Professional Documents

Culture Documents

Heat Exchanger Design Aircooled V7.1: File: Untitled - Edr Date: 8/15/2011 Time: 12:00:35 PM

Uploaded by

Ehsan MoemeniOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Heat Exchanger Design Aircooled V7.1: File: Untitled - Edr Date: 8/15/2011 Time: 12:00:35 PM

Uploaded by

Ehsan MoemeniCopyright:

Available Formats

Heat Exchanger Design

File: Untitled.EDR

Description Headings psne Location: Service of Unit: Item No.: Date: Fluid name Remarks

AirCooled V7.1

Date: 8/15/2011

Page 1

Time: 12:00:35 PM

Our Reference: Your Reference: Rev No.: Job No.: Tube Side gas

Outside Tube air

Application Options Program calculation mode Tube side application Outside tube application Simulation calculation Simulation Gas, no phase change Dry Air Outlet temperatures on both sides (method 1)

Process Data Tube Side In Fluid name Mass flow rate (total) Temperature Vapor mass fraction Operating pressure (absolute) Heat exchanged Allowable pressure drop Fouling resistance kg/s C gas 0.0167 280 60 Out

bar kW bar m K/W

0.06895

In Air/Gas mass flow rate Required face velocity Required bundle pressure drop Air/Gas dry bulb design temperatures Minimum ambient temperature Operating pressure specification Altitude above sea level Inlet pressure (gauge) Inlet pressure (absolute) Allowable pressure drop Inlet humidity parameter Humidity ratio Relative humidity (%) kg/s m/s Pa C C

Outside Tube Out 3.2

45 -29 Absolute pressure 1000 110000 1.1 0.1 Humidity ratio

m Pa bar bar

Heat Exchanger Design

File: Untitled.EDR

Fouling Fouling option Fouling thermal conductivity W/(m K) Include fouling effect in heat transfer and pressure drop calculation Fouling fluid curve group Liquid Fouling resistance by phase m K/W

AirCooled V7.1

Date: 8/15/2011

Constant resistance

Page 2

Time: 12:00:36 PM

Cooling water curves Vapor 2-phase

Fouling resistance Velocity Temperature Quality Length

m K/W m/s C mm

Heat Exchanger Design

File: Untitled.EDR

Tubeside Databank Physical property package Tube side composition specification Vaporization curve calculation methods Condensing curve calculation method Calculation type B-JAC Weight flowrate or % Ideal Ideal Integral

AirCooled V7.1

Date: 8/15/2011

Page 3

Time: 12:00:36 PM

Pressures bar 4.13685

Aspen property method Aspen free-water method BL1(317) Aspen water solubility BL1(318) Aspen flash option Vapor-Liquid-Liquid Aspen Plus or Aspen Properties run file with file extension

Tube Side - Component

B-JAC Components Natural gas (sp.gr.=0.80) Compositions Component type Noncondensable

Tube Side - Stream Properties

Temperature C 60 91.43 122.86 154.29 185.71 217.14 248.57 280 Enthalpy kJ/kg 0 68 139 213.2 290.8 371.7 456 543.7 Vapor fraction

1 1 1 1 1 1 1 1

Tube Side - Liquid Properties

TemperatureLiquid specific Liquid thermal Liquid heat cond. viscosity C 60 91.43 122.86 154.29 185.71 217.14 248.57 280 kJ/(kg K) W/(m K) mPa s Liquid density kg/m Liquid surface tension N/m

Heat Exchanger Design

File: Untitled.EDR Tube Side - Vapor Properties

TemperatureVapor specific Vapor thermal Vapor Vapor density heat cond. viscosity C 60 91.43 122.86 154.29 185.71 217.14 248.57 280 kJ/(kg K) 2.116 2.21 2.31 2.414 2.521 2.628 2.737 2.844 W/(m K) 0.0329 0.037 0.0411 0.0454 0.0498 0.0542 0.0587 0.0634 mPa s 0.0121 0.013 0.0139 0.0148 0.0156 0.0165 0.0173 0.0181 kg/m 3.56 3.25 2.99 2.76 2.57 2.41 2.26 2.13 23.71 23.71 23.71 23.71 23.71 23.71 23.71 23.71 Vapor weight

AirCooled V7.1

Date: 8/15/2011

Page 4

Time: 12:00:36 PM

Tube Side - 2-Phase liquid

Temperature C 60 91.43 122.86 154.29 185.71 217.14 248.57 280 Liquid 2 heat kJ/(kg K) Liquid 2 cond. W/(m K) Liquid 2 viscosity mPa s Liquid 2 density kg/m Liquid 2 tension N/m

Heat Exchanger Design

File: Untitled.EDR

Rating/Simulation Bays per unit Bundles per bay Fans per bay Number of sides fan draws air from Fan configuration Fan inlet type Plenum depth Louver type Louver control Louver opening angle Steam coil 1 1 1 Forced Conical 280 Type A - DR54 p55 Auto Yes

AirCooled V7.1

Date: 8/15/2011

Exchanger frame type Tube side to outside flow orientation Angle of outside flow (0=up to 180=down) Tube side flow direction Ground clearance Chimney height above bundle

Page 5

Time: 12:00:36 PM

Standard Counter Current 0 Downward (any angle)

Tubes Number of tube types Tube shape Tube 1 Round Al-Bronze

1 Last row of tubes Tube OD Tube ID Major axis OD Minor axis OD Tube wall thickness mm mm mm mm mm 1 16 14

1 Fin type Fin material Fin frequency Fin tip diameter Mean fin thickness Fin root diameter Fin root thickness Serration width Serration length Serration fin method Number of studs per crown Stud width Major axis fin OD Minor axis fin OD Heat transfer area scaler mm mm mm 0 #/m mm mm mm mm mm mm 315 25 0.5 0 Plain tubes

Heat Exchanger Design

File: Untitled.EDR

Bundle Number of tubes per bundle Tube rows deep Tube passes Tube layout type Tube rows per pass Maximum number tubes per row per pass Bundle type Transverse pitch Longitudinal pitch Tube layout angle Tube length Effective tube length mm mm Degrees m m

AirCooled V7.1

Date: 8/15/2011

Page 6

Time: 12:00:36 PM

14 2 2 Program will design tube layout based on input above 1 7 Staggered-even rows to right 35

30 1

Headers Header type U-bend configuration Depth of header Depth of other header Nozzles

Inlet Nominal pipe size Actual OD Actual ID Wall thickness Quantity Orientation Length Flange thickness Flange diameter Degrees mm mm mm mm mm mm 1 90 300 25 1 -90 300 25 Outlet

Box U-bends in alternate passes mm mm

Nozzle flange rating Nozzle flange type

Program Program

Heat Exchanger Design

File: Untitled.EDR

Fans Fan configuration Fan inlet type Fan drive type Fan pitch control Fan diameter Fan speed (rpm) Fan drive efficiency % Fan static efficiency % Characteristic fan diameter Characteristic fan speed (rpm)

