Professional Documents

Culture Documents

5613 1 1

Uploaded by

ashuvijayOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

5613 1 1

Uploaded by

ashuvijayCopyright:

Available Formats

IS : 5613 ( Part l/Set

1 ) - 1965

Indian Standard

( Reaffirmed 1996 )

CODE OF PRACTICE FOR DESIGN, INSTALLATION AND MAlNTEKG,lNC-E OF OVERH.EAD POWER LINES

PART 1 LINES UP TO AND INCLUDING Section ( 1 Design 11 kV

First Revision )

First Reprint OCTOBER 1996

UDC 621.315.17.027.6

: 006.76

0 Copyright

1~986

BUREAU

MANAK

OF INDIAN STANDARDS

NEW DELHI 110002

BHAVAN, 9 BAHADUR SHAH ZAFAR MARG

Gr 7

June 1986

IS I 5613 ( Part l/See 1) - 1985

Indian Standard

CODE OF PRACTICE FOR DESIGN, INSTALLATION AND MAINTENANCE OF OVERHEAD POWER LINES

PART 1 LINES UP TO AND INCLUDING Section 1 ( Design 11 kV

First Revision)

Re~rrssnting Rural Electrification Corporation Ltd, New Delhi

Conductors and Accessories for Overhead Lines Sectional Committee, ETDC 60

Chairman SHRI R. D. JAIN Members Sam G. L. DUA ( Affernate to Shri R. D. Jain ) ADDITIONAL GENERAL MANA~HI: Indian Posts and Telegraphs Department, New Delhi (IT) DIVIWONAL ENOINEHRf TELR 1 C/P ( Alttrnate ) SHRI M. K. AHUJA Delhi Electric Supply Undertaking, New Delhi SERI V. P. ANAND Electrical Manufacturing Co Ltd, Calcutta Ssnr S. C. MALHOTRA ( Allarnate ) SHRI R. S. AR~HA Directorate General of Supplies and Disposals, New Delhi SHRI J. S. Pnssr ( Alfernale ) SHRI R. T. CHAR1 Tag Corporatjon, Madras SHRI A. ARUNEUYAR ( Alternate ) SHHI R. S. CIIAWLA Industrial Fasteners & Gujarat Pvt Ltd, Vadodara SHRI D. P. MEIII) ( Al&~tate ) C a I E B ENQINEHR ( THAININQ & Maharashtra State Electricity Board, Bombay PLANNINo ) SUPERINTENDINBEWINEEH ( 400 kV ) ( Alternate I ) SUPERINTENDXN~ EN~INEEH ( 200 kV ) ( Alfcrnate II ) ( Continued on page 2 ) @ Copyright 1986 BUREAU OF INDIAN STANDARDS This publication is protected under the Indian Copyright Act ( XIV of 1957 ) and reproduction in whole or in part by any means except with written permission of the publisher shall be deemed to be an infringement of copyright under the said Act.

