Professional Documents

Culture Documents

EGD eRAN2.2 Customer Preparation Guide For BTS3900 LTE Installation-20110726-C-1.1

Uploaded by

cspkerOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EGD eRAN2.2 Customer Preparation Guide For BTS3900 LTE Installation-20110726-C-1.1

Uploaded by

cspkerCopyright:

Available Formats

Guide to Customers Preparation for BTS3900 LTE Installation

INTERNAL

Document Number Intended Users Client/Engineer/Cooperation Partner

Product Name Product Version

BTS3900 LTE LTE V100R002C00 LTE V100R003C00 LTE V100R004C00

Issued by

Wireless Product Rollout Dept, TSD

Document Version

1.1

Guide to Customers Preparation for BTS3900 LTE Installation

Prepared by Reviewed by Reviewed by Approved by

Xu chong, Ding Hui

Date Date Date Date

2011-7-26

HUAWEI TECHNOLOGIES CO., LTD.

2011-08-16

HUAWEI Confidential

Page 1, Total 47

Guide to Customers Preparation for BTS3900 LTE Installation

INTERNAL

Change History

Date 2010-7-15 2010-12-10 2011-07-26 Version V1.0 V1.1 V1.2 Description First issue Second issue Third Issue Author Xu chong Chen Fei DingHui, Konglidong

2011-08-16

HUAWEI Confidential

Page 2, Total 47

Guide to Customers Preparation for BTS3900 LTE Installation

INTERNAL

Contents

3.1 Introduction of BTS3900 LTE...............................................................................................................................11 3.2 Site Requirements of the BTS3900 LTE................................................................................................................13 3.2.1 Site Selection Requirements of the eNodeB.....................................................................................................13 3.2.2 Space Requirements of the BTS3900...............................................................................................................14 3.2.3 Construction Requirements for the BTS3900 Equipment Room.....................................................................17 3.2.4 Operating Environment Requirements of the BTS3900...................................................................................21 3.3 Power Supply Requirements of the BTS3900........................................................................................................22 3.4 Grounding Requirements of the BTS3900.............................................................................................................22 3.5 Transmission Requirements for the eNodeB Site...................................................................................................23 4.1 Auxiliary Facilities Preparations for the BTS3900 Site.........................................................................................25 4.1.1 Preparing Cable Racks......................................................................................................................................25 4.1.2 Preparing the Grounding System......................................................................................................................25 4.2 Preparing Auxiliary Facilities for the BTS3900 Antenna System..........................................................................29 4.2.1 Requirements for the Tower.............................................................................................................................29 4.2.2 Preparing the Antenna Support on the Tower...................................................................................................30 4.2.3 Preparing the Antenna Support on the Rooftop................................................................................................32 4.2.4 Preparing the Feeder Window..........................................................................................................................36 4.3 Cable Requirements of the eNodeB.......................................................................................................................37 4.3.1 Requirements for Materials of the Indoor eNodeB Cables..............................................................................37 4.3.2 General Cabling Specifications for the eNodeB...............................................................................................38 4.4 Preparation of Personnel for the Installation..........................................................................................................40 5.1 Acceptance Items for the Environment of the Equipment Room...........................................................................41 5.2 Acceptance Items for Power Supply.......................................................................................................................42 5.3 Acceptance Items for Surge Protection Grounding ...............................................................................................43 5.4 Acceptance Items for the eNodeB Antenna System...............................................................................................44 6.1 BTS3900 LTE Engineering Specification..............................................................................................................46

2011-08-16

HUAWEI Confidential

Page 3, Total 47

Guide to Customers Preparation for BTS3900 LTE Installation

INTERNAL

6.1.1 Engineering specification.................................................................................................................................46 6.1.2 Environmental specification.............................................................................................................................46

2011-08-16

HUAWEI Confidential

Page 4, Total 47

Guide to Customers Preparation for BTS3900 LTE Installation

INTERNAL

Figures

Figure 3-1 Architecture of the BTS3900 LTE:....................................11 Figure 3-2 Internal structure of the BTS3900 LTE (48 V DC).............12 Figure 3-3 Internal structure of the BTS3900 LTE (+24 V DC)............12 Figure 3-4 Internal structure of the BTS3900 LTE (220 V AC).............13 Figure 3-5 Space requirements for installing the BTS3900 cabinet....16 Figure 3-6 Requirements for the layout of the BTS3900 cabinet........17 Figure 4-7 Grounding grid of the eNodeB........................................26 Figure 4-8 Grounding system of the eNodeB equipment room (with dedicated rectifier)........................................................................27 Figure 4-9 Grounding of metal tower and buildings..........................27 Figure 4-10 Grounding copper bar of the eNodeB.............................28 Figure 4-11 Tower for telecommunication purpose...........................29 Figure 4-12 Directional antenna support on a tower.........................30 Figure 4-13 Support for the omni-directional antenna on a tower.....31 Figure 4-14 Installing the antenna support on the rooftop................32 Figure 4-15 Structure of the pole on the rooftop..............................33 Figure 4-16 Fixing the directional antenna on the rooftop (1)...........34 Figure 4-17 Fixing the directional antenna on the rooftop (2) Preparing the Omni-Directional Antenna Support and Pole on a Rooftop.........................................................................................35 Figure 4-18 Installing an omni-directional antenna..........................35

2011-08-16

HUAWEI Confidential

Page 5, Total 47

Guide to Customers Preparation for BTS3900 LTE Installation

INTERNAL

Figure 4-19 Installing an omni-directional antenna support..............36 Figure 4-20 Dimensions of the 12-hole feeder window (unit: mm).....37

2011-08-16

HUAWEI Confidential

Page 6, Total 47

Guide to Customers Preparation for BTS3900 LTE Installation

INTERNAL

Tables

Table 3-1 Climatic requirements......................................................21 Table 3-2 Power supply requirements of the BTS3900......................22 Table 4-3 Requirements for materials of the indoor eNodeB cables. . .37 Table 4-4 Requirements for bending radius of the cables..................38 Table 6-5 Engineering specification.................................................46 Table 6-6 Environmental specification.............................................46

2011-08-16

HUAWEI Confidential

Page 7, Total 47

Guide to Customers Preparation for BTS3900 LTE Installation

INTERNAL

About This Document

Thank you for choosing Huawei eNodeB (BTS3900 LTE). You are expected to make all the preparations described in this guide before Huawei technical staffs arrive on site, so that the equipment can be put into operation as soon as possible. This can ensure that you reap social benefits and economic interests at the earliest. Before making the installation preparations, read the following contents carefully: After you complete all the installation preparations, please contact the Huawei local representative office on time, so that Huawei can arrange technical staff to start the installation. If the installation is implemented before the installation preparations are fully completed owing to some reason, you should arrange related staff to finish the uncompleted part as early as possible to ensure the smooth implementation of the project. If the installation started before the preparations are fully completed owing to some reason, and later installation cannot go on because of insufficient preparations, Huawei has the right to stop the installation. After all the preparations are made, both parties can discuss and arrange to restart the installation. The operator is welcome to consult Huawei local or regional representative office for any support about site preparation at any time. Address of the Local Huawei Representative Office: Phone/Fax: Contact Person and Phone Number:

2011-08-16

HUAWEI Confidential

Page 8, Total 47

Guide to Customers Preparation for BTS3900 LTE Installation

INTERNAL

Introduction to Huawei Installation Process

To strengthen understanding and for better cooperation between two parties, this section provides a brief overview of the Huawei equipment installation process. Huawei equipment installation process starts when the contract is signed and validated and ends when the equipment passes the final acceptance test and enters the maintenance period. The process is as follows:

2011-08-16

HUAWEI Confidential

Page 9, Total 47

Guide to Customers Preparation for BTS3900 LTE Installation

INTERNAL

Both parties sign the contract and the execution starts.

