Professional Documents

Culture Documents

Weld Metal Cost Calculator 3

Uploaded by

Naresh TammineediOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Weld Metal Cost Calculator 3

Uploaded by

Naresh TammineediCopyright:

Available Formats

Handbook - Calculations

Page 1 of 1

Covered Electrodes

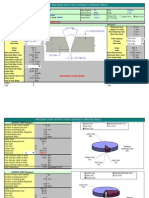

ESAB Weld Metal Cost Worksheet

Prepared For: Customer Name (1) Proposed Method Cost Calculation Formulas for Calculating Cost per Pound Deposited Weld Metal Dual Shield 7100 Ultra (E71T-1) 1/16" (1.6 mm) @ 300 Amps (4) = $45.00 10.2 X 0.45 (4) Electrode Cost/lb Deposition Efficiency (3) Gas Flow Rate (Cu ft/hr) X Gas Cost/Cu ft. Deposition Rate (lbs/hr) = 1.78 0.87 (4) = 40 X 0.02 = 0.8 10.2 = = = $45.00 4.59 (9) = = (5) $9.80 (4) $45.00 = 5.4 X 0.3 = (4) 0.85 0.64 2" (50mm) stub (4) 0 X 0 = 0 5.4 = = $45.00 1.62 = Date: (2) Present Method Cost Calculation E7018 3/16" (4.8 mm) @250 Amps (6) $27.78 Result (Cost Reduction) Cost Increase (5-6) ($17.98)

Stainless Steel Products

Solid Wire & Rod Products ESAB TIG & MIG Wires Cored Wire Products Submerged Arc Products Hardsurfacing Products

Labor & Overhead Labor & = Cost/Hr Overhead Deposition XOperating Rate Factor (3)

(3)

(5) 2.05

(6) 1.33

(5-6) 0.72

Electrode

(5) 0.08

(6) 0

(5-6) 0.08

Gas

Sum of the Above

Total Variable Cost/lb Deposited Weld Metal

(7) = $11.93

Total Variable Cost/lb Deposited Weld Metal

(8) = $29.11

(7-8) ($17.18) Total

Pounds of Weld Metal and Welder Man Hours Required to Amortize Equipment Cost Equipment Cost Power Supply Wire Feeder Gun & Accessories Equipment Cost in Dollars Savings/lb $2,900 $2,900 $17.18 Pounds of Weld Metal Deposition Factor Required to Amortize Cost (9) = 168.8 4.59 = Welder Man Hours Required to Amortize Cost 37 Hours

Filler Metal Consumption StubLoss Correction

Total

Calculations

Electrode/Wire Consumption

Filler Metals ASTM Steels

Weld Metal Cost Worksheet Weight/Foot Weld Metal Weight/Meter Weld Metal

Conversion Tables

http://www.esabna.com/EUWeb/FM_handbook/577fm8_8.htm

8/23/2011

You might also like

- Weld Cost CalculationDocument27 pagesWeld Cost Calculation-Abdul Khodir Van Java-100% (7)

- Productivity and EcononyDocument69 pagesProductivity and EcononyVijayan MunuswamyNo ratings yet

- Welding Prcesses Estimation RecordDocument5 pagesWelding Prcesses Estimation RecorddineshshankarNo ratings yet

- Determining The Cost of WeldingDocument22 pagesDetermining The Cost of WeldingSanjay J NNo ratings yet

- Estimation of Welding CostDocument41 pagesEstimation of Welding CostAnkur2592% (13)

- Welding Cost Estimation For 12 Joints in 8 NPS Sch. 80Document1 pageWelding Cost Estimation For 12 Joints in 8 NPS Sch. 80WeldPulse100% (2)

- Weld Cost Calc XL1.3.2mmDocument3 pagesWeld Cost Calc XL1.3.2mmVipin JoseNo ratings yet

- AWSPipeWeld - American Welding SocietyDocument2 pagesAWSPipeWeld - American Welding Societybarukomkss100% (1)

- 4.2. Consumable Consumption and Welding Time 4.2.1 Calculation of Electrode ConsumptionDocument9 pages4.2. Consumable Consumption and Welding Time 4.2.1 Calculation of Electrode ConsumptionNejat Ababay50% (2)

- Weld CostsDocument2 pagesWeld CostsJina Chandran100% (1)

- Weld Consumable Calculator ComDocument7 pagesWeld Consumable Calculator Comchetan85No ratings yet

- Welding Cost Estimation For 12 Joints in 8 NPS SCH 80 PDFDocument1 pageWelding Cost Estimation For 12 Joints in 8 NPS SCH 80 PDFAnonymous VRspXsmNo ratings yet

- Weld Cost Calc XLDocument63 pagesWeld Cost Calc XLRobert WhitakerNo ratings yet

- Welding Cost Estimator PubDocument8 pagesWelding Cost Estimator Pubrockufool100% (4)

- Welding Economy and ProductivityDocument29 pagesWelding Economy and Productivitykmas1612100% (4)

- Electrode CalculationDocument2 pagesElectrode Calculationkoyahassan100% (10)

- A Guide To Estimating The Consumption of Welding Consumables-NADocument1 pageA Guide To Estimating The Consumption of Welding Consumables-NAManuel Antonio Santos VargasNo ratings yet

- How To Calculate Filler Metal ConsumptionDocument3 pagesHow To Calculate Filler Metal ConsumptionASHIL PRABHAKAR100% (2)

- How To Calculate MIG Welding CostDocument5 pagesHow To Calculate MIG Welding CostTiago FerreiraNo ratings yet