IS : 5613 ( Part l/Set 1) - 1985

( Conlinucdfrom pugc 1 ) Members Rt@cscnting Special Steels Ltd, Bangalore SHRI M. R. Dooron SHRI v. c. TRrCEUlr ( Allcrnalc) Central Power Research Institute, Bangalore DIREC,~~R Snrtr T. V. GOPALAN ( Alternate ) Central Electricity Authority ( Transmission DIRECTOIL( TRANSMISSION ) Directorate ), New Delhi DEPUTY DIRECTOR ( TRANSYISSI~N ) ( Alternate ) DIRECTOR ( TI ), RDSO Ministry of Railways JOINT DIRECTOH. TI )-I ( Affsrnate ) ( Cable and Conductor Manufacturers Association SHRI M. K. JUNJEIJNWALA of India, New Delhi SHRI T. S. PADMANABEAN ( Alternate ) SHRI H. C. KAUSHIK Haryana State Electricity Board, Chandigarh U. P. State Electricity Board, Lucknow SERI K. B. MATHU~ SHBI V. II. SINQH ( Altcrnats ) SHRI B. MUKUOPADIIYAY National Test House, Calcutta SHRI U. S. V~anra (Alternate ) SHRI N. D. PARIKH KEC International Ltd. Bombay SERI S. D. DAND ( Altsrnats ) SHRI C. K. RAOUNATH Tamil Nadu Electricitv , Board. Madras SHRI M. U. K. MENON ( Alternate ) Power Corporation Ltd, National Thermal SHRI A. K. RAZACRANDRA New Delhi SRRI S S. RAO ( Alternate ) SAUI R. P. SACHDEVA Bhakra Beas Management Board, Chandigarh SHIZI H. S. C~OPILA ( Alternate ) National Insulated Cable Co of India Ltd, SHRI S. N. SEN~UPTA Calcutta SEIRI B. GANCJULY ( Alfernate ) SIIRI V. K. SRARMA National Hydro-Electric Power Corporation Ltd, New Delhi SHRI MAHENDI~A KUMAR ( Alternate ) Electro-Metal Industries, Bombay SHIII R. D. SHETIi SHRI G. J. DEVASSYKUTTY ( Alternate ) Sun1 T. SINon Indian Cable Co Ltd, Calcutta SBRI S. K. GLJPTA ( Atfernofe ) SRHJ D. SIVASUBRAMANIAM Aluminium Industries Ltd, Kundara SJ!RI K. M. JACOB ( Alterttate ) PROF M. VENU~OPAL Indian Institute of Technology, Madras PROF Y. NARAYANA RAO r Alternate 1 Tata Hydro.Electric Supply Co Ltd, Bombay SHRI WADJXWA SHRI P. P. BEISEY ( Alternate ) SHRI S. P. SACBDEV, Director General, IS1 ( Ex-o#cio Member ) Director ( Elec tech ) Secretary SIiF3 SUKH Bm SINQR Deputy Director (Elec tech ), IS1

ES : 5613 ( Part

l/Set 1) - !965

Indian Standard

CODE OF PRACTICE FOR DESIGN, INSTALLATION AND MAINTENANCE OF OVERHEAD POWER LINES

PART 1 LINES UP TO AND INCLUDING Section 1 Design ) 11 kV

( First Revision

0. FOREWORD

0.1 This Indian Standard ( Part l/Set 1 ) ( First Revision ) was adopted by the Indian Standards Institution on 22 January 1985, after the draft finalized by the Conductors and Acctsaories for Overhead Lines Sectional Committee had been approved by the Electrotechnical Division Council. 0.2 The design, installation and maintenance practice of overhead power lines varies widely from state to state and in various orgamzations. This variation leads to uneconomic designs and higher installation and maintenance cost. The necessity was, therefore, felt to prepare a standard on this subject which would result in unification of designs of overhead lines and also in savings in cost. 0.3 This standard was first published in 1970. The revision of this standard has been undertaken to include the developments that have taken place since the last publication of this standard. 0.4 This standard Part Part Part is being prepared in the following 11 kV, 220 kV, and three parts:

1 Lines up to and including 2 Lines above

11 kV and up to and including

3 Lines above 220 kV. 1 covers of over-

Each part has been further divided in two sections. Section design aspects and Section 2 covers installation and maintenance head power lines. 3

IS t 5613 ( Part l/Sea

1) - 1985

0.5 In the preparation of this standard, considerable assistance has been derived from Rural Line Standards, Construction Manual, prepared by Rural Electrification Corporation Ltd, New Delhi. 0.6 For the purpose of deciding whether standard is complied with, the final value, ing the result of a test or analysis shall be The number of significant IS : 2-1960*. off value should be the same as that standard. a particular requirement of this observed or calculated, expressrounded off in accordance with places retained in the rounded of the specified value in this

1. SCOPE 1.1 This standard ( Part l/Set up to and including 11 kV. 1.2 Protection code. and control 1 ) covers design of overhead power power lines in this

of overhead

lines is not covered

2. TERMINOLOGY 2.1 For the purpose of this code, 32 ) - 197 It shall apply. 3. GENERAL 3.1 Conformity with Indian Electricity Rules and Other RegulaAl1 overhead power lines shall comply with the latest provisions tions of Indian Electricity Rules and with any other regulations that may be applicable. The Rules No. 29, 61, 74 to 93 of the Indian Electricity Rules, 1956 are particularly applicable. 3.1.1 It is desirable that the local authorities concerned in the administration of the rules and regulationsrelating to choice of route, etc, be consulted in regard to the rules and regulations that may be applicable. Highways department and aerodrome authorities should also be consulted wherever the power lines run near or across the area under their jurisidiction. 3.1.2 All overhead power lines which cross railway tracks shall be laid in accordance with the rules stipulated in regulations for electrical crossing of railway track framed by Railway Board. *Rules for rounding off the numerical values ( r&cd ). tElectrotechnica1 vocabulary: Part 32 Ovrrhcad transmission and distribution of electrical energy. the definitions given in IS : 1885 ( Part