Volumetric rate m/s Static pressure Pa Static

AirCooled V7.1

Date: 8/15/2011

Page 7

Time: 12:00:36 PM

Forced Conical Program Program m 0.7

95 65 m 0.7

Materials Tube Header Plugs Gasket Al-Bronze Carbon Steel

Fin material Fin thermal conductivity Fin material density W/(m K) kg/m

Tube thermal conductivity Tube material density Header density

W/(m K) kg/m kg/m

Heat Exchanger Design

File: Untitled.EDR

Design Constraints Tube length Bay width Bundle width Tube rows deep Tube passes per bundle Bays per unit Bundles per bay Fans per bay Tube side fluid velocity Outside fluid face velocity Tube side RhoV2 Fan power maximum m mm mm Increment 0.5 Minimum 2 1000 1000 3 1 1 1 1 Maximum 10 6000 3000 8 16

AirCooled V7.1

Date: 8/15/2011

Page 8

Time: 12:00:36 PM

m/s m/s kg/(m s) kW

1000

6 6000

Thermal Analysis Options Tube Side Vapor heat transfer coefficient 2-phase heat transfer coefficient Liquid heat transfer coefficient Calculation steps per tube Number main iterations Detailed calculation accuracy % Main iteration accuracy % W/(m K) W/(m K) W/(m K) 12 300 4 0.2 Outside Tube

Methods Use wet wall desuperheating for condensation applications Tube side flow distribution Velocity heads for perforated pass plate pressure drop Highfin tube calculation method Lowfin tube calculation method Exit pressure recovery coefficient Fan guard pressure loss coefficient Fan guard support pressure loss coefficient Include outside radiation heat transfer Mole fraction of radiating gases in flue gas No 0.22 Yes Not Activated 0

HTFS / ESDU

Tubeside Enhancements Enhancement type Heat transfer coefficient factor Frictional pressure gradient factor Reynolds number Heat transfer j factor Frictional f factor Enhancement Starts at pass Twisted tape thickness 180 Degree twist pitch Stops at pass mm mm

Heat Exchanger Design

File: Untitled.EDR Tube Side Enhancement

Reynolds number Colburn factor Friction factor

AirCooled V7.1

Date: 8/15/2011

Page 9

Time: 12:00:36 PM

Outside Enhancement

Format of input data Perf. DBase selection Pt. 1 Flow parameter Pt. 1 Ho parameter Pt. 1 PD parameter Pt. 2 Flow parameter Pt. 2 Ho parameter Pt. 2 PD parameter Ho curve Coefficient Ho curve Exponent PD curve Coefficient PD curve Exponent Ho scaling factor

OutSideFlowDistribution

1

OutSideTempDistribution

1 C

Heat Exchanger Design

File: Untitled.EDR Warnings and Messages

Description 106 564 565 616 4502 4519 8824

AirCooled V7.1

Date: 8/15/2011

Page 10

Time: 12:00:36 PM

Tubeside Component 1 only has vapor properties available in the databank. Program has assumed component is a noncondensable for VLE calculations. The inlet nozzle diameter has not been input or has been set to zero. The diameter will be calculated to ensure that RV2 is less than 6000 kg/(m*s2) The outlet nozzle diameter has not been input or has been set to zero. The diameter will be calculated to ensure that RV2 is less than 6000 kg/(m*s2) The outside tube correlations used for plain tubes are: ESDU(1983) for heat transfer and HEDH(1983) for pressure drop The depth of the plenum 280 mm is less than the recommended minimum value 4098.6 mm. The program has continued using the value calculated. Please increase the plenum depth if possible The fan diameter input (700 mm) is either greater than the bay width (414.9 mm) or has not been set. The fan diam. has been calculated to give 40% bundle coverage per fan (365.64 mm) P54: Physical Properties data for Stream 1 have been supplied at 4.13685 bar. The expected value for the exchanger is 5.93105 bar. Pressure extrapolation will be used, but may be a cause of significant inaccuracy.

Heat Exchanger Design

File: Untitled.EDR Optimization Path

Per bundle Tube Rows No. Deep Tube Length Pass m 1 14 2 1 2 1 1 Bundle Bays P Actual m 0.7 Area Required Area ratio Outside m 0.7 1 Pa 229 0.02 Dp ratio Outside Per Unit Pressure Drop Tube bar 0.01464 0.21

AirCooled V7.1

Date: 8/15/2011

Page 11

Time: 12:00:36 PM

Total Dp ratio side Price Dollar(US) 3082 Power kW 1.284

X-side Operating Outlet Face velocity cost temperaure Dollar(US) C m/s 616 47.15 10.26

Heat Exchanger Design

File: Untitled.EDR Recap of Designs

Tubes per bundle Tube rows deep Tube length Tube passes Bundles in parallel Bays in parallel Area, required Area, actual Area ratio (Actual/Reqd.) Pressure drop, outside Xflow outlet temperature Pressure drop, tube side Dp ratio tubeside Total price Operating cost m A 72 3 2 9 1 1 13.1 73.3 5.59 30 42.8 0.02406 0.35 8904 79 B 72 3 2 9 1 1 13.1 73.3 5.59 30 42.8 0.02406 0.35 8904 79 C 36 2 0.7 2 1 1 14 14 1 171 42.49 0.01194 0.17 5217 445 D 36 2 0.85 2 1 1 17.2 17.2 1 117 42.65 0.01152 0.17 5350 306 E 36 2 0.85 2 1 1 17.2 17.2 1 117 42.65 0.00422 0.06 5607 306 F 36 2 0.85 2 1 1 17.2 17.2 1 117 42.65 0.01152 0.17 5350 306 G 36 2 0.85 2 1 1 19.3 19.3 1 71 42.88 0.01469 0.21 4877 186 H 8 2 4 2 1 1 20.3 20.3 1 -2 43.04 0.20914 3.03 3682 0 I 8 2 4 2 1 1 18.3 18.3 1 147 43.02 0.02459 0.36 3834 384

AirCooled V7.1

Date: 8/15/2011

J 8 2 3.7 2 1 1 16.9 16.9 1 151 43.01 0.02381 0.35 3761 393 K 8 2 3.7 2 1 1 16.9 16.9 1 154 47.97 0.02413 0.35 3761 414 L 14 2 1.8 2 1 1 14.5 14.5 1 173 47.88 0.01356 0.2 3796 464

Page 12

Time: 12:00:36 PM

M 14 2 1.8 2 1 1 14.5 14.5 1 173 47.88 0.01356 0.2 3796 464 N 14 2 1.8 2 1 1 14.5 14.5 1 173 47.88 0.01356 0.2 3796 464 O 14 2 1.8 2 1 1 1.2 1.2 1 -7 47.54 0.01479 0.21 3796 0 P 14 2 1 2 1 1 0.7 0.7 1 229 47.15 0.01464 0.21 3082 616

m m Pa C bar Dollar(US) Dollar(US)

