Professional Documents

Culture Documents

Hydraulic Top Upgrade Instructions

Uploaded by

Don ErdmannOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hydraulic Top Upgrade Instructions

Uploaded by

Don ErdmannCopyright:

Available Formats

Jaguar XK/XKR Hydraulic Convertible Top Upgrade Instructions Background Information: This upgrade kit is designed for the

Jaguar XK8/XKR model years 1996-2005. The automatic convertible top in these model years is operated by a hydraulic system manufactured for Jaguar by the Power Packer company. Power Packer is the primary designer and manufacturer of convertible top systems that are also used by Mercedes and BMW, plus many others. This system has suffered from a variety of premature failures. This kit is designed to overcome flaws in the design of the Power Packer roof system and improve reliability. The failures, in approximate order of severity, have been the latch hoses, where they fasten to the latch cylinder, the latch cylinder seals, the lift cylinder seals (located behind the rear jump seat on both sides), and sporadically hoses in random locations. The observed failures have been in majority related to high operating temperatures in the latch area. Hydraulic components are rated by maximum operating pressure and temperature. These two parameters interact such that a hose with higher temperature rating will have lower pressure rating at that temperature and visa versa. The operating temperature in the Jaguar is beyond our control but this upgrade kit is able to reduce operating pressure by over 30% without affecting operation. This large pressure reduction therefore increases the operating temperature range of the system. The relative effect amounts to about 600 pounds of force that no longer must be contained by the hose and seals. Model years up to about 2001 used Nylaflow hose manufactured by Parker. This hose was particularly unreliable. Later models have Polyflex hose (also manufactured by Parker) installed. Polyflex hose has performed better but still has an unacceptable failure rate in this system. Both of these hoses are custom for Power Packer and not commercially available. The name of the hose is clearly printed on the hose. Also printed on the hose is a date code in the form 1-Q-03 which in this case is the first quarter of 2003. This date can be matched to the model year and other hoses in the system to diagnose what has been done to the hydraulic system in the past. The installation of hoses of different type and/or date code is an indication of prior replacement and subsequent years of service. Failures in the latch area are obvious as the driver can readily see the effects of the leak. Failures of the lift cylinders are less obvious because the escaping oil drains out of the bottom the car with no obvious symptoms beyond a small wet spot in front of one of the rear wheels. If the reservoir level is persistently going down and requires periodic attention, then the cause is probably a leaking lift cylinder. The leak occurs in the seals that ride on the shaft as it goes in and out to raise and lower the top. A quantity of oil is lost during each roof operation. IMPORTANT: Do not open the kit before Installation Step 5 (Port 1, Figure 2) below. In rare instances the plug cannot be removed. We will accept returns on unopened kits with no restocking charges. There will be a small charge on kits that have been opened but not installed.

Jaguar XK Hydraulic Upgrade Kit Contents: 1 - custom hydraulic valve. 1 - 10 inch hose assembly (Hose 2) with female fittings both ends. 1 - 10 inch hose assembly (Hose 1) with female fitting and male fitting. 1 - hose Adapter. 2 - plastic Tie Wraps.

Figure 1 Kit Part Identification Tools Required: T30 bit with right angle socket driver. 13mm socket. 11/16, 7/16, 5/8 Open End Wrenches Pan or paint roller tray to catch hydraulic oil drips Installation Instructions: Make sure that the top system is working properly before installing this upgrade. Installing the upgrade in a malfunctioning system will only complicate diagnosis of the problem. Refer to Figure 1 to assist with part identification. The fittings in this kit have either O-ring seals or Teflon Tape. Tighten to the point that the fitting is snug but dont overdo. Excessive torque risks damage to the O-ring or the threads. When tightening the O-ring parts you will feel a point where the O-ring is fully compressed and that is the place to stop. It is especially important to not damage the pump assembly. 1. Remove the hydraulic pump assembly. The pump is located in the trunk, behind the fascia that covers the stereo and navigation equipment. There are different configurations for MY 1996-1999 and 2000 on. This procedure refers to the MY2000+ configuration that has the taller electronics rack that places the pump up under the fender. The earlier MYs have the shorter rack and a different arrangement for the fascia. 2. Pull the fascia out and fold it flat against the floor of the trunk compartment. Put the catch pan on top of the folded fascia to hold the pump assembly during installation. a. Use the T30 bit with a drive socket (or right angle T30 if available) to remove the two screws that hold the pump in place. b. Make note of the hydraulic oil level in the tank. It should be between the two lines on the tank. If not you will need to top off before reinstalling. c. Carefully unplug the two wire harness connections to the pump motor and solenoids. Do not pull on the wires when disconnecting as this can break

