Professional Documents

Culture Documents

Stainless Steel Grades

Uploaded by

Kanishka AhirwarOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Stainless Steel Grades

Uploaded by

Kanishka AhirwarCopyright:

Available Formats

STAINLESS STEELS

MARTENSITIC STAINLESS STEEL

Martensitic stainless steels are the first branch of the plain chromium stainless steels. These were the first stainless steels industrially

developed (in the form of stainless steel cutlery). This group has a relatively high carbon content & a chromium content of 12-18% Cr. The

common specifications are 410, 420 and 431.

Basic Properties:

Moderate corrosion resistance

Hardenable by heat treatment and therefore high strength and hardness levels can be developed

Poor weldability due to the high carbon content and the hardenable nature. Common Usage:

Common uses include applications, which need strength and hardness such as knife blades, surgical instruments, fasteners, spindles,

nozzles, shafts and springs. Martensitic Stainless Steel is generally available in the form of a bar or strip.

FERRITIC STAINLESS STEEL

These are plain chromium stainless steels. They have varying chromium content of 12-18%, but a lower carbon content than the Martensitics.

The common specifications are 430 & 409

Basic Properties:

Moderate to good corrosion resistance, which increases with the chromium content

Magnetic, non hardenable and always used in annealed condition

Weldability is poor which generally limits their applications as weld components to thin gauge material.

Common Usage:

The most common uses of this type of steel include builders' hardware, sinks, domestic equipment and architectural trims. Thick gauge

applications include liners, decking plates, spillways, chain conveyors and dust & fumes extractors.

Due to their predominant use as thin gauge material this type of stainless steel is available in the form of sheet & coil. They are less

commonly available in the form of plates & welded tube.

AUSTENITIC STAINLESS STEEL

When nickel (Ni) is added to stainless in sufficient quantities the crystal structure is changed to austenite, hence the term Austenitic Stainless

Steel. The basic composition of the austentic stainless steel is 18% chromium and 8% nickel, termed as 18/8. If additional corrosion resistance

is required 2-3% molybdenum is added, termed 18/8/3. The carbon content is low 0.08% max.

The common specifications include 304, 304L, 321, 316, 316L, 316Ti and 317L.

Basic Properties:

Excellent corrosion resistance

Excellent cleanability and hygiene factor Easily fabricated and formed with ease

Excellent weldability

Hardened by cold work, not by heat treatment

Used in the fully annealed condition in which they are non - magnetic

The ability to handle both extremely low (cryogenic) temperatures and high temperatures (up to 925 degree centigrade).

Common Usage:

Austenitic Stainless Steel has a very wide scope of applications. Some of these are hollowware, builders' hardware, architectural applications,

abattoir, beer and beverage production and food processing equipment, which require the cleanability and hygienic corrosion resistance

properties.

STAINLESS STEEL GRADES -CHEMICAL COMPOSITION

CHEMICAL COMPOSITION ( IN PERCENTAGE )

Grade

C (Max)

Mn (Max)

P (Max)

S (Max)

Si (Max)

Cr

Ni

Mo

SS-301

0.15

2.00

0.045

0.030

1.00

16.00 - 18.00

6.00 - 8.00

Nitrogen

(Max)

