Professional Documents

Culture Documents

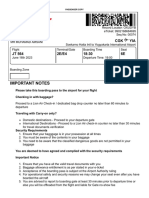

Cargo Change Over Checklist

Uploaded by

Rajat K. ChauhanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cargo Change Over Checklist

Uploaded by

Rajat K. ChauhanCopyright:

Available Formats

INTERNATIONAL SAFETY GUIDE FOR OIL TANKERS AND TERMINALS

14.1.12 Testing of Cargo Tanks and Enclosed Spaces on Dry Bulk Voyages

Before loading a dry bulk cargo, all spaces that have previously contained oil should be cleaned, gas freed and inspected internally. Once all tank cleaning has been completed, daily checks for hydrocarbon gas should be made in all empty cargo holds, empty cargo tanks and empty double bottom and ballast tanks, as well as pumprooms, pipe ducts, cofferdams, stool tanks and similar void spaces. If no hydrocarbon gas has been detected after 14 days, the frequency of the readings may be reduced to every two days, unless the ship passes through areas with higher sea or air temperatures, in which case the daily checks should continue. If the following voyage is to continue in dry bulk cargoes, the readings on that voyage need be taken only every three days. If hydrocarbon gas is detected during any dry cargo voyage, the space should be ventilated with air. If the hydrocarbon gas cannot be controlled by ventilation, the space should be inerted and remain so until it can be cleaned again.

14.1.13 Cargo Changeover Check-Lists

The following check-lists are of a general nature and each ship should use them as a guide when developing its own comprehensive check-lists. Oil to Dry Bulk Cargo q Wash cargo holds and tanks, including access trunks.

q q q

Flush all main suctions into cargo holds and tanks and strip dry. Gas free all cargo holds and tanks. Hose off, blow through, disconnect and stow portable heating coils as required. Plug securing sockets as necessary. Ensure fixed heating coils are free of oil before blanking ends. Complete hand hosing and digging of holds and sumps to the requirements of the next cargo. Drain cargo holds and suction wells. Blank off main suctions to holds as necessary. Ensure the stripping discharge line to after hold is securely blanked. Ensure sounding pipes to bilge wells are open and clear of obstructions. Fit main and stripping suction recess doors as necessary. Also fit heating coil connecting pipe recess doors. Wash cargo pipeline system thoroughly, including pumps, deck lines, bottom lines and pumproom. Ensure gauging system, where fitted, is stowed or blanked as necessary to manufacturers recommendations. Drain, vent and prove gas free all gas lines and risers. Blank off gas lines to holds as necessary. Set venting system to the requirements of the next cargo. Check hatch cover sealing arrangements and closing devices. Check ballast tanks, void spaces, cofferdams and pumprooms for flammable gas. Ventilate as necessary and prove gas free.

q q

q q

q q q q q

238

ICS/OCIMF/IAPH 2006

SPECIAL SHIP TYPES

If slops are retained, ensure designated pipeline segregations are fitted, slop tanks are fully inerted and the relevant venting system adopted, as necessary.

q q

Dry Bulk Cargo to Oil Sweep holds clean and lift cargo remains out of hold for disposal. Wash cargo remains off bulkheads with a high pressure water jet, stripping slowly to remove water, leaving solid residues. Remove solid residues from the tank top and sumps, and prove that the stripping suction is clear. Remove suction doors and attach securely to stowage positions. Close off sounding pipes to sumps as required. Remove blanks from main cargo suctions and stripping discharges to after hold. Lower and secure heating coils in place, connect and prove tight, as necessary. Remove requisite blanks from gauging system and render fully operational. Wash all stripping lines thoroughly to remove solid residues. As far as possible, test stripping valves for tightness to ensure valve seats are not damaged by solid residues. Open, clean and check all strainers in cargo systems. Check and clean hatch cover sealing arrangements, trackways etc. Check hatch cover sealing arrangements and closing devices. Remove blanks from gas lines, as necessary. Set venting system for next cargo. Prove all valves and non-return valves in cargo system are operational. Inert holds prior to loading. During inerting, prove tightness of hatch covers, tank cleaning covers, access hatches and all openings into cargo spaces.