3.2 Before deciding the basic parameters of the line, information regarding the total load, including future extensions, point of supply or area to be covered, should be exchanged between the designer and distribution authorities. On the basis of this load and the length of the line the designer should predict the most economic system of voltage and conductor size. 3.3 For economical and practical reasons almost all present day power stations in the country generate electrical power at three-phase 50 Hz ac, while the transmission and distribution of power is done on 3-phase S-wire at high voltages and J-phase 4-wire for voltages up to 650 volts. 3.4 The transmission and distribution voltages and are given in IS : 585-1962*. have been standardized

3.5 Lines may be broadly classified as feeders and distributors. With feeders, the main consideration is economy and with distributors, it is the voltage drop. 3.6 Lines supplying mixed load are generally designed for a Rower faetor of 0.8. lagging. 4. CHOICE OF VOLTAGE

4.1 The cost of the lines is one of the deciding factors in the choice of voltage. The general rule is that the voltage of the line is taken as 0.6 kV per km of the length of the line. For the purpose of this code, however, the voltage is limited to 11 kV and there is vttry little choice to be made; 3 3 kV and 6.6 kV lines are not very common these days except for the extensions of already existing lines or within industrial premises. The most common voltage for short distance lines is 11 kV while 415/240 V is used for distribution to consumers. Si CHOICE OF ROUTE

5.1 The proposed route of the line should be the shortest practicable distance. The following areas should be avoided as far as possible: a) Rough and difficult country, b) Urban development, c) High amenity area, d) Restricted access for transport vehicles, e) Abrupt changes in line route, f) Way-leave problems,

( revised).

+SpeciKcation voltagesand frequencyfor ac transmission distribution for and system,

IS I 5613 ( Pirt l/Set 1 ) - 1985 g) Difficdt

h) Natural j) Proximity crossings, hazards, and to aerodromes. lines should run away from the buildings containing

5.1.1 Overhead explosives. 6. CONDUCTORS

6.1 Type of Line Conductors

- There is a good _range of conductors __. available these days for carrying power through ~overhead lines. The most commonly used conductors for distribution of power up to 11 kV are steel reinforced aluminium conductors ( ACSR ), all aluminium conductors, galvanized steel conductors and copper conductors.

NOTE- Due to the shnrtage of copper and zinc in the country, it is recommended not to use copper and galvanized steel conductors. Attention is drawn to the use of aluminized steel reinforced aluminium conductors and aluminium alloy stranded conductors. Requirements for these types of conductors have also been covered in the appropriate parts of IS : 398..

6.1.1 Steel Reinforced Aluminium Conductors ( ACSR ) - These conductors are made up of a galvanized steel core surrounded by stranded aluminium wires. The principal advantages of these conductors are high tensile strength, light weight giving small sags, longer spans and much higher corona limit due to bigger diameters. The principal disadvantage is that larger diameters increase the pole loading due to windage necessitating heavier poles. Their ultimate strength ranges from 125 percent for small size to about 180 percent for large sizes as compared with 100 percent of copper.

6.1.1.1 In coastal, industrial and other corrosive preferable to coat the steel core with suitable corrosion to mitigate galvanic action and galvanic corrosion. atmospheres it is preventive grease

6.1.2 All Aluminium Conductors - These are stranded conductors -made of aluminium wires. These conductors are strong, durable, light weight and possess high conductivity. The ~average ultimate strength of stranded aluminium is about 65 percent of stranded copper. ~They need special care in handling. All aluminium conductors cannot take much tension as compared to ACSR conductors and, therefore, the span length gets restricted.

l Specification for aluminium conductors for overhead transmission DurDoses:

Part Part Part Part 1 Aluminium 2 Aluminium 3 Aluminium 4 Aluminium

stranded conductors ( second conductors, galvanized steel conductors, aluminized steel alloy stranded conductors type ) ( second revision ) .

reoision ). r L reinforced ( second revision ). reinforced ( second reuision ). ( aluminium-magesium-silicon

IS I 5613 ( Part l/&c

I ) - 1985

6.1;3 Galvanized Steel Conductors These are stranded conductors made of galvanized steel wires. The principal disadvantage with these conductors is their relatively short life, which is about 16 years in rural areas and about 9 years in industrial areas and during which period iron insulator binders require frequent renewal owing to rapid corrosion. They are easy to handle, have greater strength and are cheaper.