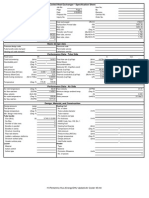

Air-Cooled Heat Exchanger Specification Sheet

Location: Service of Unit: Our Reference: Item No.: Your Reference: Date: Rev No.: Job No.: Type Number of Bays Size & Type 1.6 0.4149 Forced 1 m Area ratio Bare area/bundle 7 Surf/Unit-Finned Tube 0.7 0.7 m 1 m MTD, Eff 8 Heat exchanged 6.9 140.88 kW C Clean 9 Transfer Rate-Finned 71.1 Bare, Service 71.1 71.1 W/(m K) 10 PERFORMANCE DATA - TUBE SIDE In/Out 11 Fluid Circulated gas 12 Total Fluid Entering 60 Density, Liq kg/h kg/m In/Out 13 Density, Vap 3.09 4.38 kg/m 14 Temperature 280 117.78 Specific Heat, Liq kJ/(kg K) C 15 Liquid 0 0 2.844 2.294 Specific Heat, Vap kJ/(kg K) kg/s 0.0167 0.0167 16 Vapor Therm. Cond, Liq W/(m K) kg/s 17 Noncondensable kg/s 0.0634 0.0405 0 0 Therm. Cond, Vap W/(m K) Freeze Point 18 Steam C kg/s 19 Water Bubble / Dew point C 20 Molecular wt, Vap Latent heat 23.71 23.71 kJ/kg Inlet pressure (abs) bar 6 21 Molecular wt, NC Pres Drop, Allow/Calc 0.06895 0.01464 22 Viscosity, Liq mPa s 23 Viscosity, Vap 0.0181 0.0138 Fouling resistance m K/W 24 PERFORMANCE DATA - AIR SIDE 25 Air Quantity, Total 3.2 kg/s Altitude 1000 m 26 Air Quantity/Fan 2.656 Temperature In 45 m/s C 27 Static Pressure 229 Temperature Out 47.15 Pa C 28 Face Velocity 10.26 m/s Mass velocity 12.36 kg/s/m Design Ambient -29 C 29 DESIGN-MATERIALS-CONSTRUCTION 8 bar 30 Design pressure Code Test Pressure Design temperature 400 C 31 TUBE BUNDLE Header Tube Al-Bronze 1.6 32 Size Type Box Material m Carbon Steel 1 33 Number/bay Material Specifications 1 mm 16 2 2 34 Tube Rows Min Thk. Passes OD 14 Lng 1 m 35 Arrangement Plug Mat. No./Bun 35 30.31 30 Degrees 1 36 Bundles par Gasket Mat. Pitch 1 37 Bays par Corr. Allow. mm FIN Plain tubes 22.28 mm 38 Bundle frame Inlet nozzle ( 1 ) Type 39 15.8 mm Outlet nozzle ( 1 ) Material MISCELLANEOUS 40 Struct. Mount. Special Nozzles OD Tks mm 41 Surf.Prep Rating No. #/m Design Temp C 42 Louvers Type A - DR54 p55 TI Code PI 43 Vibration Switches Specs Chem Cleaning Stamp 44 MECHANICAL EQUIPMENT 45 Fan,Mfr., Model Speed Reducer, Type Driver, Type 1 RPM 46 No./Bay Mfr.&Model Mfr. 47 Dia. 0.3656 m Blade(s) No./Bay No./Bay 48 Pitch Angle Rating hp RPM 49 Blade(s) Hub Enclosure Ratio 50 hp/Fan 1.284 kW Min. Amb V/Phase/Hz Support Open 51 Control Action on Air FailureLouvers 52 Degree Control of Outlet Process Temperature Yes 53 Recirculation Steam Coil 82.3 82.3 kg 54 Plot Area Drawing No. Wt.Bundle Wt. Unit m 55 Notes: 56 57 58 1 2 3 4 5 6 psne

Heat Exchanger Design

File: Untitled.EDR

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 / 0.4149 / 0.0606 1.6 m Unit Length/Width/Height 1 2 Baysperunit Bundles per bay 1 Tube Rows Passes Staggered-even rows to right 0.7 0.7 Total surface Ext surface/bundle Bare/Bundle 0.7 Simulation Performance of the Unit Process Data kg/s Total flow Gas Vapor Liquid Cond./Evap. C Temperature Quality/Humidity ratio Pressure bar Pa DP Velocity m/s Liquid Properties kg/m Density Viscosity mPa s kJ/(kg K) Specific heat Th Cond W/(m K) N/m Surface tension Vapor Properties Density kg/m Viscosity mPa s Specific heat kJ/(kg K) Th Cond W/(m K) Two-Phase Properties Latent heat kJ/kg Molecular weight 3.09 0.0181 2.844 0.0634 4.38 0.0138 2.294 0.0405 1.2 0.0193 1.008 0.0277 1.2 0.0194 1.008 0.0278 Tube Side In Out 0.0167 0.0167 0 0 280 1 6 117.78 1 5.98536 45 0.0167 0 0 47.15 X-Side In 3.2 3.2 3.2 Out

AirCooled V7.1

Date: 8/15/2011

2 m Tube inclination X-side flow direction Tube flow orientation Ratio (Total/Bare) Horizontal 0 Degrees Counter Current 1

Page 14

Time: 12:00:36 PM

Heat Transfer Parameters Total heat load kW C Effective MTD Actual/required area ratio(dirty/clean) Coef/Resist (Bare) Tube side film Tube side fouling Tube wall Outside fouling Outside film Overall fouled Overall clean W/(m K) 120.7 66200.4 173.4 71.1 71.1

6.9 140.88 1 1 / m K/W 0.00828 0 0.00002 0 0.00577 0.01407 0.01407 % 58.89 0 0.11 0 41

110000 0.01464 5 3.53 20.3

110000 229 20.43

Tube Side Pressure Drop Inlet nozzle Inlet header Inside tubes Across pass connections Other header Outlet nozzle Outside Pressure Drop Ground clearance Fan inlet Bundle Louvers Steam Coil Plenum Heat Load Vapor Cond./Evap. Liquid Input/Actual duty ratio

23.71

28.96

bar 0.0031 0 0.002 0.00012 0 0.00412 Pa 0 116 168 16 30 53 kW 6.9 0 0 0.77

% 33.19 0.01 21.39 1.33 0.01 44.06 % 0 30.18 43.85 4.05 7.94 13.77

Heat Transfer Parameters Reynolds No. vapor 11936.75 15745.51 Reynolds No. liquid Prandtl No. vapor 0.81 0.78 Prandtl No. liquid Tubes / Fin Tubes per bundle Tube material Length effective m Length actual m Transverse pitch mm Longitudinal pitch mm Pitch angle Th Cond W/(m K) Surface effectiveness X-side and Fan Type draft Fans/bay Vol./fan (Act/Std) Face vel. (Act/Std) Fan diam./% cov. Sum./Win. des. Temp Abs pwr/fan-Winter Abs pwr/fan-Summer Drive efficiency Fan efficiency