q q q

q q q q q q

14.2

LPG Carriers Carrying Petroleum Products

14.2.1 General

Some LPG carriers are certified to carry other petroleum products, for example light naphtha, jet fuel and mogas. The ships Certificate of Fitness will identify the cargoes that can be carried. The vessels classification society will also have laid down carriage criteria related to maximum tonnages in each tank, maximum densities and, where applicable, sloshing limits. Some petroleum products are also classified as Noxious Liquid Substances (NLS). In this case, special rules apply in accordance with MARPOL Annex II, including the requirement to maintain a dedicated Cargo Record Book for Ships Carrying NLS in Bulk. Such ships are also provided with a Procedures and Arrangements Manual. Benzene precautions may need to be taken, as described in Section 2.3.5.

ICS/OCIMF/IAPH 2006

239

You might also like

- 0 Crude Oil Washing Precautions and ProceduresDocument2 pages0 Crude Oil Washing Precautions and ProceduresArun Rocky100% (1)

- Chemical Tanker: Main Characteristics of Chemical TankersDocument6 pagesChemical Tanker: Main Characteristics of Chemical TankersTri Wahyu PrastiyoNo ratings yet

- Tanker Contam ChecklistDocument12 pagesTanker Contam ChecklistSudheer ChitlaNo ratings yet

- Cargo Line Clearance Safe Procedure For Chemical TankersDocument8 pagesCargo Line Clearance Safe Procedure For Chemical TankersJeet SinghNo ratings yet

- Gas Freein ProceduresDocument3 pagesGas Freein ProceduresSamarinerSingh100% (1)

- Tanker Operation ProcedureDocument2 pagesTanker Operation ProcedureAnand KhotNo ratings yet

- Marine Cargo OperationDocument15 pagesMarine Cargo OperationJohn Raj100% (1)

- Oil Tanker OperationsDocument36 pagesOil Tanker Operations302835100% (1)

- Gas-Freeing Purging Process EquipmentDocument2 pagesGas-Freeing Purging Process Equipmentrenjithv_4100% (1)

- OCTFDocument30 pagesOCTFVidhyaNo ratings yet

- H2S AwarenessDocument30 pagesH2S AwarenessHashem Rezayi100% (1)

- Inert Gas Venting VOCDocument2 pagesInert Gas Venting VOCRahulChoudharyNo ratings yet

- Bunkering Is Dangerous: Procedure For Bunkering Operation On A ShipDocument3 pagesBunkering Is Dangerous: Procedure For Bunkering Operation On A ShipSurajitSarkar100% (1)

- Periodic Servicing of Lifeboats and Rescue BoatsDocument37 pagesPeriodic Servicing of Lifeboats and Rescue BoatsDalibor Mimica100% (1)

- Crude Oil Washing 2Document8 pagesCrude Oil Washing 2Subir BairagiNo ratings yet

- Octo Q and Ans CE PADAMDocument90 pagesOcto Q and Ans CE PADAMPadam Nabh100% (1)

- Prevention of Marine Litter PollutionDocument35 pagesPrevention of Marine Litter Pollutionrmb2007No ratings yet

- Cargo Operation Equipment For TankersDocument172 pagesCargo Operation Equipment For TankersDon Sheens100% (1)

- Confined Space Safe Practice: (2000) Rev.1 (October 2003) Rev.2 (April 2007)Document24 pagesConfined Space Safe Practice: (2000) Rev.1 (October 2003) Rev.2 (April 2007)Karwan Dilmany100% (1)

- Tank Cleaning MethodDocument6 pagesTank Cleaning MethodSnehilNo ratings yet

- MEPC 185 (59) - Guidelines For The Development of A VOC Management PlanDocument3 pagesMEPC 185 (59) - Guidelines For The Development of A VOC Management PlancaptsantoshNo ratings yet

