A 220V To 110V Converter Circuit - Homemade Circuit ProjectsDocument1 pageHow To Make A 220V To 110V Converter Circuit - Homemade Circuit ProjectsChanna PrasadNo ratings yet

- 700-HG Power Relay: - Description Contact Ratings Wiring Diagrams Coil Voltage Cat. NoDocument1 page700-HG Power Relay: - Description Contact Ratings Wiring Diagrams Coil Voltage Cat. NoArif KhanNo ratings yet

- Energy, Work & Power 09 QPDocument10 pagesEnergy, Work & Power 09 QPRahat RizwanNo ratings yet

- DCE Biodiesel Information BrochureDocument10 pagesDCE Biodiesel Information BrochureIshwar ChandraNo ratings yet

- Process Guide: TechnipDocument3 pagesProcess Guide: TechnipДмитрий ГоршковNo ratings yet

- Chapter 12-Heating, Air Conditioning, and Ventilating: 1 Healthy Housing Reference ManualDocument21 pagesChapter 12-Heating, Air Conditioning, and Ventilating: 1 Healthy Housing Reference ManuallmelendeziNo ratings yet

- List of FINAL TOPICS 23-24 N-SBDocument9 pagesList of FINAL TOPICS 23-24 N-SBAkashdeep Sunil WaghmareNo ratings yet

- 220MW Turbine Generator Technical SpecificationDocument9 pages220MW Turbine Generator Technical SpecificationOry'sSebayangNo ratings yet

- Pamilacan IslandDocument4 pagesPamilacan IslandRogen QuibolNo ratings yet

- 93 Physics MCQ and Answers IAS ExamDocument73 pages93 Physics MCQ and Answers IAS Examnsvasanthasena89% (47)

- Inverter Selection GuideDocument8 pagesInverter Selection GuideboisNo ratings yet

- Catalogue - Central Battery SystemDocument12 pagesCatalogue - Central Battery SystemarifzakirNo ratings yet