the connectors. The solenoid connector has a release latch that must be pressed to remove. Note that early cars must be unplugged at the solenoids while later cars (2000+) have one connector at the rear of the electronics rack. The motor connector should be gently wiggled while holding the plastic shell to separate the two parts. d. Slide the pump assembly forward as far as possible and then rotate the tank end toward the trunk compartment. Gently work the pump out, tank end first, through the opening in front of the electronics rack and put it in the spill tray. 3. Turn the manual valve (device on inboard side of the pump with the T handle in Figure 2) counter clockwise slightly to allow any residual pressure in the system to drain back into the tank. It is only necessary to crack this valve. Then turn the valve back to the full clockwise position. 4. Roll the pump assembly on its side with the manual handle up to prevent oil from leaking out due to gravity. 5. Use the T30 bit to remove the plug that is located below the lowest hose fitting. This is the red item in Figure 2. On some pump assemblies it might be necessary to twist the adjacent elbow for the latch hose out of the way. NOTE: This fitting is sealed (the red stuff) and can be difficult to remove. Be extra careful to not strip the head. Use a high quality T30 tool made from hardened steel. Fastening the pump back in the original position allows for better leverage. If all else fails the hoses can be removed (mark them carefully) and the pump removed for more secure fixturing.

Figure 2 PORT 1

6. Install the male fitting on Hose 1 (see picture) into the hole where the plug was removed. Use the 7/16 wrench to tighten. 7. Fasten the other end of this hose to Port 1 on the valve included in the kit. Use the 11/16 wrench to tighten the fitting. 8. Position the pump so the opposite side is up as in Figure 3. Use the 13mm socket wrench to remove the brass plug that is in the metal body near the tank. Use caution as the tank can empty through this port.

Figure 3 Port 2 9. Install the small end of the included Adapter fitting into this hole. Use the 5/8 wrench to tighten the fitting. See Figure 4. 10. Attach one end of Hose 2 to the Adapter and tighten using the 11/16 wrench.

Figure 4 Port 2 Adapter and Hose 2 11. Position the Hydraulic Valve on the top side of the pump motor with the pointed end toward the front of the car and fasten the other end of Hose 2 to Valve Port 2 and tighten with the 11/16 wrench. Refer to Figure 5. 12. Adjust the position of the Valve and hoses to be on top of the motor with the pointed end toward the front of the car. Thread the included wire ties under the hoses and around the motor body and the valve. One tie can pass through the two recessed spots in the Valve Body. The second can go over the recess at the junction of the Valve and the rectangular Valve Body. Tighten the ties to hold the valve in place. Do not pinch hoses under the tie.

Figure 5 Pump and kit installed 13. Top off the hydraulic reservoir with oil if necessary. If the installation has been done carefully only a few drops of oil have been lost. When held level the oil should fall between the marks on the tank. 14. Before re-installing the pump, test the roof operation by temporarily connecting the two wiring harness parts, position the pump upright and approximately level, turn the engine on (to not stress the battery) and lower and raise the roof at least twice. Check to make sure there are no leaks at the pump. If the roof fails to operate properly after two cycles refer to the Troubleshooting Section. The pump will be noticeably quieter especially at the end of operation before the chime sounds. If the top fails to operate properly make sure to hold the top operate switch for at least 40 seconds to allow the control circuits to finish the cycle. 15. If the roof raises and lowers properly then disconnect the two electrical connectors and re-install the pump by reversing the sequence in Step 1. The valve and new hoses will protrude slightly, so be patient when fitting the pump back in place, as some extra wiggling will be required.

Troubleshooting Guide: Note: This guide assumes that the roof system was working properly before this installation. This upgrade will not fix existing problems in the system. The purpose of this upgrade is to help prevent future problems. Pump does not turn on: The pump motor should make a noticeable whirring sound when running. Make sure the connector to the motor has made contact. The contacts have a tendency to pull out of the housing. Push the wires together to make the connection. Pump runs but top does not move: a. Make sure the manual valve is fully closed in the clockwise direction. b. Double check that the connections to the solenoids are made. The solenoids are the two cylindrical devices on the top of the assembly. The connector housings on each solenoid and at the rear of the electronics rack have been known to come apart due to careless handling. Top operates partially: a. Verify that the pump is not sucking air. Watch the reservoir tank while a partner operates the top. If the pump is sucking air (this will be obvious to the observer) the oil is low or the pump needs to be leveled. b. The operating pressure is too low. This will be apparent if the top stops about half way through the raise movement as this is the point of highest operating pressure. A lift cylinder that is leaking or otherwise impaired could require more pressure to operate The valve has been pre-adjusted to work with cars that have properly operating mechanical parts but inefficient mechanics can require more pressure to operate. Use a inch hex wrench to increase pressure. Insert the wrench into the pointed end of the valve. Turn clockwise to increase pressure. Adjust turn at a time. If increasing pressure does not remedy the problem contact Technical Support. The latch fails to close fully: Some latches have been noted to have excessive friction due the complex arrangement of sliding metal parts. This can be remedied by removing the cover across the top of the latch area and lubricating the latch mechanism with light grease. Technical Support: Phone: 717-762-2191 Email: info@lsi-controls.com