20274.92 0.7

20173.39 0.7

14 Al-Bronze 0.984 1 35 30.31 30 70.6138 1

Last row number Tube OD / ID mm Fin type Fin material mm Fin tip diameter mm Fin thickness #/m Fin frequency mm Root diameter W/(m K) Th Cond Surface effectiveness

2 16 / 14 Plain tubes

1 Weights Inlet header Other header Inlet nozzle Outlet nozzle Tubes and fins Side frms/supports Bundle - dry Bundle - wet Unit bundles - dry Unit bundles - wet kg 23.4 23.5 1 0.6 5.3 51.9 82.3 88.9 82.3 88.9

Headers and Nozzles Forced 1 2.656 2.667 10.26 10.33 0.3656 40 45 -29 1.284 0.985 95 65 Header type Header depth Inlet Box 300 In 1 22.28 13.82 591 Other Box 300 Out 1 15.8 19.42 1651

m/s m/s m C kW kW

mm

No. of nozzles mm Nozzle ID m/s Hom. Velocity Rho*V2 kg/(m s)

Heat Exchanger Design

File: Untitled.EDR Thermal Details - General

Simulation Total mass flow rate Vapor mass Liquid mass Vapor mass quality Temperature Dew / bubble point temperatures Humidity ratio Operating pressure Film coefficients Fouling resistance Velocity (highest) Pressure drop (allow/calc.) Total heat exchanged Overall bare coeff. (dirty/clean) Effective MTD Effective surface (bare tube) Effective surface (total) Area ratio: actual/required Pa kW W/(m K) C m m 71.1 Pa bar W/(m K) m K/W m/s bar 6.9 71.1 140.88 0.7 0.7 1 20.3 10000 Bay per unit Bundles/bay Tubes/bundle Rows deep Tube passes Fans/bay 110000 173.4 0 20.43 229 1 1 14 2 2 1 C C kg/s kg/s kg/s 0 45 0 3.2 Outside 3.2 3.2

AirCooled V7.1

Date: 8/15/2011

Page 15

Time: 12:00:37 PM

Tube Side 0.0167 0.0167 0 1 280 47.15 0.0167 0 1 117.78

110000

6 120.7 0 5 0.06895 Tube OD Tube tks Tube Length Fin OD Fin tks Fin frequency

5.98536

3.53 0.01464 16 1 1 mm mm m mm mm #/m

Overall Coefficient/Resistance Summary Area required (total) Area required (bare tube) Area ratio: actual/required Overall coefficient Overall resistance Outside fouling Tube side fouling Resistance Distribution Outside film Outside fouling Tube wall Tube side fouling Tube side film (bare) 120.7 66200.4 W/(m K) 173.4 m K/W 0.00577 0 0.00002 0 0.00828 W/(m K) m K/W m K/W m m

Clean 0.7 0.7 1 71.1 0.01407 0.0 0.0 % 41 0.11 58.89

Dirty 0.7 0.7 1 71.1 0.01407 0 0 % 41 0 0.11 0 58.89

Max Dirty 0.7 0.7 1.0 71.1 0.01407 0 0 % 41 0 0.11 0 58.89

Heat Exchanger Design

File: Untitled.EDR Thermal Details - Coefficients

Film Coefficients Overall film coefficients Multiple phase coefficients Vapor sensible Two Phase Liquid sensible Heat Transfer Parameters Prandtl numbers Reynolds numbers Reynolds numbers Vapor Liquid Vapor (Diameter) Liquid (Diameter) Vapor(Hydraulic) Liquid(Hydraulic) 44364.52 44142.36 20274.92 20173.39 In 0.7 Out 0.7 173.4 W/(m K) Outside 173.4

AirCooled V7.1

Date: 8/15/2011

Page 16

Time: 12:00:37 PM

Tube Side 120.7 120.7

In 0.81 11936.75

In 0.78 15745.51

Heat Load Summary kW Vapor only 2-phase Liquid only Total 6.9 6.9 0

Outside % total 100 0 kW 6.9 0 0 100 6.9

Tube Side % total 100 0 0 100

Extreme Tube Wall Surface Temperatures

Bundle Tube pass Row Tube Tube Mean Max group temperature C 1 2 2 1 1 1 115.05 87.76 C 142.23 102.05 Tube Side Fouling ID Min Tube ID Max Min Base Tube OD Max Min Outside Fin Tip Max Min Fin Tip Fouling Max Min

C 93.4 76.01

C 142.23 102.05

C 93.4 76.01

C 141.94 101.92

C 93.26 75.94

C 0* 0*

C 0* 0*

C 141.94 101.92

C 93.26 75.94

Heat Exchanger Design

File: Untitled.EDR Thermal Details - Pressure Drop

Tube Side Pressure Distribution Inlet nozzle Inlet header Through tubes Across passes Other header Outlet nozzle Pressure drop (allow/calc.) 0.06895 bar 0.0031 0 0.002 0.00012 0 0.00412 0.01464

AirCooled V7.1

Date: 8/15/2011

Page 17

Time: 12:00:37 PM

%dp 33.19 0.01 21.39 1.33 0.01 44.06

Tube Side Pass To Pass Pressure Losses

Pass No. Entering tubes bar Pass 1 Pass 2 0.00059 0 Through tubes bar 0.00081 0.00067 Exiting tubes bar 0 -0.00007 Across pass connections bar 0.00012

Outside Pressure Distribution Pressure Gain Fan Plenum Pressure Loss Ground clearance Fan guard Fan inlet Fan support Plenum penalty Steam coil Bundle Louvres Exit Buoyancy Acceleration

m/s

Pa

%dp

25.3 10.12

229 154 0

59.76 40.24 0 0 30.18 0 13.77 7.94 43.85 4.05 0 0 0.22

25.3 25.3 25.3 10.12 7.14 20.28 4.08 4.08

0 116 0 53 30 168 16 0 0 1

Heat Exchanger Design

File: Untitled.EDR Mechanical Details - Bundle

Unit Bays in parallel per unit Bundles in parallel per bay Fans per bay Bay width Bundle width Unit length Unit width Unit height Bundle Tubes per bundle Tube rows per bundle Tubes per row per bundle Tube passes per bundle Total tube length Effective tube length Tubesheet(s) thickness Tube support width Number of tube supports m m mm mm 14 2 7 2 1 0.984 16 25 Number of tube types Tube row arrangement Tube transverse pitch m m m m m 1 1 1 0.4149 0.2625 1.6 0.4149 0.0606 A or V frame Tube inclination Tube side flow orientation