The customer makes the preplanning and identifies the site Huawei . provides the customer's preparation guide.

The customer makes the prepayment.

The customer starts the installation preparation according to the Operator's Preparation Guide, and completes the project survey and data planning together with the surveyors.

Huawei organizes the goods manufacturing and delivery . Huawei provides consultation service for the customer about the installation preparation and the customer completes , the preparation before project kickoff .

Goods are delivered to the site.

Huawei and the customer determine the kickoff date and designate the persons in charge for each party .

Huawei and the customer unpack and inspect the goods .

Huawei performs hardware installation and software debugging .

The system is put into trial run after the system installation debugging , system preliminary acceptance and cutover .

The installation is complete after the final acceptance .

This process shows that smooth completion of an installation project requires close cooperation between you and Huawei. We sincerely hope for smooth completion of the project.

2011-08-16

HUAWEI Confidential

Page 10, Total 47

Guide to Customers Preparation for BTS3900 LTE Installation

INTERNAL

Installation Requirements of the BTS3900

3.1 Introduction of BTS3900 LTE

The BTS3900 LTE features a distributed architecture. The two basic modules of the BTS3900 LTE consists of the BBU3900 (BaseBand control Unit) and LTE Radio Frequency Unit (RFU). The BBU3900 and RFU are inter-connected through the Common Public Radio Interface (CPRI) using electrical cables.

Figure 3-1 Architecture of the BTS3900 LTE:

The indoor macro cabinet BTS3900 LTE houses the BBU3900 and RFUs. In addition, the BTS3900 LTE provides the functions such as power distribution, heat dissipation, and surge protection. A single BTS3900 LTE can be installed with a maximum of six RFUs. The BTS3900 LTE supports 48 V DC power input. If configured with suitable power modules, it can also support +24 V DC or 220 V AC power input. Figure 3-2, Figure 3-3 and Figure3-4 show the internal structure of the BTS3900 LTE cabinets with three types of power input.

2011-08-16

HUAWEI Confidential

Page 11, Total 47

Guide to Customers Preparation for BTS3900 LTE Installation

INTERNAL

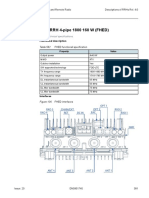

Figure 3-2 Internal structure of the BTS3900 LTE (48 V DC)

The direct current distribution unit (DCDU-01) module supplies power to all the components in the cabinet.

Figure 3-3 Internal structure of the BTS3900 LTE (+24 V DC)

2011-08-16

HUAWEI Confidential

Page 12, Total 47

Guide to Customers Preparation for BTS3900 LTE Installation

INTERNAL

The Power Supply Unit (PSU) converts +24 V DC power into 48 V DC power.

Figure 3-4 Internal structure of the BTS3900 LTE (220 V AC)

The Power and Environment Monitoring Unit (PMU) provides power system management, power distribution detection, and alarm report functions.

The PSU converts the 220 V AC power into the 48 V DC power.

3.2 Site Requirements of the BTS3900 LTE

The installation, commissioning, and operation of the BTS3900 are ensured only when the equipment room and installation space meet the site requirements. The site requirements of the BTS3900 involve the site selection, installation space, equipment room construction, and working environment.

3.2.1 Site Selection Requirements of the eNodeB

To ensure the stable running of the eNodeB over a long term, the site for the eNodeB

2011-08-16

HUAWEI Confidential

Page 13, Total 47

Guide to Customers Preparation for BTS3900 LTE Installation

INTERNAL

must meet the requirements for telecommunication network planning, communications technology, hydrology, geology, and transportation. The specific requirements for site selection are as follows: The site should not be exposed to excessive heat, dust, harmful gases, flammable or explosive materials, or unstable voltage.

The site should be located at a place where earthquakes or strong noise are unlikely to occur.

The site should be located far away from power substations, industrial boilers, and heating boilers.

The site should be far away from high-power radio transmitters, radar stations, or other interference sources. The interference field intensity should not be higher than the shielding specifications of the eNodeB for useless radiation.

The equipment room for the indoor eNodeB should be constructed at least 3.7 km away from the seaside or a salt lake. If this is not possible, the equipment room should be closed and air conditioned. In addition, avoid using salt soil as the building material for the room. Otherwise, the equipment that can be operated in extreme and unfavorable environment must be used.

The outdoor eNodeB should be located more than 500 m away from the sea

side. The site should be located far from sources of pollution. If this requirement cannot be met, select a site that is in the perennial upwind direction of the pollution source.

The site should be constructed at least 5 km from heavy pollution sources such as a smelting plant or a coal mine.

The site should be constructed at least 3.7 km from medium pollution sources such as a chemical plant, a rubber plant, or an electric plating plant.

The site should be constructed at least 2 km from light pollution sources such as a food product factory or a leather product factory.

The air inlets of the communication equipment should be far away from the sewer pipe, septic tank, and sewage disposal pool. The air pressure inside the equipment room should be higher than the air pressure outside the equipment room. Otherwise, corrosive gases may enter the equipment room and corrode the components and circuit boards.

Livestock rooms or fertilizer warehouses cannot be used as the equipment room for the indoor eNodeB. If this is not possible, it should be located at a place that is in the upwind direction of the livestock room or fertilizer warehouse.

It is recommended that the equipment room for the indoor base station be located on the second floor or above. If this requirement cannot be met, the ground for the equipment room should be at least 600 mm higher than the maximum flood level recorded in the area.

3.2.2 Space Requirements of the BTS3900

The space requirements for installing the BTS3900 cabinet are as follows:

2011-08-16

HUAWEI Confidential

Page 14, Total 47

Guide to Customers Preparation for BTS3900 LTE Installation

INTERNAL

The cabinet back can be installed against the wall. The cabinet side can be installed against the wall. A minimum of 800 mm distance is reserved in front of the cabinet for maintenance. A minimum of 200 mm distance is reserved on top of the cabinet for feeder routing when a single cabinet is installed. A minimum of 200 mm distance is reserved on top of the cabinet for feeder routing when cabinets are installed in stack mode. The BTS3900 cabinets should be installed side by side firstly, and should be installed in stack mode only if there is no enough space in equipment room.

2011-08-16

HUAWEI Confidential

Page 15, Total 47

Guide to Customers Preparation for BTS3900 LTE Installation

INTERNAL

Figure 3-5 Space requirements for installing the BTS3900 cabinet

2011-08-16

HUAWEI Confidential

Page 16, Total 47

Guide to Customers Preparation for BTS3900 LTE Installation

INTERNAL

Requirements on the layout of the BTS3900 cabinet are as follows:

The cabinet is installed as close to the feeder window as possible to reduce the feeder length. No space is required when the cabinet is installed side by side with other equipment.

Figure 3-6 Requirements for the layout of the BTS3900 cabinet

3.2.3 Construction Requirements for the BTS3900 Equipment Room

When specifying the BTS3900 equipment room, you should consider aspects such as area, height, weight bearing, floor, doors and windows, processing of the roof surface and wall surface, quakeproof capability, antistatic and anti-interference capability, illumination, air conditioning, and fire protection.

Area Requirements

The area of the equipment room meets the requirements for equipment installation and layout and for capacity expansion in the future. The feeder window can be installed and feeders can be routed in the equipment room. Installation or maintenance engineers can conveniently install or maintain the devices. Cabinet doors can be opened and closed freely.