6.1.4 Copper Conductors - Copper conductors are the oldest and most commonly us~ed overhead line conductors. These are the basis of comparison for all other types which are rated according to their copper equivalent current carrying capacity. The principal advantages are high conductivity, long life, simplicity of jointing, less windage effect due to small diameters and thus lighter poles and high scrap value. The principal disadvantages are low line tensions and hence large sags, short spans and greater number of poles. 6.1.5 Physical and electrical properties of ACSR and all aluminium conductors and copper conductors shall be in accordance with appropriate parts of IS : 398* and IS : 282-19827 respectively. 6.2 Earthing Conductors - There are two methods of earthing associated with overhead lines for reducing the damage to life and plant in case the protection system fails to operate or in case of lightning hazards. They are: a) Continuous overhead earth wires; and b) Individual earthing of each pole. 6.2.1 Continuous overhead earth wire is more commonly used and its main functions are : a) to form a continuous and low resistance return path for earth leakage currents necessary for the operation of protective systems, and b) to reduce the effects of induced voltage in adjacent communication circuits under fault conditions. 6.2.1.1 Individual earthing of poles does not provide a continuous return path for earth currents although it reduces the effects of induced voltage in adjacent communication circuits under fault conditions. 6.2.2 Galvanized steel wires are very commonly used as earthing conductors. The size of the wire depends upon the span and the expected fault current.

for aluminium conductors for overhead transmission purposes: Aluminium stranded conductors ( second revision ). Aluminium conductors, galvanized steel reinforced (secona revision ). Aluminium conductors, aluminized steel reinforced ( sscond revision ). Aluminium alloy stranded conductors ( aluminium-magnesium-silicon type ) ( second r&ion ). tSpecification for hard-drawn copper conductors for overhad ~powcr transmission. *Specification Part I Part 2 Part 3 Part 4

( srcond

revision

).

18 : 5613 ( Part

l/See 1 ) - 1985

6.2.3 For earthing of overhead power lines, reference IS : 3043-1966*, particularly to I8 of this code.

is also invited

to

The physical and electrical properties of 6.3 Choice of Conductors different conductors shall be in accordance with relevant Indian Standards. All conductors shall have a breaking strength of not less than 350 kg. However, for low voltage lines with spans less than 15 m and installed either on owners or consumers premises, conductors with breaking strength of not less than 140 kg may bemused. 6.3.1 The choice of the size of conductors upon the following: a) b) c) d) Power to be transmitted, Length of the line, Line voltage, Permissible voltage regulation, strength. for a line mainly depends

and

e) Mechanical

6.3.2 In accordance with the Indian Electricity Rules voltage variation for low voltage lines should not be more than f 6 percent and for high voltage lines should not bc more than + 6 percent to --9 percent. 6.3.3 The kW-km that can be transmitted at a particular particular type of conductors are given in Tables 1 and 2. 6.3.4 Power loss and voltage the following formulae: 6.3.4.1 Fewer loss W= where power loss per km per conductor in watts, Z - line current in amperes, and R = ac resistance per km per conductor of the line in ohms. 6.3.4.2

Voltage drop W =

voltage

with by

drop of a short line may be calculated

IR

a) For single-phase

lines

UP;2(IRcoqb+IXsin+),and b) For three-phase lines U 3 43 ( ZR cos+ + IX sin+ ) -*Code of practice for earthing.

S

IS : 5613 ( Part l/Set 1 ) - 1985

TABLE 1 kW-km FOR 415/240 VOLTS LINES WITH 5 PERCENT VOLTAGE REGULATION ( CONDUCTOR MATERIAL - ALL ALUMINIUM AND COPPER ) (Clause 6.3.3)

kW- km

AT

80 PERCENT POWER FACTOR NOR VARIOUS CON~IQURATIONS

AREA OB CONDUCTORS mm +-200 mm 200 mm 200 mm f +-

300 mm ..j,,,i 300 mm 300 mm 7 -mm

. L50

mm

. i..oL-600-L600~

mm

.