AirCooled V7.1

Date: 8/15/2011

Page 18

Time: 12:00:37 PM

None Horizontal Counter Current Degrees m m m m 0 0.3656 0.28 0.5485

Outside stream flow direction Fan diameter Plenum depth Ground clearance

Distance from bundle to exchanger exit

1 Staggered-even rows to right mm mm Degrees 35 30.31 30 1 1

Tube row longitudinal pitch Layout angle Area ratio finned to bare Total surface effectiveness External enhancement Internal enhancement

Mechanical Details - Fan

Fan Draft type Total number of fans Fans per bay Fan diameter Bundle face area Fan coverage % Number of blades Fan blade pitch Fan hub diameter Vendor for actual fan Fan Noise Level Fan rotational speed Sound power level (per fan) Sound power level (per unit) Sound pressure level (1 m from fan) Sound pressure level (0.3 m from bundle) RPM dB dB dB dB m m m Forced 1 1 0.3656 0.3 40 Air quantity (Act / Std) Face velocity (Act/Std) Temperature (Act/Std) Pressure (Act/Std) Density (Act/Std) Design temperature (summer/winter) Brake power (summer/winter) Total brake power (winter) Fan drive efficiency % Fan efficiency % Low Performance 6265.7 108.88 108.88 103.19 108.49 High Performance 3817.32 96.86 96.86 91.16 96.46 Actual m/s m/s C bar kg/m C kW kW 2.656 10.26 45 1.09884 1.2 45 0.985 2.667 10.33 21.1 1.013 1.2 -29 1.284 1.284 95 65

Heat Exchanger Design

File: Untitled.EDR Mechanical Details - Tubes

Tube Type OD ID Wall thickness Flow area Fin Type Type Material Tip diameter Fin height Bundle Hyd. Diameter Minimum flow area Mean fin thickness Fin frequency Fin root diameter Conductivity Density Surface effectiveness mm mm mm mm mm #/m mm W/(m K) kg/m 1 35.01 130872 mm mm mm mm 1 16 14 1 154 1 Plain tubes 2 2

AirCooled V7.1

Date: 8/15/2011

Page 19

Time: 12:00:37 PM

Mechanical Details - Nozzles and Headers

Nozzle Number (per circuit) Inside diameter Outside diameter Orientation Homogenous velocity Rhov2 Flange diameter Flange thickness Header Material Type Depth Thickness, short wall Thickness, long wall Cover thickness Tubesheet thickness mm mm mm mm mm mm mm Degrees m/s kg/(m s) mm mm Inlet 1 22.28 33.4 90 13.82 591 118.4 25 Inlet Carbon Steel Box 300 14 14 8 16 Outlet 1 15.8 21.34 -90 19.42 1651 106.34 25 Other Carbon Steel Box 300 14 14 8

Heat Exchanger Design

File: Untitled.EDR Mechanical Details - Weights and Volumes

Weights Inlet header Other header Inlet nozzle(s) Oulet nozzle(s) Tubes and fins Frame support Bundle (Dry) Bundle (Filled with water) Unit weight (Dry) Unit (Filled with water) kg 23.4 23.5 1 0.6 5.3 51.9 82.3 88.9 82.3 88.9 Unit Bundle Volumes Inlet header Other header Inlet nozzle(s) Outlet nozzle(s) Tube(s)

AirCooled V7.1

Date: 8/15/2011

Page 20

Time: 12:00:38 PM

m 0.003 0.003 0.0001 0.0001 0.0022

0.0084

0.0084

Heat Exchanger Design

File: Untitled.EDR Mechanical Details - Setting Plan

AirCooled V7.1

Date: 8/15/2011

Page 21

Time: 12:00:38 PM

Inlet & Outlet Nozzles

17

316 Tube length 1000 Bundle slope = 0 deg

1444 660 160

700 1552 2100

35

435

Location:

3760 366 fan dia (Typ)

160

Service of Unit: Item No.: Date: Rev No.:

Our Reference: Your Reference: Job No.:

Aspen AirCooled

Setting Plan

Design Codes

Drawing Number

Customer Specifications

Revision Date 8/15/2011 Drawing App.

Heat Exchanger Design

File: Untitled.EDR Mechanical Details Tube Layout

AirCooled V7.1

Date: 8/15/2011

Page 22

Time: 12:00:38 PM

1 2 2

1 2

1 2

1 2

1 2

1 2

X-Flow Direction

Heat Exchanger Design

File: Untitled.EDR Mechanical Details - Cost Analysis

Cost data Labor cost Tube material cost Total material cost (excluding tubes) Total fan cost Equipment cost Power cost per KWhr Operating period Operating cost Hours Dollar(US) 863 111 2063 45 3082 0.06 8000 616 Unit weight (Dry) Operating and equipment cost 3699 Unit (Filled with water) Weights Inlet header Other header Inlet nozzle(s) Oulet nozzle(s) Tubes and fins Frame support Bundle (Dry)

AirCooled V7.1

Date: 8/15/2011

Page 23

Time: 12:00:38 PM

kg 23.4 23.5 1 0.6 5.3 51.9 82.3 88.9

Bundle (Filled with water)

82.3 88.9

Heat Exchanger Design

File: Untitled.EDR Calculation Details - Tube Side - Interval Analysis

Pass No. Row No. Distance Pressure Vapor flowLiquid flow mm 1 1 1 1 1 1 1 1 1 1 1 1 1 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 1 1 1 1 1 1 1 1 1 1 1 1 1 0 82 164 246 328 410 492 574 656 738 820 902 984 984 902 820 738 656 574 492 410 328 246 164 82 0 bar 5.99926 5.99918 5.9991 5.99903 5.99896 5.99889 5.99883 5.99876 5.9987 5.99864 5.99857 5.99851 5.99845 5.99832 5.99826 5.9982 5.99814 5.99809 5.99803 5.99798 5.99792 5.99787 5.99782 5.99776 5.99771 5.99766 kg/s 0.0024 0.0024 0.0024 0.0024 0.0024 0.0024 0.0024 0.0024 0.0024 0.0024 0.0024 0.0024 0.0024 0.0024 0.0024 0.0024 0.0024 0.0024 0.0024 0.0024 0.0024 0.0024 0.0024 0.0024 0.0024 0.0024 kg/s 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 Vapor Fraction Stream temp C 280 268.4 257.47 247.12 237.03 227.52 218.57 209.83 201.55 193.75 186.39 179.18 172.37 172.37 166.63 161.17 155.99 150.92 146.03 141.39 136.98 132.79 128.81 125.03 121.36 117.78 Metal temp. C 142.23 136.69 131.48 126.6 121.9 117.55 113.5 109.59 105.93 102.52 99.34 96.28 93.4 102.05 99.23 96.55 94.02 91.57 89.22 87.01 84.92 82.94 81.08 79.33 77.64 76.01