2011-08-16

HUAWEI Confidential

Page 17, Total 47

Guide to Customers Preparation for BTS3900 LTE Installation

INTERNAL

Height Requirements

The height of the equipment room indicates the net distance between the beam or air duct and the ground. The height of the equipment room should meet requirements for installing cabling racks and routing cables and feeders. Generally the height of the equipment room is 3 m to 3.5 m.

Weight Bearing Requirements

When the base station is heavy, before installation, construction and structure engineers should verify the weight bearing capacity of the equipment room based on the weight, basal area, and installation position of the base station. Generally, the weight bearing capacity of the equipment floor should be greater than 450 kg/m2. If the weight bearing capacity is not great enough, you should reinforce the building.

Floor Requirements

The floor of the equipment room should be semi-conductive without dusting. Generally, ESD floors should be laid. The plates must be firmly placed on the floor, and the horizontal deviation per square meter is no greater than 2 mm.

When the ESD floor is unavailable, the floor should be laid with static conducive materials with the volume resistivity of 1.0 x 107 to 1.0 x 1010 .

The static conducive and ESD floors should be provided with antistatic grounding. That is, the static conducive and ESD floors are connected to grounding devices through current limiting resistance and wires. The value of the current limiting resistance is 1 M. Through tests, terrazzo floors (including concrete floors) can meet such requirements.

All cable holes on the floor must be covered with plates. The cable holes should be drilled according to the design and the size should be accurate to avoid difficulties arisen during equipment installation.

Requirements for Doors and Windows

The minimum size of the door is 2 m (H) x 1 m (W). Doors and windows must be sealed with dust-proof plastic bag. Windows where the sun can directly shine must be pasted with reflective sheeting or use tinted glass. When the sunshine meets relevant requirements, windows can be sealed or blocked.

Requirements for the Roof Surface and Wall Surface

The roof surface and wall surface are equipped with capabilities such as durability, heat insulation, and leak proof. When antenna poles and engineering holes are provided on the rooftop, take appropriate leak proof measures and consider the weight bearing capacity of the poles and holes. You can apply wallpapers or lusterless paint on the wall rather than pulverized paints.

2011-08-16

HUAWEI Confidential

Page 18, Total 47

Guide to Customers Preparation for BTS3900 LTE Installation

INTERNAL

Quakeproof Requirements

The seismic fortification intensity designed for an equipment room should be one degree above the local basic seismic intensity. If the seismic fortification intensity of the equipment room cannot meet the requirement, the equipment room should be reinforced.

Antistatic and Anti-interference requirements

The equipment room should adopt the ESD floor or ESD ground and be well grounded. The equipment room should be provided with antistatic clothing and ESD wrist strap. The equipment room should be free from electromagnetic interference. The electric field intensity should be smaller than 300 mV/m whereas the magnetic field intensity should be lower than 11 GS.

Illumination Requirements

The equipment room should avoid exposure to direct sunlight. When exposed to direct sunlight for a long time, the PCBs and other components are easily aged or deformed. The battery room should be provided with explosion-proof lamps with soft light. Ordinary base stations are barely attended. As a result, such base stations can be provided with regular lighting provided by the mains supply. Base stations with large capacity and great influence must be provided with the DC emergency lighting system for backup.

Air Conditioning Requirements

The capacity of the air conditioner is determined by the area of the equipment room and the heat productivity of the base station. For details on how to calculate the air conditioner capacity, see relevant engineering design specifications. The air conditioner capacity is mainly determined by the heat productivity of the base station, involving both the heat output of the base station and the heat consumption of the auxiliary power supply system. Wherein, the heat output of the base station is calculated by the input power minus the antenna radiation power. The heat consumption of the power supply system mainly stems from the AC/DC conversion coefficient. For equipment rooms powered by AC power supply, the heat output is calculated differently for the following two scenarios: When the base station is powered by DC power supply: Q = V x A/0.86 - W Wherein: Q indicates the heat output of the base station (unit: W).

2011-08-16

HUAWEI Confidential

Page 19, Total 47

Guide to Customers Preparation for BTS3900 LTE Installation

INTERNAL

V indicates the voltage of the DC power supply (unit: V). A indicates the average consumed power in busy hours (unit: A). W indicates the effective radiation power of the antenna (unit: W). The number 0.86 indicates the AC/DC conversion coefficient. When the base station is powered by AC power supply: Q = 0.99 x V x A - W Wherein: Q indicates the heat output of the base station (unit: W). V indicates the voltage of the AC power supply (unit: V). A indicates the average consumed power in busy hours (unit: A). W indicates the effective radiation power of the antenna (unit: W). The number 0.99 indicates the power coefficient. For ordinary base stations, two air conditioners are equipped and work alternatively. The air conditioners are set as follows: Relative humidity: 30% to 75% (50% to 60% preferred) Temperature: 18C to 28C (20C to 25C preferred)

Fire Fighting Requirements

Communication buildings are major fire protection objects and the fire-resistance design level should comply with relevant national and regional stipulations. Flammables and explosives are forbidden in the equipment room. Workable firefighting equipment must be provided on site. For example, smoke sensors and temperature sensors are furnished and function appropriately. Sockets that output different voltages in the equipment room should be clearly labeled. Reserved holes in the floor slab must be covered with safety plates. In addition to fire alarm devices and smoke sensors, automatic fire extinguishers can be provided in the equipment room so that the fire can be put down or controlled at the early stage. In addition, a certain number of handheld fire extinguishers should be provided in the aisle outside the equipment room to put down a fire at early stage. When the fire pool is required according to relevant fire fighting specifications, the pool should provide the amount of water necessary for outdoor and indoor fire fighting

2011-08-16

HUAWEI Confidential

Page 20, Total 47

Guide to Customers Preparation for BTS3900 LTE Installation

INTERNAL

(supposing that a fire lasts two hours). The fire hydrant should not be placed in the equipment room, but in the aisle or near stairs where the fire hydrant is obviously seen and easily fetched.

Requirements on Aisles Leading to or Extending from the Equipment Room

The transportation aisles should be wider than 1.5 m and higher than 2.5 m. The escape aisle should be obstacle-free, and directions to the escape aisle should be marked in outstanding positions in the equipment room. The elevator height is greater than 2.4 m.

3.2.4 Operating Environment Requirements of the BTS3900

The operating environment of the BTS3900 consists of requirements related to climatic conditions, biological environment, and air purity specifications.

Climatic Requirements

The climatic requirements for the operating environment of the BTS3900 are as following. Table 3-1 Climatic requirements

Item Altitude

Specification 4000 m; normal work within the range of -60 m to +3000 m, in degraded use within the range of 3000 m to 4000 m (the ambient temperature decreases 1C when the height increases by 100 m from 3000 m) 70 kPa to 106 kPa 20C to +55C 5% to 95% IP20

Air pressure Temperature Relative humidity Protection level

Biological Environment Requirements

The operating environment of the BTS3900 must meet the following biological requirements: No fungus or mildew should grow in the operating environment.

Air Purity Requirements

The air purity requirements related to the running environment are as follows:

2011-08-16

HUAWEI Confidential

Page 21, Total 47

Guide to Customers Preparation for BTS3900 LTE Installation

INTERNAL

There should not be any explosive, conductive, magnetic conductive or corrosive dust in the air.

3.3 Power Supply Requirements of the BTS3900

Both AC power and DC power can be used in the BTS3900 power supply system. The parameters of the supplied power must meet the corresponding specifications to ensure proper operation of the power system.