- Loaders AND Bobcats in General Are Used To Gather Bulk Cargo Residues in The Middle of Holds So That Unloading CAN Continue UninterruptedDocument22 pagesLoaders AND Bobcats in General Are Used To Gather Bulk Cargo Residues in The Middle of Holds So That Unloading CAN Continue Uninterruptedber100% (1)

- Musters and Drills and On-Board Training & Instruction: Manx Shipping NoticeDocument7 pagesMusters and Drills and On-Board Training & Instruction: Manx Shipping NoticeAnkit Khokhar100% (1)

- Ballast Water Management: S M Tomiz Uddin:1055 Mfa 25, A1MC20180601-A (24) ALAM015268Document9 pagesBallast Water Management: S M Tomiz Uddin:1055 Mfa 25, A1MC20180601-A (24) ALAM015268Taufiq JahanNo ratings yet

- Cargo Hold Cleaning Kit & Chemical Washing TechnicsDocument8 pagesCargo Hold Cleaning Kit & Chemical Washing Technicsrojoubeda63No ratings yet

- Crude Oil WashingDocument2 pagesCrude Oil WashingMin Soe100% (1)

- ISGOTT 6 Breakdown of POI For InspectorsDocument4 pagesISGOTT 6 Breakdown of POI For InspectorsSam BNo ratings yet

- Doing Hot Work On Gas ShipDocument5 pagesDoing Hot Work On Gas ShipAnonymous icnhaNsFNo ratings yet

- Phase 1 - Tanker Notes As Per Syllabus & MMD PapersDocument59 pagesPhase 1 - Tanker Notes As Per Syllabus & MMD PapersJiby John Joseph100% (2)

- 1-Marine PollutionDocument94 pages1-Marine PollutionAhmed ElrahidyNo ratings yet

- Tanker BodyDocument5 pagesTanker BodyAghil BuddyNo ratings yet

- Supervision of Crude Oil Washing (COW) OperationsDocument6 pagesSupervision of Crude Oil Washing (COW) Operationstony100% (1)

- CARGO CYCLe Oil TankerDocument19 pagesCARGO CYCLe Oil Tankersukhjit78100% (1)

- Bunkering Safety Checklist and GuidelinesDocument6 pagesBunkering Safety Checklist and GuidelinesvaaliNo ratings yet

- Vapour Emission Control System Operation ProcedureDocument2 pagesVapour Emission Control System Operation ProcedureRahulChoudharyNo ratings yet

- 4.7 Cargo Sampling ProcedureDocument7 pages4.7 Cargo Sampling ProcedureHasan CosalevNo ratings yet

- Ship Shore Safety CheckllistDocument2 pagesShip Shore Safety CheckllistHimanshu Shekhar TiwariNo ratings yet

- Gangways EnglishDocument12 pagesGangways EnglishNareshNo ratings yet

- Tank AtmosphereDocument28 pagesTank AtmosphereBhupender RamchandaniNo ratings yet

- Imdg SegregationDocument52 pagesImdg Segregationcaptlakho6501No ratings yet

- Valero Marine Assurance Vetting Assessment Policy (Summary) (Final 01-04-12) v1Document4 pagesValero Marine Assurance Vetting Assessment Policy (Summary) (Final 01-04-12) v1goldysanNo ratings yet

- Tanker LCC Operating ProceduresDocument37 pagesTanker LCC Operating ProceduresCiocio CiohodaruNo ratings yet

- Annual Survey ChecklistDocument15 pagesAnnual Survey ChecklistharryNo ratings yet

- L3-Care of Cargo During Carriage (Part 2)Document26 pagesL3-Care of Cargo During Carriage (Part 2)Ganesh Bharath Kumar100% (1)

- Inerting of Cargo TanksDocument20 pagesInerting of Cargo TanksFlexi100% (1)

- Hold CleaningDocument5 pagesHold CleaningBiplab SharmaNo ratings yet

- HazardsDocument17 pagesHazardsNavin DipaliNo ratings yet

- Check List 84 - BALLASTING, DeballastingDocument1 pageCheck List 84 - BALLASTING, Deballastingprakash7kNo ratings yet

