Professional Documents

Culture Documents

Metal Fabrication Shop

Uploaded by

Saurabh BhootaraOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Metal Fabrication Shop

Uploaded by

Saurabh BhootaraCopyright:

Available Formats

METAL FABRICATION SHOP

PRODUCTION PROCESS AND TECHNOLOGY The metal fabrication industry is primarily concerned with Forming and shaping metals by hot and/or cold processes, essentially heating/welding and shearing/forming operations. Shearing operations cut materials into a desired shape and size and include punching, piercing, blanking, cutoff, parting, shearing and trimming activities. These produce holes or openings, or produce blanks or parts, the most common hole-making operation being punching. Cutoff, parting and shearing are similar operations with different applications. Forming operations bend or conform materials into specific shapes by turning, twisting, extruding, drawing, rolling, spinning, coining, and forging metal into a specific configuration. Machining refines the shape of a work piece when shearing and forming are complete, by removing material from pieces of raw stock with machine tools. The main processes involved are drilling, milling, and turning, shaping/planning, broaching, sawing, and grinding. Holding the different pieces together is achieved either by riveting, bolting or more permanently by welding. Welding is the process primarily used to join metals; most welds are by fusion in which the materials joined are melted at, and around, the joint between them. The essential feature of a fusion welding process is a heat source either in the form of a flame from a gas torch (most often oxyacetylene or propane) or an electric arc. Gas Welding: In oxyacetylene and similar gas welding, the main source of heat is the combustion of the fuel gas with pure oxygen, fed from cylinders through flow regulators into a torch. The oxyacetylene flame can be adjusted by changing the ratio of the volume of oxygen to acetylene and can attain peak temperatures of 3,200 C, sufficient to w eld steels and most other metals, (steel melts above 1,500 C.) However , other gases, primarily propane, is used for joining lower melting point non-ferrous metals, and for brazing and silver soldering. Arc Welding: An arc is arranged to run between an electrode in a rod holder (torch) and the metals being welded the heat generated being as typically 15,000 to 20,000 C. Some form of inert gas shiel ding is usually required to C prevent oxidation of the metals in this process either Argon, Helium or

Carbon Dioxide is used. Gas shielded welding has many variants and techniques including replacement of the torch-held electrode by wire feeding off a roll. Shielded Metal Arc Welding (SMAW) is frequently called Stick or Covered Electrode welding is a process that uses a consumable electrode coated in flux to lay the weld. As the weld is laid, the flux coating of the electrode disintegrates, giving off vapors that serve as a shielding gas and providing a layer of slag, both of which protect the weld area from atmospheric contamination. Gas Metal Arc Welding (GMAW) is frequently referred to as MIG welding, a high deposition rate welding process in which a continuous and consumable wire electrode and a shielding gas are fed through a welding gun. The primary shielding gasses used are Argon, Argon/Helium and CO2 in its pure form. However, in some applications the presence of CO2 in the shielding gas may adversely affect the mechanical properties of the weld. Gas Tungsten Arc Welding (GTAW) is frequently referred to as TIG welding, a high quality welding process is an arc welding process that uses a non consumable tungsten electrode to produce the weld. The weld area is protected from atmospheric contamination by a shielding gas (usually an inert gas such as argon), and a filler metal is normally used. Shielding Gases are the usual Argon or Argon + Helium. An Argon Hydrogen mix is also used resulting in cleaner looking welds.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- IWE SubjectsDocument2 pagesIWE SubjectsAdnan Rana100% (3)

- 631 PDFDocument3 pages631 PDFdarshanNo ratings yet

- Welding Defects - Causes and RemediesDocument51 pagesWelding Defects - Causes and Remediesmilind94% (18)

- SKF Special MaterialsDocument2 pagesSKF Special MaterialsKamolwan WeerachatsakulNo ratings yet

- Aluminum and Steel Factories in RomaniaDocument12 pagesAluminum and Steel Factories in RomaniaPacific HRNo ratings yet