Table 3-2 Power supply requirements of the BTS3900

Power -48 V DC +24 V DC 200/346 V AC to 240/415 V AC, 50 Hz/60 Hz 200 V AC to 240 V AC, 50 Hz/60 Hz

Permitted Range -38.4 V DC to -57 V DC +21.6 V DC to +29 V DC 176/304 V AC to 290/500 V AC, 45 Hz/65 Hz 176 V AC to 290 V AC, 45 Hz to 65 Hz

Remarks Three-phase AC input Single-phase AC input

When DC power is led into the BTS3900 equipment room, the power supply system must meet the following requirements: When planning the capacity of the DC power supply system, you should consider the maximum load of the system in dynamic and static modes and reserve a certain capacity.

The power equipment is placed nearest possible to the communication equipment to minimize the DC feeder consumption.

When AC power is led into the BTS3900 equipment room, the power supply system must meet the following requirements: When planning the capacity of the AC power supply system, you must consider the working current and fault current of the equipment.

Each of equipment has an independent AC distribution protection device.

The current threshold of the distribution protection switch for the equipment is greater than that for the lower-level equipment

3.4 Grounding Requirements of the BTS3900

The BTS3900 equipment installation must meet the grounding requirements to ensure stable running of the eNodeB.

2011-08-16

HUAWEI Confidential

Page 22, Total 47

Guide to Customers Preparation for BTS3900 LTE Installation

INTERNAL

For a single BTS3900 cabinet, The PGND cable of the cabinet should be connected to the nearby external grounding bar. The green and yellow PGND cable should be copper-based and plastic-insulated with a cross-sectional area of at least 25 mm2.

When two BTS3900 cabinets installed in stacked mode, the following requirements must be met: The cabinets should be interconnected through a copper-based cable to ensure equal electric potential. Note that the cable must be copper-based and insulated with green and yellow plastic jackets and the cross-sectional area is at least 16 mm2.

The PGND cable of the lower cabinet should be connected to the grounding bar in the equipment room. The PGND cable should be copper-based and insulated with green and yellow plastic jackets. The cross-sectional area of the PGND cable is at least 25 mm2.

Fuses or switches are not allowed on the PGND cable. The grounding terminals should be anti-corrosive and antirust. Connection of the PGND cable is secure. The grounding bar should be located nearest possible to the eNodeB equipment. The maximum distance permitted is 30 m if the distance between the grounding bar and the eNodeB equipment is greater

than 30 m, reinstall the grounding bar nearby.

3.5 Transmission Requirements for the eNodeB Site

Before the site construction, the transmission devices and auxiliary devices should be prepared based on the practical application. Transmission requirements of the eNodeB site involve the ODF, and transmission mode. Requirements for ODF If optical transmission is applied, and the optical cables on the eNodeB side are connected to the transmission device through the ODF. The requirements for the ODF are listed as follows: The delivered transmission cables and connectors match the connectors on the ODF on the transmission device side. Before you install the eNodeB, the ODF is installed and external optical cables are connected to the ODF. It is recommended that the copper wires be used to connect the ODF and the grounding bar of the equipment room. Requirements for the Transmission Mode Transmission resources should meet the upcoming requirements of the eNodeB site and extra resources are reserved for capacity expansion. When the BBU3900 uses GE electric transmission, a 10 m long Ethernet cable is configured for each site by default. When the required GE Ethernet cable for BBU3900 is longer than 10 m, provide the required length. If the eNodeB is within the Line of Sight (LOS) of microwave transmission, and the HUAWEI Confidential Page 23, Total 47

2011-08-16

Guide to Customers Preparation for BTS3900 LTE Installation

INTERNAL

microwave transmission is used. The indoor units of the microwave transmission devices should be installed in the space for the transmission devices in the cabinet.

If the eNodeB is not within the Line of Sight (LOS) of microwave transmission, and the xDSL transmission is used. It is recommended that the devices for xDSL transmission be installed in the space reserved in the cabinet.

2011-08-16

HUAWEI Confidential

Page 24, Total 47

Guide to Customers Preparation for BTS3900 LTE Installation

INTERNAL

Construction Preparations of the BTS3900

4.1 Auxiliary Facilities Preparations for the BTS3900 Site

4.1.1 Preparing Cable Racks

Cable racks are classified into indoor cable racks and outdoor cable racks. The cable racks should be installed before the installation of the eNodeB. The recommended specifications of the indoor cable rack are as follows: width: 400 mm; height: 2.4 m. The cable rack should be installed according to the engineering design. Generally, the indoor cable rack is installed against a suspending lever. If the indoor cable rack is installed against a wall, a tripod or ground support can be used. The outdoor cable rack consists of the horizontal cable rack and the vertical cable rack. The outdoor cable rack should be installed according to the engineering design. The indoor cable rack is connected to the indoor grounding bar through cables. The outdoor cable rack is welded to the lightning rod of the building through the reinforcing steel bar, thus connecting to the antenna support. If required, wires should be added to improve electric connectivity between the cable racks.

4.1.2 Preparing the Grounding System

The grounding system of the eNodeB consists of the indoor grounding system and the outdoor grounding system.

Figure 4-1 shows the grounding grid of the eNodeB (the outdoor grounding system).

2011-08-16

HUAWEI Confidential

Page 25, Total 47

Guide to Customers Preparation for BTS3900 LTE Installation Figure 4-7 Grounding grid of the eNodeB

INTERNAL

The grounding grids of the power transformer, tower, and equipment room constitute an integrated grounding grid. (The grounding grid should be connected to the building and reinforced concrete bars of the tower. Generally, the grounding grid should be connected to at least two reinforced concrete bars.)

The outdoor grounding ring can be laid out in L-shaped or C-shaped according to the field situation of the equipment room. If the soil conductibility is poor or there is little soil in the rocky area, it is recommended that the grounding extension style and concrete bridge be used. The cable embedded concrete bridge radiates outwardly through the grounding ring and the four corners of the tower grounding ring. The concrete bridge has strong hygroscopy. The recommended length of the concrete bridge is 10 m to 30 m. It is recommended that the grounding stake be coated with hot galvanized steel. The specifications are as follows: Steel pipe ( 50 mm, wall depth greater than 3.5 mm) Angle steel (at least 50 mm X 50 mm X 5 mm) Flat steel (at least 40 mm X 4 mm) The proper length of the grounding stake is from 1.5 m to 2.5 m, and the interval is 1.5 to 2 times the length of the grounding stake. The space between the top of the grounding stake and the ground is at least 0.7 m. For cold districts, bury the grounding stake under the frozen soil. The depth of the grounding ring must be 0.7 m under the concrete base. You should determine whether to add resistivity reduction mixture based on the equipment room location and soil conditions.

2011-08-16

HUAWEI Confidential

Page 26, Total 47

Guide to Customers Preparation for BTS3900 LTE Installation

INTERNAL

Figure 4-8 Grounding system of the eNodeB equipment room (with dedicated rectifier)

The equipment room is configured with a primary grounding bar that is connected to the grounding grid of all the equipment and the DC power inside the equipment room. It is recommends that you use the galvanized flat steel of 40 mm x 4 mm or 50 mm x 5 mm as the grounding cable. The part of the grounding cable outside the earth should be protected against mechanical damage. As shown in 4.1.2, the outdoor grounding system consists of the tower grounding, feeder grounding, grounding grid, rooftop surge protection grounding bar, cable rack grounding, and outdoor grounding copper bus bar.