- IG System 2Document17 pagesIG System 2Sergioi IndurainNo ratings yet

- Appendix 1 - Hold Cleaning After Discharging CementDocument4 pagesAppendix 1 - Hold Cleaning After Discharging CementGeorge Ponparau100% (1)

- Stolt 1Document12 pagesStolt 1PeterWangNo ratings yet

- 3.0 Cargo CareDocument12 pages3.0 Cargo CareNelum Perera100% (1)

- 12.2 Entry in To The Enclosed SpaceDocument11 pages12.2 Entry in To The Enclosed SpaceHasan Cosalev100% (1)

- SHIPOWNERS Sampling Procedures For TankersDocument5 pagesSHIPOWNERS Sampling Procedures For TankersErsin SaltNo ratings yet

- Inert Gas OverviewDocument6 pagesInert Gas OverviewRahulChoudharyNo ratings yet

- 8.04 Carriage of Coal in BulkDocument49 pages8.04 Carriage of Coal in BulkRoken Zgoul100% (2)

- Preparation For LoadingDocument2 pagesPreparation For LoadingTjah YanniNo ratings yet

- Oil TankerDocument3 pagesOil Tankerbruzlik100% (1)

- 10 Important Points To Remember After Completing Cargo Operations On TankersDocument5 pages10 Important Points To Remember After Completing Cargo Operations On TankerscassandraNo ratings yet

- 10 Important Points To Remember After Completing Cargo Operations On TankersDocument4 pages10 Important Points To Remember After Completing Cargo Operations On Tankersindumarnicaragua100% (3)

- Garuda Indonesia PDFDocument34 pagesGaruda Indonesia PDFYosua GerryNo ratings yet

- Name: Jafarmusa Salarov ID: 0174VMVM0612 Module Title: Professional Development I Programme: BABS Semester: Two Lecturer: Mr. Francis AsirvathamDocument15 pagesName: Jafarmusa Salarov ID: 0174VMVM0612 Module Title: Professional Development I Programme: BABS Semester: Two Lecturer: Mr. Francis AsirvathamAhmet BabayevNo ratings yet

- Surface Markings and NotamsDocument37 pagesSurface Markings and NotamsRajib DasNo ratings yet

- Aviation Security (Tailored Services Packages)Document4 pagesAviation Security (Tailored Services Packages)Gemy232No ratings yet

- Jet Airways Flight SchedulesDocument808 pagesJet Airways Flight SchedulesSyed Jameel Al HassaniNo ratings yet

- Aviation Vocabulary 4 20 Multiple Choice QuestionsDocument3 pagesAviation Vocabulary 4 20 Multiple Choice QuestionsALOK FREE FIRENo ratings yet

- Usavvh - Ahmad Ahmad MRDocument1 pageUsavvh - Ahmad Ahmad MRYafieNo ratings yet

- Amadeus AirDocument53 pagesAmadeus Airbarokgs119079No ratings yet

- Manual de Inglés 1Document40 pagesManual de Inglés 1Katherine FresitaNo ratings yet

- (Ccu) (Ixb)Document1 page(Ccu) (Ixb)Mr David SarkarNo ratings yet

- Air Cabin Crew: Work ActivitiesDocument7 pagesAir Cabin Crew: Work ActivitiesRycko PareiraNo ratings yet

- UK Air Mobility Consortium CONOPSDocument84 pagesUK Air Mobility Consortium CONOPSdkfk9854No ratings yet

- 0904-2 - Exercise of Airport Terminal Planning (QuestionDocument15 pages0904-2 - Exercise of Airport Terminal Planning (Questionlan AnhNo ratings yet

- Metar and Speci CodeDocument7 pagesMetar and Speci CodeDawood waheedNo ratings yet

- ALBATROSS Fixed Wing UAVDocument2 pagesALBATROSS Fixed Wing UAVPresa Kautsar100% (1)

- ACE Engineering College: Solar Powered AircraftDocument16 pagesACE Engineering College: Solar Powered Aircraftsai deepthiNo ratings yet

- Performance Retention and Fuel Saving A330 A340Document68 pagesPerformance Retention and Fuel Saving A330 A340Lbrito01100% (1)