AirCooled V7.1

Date: 8/15/2011

Page 24

Time: 12:00:38 PM

Heat flux kW/m 0 18.7 17.6 16.6 15.6 14.7 13.9 13.1 12.3 11.6 10.9 10.3 9.7 0 8.2 7.8 7.4 7 6.7 6.3 6 5.7 5.4 5.2 4.9 4.7 Heat load kW 0 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

TS Film coef. TS Fouling W/(m K) 139.8 137.7 135.6 133.6 131.7 129.9 128.2 126.5 125 123.5 122 120.7 119.4 119.4 118.3 117.2 116.2 115.2 114.3 113.4 112.6 111.8 111 110.3 109.6 108.9 m K/W 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Calculation Details - Tube Side - Properties

Temperature Pressure Vapor fraction Liquid density Liquid specific heat Liquid thermal cond. Liquid viscosity Surface tension Laten heat Vapor density Vapor specific heat Vapor thermal cond. Vapor viscosity kg/m C bar 280 6 1 3.09 kJ/(kg K) 2.844 W/(m K) 0.0634 mPa s 0.0181 N/m 3.4161 kJ/kg kg/m 3.09 3.17 2.798 0.0614 0.0178 3.25 2.751 0.0594 0.0174 3.34 2.704 0.0574 0.0171 3.43 2.655 0.0553 0.0167 3.53 2.606 0.0533 0.0163 3.64 2.556 0.0512 0.0159 3.77 2.504 0.0491 0.0155 3.9 2.453 0.047 0.0151 4.04 2.4 0.0448 0.0147 4.2 2.347 0.0427 0.0142 4.38 2.294 0.0405 0.0138 kJ/(kg K) 2.844 W/(m K) 0.0634 mPa s 0.0181 266.6 5.99867 1 3.17 2.798 0.0614 0.0178 3.4161 252.96 5.99734 1 3.25 2.751 0.0594 0.0174 3.4161 239.08 5.99601 1 3.34 2.704 0.0574 0.0171 3.4394 224.97 5.99468 1 3.43 2.655 0.0553 0.0167 3.4394 210.58 5.99335 1 3.53 2.606 0.0533 0.0163 3.4326 195.93 5.99202 1 3.64 2.556 0.0512 0.0159 3.4326 180.97 5.99069 1 3.77 2.504 0.0491 0.0155 3.3909 165.71 5.98936 1 3.9 2.453 0.047 0.0151 3.3909 150.11 5.98803 1 4.04 2.4 0.0448 0.0147 3.3091 134.18 5.9867 1 4.2 2.347 0.0427 0.0142 3.3091 117.87 5.98536 1 4.38 2.294 0.0405 0.0138 3.1815

Heat Exchanger Design

File: Untitled.EDR Calculation Details - Tube Side - Pressure Change

Pressure Change Pass No. Row No. Distance mm 82 164 246 328 410 492 574 656 738 820 902 984 902 820 738 656 574 492 410 328 246 164 82 0 Friction Momentum Gravity bar -0.00007 -0.00007 -0.00007 -0.00007 -0.00007 -0.00007 -0.00007 -0.00006 -0.00006 -0.00006 -0.00006 -0.00006 -0.00006 -0.00006 -0.00006 -0.00006 -0.00006 -0.00005 -0.00005 -0.00005 -0.00005 -0.00005 -0.00005 -0.00005 bar 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 bar 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 Total bar -0.00007 -0.00007 -0.00007 -0.00007 -0.00007 -0.00007 -0.00007 -0.00006 -0.00006 -0.00006 -0.00006 -0.00006 -0.00006 -0.00006 -0.00006 -0.00006 -0.00006 -0.00005 -0.00005 -0.00005 -0.00005 -0.00005 -0.00005 -0.00005 X

AirCooled V7.1

Date: 8/15/2011

Flow Pattern Data Y Flow pattern Regime

Page 25

Time: 12:00:38 PM

1 1 1 1 1 1 1 1 1 1 1 1 2 2 2 2 2 2 2 2 2 2 2 2

2 2 2 2 2 2 2 2 2 2 2 2 1 1 1 1 1 1 1 1 1 1 1 1

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

HF HF HF HF HF HF HF HF HF HF HF HF HF HF HF HF HF HF HF HF HF HF HF HF

SNGVAP SNGVAP SNGVAP SNGVAP SNGVAP SNGVAP SNGVAP SNGVAP SNGVAP SNGVAP SNGVAP SNGVAP SNGVAP SNGVAP SNGVAP SNGVAP SNGVAP SNGVAP SNGVAP SNGVAP SNGVAP SNGVAP SNGVAP SNGVAP

Heat Exchanger Design

File: Untitled.EDR Calculation Details - Outside - Interval Analysis

Pass Row No. Distance Pressure Liquid Vapor flow Temp In Temp Out Humidity No. drop removed ratio mm 1 1 1 1 1 1 1 1 1 1 1 1 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 1 1 1 1 1 1 1 1 1 1 1 1 41 123 205 287 369 451 533 615 697 779 861 943 943 861 779 697 615 533 451 369 287 205 123 41 Pa 0 0 0 0 0 84 0 0 0 0 0 0 0 0 0 0 0 0 84 0 0 0 0 0 kg/s 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 kg/s 0.0381 0.0381 0.0381 0.0381 0.0381 0.0381 0.0381 0.0381 0.0381 0.0381 0.0381 0.0381 0.0381 0.0381 0.0381 0.0381 0.0381 0.0381 0.0381 0.0381 0.0381 0.0381 0.0381 0.0381 C 45.49 45.51 45.54 45.56 45.59 45.67 45.7 45.73 45.77 45.8 45.84 45.88 45 45 45 45 45 45 45 45 45 45 45 45 C 47.49 47.41 47.33 47.26 47.15 47.14 47.09 47.04 47.01 46.97 46.95 46.92 45.88 45.84 45.8 45.77 45.73 45.7 45.67 45.59 45.56 45.54 45.51 45.49 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 OT Film coef. W/(m K) 201.6 201.6 201.5 201.5 201.4 201.4 201.3 201.3 201.2 201.2 201.2 201.1 148.5 148.4 148.4 148.4 148.4 148.3 148.3 148.3 148.3 148.2 148.2 148.2

AirCooled V7.1

Date: 8/15/2011

OT Fouling m K/W 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 Dew pt. C 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Page 26

Time: 12:00:38 PM

Fin root temp. Fin tip temp. OT Overall coef. C 136.42 131.22 126.36 121.67 117.33 113.29 109.4 105.75 102.35 99.18 96.12 93.26 99.11 96.43 93.91 91.46 89.12 86.92 84.83 82.86 81 79.25 77.56 75.94 C 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 W/(m K) 81.7 81 80.3 79.6 78.9 78.2 77.6 77 76.4 75.9 75.3 74.8 65.8 65.4 65.1 64.8 64.5 64.2 63.9 63.7 63.4 63.2 62.9 62.7