Figure 4-9 Grounding of metal tower and buildings

2011-08-16

HUAWEI Confidential

Page 27, Total 47

Guide to Customers Preparation for BTS3900 LTE Installation

INTERNAL

Ground the feeder pipe when it is on the tower, and before it is connected to the cable rack and routed through the feeder window. If the tower is higher than 60 m, ground the feeder pipe in the middle of the tower. The outdoor grounding copper bar should be installed under the outdoor feeder window and be connected to the outdoor grounding ring. The feeders and indoor surge protector should be connected to the outdoor grounding copper bar.

Figure 4-4 shows the grounding copper bar.

Figure 4-10 Grounding copper bar of the eNodeB

1 M8 bolt

2011-08-16

HUAWEI Confidential

Page 28, Total 47

Guide to Customers Preparation for BTS3900 LTE Installation

INTERNAL

4.2 Preparing Auxiliary Facilities for the BTS3900 Antenna System

4.2.1 Requirements for the Tower

A tower for telecommunication purpose is required when the eNodeB in a network covers a wide area and the antennas are installed at a height. Figure shows the tower for communication purpose.

Figure 4-11 Tower for telecommunication purpose

The requirements for the tower are as follows:

The height of the tower depends on the field requirements of the eNodeB.

Typically, the tower has an operating platform of one to three layers with a round or hexagon structure. The minimum diameter of the circle is 4 m and the spacing between two platforms is 6 m. One-meter-high guard rails are required on the platforms. The minimum weight-bearing capacity of the platforms is 150 kg/m2. The tower must be able to carry 27 directional antennas and 27 7/8-inch feeders. Each antenna should weigh 30 kg with the front face area of 0.5 mm2. Each feeder should be 0.49 kg/m with the diameter 28 mm.

A ladder for maintenance should be installed on the tower. The reinforcing angle steel should be installed every 1 m on both sides of the ladder, and the angle steel should extend 0.5 m out of the ladder on either side.

A lightning rod should be installed 8 m above the upper platform to ensure that all the feeders on the tower are within the coverage of the lightning rod.

Even in the face of the strongest wind that blow once every 30 years, the maximum axial

2011-08-16

HUAWEI Confidential

Page 29, Total 47

Guide to Customers Preparation for BTS3900 LTE Installation

INTERNAL

wobble and torsion of the tower body must be within 1. The tower should be designed to resist one degree of seismic intensity over the limit stipulated in local regulations. When earthquake occurs, the tower can withstand the earthquake and devoid of any distortion that affects the quality of communication.

A cable rack that can bear the weight of a person should be installed on the tower. Surge protection and lightning induction devices should be installed on the tower. Solar energy lamps should be used for the tower.

Power cables with metal jackets should be used for the aeronautical lights that use AC power. Ensure that the metal jackets are grounded at the top of the tower and at positions where the cables are led into the equipment room. Surge protection devices should be installed on the control cables of the tower lamps and on the phase lines of the power cables at the positions where the cables are led into the equipment room. The neutral lines are directly grounded.

The wind speed and earthquake intensity level comply with the local stipulations.

4.2.2 Preparing the Antenna Support on the Tower

There are many types of antenna support. You need to select a suitable type according to the antenna type and installation scenario. When installing the antenna support on the tower, adhere to the following principles: 1. The installation plane of the antenna support should be perpendicular to the horizontal plane. 2. The pole for the lightning rod should be installed separately on the tower. The lightning rod should be placed high enough to bring the protection areas of all the antennas below 45. 3. The antenna support should be installed in the direction that does not affect the transmit/receive performance and direction adjustment of the antenna. 4. A stiffener is used to fasten the rotating lever. The expansion lever and the rotating lever should be cut to an appropriate length. The cross-section should be welded with a waterproof cover. 5. The antenna support must not have any dry and open welds. It is recommended that the support be made of galvanized steel. The surface of the support should be coated with antirust paint. 6. For the directional antenna, the length of the pole depends on that of the antenna. In wide coverage application, high gain antennas are generally used. Such antennas are long, so it is recommended that the length of the pole be greater than 3 m and that the diameter range from 60 mm to 114 mm (generally 75 mm).For the uni-polarization antenna, the distance between the two diversities of the two antennas serving one sector should be at least 2 m. 6 shows the recommended directional antenna support on a tower.

Figure 4-12 Directional antenna support on a tower

2011-08-16

HUAWEI Confidential

Page 30, Total 47

Guide to Customers Preparation for BTS3900 LTE Installation

INTERNAL

7. Generally, an omni-directional antenna is a uni-polarization antenna. The distance between diversities should be at least 2 m. The length of the support lever of pole should be greater than 1.5 m. The pole must be made of 75 mm round steel and it should have minimum length of 1 m and a diameter of 60114 mm. During installation, the pole should be flush with the fixing hoop of the antenna. The pole should not be installed at a very high position because the omni-directional antenna is long. The top of the antenna should be within the protection angle of the lightning rod. Figure 4-7 shows the recommended support for the omni-directional antenna on a tower.

Figure 4-13 Support for the omni-directional antenna on a tower

2011-08-16

HUAWEI Confidential

Page 31, Total 47

Guide to Customers Preparation for BTS3900 LTE Installation

INTERNAL

4.2.3 Preparing the Antenna Support on the Rooftop

There are many types of antenna support. You need to select a suitable type according to the antenna type and installation scenario. When installing the antenna support on the rooftop, adhere to the following principles: 1. The strength of the materials for the antenna support and pole should meet the requirements of antenna load capacity and wind load. 2. The connecting pieces for the stiffener should be installed in the positions where the regulation of the antenna orientation and tilt is not affected. 3. The antenna support should be perpendicular to the horizontal plane.

4. The base of the antenna support, the anchor of the stiffener, and their expansion bolts should be covered with concrete. 5. When a directional antenna is installed on the rooftop, a lightning rod should be installed on the antenna support, and the antenna support should be connected to the grounding grid of the building. When an omni-directional antenna is installed on the rooftop, a lightning rod should be installed onto a separate support. 6. If a lightning rod is installed onto the support of the omni-directional antenna, the omnidirectional antenna should be extended from the support for 1 to 1.5 m. 7. If there are enclosing walls on the rooftop, the antenna support can be installed on an enclosing wall. Ensure that the main supporting post is vertical to the surface of the rooftop. In addition, ensure that the antenna support is equipped with a surge protector and connected to the grounding grid of the building. Preparing the Directional Antenna Support and Pole on a Rooftop (1) For the uni-polarization directional antenna, because of the requirements for diversity spacing, the distance between the two poles supporting the two antennas should be at least 2 m. (2) The length of the pole depends on that of the antenna. It is recommended that the length of the pole be greater than 2.5 mm and that the diameter range from 60 mm to 114 mm. (3) The main supporting post of antenna support should be longer than the antenna. The relation between h and d should meet the specifications illustrated in 7 and listed in Table, where h indicates the valid vertical distance between the lower edge of the antenna and the rooftop in the direction that the antenna faces, and d indicates the distance between the edge of the rooftop in the direction that the antenna faces and the antenna support.

Figure 4-14 Installing the antenna support on the rooftop

2011-08-16

HUAWEI Confidential

Page 32, Total 47

Guide to Customers Preparation for BTS3900 LTE Installation

INTERNAL

Height 0.5 m 1m 2m

Diameter 0 m to 2 m 2 m to 10 m More than 10 m

The Height and Diameter in the table above is shown in Figure 4-8.

Figure 4-15 Structure of the pole on the rooftop

2011-08-16

HUAWEI Confidential

Page 33, Total 47

Guide to Customers Preparation for BTS3900 LTE Installation

INTERNAL

(1) Lightning rod for the antenna (5) Use concrete to cover and fix.