0.10

SS-304

0.08

2.00

0.045

0.030

0.75

18.00-20.00

8.00 - 10.50

0.10

SS-304H

0.04 - 0.1

2.00

0.045

0.030

0.75

18.00 - 20.00

8.00 - 10.50

SS-304L

0.030

2.00

0.045

0.030

0.75

18.00 - 20.00

8.00 - 12.00

0.10

SS-304LN

0.030

2.00

0.045

0.030

0.75

18.00 - 20.00

8.00 - 12.00

0.10 - 0.16

SS-309

0.20

2.00

0.045

0.030

0.75

22.00 - 24.00

12.00 - 15.00

SS-309S

0.08

2.00

0.045

0.030

0.75

22.00 - 24.00

12.00 - 15.00

SS-310

0.25

2.00

0.045

0.030

1.50

24.00 - 26.00

19.00 - 22.00

SS-310S

0.08

2.00

0.045

0.030

1.50

24.00 - 26.00

19.00 - 22.00

SS-316

0.08

2.00

0.045

0.030

0.75

16.00 - 18.00

10.00 - 14.00

2.00 - 3.00

0.10

SS-316L

0.030

2.00

0.045

0.030

0.75

16.00 - 18.00

10.00 - 14.00

2.00 - 3.00

0.10

SS-316LN

0.030

2.00

0.045

0.030

0.75

16.00 - 18.00

10.00 - 14.00

2.00 - 3.00

0.10 - 0.16

SS-316Ti

0.08

2.00

0.045

0.030

0.75

16.00 - 18.00

10.00 - 14.00

2.00 - 3.00

0.10

SS-317

0.08

2.00

0.045

0.030

0.75

18.00 - 20.00

11.00 - 15.00

3.00 - 4.00

0.10

SS-317L

0.030

2.00

0.045

0.030

0.75

18.00 - 20.00

11.00 - 15.00

3.00 - 4.00

0.10

SS-317LN

0.030

2.00

0.045

0.030

0.75

18.00 - 20.00

11.00 - 15.00

3.00 - 4.00

0.10 - 0.22

SS-321

0.08

2.00

0.045

0.030

0.75

17.00 - 19.00

9.00 - 12.00

SS-347

0.08

2.00

0.045

0.030

0.75

17.00 - 19.00

9.00 - 13.00

SS-409

0.030

1.00

0.040

0.020

1.00

10.50 - 11.75

0.50 max

0.030

Ti=6X(C+N) Min., 0.75 Max.

SS-409RC

0.02

1.00

0.040

0.030

1.00

10.50 - 11.75

0.50 max

0.020

Ti=6X C Min., 0.75 Max.

SS-409M

0.03

0.8 - 1.5

0.03

0.030

1.00

10.80 - 12.50

1.50 max

0.030

Ti=0.75 Max.

SS-410

0.15

1.0

0.040

0.030

1.00

11.50 - 13.50

0.75 max

SS-410S

0.08

1.00

0.040

0.030

1.00

11.50 - 13.50

0.60 max

SS-405

0.08

1.00

0.04

0.030

1.00

11.50 - 14.50

0.60

SS-430

0.12

1.00

0.04

0.030

1.00

16.00 - 18.00

0.75 max

SS-430Ti

0.030

1.00

0.04

0.030

1.00

16.00 - 19.00

SS-436

0.12

1.00

0.040

0.030

1.00

16.00 - 18.00

SS-420

0.15 min

1.00

0.040

0.030

1.00

12.00 - 14.00

0.10

Cu

Others

Ti=5X(C+N) Min., 0.70Max.

Ti=5X(C+N) Min., 0.70Max.

Cb=10XC Min., 1.00 Max.

Al=0.10-0.30

Ti =0.10-1.0

0.75 - 1.25

0.75 max

Cb=5X C Min., 0.80max

Mo=0.50 Max.

You might also like

- 6113Document7 pages6113Kanishka AhirwarNo ratings yet

- Rogowski CoilDocument13 pagesRogowski CoilKanishka AhirwarNo ratings yet

- Pu SystemDocument3 pagesPu SystemKanishka AhirwarNo ratings yet

- Vai - ms4 - 1cont Effect of Alloying ElementsDocument2 pagesVai - ms4 - 1cont Effect of Alloying ElementsKanishka AhirwarNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- GC120 Outline Rev SGDocument2 pagesGC120 Outline Rev SGsong perezNo ratings yet

- Curriculum Vitae: Dr.N.PRABHU, M.SC., M.Phil, PH.DDocument6 pagesCurriculum Vitae: Dr.N.PRABHU, M.SC., M.Phil, PH.DPavanNo ratings yet

- Adjustable Juice Groove Jig: Step 1: Jig Base and Bit DistanceDocument5 pagesAdjustable Juice Groove Jig: Step 1: Jig Base and Bit DistanceRod HyattNo ratings yet