- Weld Cost CalculationDocument15 pagesWeld Cost CalculationMustafa KaramürselNo ratings yet

- Electrode CalculationDocument2 pagesElectrode CalculationTejas PatelNo ratings yet

- Weld WeightDocument10 pagesWeld WeightDivyesh PatelNo ratings yet

- Pipeline Unit Cost Estimator May-08 PDFDocument1 pagePipeline Unit Cost Estimator May-08 PDFGeorge DeriNo ratings yet

- Determining The Cost of WeldingDocument7 pagesDetermining The Cost of WeldingGilbertoUGO0% (1)

- Weld Consumable CalculatorDocument7 pagesWeld Consumable Calculatorjappozander86% (7)

- How To Estimate Pipe Welding - EhowDocument2 pagesHow To Estimate Pipe Welding - EhowKalai Kumar100% (3)

- Double V Weld CalculationDocument8 pagesDouble V Weld CalculationHgagselim SelimNo ratings yet

- Introduction To Cost EstimatingDocument22 pagesIntroduction To Cost EstimatingArwa HusseinNo ratings yet

- Reconciliation of Welding ConsumablesDocument24 pagesReconciliation of Welding ConsumablesHema Nandh100% (1)

- Thumb RuleDocument27 pagesThumb Ruleavinashudupa67% (6)

- Weld Deposition DataDocument5 pagesWeld Deposition Datachetan85100% (4)

- Welding CalculationsDocument14 pagesWelding Calculationsjitulpatil100% (6)

- Reconcilation of Welding Consumable and Associated Consumable For Piping and StructureDocument44 pagesReconcilation of Welding Consumable and Associated Consumable For Piping and StructureRakesh Ranjan50% (2)

- Butt welding deposit and wire calculations for CS vesselDocument2 pagesButt welding deposit and wire calculations for CS vesselAsebaho Badr100% (1)

- 101.lean - Welds Cost Calculator Customer Welding Position: HorizontalDocument4 pages101.lean - Welds Cost Calculator Customer Welding Position: HorizontalSamNo ratings yet

- Project Staffing and Cost BreakupDocument33 pagesProject Staffing and Cost BreakupVinayak PujariNo ratings yet

- CS Pipes Installation CostDocument12 pagesCS Pipes Installation Costrajkamal_e100% (1)

- Demo Weld Cost Calc XL-UnprotectedDocument10 pagesDemo Weld Cost Calc XL-UnprotectedA R0% (1)

- Estimating WorksheetDocument22 pagesEstimating WorksheetFlashfire GpqNo ratings yet

- Estimates For Epcc/ Epcm SkidsDocument3 pagesEstimates For Epcc/ Epcm SkidsshrieersNo ratings yet

- Welding CalculatorDocument10 pagesWelding Calculatorneel0% (2)

- Demo Weld Cost Calc XL (Recovered)Document9 pagesDemo Weld Cost Calc XL (Recovered)Bhagyesh B. MaskeNo ratings yet

- Electrode CalculationDocument2 pagesElectrode CalculationKenshin HimuraNo ratings yet

- Structural Steel Works Man-HoursDocument2 pagesStructural Steel Works Man-HoursRenny DevassyNo ratings yet

- Technical Calculation and Estimator's Man Hour Manual - Marko Bulic's 20031Document107 pagesTechnical Calculation and Estimator's Man Hour Manual - Marko Bulic's 20031Rezza Aditya47% (17)

- Pipe DataDocument1 pagePipe Dataakhilsyam21No ratings yet

- Weld CalculatorDocument6 pagesWeld Calculatorshahid khanNo ratings yet

- Cs Pipe Fab Amp Erect CostsDocument6 pagesCs Pipe Fab Amp Erect CostsBudi SantonyNo ratings yet

- Miller RMDDocument4 pagesMiller RMDRony Lesbt100% (1)

- ESAB Weld Metal Cost Worksheet: Labor & Ov ErheadDocument1 pageESAB Weld Metal Cost Worksheet: Labor & Ov ErheadsachinshirnathNo ratings yet

- Handbook - Calculations0Document10 pagesHandbook - Calculations0paimpillyNo ratings yet

- ESAB Weld Metal Cost Worksheet: Labor & OverheadDocument1 pageESAB Weld Metal Cost Worksheet: Labor & OverheadSmith SivaNo ratings yet

- How To Calculate Total LaborDocument2 pagesHow To Calculate Total LaborAnonymous cekPJylABoNo ratings yet

- ESAB Calculating Filler Metal Consumption PDFDocument10 pagesESAB Calculating Filler Metal Consumption PDFRuben Cruz S0% (2)

- CIGWELD DEPOSITION DATADocument7 pagesCIGWELD DEPOSITION DATAgitaNo ratings yet

- FCAW For COR TEN Structure: Technical and Economical ConsiderationsDocument9 pagesFCAW For COR TEN Structure: Technical and Economical ConsiderationsDan PopaNo ratings yet

- Weld Cost1Document25 pagesWeld Cost1Denis Hinojosa ZeballosNo ratings yet

- The Economics of HardfacingDocument6 pagesThe Economics of Hardfacingemad sabri100% (1)

- Weld Cost CalculationDocument30 pagesWeld Cost CalculationDenial BasanovicNo ratings yet

- Costing of Joining Methods - Arc Welding CostsDocument27 pagesCosting of Joining Methods - Arc Welding CostsTasmanijskaNemaNo ratings yet