(2) Main support (6) Solder the stiffener to the main supporting post.

(3) Stiffener (8) Fix the stiffener to the ground.

(4) Base of the antenna support (8) Ladder

Figure 4-10 and Figure 4-11 show how to fix the directional antenna on the rooftop.

Figure 4-16 Fixing the directional antenna on the rooftop (1)

2011-08-16

HUAWEI Confidential

Page 34, Total 47

Guide to Customers Preparation for BTS3900 LTE Installation

INTERNAL

Figure 4-17 Fixing the directional antenna on the rooftop (2) Preparing the OmniDirectional Antenna Support and Pole on a Rooftop

(1) Generally, an omni-directional antenna is a uni-polarization antenna. To meet the requirements of diversity spacing, ensure that the distance between two antenna poles is greater than 2 m. (2) After installation, the top of the pole should be flush with the fixing hoop in the lower part of the antenna. Therefore, the omni-directional antenna pole does not need to be long. The length of the pole only needs to meet the specifications. (3) Generally, the omni-directional antenna pole should have a diameter of 60 mm to110 mm and should be made of 75 mm round steel. (4) The omni-directional antenna is long and therefore the antenna top is much higher than the pole top. In this case, the surge protector should not be welded directly to the pole but should be installed separately in the middle of the two antenna poles. Ensure that the top of omni-directional antenna is within the protection angle of the surge protector, as shown in 7.In some cases the surge protector may not be prepared independently due to limited conditions. Instead, you can use the following method shown in Figure . Figure 4-12 shows the installation of omni-directional antenna.

Figure 4-18 Installing an omni-directional antenna

2011-08-16

HUAWEI Confidential

Page 35, Total 47

Guide to Customers Preparation for BTS3900 LTE Installation

INTERNAL

Figure 4-19 Installing an omni-directional antenna support

4.2.4 Preparing the Feeder Window

Feeders are led into the equipment room through the feeder window. There are two types of feeder window: 12-hole feeder window and 27-hole feeder window. The 12-hole feeder window is

2011-08-16

HUAWEI Confidential

Page 36, Total 47

Guide to Customers Preparation for BTS3900 LTE Installation

INTERNAL

commonly used, as shown in Figure 4-14. The feeder hole should be 100 mm higher than the indoor cable rack.

Figure 4-20 Dimensions of the 12-hole feeder window (unit: mm)

When installing the feeder window, adhere to the following principles: 1. The feeder window should be installed at a position nearest to the cable rack.

2. The feeder window should be installed on the wall either indoors or outdoors, but the side with steel hoops must face outdoors. 3. If feeders are led into the room from the rooftop, the feeder window is installed on the roof and the side with steel hoops must face outdoors.

4.3 Cable Requirements of the eNodeB

4.3.1 Requirements for Materials of the Indoor eNodeB Cables

Generally, the power cables, PGND cables, and transmission cables are delivered with the equipment. If you prepare these cables yourself, the cables should comply with related requirements.

Table 4-3 Requirements for materials of the indoor eNodeB cables

2011-08-16

HUAWEI Confidential

Page 37, Total 47

Guide to Customers Preparation for BTS3900 LTE Installation

INTERNAL

Cable Power cable

Specification The power cables without jackets should be insulated with PVC materials. If the power cables are required to be weatherproof or high/lowtemperature resistant, materials such as silicone rubber, FEP, or PFA can be used for insulation. The power cables with PVC jackets should be insulated through PVC or XLPE materials. If there are fire-resistant requirements such as halogenfree and low smoke, use power cables with LSZH jackets. The high/low-temperature resistant power cables should be generally coated with FEP jackets.

Symmetric cable

The symmetric cables should be insulated through PE, PP, or PVC materials and coated with PVC or PE jackets. If there are fire-resistant requirements such as halogen-free and low smoke, use power cables with LSZH jackets. The coaxial cables should be insulated through PE, PTFE, or FEP materials and coated with PVC or FEP jackets. The PGND cables should be copper-based and insulated with green and yellow plastic jackets.

Coaxial cable PGND cable

When selecting the indoor cables, you should consider the fire-resistant requirements. Weather proofing requirements for the indoor cables are not high. Therefore, use cables coated with PVC jackets as indoor cables. If fire-resistant requirements for the cables are high, use cables that are insulated with fire-resistant materials such as PE or PVC and coated with fire-resistant PVC jackets. If there are strict requirements for smoke density, and transmittance of the halogen gas released after the cables caught fire, use cables coated with comparatively expensive LSZH jackets. Insulating materials and protection jackets of the cables must comply with the Restriction of Hazardous Substance (RoHS) requirements. The cable materials can either be customized or comply with local regulations.

4.3.2 General Cabling Specifications for the eNodeB

The power cables and signal cables should be routed in compliance with the cabling specifications to avoid electromagnetic interference to the signals.

Table 4-4 Requirements for bending radius of the cables

Cable Feeder 1/2" feeder 7/8" feeder 5/4" feeder

Requirements for the Bending Radius 127 mm 250 mm 380 mm

2011-08-16

HUAWEI Confidential

Page 38, Total 47

Guide to Customers Preparation for BTS3900 LTE Installation

INTERNAL

Cable 13/8" feeder Jumper 1/4" jumper 1/2" jumper Single-jacket cable 2.5 mm D 4.5 mm D 4.5 mm Two-wire or multi-wire cables with/without shielding layers Optical cable 6.5 mm D 12.5 mm D 12.5 mm

Requirements for the Bending Radius 510 mm 35 mm 50 mm R2D R3D R2D R3D R 20 D

In Table 4-2, D refers to the diameter of the cable jacket and R refers to the bending radius of the cable.

Requirements for Binding Cables

Cables of different types should be routed separately and cannot be kinked. The cables should be bound tightly and neatly without damage to cable jackets.

The cable ties should be at an interval of 200 mm and face the same direction. The cable ties at the same position should be placed at the same level. The cut surface of the cable ties should be smooth without sharp projections.

Labels or nameplates should be attached to the installed cables.

General Cabling Requirements

Cables of different types should be routed separately. Cables of different types cannot be crossed.

The spacing between cables of different types should be greater than 30 mm when the cables are routed parallel in the cabinet. The spacing between cables of different types should be greater than 100 mm when the cables are routed parallel outside the cabinet. If such requirements cannot be met, the cables should be separated with specific objects.

Cabling Requirements for Power Cables and PGND Cables

The power cables and PGND cables should be routed in compliance with the engineering design and general cabling specifications.

If the cable is not long enough, replace the cable. Do not add connectors or solder joints to lengthen the cable.

The cables should be insulated if they are bound and routed on the metal cable rack. Fuses or switches cannot be installed on the cables.

2011-08-16

HUAWEI Confidential

Page 39, Total 47

Guide to Customers Preparation for BTS3900 LTE Installation

INTERNAL

The -48 V power cable and the GND cable should be bound together.

Both ends of the grounding cables should be anti-corrosive and anti-rust. Connections of the grounding cables should be secure. The low-voltage AC power cable for the base station should be led through a metallic conduit and buried in the ground for at least 50 m before it is led into the equipment room. If the AC power cable is shorter than 50 meters, it should be completely routed under the ground. If such cables are routed overhead and led into the room, surge protection for the connectors of the AC power cables is seriously affected.

The PGND cable should be buried completely in the ground or routed indoors. The PGND cable cannot be routed overhead outdoors before it is led into the equipment room.

Cabling Requirements for Optical Cables

The optical cables should be routed in compliance with the engineering design and general cabling specifications.