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- b.6.19 - Std. Specification-Site GradingDocument5 pagesb.6.19 - Std. Specification-Site GradingdlloitNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Ce Solutions Brochure FINALv1 4Document11 pagesCe Solutions Brochure FINALv1 4Dhafir MohammedNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- 14.H Out of Specification ResultsDocument10 pages14.H Out of Specification Resultsعبدالعزيز بدرNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Datasheet Blue Solar Charge Controller MPPT 75 10, 75 15 & MPPT 100 15 enDocument1 pageDatasheet Blue Solar Charge Controller MPPT 75 10, 75 15 & MPPT 100 15 enRadoi RaduNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- C747 Transcripts Part1Document224 pagesC747 Transcripts Part1Jose0% (1)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- NVS 345 50 110 120 - EngDocument4 pagesNVS 345 50 110 120 - EngMihaiCiorbaruNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Automation Runtime SG4 G3.10: B&R Revision InformationDocument20 pagesAutomation Runtime SG4 G3.10: B&R Revision InformationEdson VargasNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- S 400 MasterDocument41 pagesS 400 MasterAnonymous 7BSmANoUY0% (1)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Network Code For Requirements For Grid Connection Applicable To All GeneratorsDocument85 pagesNetwork Code For Requirements For Grid Connection Applicable To All GeneratorsEliza Maria CloteaNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Astm 183 PDFDocument5 pagesAstm 183 PDFA.YOGAGURUNo ratings yet

- ExcelTOCI Troubleshooting Guide v2Document24 pagesExcelTOCI Troubleshooting Guide v2Veer PolavarapuNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Mitutoyo Digimatic IndicatorDocument12 pagesMitutoyo Digimatic IndicatorxbudzekNo ratings yet

- Aluminum WiringDocument2 pagesAluminum WiringJorge Ignacio MVNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Mks MFC Gseries ManualDocument113 pagesMks MFC Gseries Manual薛翔峻No ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- YALE (C875) GLP60VX LIFT TRUCK Service Repair Manual PDFDocument22 pagesYALE (C875) GLP60VX LIFT TRUCK Service Repair Manual PDFhfjsjekmmdNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- 020-Aircraft General Knowledge 1 PDFDocument190 pages020-Aircraft General Knowledge 1 PDFPedro SantosNo ratings yet

- c116 Ca505 - en PDocument143 pagesc116 Ca505 - en PVictor Gaona RomeroNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Risk and Compliance Technical Officer (Tunisian Nationals Only) - ReliefWebDocument5 pagesRisk and Compliance Technical Officer (Tunisian Nationals Only) - ReliefWebshaNo ratings yet

- EDN612 ESN212 EPN210 Installation GuideDocument28 pagesEDN612 ESN212 EPN210 Installation GuideOnofreNo ratings yet

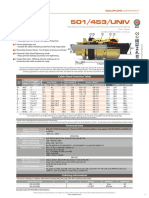

- 501/453/UNIV: Cable Gland Selection TableDocument1 page501/453/UNIV: Cable Gland Selection TableAkmalNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- ONTAP 9 NDMP Configuration Express GuideDocument22 pagesONTAP 9 NDMP Configuration Express Guidestreet_carpNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Split Case Fire Pumps: Fairbanks NijhuisDocument4 pagesSplit Case Fire Pumps: Fairbanks NijhuisRishard Ahamed AkramNo ratings yet

- TanroadsDocument20 pagesTanroadsEmmanuel YwfNo ratings yet

- UGHEV Parts Version 1.0 Price ListDocument10 pagesUGHEV Parts Version 1.0 Price ListMamah NadineNo ratings yet

- Vivek Paul Engineer (Tech.) KLG Systel LTDDocument61 pagesVivek Paul Engineer (Tech.) KLG Systel LTDFirasat AliNo ratings yet

- Company Profile KsiDocument10 pagesCompany Profile KsiarieprachmanNo ratings yet

- Eaton APS6-600 SeriesDocument2 pagesEaton APS6-600 SeriesDocUploader22No ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Wifisky Wireless AdapterDocument9 pagesWifisky Wireless AdapterVan HusenNo ratings yet

- 4NM Winker Light - Jul 2012Document1 page4NM Winker Light - Jul 2012Tripod1970No ratings yet

- bt201 IER PrinterDocument2 pagesbt201 IER PrinteraircalNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)