- UntitledDocument103 pagesUntitledCláudio Regis100% (1)

- BIOMIMICRYDocument18 pagesBIOMIMICRYVedant GawadeNo ratings yet

- Group Assignment Opm554 Nbo4b Group 5Document24 pagesGroup Assignment Opm554 Nbo4b Group 5Afiq Najmi RosmanNo ratings yet

- Assignment Brief For Learners & Feedback Form: Learner's DeclarationDocument10 pagesAssignment Brief For Learners & Feedback Form: Learner's DeclarationJagadish JagsNo ratings yet

- Module 1 and Module 2 Intro To Transport and Air Transportation EudelaDocument111 pagesModule 1 and Module 2 Intro To Transport and Air Transportation EudelaKatherine Barreto100% (1)

- Draft CAR 7B XIX-comments by 10feb24Document16 pagesDraft CAR 7B XIX-comments by 10feb24suryaammu51No ratings yet

- V-Speeds (Cessna - 172)Document2 pagesV-Speeds (Cessna - 172)mahmoud deyaaNo ratings yet

- American Military Transport Aircraft Since 1925 PDFDocument489 pagesAmerican Military Transport Aircraft Since 1925 PDFGana tp100% (2)

- File MR. PRADIPKUMAR DHOOTDocument1 pageFile MR. PRADIPKUMAR DHOOTex faplNo ratings yet

- Adp 2 Final Report (1) - 1Document58 pagesAdp 2 Final Report (1) - 1FAROOK FAKRUNo ratings yet

- Operation Olympic Naval Order ComPhibPac A11-45 Annex (H) Air Support PlanDocument11 pagesOperation Olympic Naval Order ComPhibPac A11-45 Annex (H) Air Support PlanDownfall1100% (1)

- Aviation DictionaryDocument11 pagesAviation DictionarySuliman Omar100% (1)

- MR MUHAMAD AMSANI TiketDocument2 pagesMR MUHAMAD AMSANI TiketMuhamad AmsaniNo ratings yet

- Analog Design and Simulation Using OrCAD Capture and PSpiceFrom EverandAnalog Design and Simulation Using OrCAD Capture and PSpiceNo ratings yet

- Transformed: Moving to the Product Operating ModelFrom EverandTransformed: Moving to the Product Operating ModelRating: 4 out of 5 stars4/5 (1)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsFrom EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsNo ratings yet

- The Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsFrom EverandThe Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsRating: 5 out of 5 stars5/5 (1)

- The Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsFrom EverandThe Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsNo ratings yet

- 507 Mechanical Movements: Mechanisms and DevicesFrom Everand507 Mechanical Movements: Mechanisms and DevicesRating: 4 out of 5 stars4/5 (28)

- Laws of UX: Using Psychology to Design Better Products & ServicesFrom EverandLaws of UX: Using Psychology to Design Better Products & ServicesRating: 5 out of 5 stars5/5 (9)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchFrom EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchRating: 4 out of 5 stars4/5 (10)

- Articulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceFrom EverandArticulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceRating: 4 out of 5 stars4/5 (19)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- Practical Reservoir Engineering and CharacterizationFrom EverandPractical Reservoir Engineering and CharacterizationRating: 4.5 out of 5 stars4.5/5 (3)

- Lean vs Agile vs Design Thinking: What You Really Need to Know to Build High-Performing Digital Product TeamsFrom EverandLean vs Agile vs Design Thinking: What You Really Need to Know to Build High-Performing Digital Product TeamsRating: 4 out of 5 stars4/5 (2)

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- The Maker's Field Guide: The Art & Science of Making Anything ImaginableFrom EverandThe Maker's Field Guide: The Art & Science of Making Anything ImaginableNo ratings yet

- Heat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersFrom EverandHeat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersRating: 4 out of 5 stars4/5 (13)

- Practical Troubleshooting of Electrical Equipment and Control CircuitsFrom EverandPractical Troubleshooting of Electrical Equipment and Control CircuitsRating: 4 out of 5 stars4/5 (5)