Proper cable surpluses should be left at the turning of the optical cables.

Do not stretch, step over, or place heavy objects on the optical cables. Keep the cables away from sharp objects to avoid damage. The optical cable that is curved or pressed or the optical connector which is damaged cannot be used. Extra optical cables should be coiled on the specified device such as the fiber coiler. Coil extra optical cables properly. Do not bend the cables forcibly to avoid damaging the cables.

The bare optical cables must be configured with protection tubes if required. The idle connectors of the optical cables should be covered with dustproof caps.

If one end of the optical cable is connected to an optical device, do not look directly at the end face of the optical connector. Otherwise, you may damage your eyes. Fill soft materials such as fireproof cottons in the optical cable inlets at the top of the cabinet to protect the optical cables.

You need to check whether the optical connectors are clean before installation. If the optical connectors are dirty, clean them by using a dustfree cloth or fiber cleaner.

4.4 Preparation of Personnel for the Installation

The equipment installation process is also a process of on site training. It is recommended that the maintenance personnel participate in the training. In this way, the maintenance personnel can get familiar with the equipment as soon as possible.

2011-08-16

HUAWEI Confidential

Page 40, Total 47

Guide to Customers Preparation for BTS3900 LTE Installation

INTERNAL

5

Acceptance Item Height of the equipment room Load bearing capacity Wall surface

Appendix 1 Checklist for the Installation Preparations

5.1 Acceptance Items for the Environment of the Equipment Room

Methods and Requirements Minimal distance between the girder and the floor Load bearing capacity of the floor Lusterless paint or wallpaper is applied on the walls. The floor should be made from semiconductor and be dustproof. Long-term Long-term Specification 3 m to 3.5 m Result Remarks

Greater than 450kg/m2 The mat vanish does not chalk off easily. ESD floor

Floor

Temperature Humidity

-20C to +50C 5% RH to 85% RH

Electromagnetic interference proof Antistatic Measures

Electric field Magnetic field ESD floor ESD ground

Within 300 mV/m Less than 11 Gs

2011-08-16

HUAWEI Confidential

Page 41, Total 47

Guide to Customers Preparation for BTS3900 LTE Installation

INTERNAL

Acceptance Item Dust proof

Methods and Requirements

Specification

Result

Remarks

The diameter of the dust granule should be greater than 5 m. The density of the dust granule should be less than 3 x 104 granule/m.3

Quake proof

Design the degree of seismic intensity for the equipment room according to the local capital construction. Avoid direct radiation of sunlight. Type and power

Raise one degree

Lighting

Average intensity of illumination: 150 LX to 200 LX The air conditioning output should meet the requirements for the temperature control of the equipment room. Meet the local fire prevention standard

Air conditioner

Fire fighting

Fire fighting equipment and label Label the sockets of different voltages.

5.2 Acceptance Items for Power Supply

Item DC power supply Test Result -48 V DC power supply Specification The operating voltage meets the range of 38.4 V DC to 57 V DC. The operating voltage meets the range of +21.6 V DC to +29 V DC. 176 V AC to 290 V AC. 176 /304 V AC to 290/500 V AC. Good Result Remarks

+24 V DC power supply

AC power supply

Single-phase AC power Three-phase AC power

Standby diesel

Recommended

2011-08-16

HUAWEI Confidential

Page 42, Total 47

Guide to Customers Preparation for BTS3900 LTE Installation

INTERNAL

Item Power cables

Test Result Route the 48 V power cables into the PDF or the junction box. Alarms related to power cut and power supply faults can be reported.

Specification Good

Result

Remarks

Power alarms

Good

5.3 Acceptance Items for Surge Protection Grounding

Test Item Main grounding bar and sub-grounding bars Methods and Requirements The distance between the copper bar and the copper cable should be short and the PGND cable should be thick. The PGND cables of all devices are connected to the same grounding busbar. Cross-sectional area of the PGND cable Installing a single BTS3900 cabinet Installing two BTS3900 cabinets in stack mode Specification The installation is complete and the contact is proper. Result Remarks

The installation is complete and the contact is proper. Not less than 25 mm2 The cross-sectional area of the PGND cable connecting the lower cabinet and the grounding bar is no less than 25 mm2. The cross-sectional area of the equipotential cable connecting cabinets is less than 16 mm2.

Grounding resistance PGND cable

Combined grounding Route the grounding cable into the DC PDF or the junction box.

eNodeB grounding: less than 10 ohm. Good

2011-08-16

HUAWEI Confidential

Page 43, Total 47

Guide to Customers Preparation for BTS3900 LTE Installation

INTERNAL

Test Item Feeder grounding

Methods and Requirements Grounding clips are installed at an interval of 20 m on the feeder. The feeder is respectively grounded 0.5 m to 1 m away from the tower and the outdoor cable rack.

Specification The installation is complete and the contact is proper.

Result

Remarks

5.4 Acceptance Items for the eNodeB Antenna System

Serial Number. 1 Item Tower Specific Requirements The tower is ready for use. They should meet the requirements for azimuth of the antenna. They should meet the requirements for the length of the antenna. They should meet the requirements for the load capacity and wind load. The outdoor cable ladder is ready for use. 3 Outdoor cable ladder The cable ladder on the tower should be suitable for routing cables. The cable rack (bridge) should meet the requirements. The pole is installed. The position of the pole should meet the requirements. The pole should meet the requirements for the length of the antenna. The pole should meet the requirements for the load capacity and wind load. The concrete base for the GPS antenna is ready for use. Result Remarks

Antenna support and pole

Pole

2011-08-16

HUAWEI Confidential

Page 44, Total 47

Guide to Customers Preparation for BTS3900 LTE Installation

INTERNAL

Serial Number.

Item

Specific Requirements The outdoor cable rack is ready for use.

Result

Remarks

Outdoor cable rack

Material of the cable rack should meet the requirements. The cable rack should be properly grounded.

Fill in the grey part in the table above when the antenna is installed on the tower platform.

2011-08-16

HUAWEI Confidential

Page 45, Total 47

Guide to Customers Preparation for BTS3900 LTE Installation

INTERNAL

Appendix 2 Engineering

Specifications of the BTS3900

6.1 BTS3900 LTE Engineering Specification

6.1.1 Engineering specification

Table 6-5 Engineering specification

Item Size(H x W x D) Weight

Specification 900mmx600mmx450mm 124Kg (with 3 RFUs) 160Kg (with 6 RFUs)

Power supply

- 48V DC( -38.4V to -57V) +24V DC(+21.6V to +29V) +220V AC( +176V to +280V, 50/60Hz) +110V AC(+90V to +135V, 50/60Hz)

6.1.2 Environmental specification

Table 6-6 Environmental specification

Item Temperature

specification 20C to +55C

2011-08-16

HUAWEI Confidential

Page 46, Total 47

Guide to Customers Preparation for BTS3900 LTE Installation

INTERNAL

Relative humidity Protected standard Air pressure

5% RH to 95% RH IP20 70 to 106 Kpa

2011-08-16

HUAWEI Confidential

Page 47, Total 47

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- (Christopher Knight, Robert Lomas) The Book of HiramDocument496 pages(Christopher Knight, Robert Lomas) The Book of Hiramcspker93% (27)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Material Price List PDFDocument2 pagesMaterial Price List PDFJp Gallardo85% (92)

- Material Price List PDFDocument2 pagesMaterial Price List PDFJp Gallardo85% (92)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- 1960 US Army Vietnam War Field Wire & Field Cable Techniques 289pDocument288 pages1960 US Army Vietnam War Field Wire & Field Cable Techniques 289pONTOS66No ratings yet