mm

;,,,imm

~&~oJi+L~oJl+~~o~

mm mm

mm

mm

kW-km AT 100 PERCENTPOWER FACTOR

EQUIVALENT SPACIHQ 255 mm _544C E: 113 *$ I 16 g 2 1 zi ,25 -t 130 r45 z I 14 & 16 40 8 1 25 20 I 4.511 5491 6378 8238 9,711 2992 4.469 6.124 8.348 60C 4437 5401 6.275 8.108 9559 2940 4.397 6029 8225 65.6% 4333 5.316 6177 7992 9.434 2.890 4.326 5935 8.111

385 mm EQUIVALENT SPACING

EQUIVALENT SPACING 470 mm

EQUIVALENT SPACING 575 mm

EQ~IVA~;~PACINQ

54.4% 4463 5.420 6281 8077 9,492 2 969 4422 6035 8185

60C 4.389 5.333 6186 7953 9.355 2919 4.350 5.943 8068

656C 4.316 5248 6087 7812 9226 2.871 4281 5852 7958

544C 4439 5383 6233 7.998 9.381 2960 4398 5.992 8103

60C 4366 5298 6135 7.876 9.249 2.910 4328 5901 7.987

656C 4295 5214 6.040 7.767 9123 2860 4258 5.810 7.879

544C 4.416 5351 6188 7.924 9281 2948 4676 5948 8.027

60C 4344 5.266 6991 7.803 9151 2898 4307 5.860 7.913

65.6% 42i4 5 184 5998 7.697 9028 2.8;2 4337 5769 7.807

544C 4384 5.303 &I24 7.820 9136 2934 4.344 5.889 7.920 10186

60C 4.313 5219 6029 7702 9.011 2.886 4274 5802 7.809 10.057

656C 4242 5.139 5.938 7599 8892 2.837 4208 5715 7706 9.933

54.4% 5.164 6463 7.696

60C 5066 6339 7.546

656C 4971 6.220 7.405

10.493 10.284 10099 12907 12659 12423 3299 5160 7.438 3.238 5063 7.298 3.171 4.968 7.160

10865 10.659 10.467 15390 15.099 14.819

10.905 10.758 10,617

10626 10.486 10351

10488 10.353 10.221

10364 10.231 10103

IS 8 5613 ( Part l/&c 1 ) - 1985

TABLE 2 kW-km FOR 11 kV LINES WITH 125 PERCENT VOLTAGE ( CONDUCTOR MATERIAL - ACSR AND COPPER ( Clausr 6.3.3 ) REGULATION )

-kW-kM

AT 80 PEROENT POWXR FACTOR FOB Vnaroos COAFIOUBATI~N~

+-

SIZE Olf

CONDGCTOR + l-9$~-" $I

600mm

+r

kW-km AT 100 PERCENT POWER FACTOR

+Irnrn

I-lfnomo-4

EQUIVALENTSPACINQ

EQUIVALENT

SPACIZ~Q

810 mm _ 544C -p60C 65*6C 5&4%

1 145 mm 60C pp-

656C

544%

60C

ti56C

I

7 894 9571 11 148 13 989 166b 7 878 10 660 9 553 16341 9 662 12 128 14 592 19 520 24438 9 756 14 061 12 250 25 512 9 477 11 896 14 309 19 151 23 957 9571 13 798 12 014 24029 9 300 11 674 14 045 18 795 23517 9 394 13 538 11 793 23586

f-13 mmp d Z{ 41 16 mti

8 216 9 967 11618 14 634 17 336 -___ 8 193 11 944 103 9

8 082 9 809 11 436 14 426 17 093 8 068 10 788 9 939 16 827

7 952 9 659 11 269 14223 16 867 7 937 10 773 9 642 16 608

8 155 9 873 11 491 14 420 17054 8 130 10 982 9851 16 780

8 023 9 719 11 312 14 231 16 818 8 002 10 82 1 b 698 16 552

120mml , 25 mrh 130mm

[425 mm dsa * 0 %j 14.75 mm dia WI 16 mm* 135 mm*

17 062

18

IS I 5613 ( Part l/&c 1 ) - 1985

where U = .Z = voltage drop per km in volts, in amperes, per km per conductor and of the line in ohms. of the line in ohms, line current

R =

+ = X = 6.4 Spacing

ac resistance

reactance

angle of lag/lead in degrees,

per km per conductor

of Conductors

of choice and no

6.4.0 The

definite

configuration of conductors is a matter recommendations can be given in this code.