- Manufacturing Processes: Multiple Choice 1. A. B. C. DDocument19 pagesManufacturing Processes: Multiple Choice 1. A. B. C. DamarparimiNo ratings yet

- Rebar: Rebar Is The Common Name For Cylindrical Shaped Steel Bars With Uniformly Spaced ProtrusionsDocument21 pagesRebar: Rebar Is The Common Name For Cylindrical Shaped Steel Bars With Uniformly Spaced ProtrusionsTimberly100% (1)

- HT 521 84054 800 ENDocument5 pagesHT 521 84054 800 ENEdward AguillónNo ratings yet

- Tenax 88s HR (E 50 6 Mn1ni B 32 h5)Document1 pageTenax 88s HR (E 50 6 Mn1ni B 32 h5)brunizzaNo ratings yet

- Material Selection - SMSDocument38 pagesMaterial Selection - SMSKong LingweiNo ratings yet

- Plasma Flame Spray Book PDFDocument176 pagesPlasma Flame Spray Book PDFAlexis O'NeillNo ratings yet

- Determination Aluminium, Calcium, Manganese and Titanium in Ferrosilicon Alloys by Atomic-Absorption SpectrophotometryDocument5 pagesDetermination Aluminium, Calcium, Manganese and Titanium in Ferrosilicon Alloys by Atomic-Absorption SpectrophotometryAhmed IsmailNo ratings yet

- La Metalografia A ColorDocument81 pagesLa Metalografia A ColorLENDNo ratings yet

- 111 - Atom Isi Wps3Document1 page111 - Atom Isi Wps3burakNo ratings yet

- Welding Aluminum Alloy 6061 PDFDocument5 pagesWelding Aluminum Alloy 6061 PDFtazzorroNo ratings yet

- NES 747 Part1 PDFDocument38 pagesNES 747 Part1 PDFRicardo Huanca TrejoNo ratings yet

- Aluminum Filler Metal Selection ChartDocument1 pageAluminum Filler Metal Selection ChartbrrrrzzzzNo ratings yet

- B Boehler Aws E316l 17 Se en 5a Mds PDFDocument1 pageB Boehler Aws E316l 17 Se en 5a Mds PDFInaamNo ratings yet

- Home Made MagnaliumDocument5 pagesHome Made Magnaliumcliffhanger1972No ratings yet

- Jominy-End Quench TestDocument16 pagesJominy-End Quench TestFirdaus Asry33% (3)

- Phase Diagram & Heat TreatmentDocument16 pagesPhase Diagram & Heat TreatmentBHARANI100% (1)

- PD Binary PDFDocument81 pagesPD Binary PDFmanilrajkrr6302No ratings yet

- Manufacturing Feature-Based Cost Estimation of Cast Parts: AbstractDocument6 pagesManufacturing Feature-Based Cost Estimation of Cast Parts: AbstractproffrahulNo ratings yet

- Task 6 - Leave Type Safety ValveDocument3 pagesTask 6 - Leave Type Safety ValveTeguh RaharjoNo ratings yet

- Report On Neelkanth Steel IndustriesDocument6 pagesReport On Neelkanth Steel IndustriesMeet PatelNo ratings yet

- Appendix 1 Part 2 Magnetic Particle Inspection 5th Edition February 2016Document12 pagesAppendix 1 Part 2 Magnetic Particle Inspection 5th Edition February 2016Alireza ZiaeddiniNo ratings yet

- SK D 15-G (MF 3-GF-60-T) PDFDocument1 pageSK D 15-G (MF 3-GF-60-T) PDFborovniskiNo ratings yet

- Chetan Mane: Personal Profile ExperienceDocument1 pageChetan Mane: Personal Profile ExperienceKetan MNo ratings yet

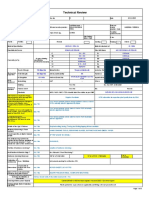

- Technical Review: (Minimum Score Required 75%)Document4 pagesTechnical Review: (Minimum Score Required 75%)Deepak HoleNo ratings yet

- Nicon Price List January 2021Document12 pagesNicon Price List January 2021niket0No ratings yet