- Employee DiscountDocument1 pageEmployee DiscountHailey Patrick100% (1)

- Dear Customer, Your Bill Has Arrears, Kindly Pay The Bill Immediately To Continue Enjoying Un-Interrupted ServicesDocument1 pageDear Customer, Your Bill Has Arrears, Kindly Pay The Bill Immediately To Continue Enjoying Un-Interrupted ServicesSaad HassanNo ratings yet

- Parts of A Mobile Cell Phone and Their FunctionDocument7 pagesParts of A Mobile Cell Phone and Their FunctionKade Ben100% (3)

- 12 Port AntennaDocument2 pages12 Port AntennacspkerNo ratings yet

- FSMFDocument32 pagesFSMFcspker100% (2)

- FRGX 2100Document7 pagesFRGX 2100cspkerNo ratings yet

- LTE link budget analysisDocument9 pagesLTE link budget analysischandan kumarNo ratings yet

- Frgu 2100Document8 pagesFrgu 2100cspkerNo ratings yet

- Frgu 2100Document8 pagesFrgu 2100cspkerNo ratings yet

- 6 Basic Tips-1Document17 pages6 Basic Tips-1cspkerNo ratings yet

- Price Region 9 - May 2019Document15 pagesPrice Region 9 - May 2019cspkerNo ratings yet

- Flexi 2TX RRHs Technical SpecificationsDocument6 pagesFlexi 2TX RRHs Technical SpecificationscspkerNo ratings yet

- FRHG 2600Document6 pagesFRHG 2600cspkerNo ratings yet

- Fsec Ovp WiringDocument9 pagesFsec Ovp WiringcspkerNo ratings yet

- Frgy 2100Document6 pagesFrgy 2100cspkerNo ratings yet

- FXEB LimitationDocument7 pagesFXEB LimitationcspkerNo ratings yet

- FRHC 2600Document6 pagesFRHC 2600cspkerNo ratings yet

- FRHG 2600Document6 pagesFRHG 2600cspkerNo ratings yet

- FHED 4-pipe 1800 160 W RRHDocument6 pagesFHED 4-pipe 1800 160 W RRHcspkerNo ratings yet

- Flexi 2TX RRHs Technical SpecificationsDocument6 pagesFlexi 2TX RRHs Technical SpecificationscspkerNo ratings yet

- l2100 - Frgu l21 RFDocument6 pagesl2100 - Frgu l21 RFcspkerNo ratings yet

- FHDB 900Document7 pagesFHDB 900cspkerNo ratings yet

- FHDB 900Document7 pagesFHDB 900cspkerNo ratings yet

- 1800 - Fhed L18 4X4Document6 pages1800 - Fhed L18 4X4cspkerNo ratings yet

- 10 Port AntennaDocument2 pages10 Port AntennacspkerNo ratings yet

- DC Cable SizeDocument1 pageDC Cable SizecspkerNo ratings yet

- Transport Ethernet - VLAN QosDocument1 pageTransport Ethernet - VLAN Qoscspker50% (2)

- Technical Information ASSET DOC LOC 5368406Document15 pagesTechnical Information ASSET DOC LOC 5368406cspkerNo ratings yet

- Downlink Throughput TroubleshootingDocument4 pagesDownlink Throughput TroubleshootingcspkerNo ratings yet

- 8 Port AntennaDocument1 page8 Port AntennacspkerNo ratings yet

- SpectrumDocument73 pagesSpectrumcspkerNo ratings yet

- Ultracapacitor Technology Powers Electronic Circuits: Director of Product DevelopmentDocument6 pagesUltracapacitor Technology Powers Electronic Circuits: Director of Product Developmentkarthikeyantce502241No ratings yet

- Cellular Mobile CommunicationDocument22 pagesCellular Mobile CommunicationChandraSudeepNo ratings yet

- The Dish AntennaDocument20 pagesThe Dish AntennaelmaraquinomoralidadNo ratings yet

- BSNL Revised Tarrif MP CircleDocument20 pagesBSNL Revised Tarrif MP CircleAnand SantNo ratings yet

- Irish ARRL RSGB Advanced Mock Exam 2 V6.2Document9 pagesIrish ARRL RSGB Advanced Mock Exam 2 V6.2John Bofarull GuixNo ratings yet

- Power Line Carrier Detailed DocumentDocument51 pagesPower Line Carrier Detailed DocumentmuzammiliqbalNo ratings yet

- Brand Standards Starwood Teledex 060712Document4 pagesBrand Standards Starwood Teledex 060712Jose CollantesNo ratings yet

- Distribution Channel of Airtel Prepaid in BhubaneswarDocument8 pagesDistribution Channel of Airtel Prepaid in BhubaneswarAvik MitraNo ratings yet

- Transients On Transmission LineDocument13 pagesTransients On Transmission LineSurya Prakash SinghNo ratings yet

- Bharti Airtel Company HistoryDocument13 pagesBharti Airtel Company HistoryChanchal SinghNo ratings yet

- TelephonyDocument35 pagesTelephonyFlanders MolNo ratings yet

- D 1501 Service Manual: DevelopDocument229 pagesD 1501 Service Manual: DevelopJoel RodriguesNo ratings yet

- RF Microwave and Millimeter Wave IC Selection Guide 2017Document56 pagesRF Microwave and Millimeter Wave IC Selection Guide 2017nboninaNo ratings yet

- Getting Started With DigipanDocument8 pagesGetting Started With Digipanverhaegen marc100% (1)

- Amphenol Connex Cable Assembly CatalogDocument32 pagesAmphenol Connex Cable Assembly CatalogAmphenolConnexNo ratings yet

- Shielded Jacketed Cables Fep (1) 2Document20 pagesShielded Jacketed Cables Fep (1) 2ankitdhimancrNo ratings yet

- Hipath 1100 Hipath 1120 Hipath 1150 Hipath 1190: Service ManualDocument389 pagesHipath 1100 Hipath 1120 Hipath 1150 Hipath 1190: Service ManualLuis Suarez100% (1)

- Early Leman RifleDocument2 pagesEarly Leman Rifleblowmeasshole1911No ratings yet

- Wireless Control For Industrial Instruments and Home Appliences at UhfDocument4 pagesWireless Control For Industrial Instruments and Home Appliences at UhfNahush Bapat100% (1)

- Huawei C8650, C8650+ Root, FirmwareDocument9 pagesHuawei C8650, C8650+ Root, FirmwareHtet Aung MoeNo ratings yet

- ALL PRICES SHOWN ARE INCLUSIVE OF GST MALAYSIA & NO CREDIT CARD SURCHARGEDocument2 pagesALL PRICES SHOWN ARE INCLUSIVE OF GST MALAYSIA & NO CREDIT CARD SURCHARGEteongNo ratings yet

- USB-A To Serial Cable: What's IncludedDocument1 pageUSB-A To Serial Cable: What's Includedabarboza4574No ratings yet

- Nokia Asha 305 Nokia Asha 306: Service Manual Level 1&2Document22 pagesNokia Asha 305 Nokia Asha 306: Service Manual Level 1&2Riza VirsadaNo ratings yet

- PowerLogic ION 7600 Installation and Basic Setup Manual 062002 PDFDocument52 pagesPowerLogic ION 7600 Installation and Basic Setup Manual 062002 PDFIsaac DiazNo ratings yet

- Panasonic KX TG 7200 Cordless PhoneDocument8 pagesPanasonic KX TG 7200 Cordless PhoneAparnaa PazhanivelanNo ratings yet