Calculation Details - Outside - Properties

Temperature Pressure Vapor fraction Vapor density Vapor specific heat Vapor thermal cond. Vapor viscosity Liquid density Liquid specific heat Liquid thermal cond. Liquid viscosity kg/m C bar 45 1.1 1 1.2 kJ/(kg K) 1.008 W/(m K) 0.0277 mPa s 0.0193 kg/m kJ/(kg K) W/(m K) mPa s 45.2 1.1 1 1.2 1.008 0.0277 0.0193 45.39 1.1 1 1.2 1.008 0.0277 0.0193 45.59 1.1 1 1.2 1.008 0.0277 0.0193 45.78 1.1 1 1.2 1.008 0.0277 0.0193 45.98 1.1 1 1.2 1.008 0.0277 0.0193 46.17 1.1 1 1.2 1.008 0.0277 0.0193 46.37 1.1 1 1.2 1.008 0.0278 0.0194 46.56 1.1 1 1.2 1.008 0.0278 0.0194 46.76 1.1 1 1.2 1.008 0.0278 0.0194 46.95 1.1 1 1.2 1.008 0.0278 0.0194 47.15 1.1 1 1.2 1.008 0.0278 0.0194

You might also like

- Sample Cross-Complaint For Indemnity For CaliforniaDocument4 pagesSample Cross-Complaint For Indemnity For CaliforniaStan Burman75% (8)

- Datasheet AcDocument9 pagesDatasheet AcMohan VarkeyNo ratings yet

- Participant Observation: Qualitative Research Methods: A Data Collector's Field GuideDocument17 pagesParticipant Observation: Qualitative Research Methods: A Data Collector's Field GuideMarta CabreraNo ratings yet

- Asan Visa Ae102901499Document2 pagesAsan Visa Ae102901499hardeep ranaNo ratings yet

- General Specifications: EJX440A Gauge Pressure TransmitterDocument12 pagesGeneral Specifications: EJX440A Gauge Pressure TransmitterapisituNo ratings yet

- Disclosure To Promote The Right To InformationDocument26 pagesDisclosure To Promote The Right To InformationHarsh ZopeNo ratings yet

- Is 1391 2 1992 PDFDocument36 pagesIs 1391 2 1992 PDFsusmitamandali100% (1)

- Technical Specification FOR Gear Pump With Drives: Std. / Doc. Number Rev. No. 00 Sheet 1 of 25Document304 pagesTechnical Specification FOR Gear Pump With Drives: Std. / Doc. Number Rev. No. 00 Sheet 1 of 25dhanu_lagwankarNo ratings yet

- Eurapipe Abs Design ManualDocument60 pagesEurapipe Abs Design ManualMatthew ButlerNo ratings yet

- ValvesDocument8 pagesValvespravin_2011No ratings yet

- Manifold PDFDocument32 pagesManifold PDFvivek_enggNo ratings yet

- ABB MAG Flow DN400 Water Master SeriesDocument52 pagesABB MAG Flow DN400 Water Master SeriesNad EemNo ratings yet

- Bis 3315 1994Document17 pagesBis 3315 1994pramod_20253No ratings yet

- Siemens Ac Drive Engineering DataDocument61 pagesSiemens Ac Drive Engineering DatabbkjbxkjNo ratings yet

- Tech Specs Part1 1589434282Document200 pagesTech Specs Part1 1589434282AulinoNo ratings yet

- Personal Data Form: Position Applied ForDocument4 pagesPersonal Data Form: Position Applied Forkapil singhNo ratings yet

- Valves & ControlsDocument16 pagesValves & ControlseborresonNo ratings yet

- Sludge Treatment: Efficient Solutions For Wastewater Treatment PlantsDocument10 pagesSludge Treatment: Efficient Solutions For Wastewater Treatment PlantsLaurentiu ApostolNo ratings yet

- Abb MVFTDocument32 pagesAbb MVFTParmar JenishNo ratings yet

- AVK Dam Reservoir Applications Glenfield PDFDocument16 pagesAVK Dam Reservoir Applications Glenfield PDFsexmanijakNo ratings yet

- Is 12592 2002Document17 pagesIs 12592 2002sharmak_anil0% (1)

- Is.13349.1992 0Document21 pagesIs.13349.1992 0tharaka.me2018No ratings yet

- K-RD-DT-28, Rev 5 (Indoor - Outdoor Dist Trafo) .Document21 pagesK-RD-DT-28, Rev 5 (Indoor - Outdoor Dist Trafo) .Muhammad KashifNo ratings yet

- Mixer Calculation PDFDocument19 pagesMixer Calculation PDFzemabder98No ratings yet

- KRT Planing Information-DataDocument110 pagesKRT Planing Information-DataNicolas Alvarez GomezNo ratings yet

- 0Document193 pages0Halilibrahim Taktak100% (1)

- Guide Lt2 UvguidanceDocument436 pagesGuide Lt2 Uvguidanceezygadlo6492No ratings yet

- Room ACis.1391.2.1992Document36 pagesRoom ACis.1391.2.1992Ajay MenonNo ratings yet

- Aeration System and Oxygen RequirementDocument7 pagesAeration System and Oxygen Requirementdzari6738No ratings yet

- Analisis RiesgoDocument2 pagesAnalisis RiesgoabenitechNo ratings yet

- Reliable OSY Flanged Gate ValveDocument2 pagesReliable OSY Flanged Gate Valvemina elromany0% (2)

- Data SheetDocument7 pagesData SheetPaulkumar RamaiahNo ratings yet

- Motor StandardsDocument17 pagesMotor Standardskodandaram100% (4)

- Wind Design - ASCE 7-16Document22 pagesWind Design - ASCE 7-16Nguyen Tan PhatNo ratings yet

- BioGas Products BrochureDocument4 pagesBioGas Products Brochureawhk2006No ratings yet

- Is 325 1996Document21 pagesIs 325 1996Ramu NallathambiNo ratings yet

- Hazardous Waste Incineration ManualDocument56 pagesHazardous Waste Incineration ManualnadyamedianaNo ratings yet

- Technical Specifications For Etp Rev 01 - Yehlanka CCPP 1488890727Document194 pagesTechnical Specifications For Etp Rev 01 - Yehlanka CCPP 1488890727Roshan KaluarachchiNo ratings yet

- CANDIDATE INFORMATION SHEET - InctureDocument2 pagesCANDIDATE INFORMATION SHEET - IncturesupreethNo ratings yet

- KSB Butterfly Valve Boax-B SeriesDocument20 pagesKSB Butterfly Valve Boax-B SeriesswcciqbalNo ratings yet

- Ansi or Nema Mg1-1998Document596 pagesAnsi or Nema Mg1-1998cuervohijoguachoNo ratings yet

- Tyco Vanessa DatasheetDocument16 pagesTyco Vanessa DatasheetJack ChavanNo ratings yet

- ABB Handbook - Flowmeters (Ingles)Document55 pagesABB Handbook - Flowmeters (Ingles)Eduardo ZapataNo ratings yet