- Chapter 14 - Storm and Sanitary Analysis PDFDocument41 pagesChapter 14 - Storm and Sanitary Analysis PDFdobridorinNo ratings yet

- Grasses Their Use in BuildingDocument8 pagesGrasses Their Use in BuildingpitufitoNo ratings yet

- Dynamic Arrays With The Arraylist Class Chapter Xii TopicsDocument38 pagesDynamic Arrays With The Arraylist Class Chapter Xii TopicsRocket FireNo ratings yet

- Pages From 0625 - w15 - QP - 33-06Document2 pagesPages From 0625 - w15 - QP - 33-06lelon ongNo ratings yet

- OE Spec MTU16V4000DS2250 3F FC 50Hz 1 14Document6 pagesOE Spec MTU16V4000DS2250 3F FC 50Hz 1 14YasirSwatiNo ratings yet

- Machining Processes Used To Produce Round Shapes: Turning and Hole MakingDocument38 pagesMachining Processes Used To Produce Round Shapes: Turning and Hole MakingCh TalhaNo ratings yet

- TPM Manual Quality - HozenDocument50 pagesTPM Manual Quality - Hozenmagudeesh100% (1)

- Cutting Temperature - Causes - Effects - Estimation (Assessment) & ControlDocument14 pagesCutting Temperature - Causes - Effects - Estimation (Assessment) & ControlvelladuraiNo ratings yet

- Lab 3 SST 4303Document5 pagesLab 3 SST 4303Muazrul MangsorNo ratings yet

- Chapter 1 Introduction To Green BuildingsDocument19 pagesChapter 1 Introduction To Green BuildingsSunil BeheraNo ratings yet

- EEC 319 Engineer in The Society DocumentDocument3 pagesEEC 319 Engineer in The Society Documentgodspower odior100% (1)

- Fabshield Offshore 71ni-1Document2 pagesFabshield Offshore 71ni-1Anonymous ejnktktkY7No ratings yet

- Kuokuang Petrochemicals Executive SummaryDocument40 pagesKuokuang Petrochemicals Executive SummaryKhoh Kai ShengNo ratings yet

- Quest CCS ProjectDocument10 pagesQuest CCS ProjecttruehemingwayNo ratings yet

- Multi Spindl Drilling MachineDocument38 pagesMulti Spindl Drilling MachineBoopathi KalaiNo ratings yet

- A Interview QuestionsDocument363 pagesA Interview QuestionsJaishankar RenganathanNo ratings yet

- Sigma Marine Coatings Manual - Part44Document2 pagesSigma Marine Coatings Manual - Part44EngTamerNo ratings yet

- Nirma University Institute of Technology B.Tech. in Mechanical Engineering Semester IVDocument2 pagesNirma University Institute of Technology B.Tech. in Mechanical Engineering Semester IVKartik aminNo ratings yet

- Body of Knowledge PDFDocument1 pageBody of Knowledge PDFAda RamirezNo ratings yet

- AAAC Guideline For Apartment and Townhouse Acoustic Rating 2010Document10 pagesAAAC Guideline For Apartment and Townhouse Acoustic Rating 2010Benjamín AlainNo ratings yet

- Lab 2Document8 pagesLab 2Hamid SaeedNo ratings yet

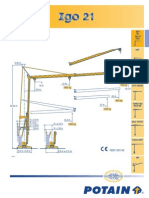

- Potain Igo 21 PDFDocument4 pagesPotain Igo 21 PDFMarco CruzNo ratings yet

- f77 f55 User ManualDocument36 pagesf77 f55 User ManualGabi GabrielNo ratings yet

- MRT PrjectDocument59 pagesMRT PrjectFahrul 2394No ratings yet

- Module 3 Density Altitude ExperimentDocument3 pagesModule 3 Density Altitude ExperimentIvan100% (1)

- 3 Esrtos IntroDocument8 pages3 Esrtos IntroVijayaraghavan VNo ratings yet

- Repair Kit Hitachi PlasmaDocument4 pagesRepair Kit Hitachi Plasmacolman123456789100% (1)