- Caesar II-Manual Calc Sustained-Ashish ShrivastavaDocument1 pageCaesar II-Manual Calc Sustained-Ashish Shrivastavaashish shrivastavNo ratings yet

- CamScanner 05-08-2022 16.37Document11 pagesCamScanner 05-08-2022 16.37nithyaupscNo ratings yet

- Bioventing DesignDocument89 pagesBioventing DesignCindhy Ade HapsariNo ratings yet

- Beneficial Uses of Municipal Wastewater Residuals (Biosolids) - Final ReportDocument26 pagesBeneficial Uses of Municipal Wastewater Residuals (Biosolids) - Final Reportrocky21stNo ratings yet

- 1 - Asme b16.1 - 0 PDFDocument70 pages1 - Asme b16.1 - 0 PDFJoseph M. Mahecha100% (1)

- Flowtite Product Guide 2010Document28 pagesFlowtite Product Guide 2010Anonymous 87xpkIJ6CFNo ratings yet

- Guideline Industrial Leakage Test 1200.compressed PDFDocument109 pagesGuideline Industrial Leakage Test 1200.compressed PDFMarzuki AlkindiNo ratings yet

- Biogas Generator Design Construction and MaintenanceDocument23 pagesBiogas Generator Design Construction and MaintenanceCoevicNo ratings yet

- AMRI ISORIA 16 Type Series Booklet DataDocument20 pagesAMRI ISORIA 16 Type Series Booklet Datarudiskw456No ratings yet

- Gen-Spc-Pip-5055 - Rev. BDocument10 pagesGen-Spc-Pip-5055 - Rev. BAHMED AMIRANo ratings yet

- InsulationDocument13 pagesInsulationBaDa Lee100% (1)

- Design HeatexchangerDocument15 pagesDesign HeatexchangerMayurMahajan100% (1)

- Application Guide Sludge Mixers en Rev 1Document8 pagesApplication Guide Sludge Mixers en Rev 1gazwang478No ratings yet

- Ejm ReporteDocument38 pagesEjm ReporteJose AndradeNo ratings yet

- Thermal Design Calculation Procedure (Rev 00)Document24 pagesThermal Design Calculation Procedure (Rev 00)mkfe2005No ratings yet

- Air Cooler 45 Case1 PDFDocument2 pagesAir Cooler 45 Case1 PDFHeny MarthaNo ratings yet

- Double Pipe Heat Exchanger Design: Chemical Engineering SpreadsheetsDocument2 pagesDouble Pipe Heat Exchanger Design: Chemical Engineering Spreadsheetsrudy_423522658No ratings yet

- Steam Tracing CalculationDocument76 pagesSteam Tracing CalculationChristina Martin63% (8)

- Heat Exchanger Specification Sheet: in FT FT Performance of One UnitDocument10 pagesHeat Exchanger Specification Sheet: in FT FT Performance of One UnitAnonymous Wd2KONNo ratings yet

- Fundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationFrom EverandFundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationNo ratings yet

- Onset Hobo Trade T Cdi 5200 5400 User ManualDocument3 pagesOnset Hobo Trade T Cdi 5200 5400 User Manualpaull20020% (1)

- LRAD Datasheet 2000XDocument2 pagesLRAD Datasheet 2000XOkkar MaungNo ratings yet

- Linear Dynamic Analysis of Free-Piston Stirling Engines OnDocument21 pagesLinear Dynamic Analysis of Free-Piston Stirling Engines OnCh Sameer AhmedNo ratings yet

- Neelima A Kulkarni ResumeDocument3 pagesNeelima A Kulkarni ResumeAcademics LecturenotesNo ratings yet

- List of Phrasal Verbs 1 ColumnDocument12 pagesList of Phrasal Verbs 1 ColumnmoiibdNo ratings yet

- Meniere's Disease - Retinal Detatchment - GlaucomaDocument3 pagesMeniere's Disease - Retinal Detatchment - Glaucomaybet03No ratings yet

- De DusterDocument6 pagesDe DusterArstNo ratings yet

- Morse Potential CurveDocument9 pagesMorse Potential Curvejagabandhu_patraNo ratings yet

- Suspend and Resume Calls: Exit PlugDocument4 pagesSuspend and Resume Calls: Exit PlugrajuNo ratings yet

- Q4 Music 6 Module 2Document15 pagesQ4 Music 6 Module 2Dan Paolo AlbintoNo ratings yet

- Bachelors - Harvest Moon Animal ParadeDocument12 pagesBachelors - Harvest Moon Animal ParaderikaNo ratings yet

- Report On Marketing Strategy of Nestle MILKPAKDocument13 pagesReport On Marketing Strategy of Nestle MILKPAKAzeem Ahmad100% (1)

- 10 Essential Books For Active TradersDocument6 pages10 Essential Books For Active TradersChrisTheodorou100% (2)

- ICD10WHO2007 TnI4Document1,656 pagesICD10WHO2007 TnI4Kanok SongprapaiNo ratings yet

- Toi Su20 Sat Epep ProposalDocument7 pagesToi Su20 Sat Epep ProposalTalha SiddiquiNo ratings yet

- IPM GuidelinesDocument6 pagesIPM GuidelinesHittesh SolankiNo ratings yet

- TMPRO CASABE 1318 Ecopetrol Full ReportDocument55 pagesTMPRO CASABE 1318 Ecopetrol Full ReportDiego CastilloNo ratings yet

- Le Chatelier's Principle Virtual LabDocument8 pagesLe Chatelier's Principle Virtual Lab2018dgscmtNo ratings yet

- Geotechnical Aspects of Open Stope Design at BHP Cannington: G C StreetonDocument7 pagesGeotechnical Aspects of Open Stope Design at BHP Cannington: G C StreetonJuan PerezNo ratings yet

- Session4 Automotive Front End DesignDocument76 pagesSession4 Automotive Front End DesignShivprasad SavadattiNo ratings yet

- TW BT 01 - Barstock Threaded Type Thermowell (Straight) : TWBT - 01Document3 pagesTW BT 01 - Barstock Threaded Type Thermowell (Straight) : TWBT - 01Anonymous edvYngNo ratings yet

- Adime 2Document10 pagesAdime 2api-307103979No ratings yet

- DxDiag Copy MSIDocument45 pagesDxDiag Copy MSITạ Anh TuấnNo ratings yet

- CL RouterAndSwitches AE Kn1of3 AnswerDocument19 pagesCL RouterAndSwitches AE Kn1of3 Answereugene ngNo ratings yet

- Project Manager PMP PMO in Houston TX Resume Nicolaas JanssenDocument4 pagesProject Manager PMP PMO in Houston TX Resume Nicolaas JanssenNicolaasJanssenNo ratings yet

- Clash of Clans Hack Activation CodeDocument2 pagesClash of Clans Hack Activation Codegrumpysadness7626No ratings yet