6.4.1 To have proper insulation clearance, in order to avoid trouble due to birds and to avoid conductors clashing due to wind, it is very essential that conductors in an overhead power line are adequately spaced. 6.4.2 There are no fixed rules for spacing arrangement of overhead line conductors. However, the following formula gives an economical spacing of conductors:

D =

where

500 + 18 U +

&

D =

U = L =

spacing

in mm, voltage in kV, and

phase-to-phase

span length in m.

7. SAG-TENSION for overhead line design, the general theory for sag-tension is based on the fact that if a flexible wire of uniform weight is suspended. at two points at the same level, it sags and assumes the shape of a catenary curve. For short spans normally adopted for transmission and distribution lines the catenary is very nearly a parabola and hence the sag is calculated by the following formula:

7.1 In practice,

where S= w= I= T E sag in m, weight of loaded conductor span length maximum in metres, working and in conductor in kg. tension 11 in kg per metre run,

18 : 5613 ( -Part l/&c 1 ) - 1985 7.1.1 For supports at diffeient which the maximum sag s which given by levels, the distance 1 of the point at occurs from taller or shorter support is

I =++$rnd

where 1 c hWI=

span length in metros, difference in level between the supports in metres, weight of loaded conductor in kg per metre run, and in kg. maximum working tension in conductor it is necessary

7.2 For calculating loading conditions: a) Maximum

sag and tension,

to consider two sets of and at maximum

wind pressure and minimum

temperature,

b) Still air condition with no ice on the conductors temperature in the region.

NOTE 1 - For the purposeof this code, weight of ice has not been taken into consideration. Where ice loading is encountered, it should be taken into account. The thickness of ice shbuld be taken based on local conditions. NOTE 2 - Guidance can be taken from IS : 875-1964. for design wind pressure for towers up to 30 m height. for reduction factor

7.2.1 The wind pressure maps and temperature and Fig. 2 respectively. 7.3 It is necessary above conditions. 7.3.1 Loading that loading

maps are given in Fig. 1 for both the

factors should be determined

factor for wind is given by: ql 2/ ws + WP

W

where

Ql =

w = w1=

loading factor, weight of unloaded conductor in kg per metre run, and wind load on conductor in kg/m.

safety of building

lGode of practice for structural

: Loading standards

( rroisrd ).

12

As in the Original Standard, this Page is Intentionally Left Blank

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Compressible Flow Presentation Compressible - Flow - Presentation - Chapter7Jane - Chapter7JaneDocument11 pagesCompressible Flow Presentation Compressible - Flow - Presentation - Chapter7Jane - Chapter7JaneAbbas MohajerNo ratings yet

- Exercise-1: Ans.: 5 MW, 360 MWH, 500 Mwh/DayDocument2 pagesExercise-1: Ans.: 5 MW, 360 MWH, 500 Mwh/DayAbreu Miguel Liliano LilianoNo ratings yet

- Physics II Problems PDFDocument1 pagePhysics II Problems PDFBOSS BOSSNo ratings yet

- Hakim-Phy-lesson-Chapter-2 Units and MeasurementDocument28 pagesHakim-Phy-lesson-Chapter-2 Units and MeasurementHakim Abbas Ali PhalasiyaNo ratings yet

- Single Phase Fully Controlled Bridge ConverterDocument6 pagesSingle Phase Fully Controlled Bridge ConverterBala Kumar100% (1)

- ANATEL Approves Electrical Safety RequirementsDocument12 pagesANATEL Approves Electrical Safety RequirementsGuilherme HenriqueNo ratings yet

- 14.kinetics of A Particle Work and EnergyDocument11 pages14.kinetics of A Particle Work and EnergyrodyNo ratings yet

- Therm o Disc 59T 66T Thermostat BulletinDocument7 pagesTherm o Disc 59T 66T Thermostat BulletinAlberto SanchezNo ratings yet

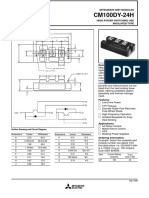

- Cm100dy 24hDocument4 pagesCm100dy 24hJulianoLuterek100% (1)

- Grid Energy Storage - WikipediaDocument27 pagesGrid Energy Storage - Wikipediapowew28978No ratings yet

- Physics Ideal Gases QUestionsDocument14 pagesPhysics Ideal Gases QUestionsjfdioajfdsNo ratings yet

- Power ElectronicsDocument7 pagesPower ElectronicsNarasimman DonNo ratings yet

- WEG WMO Wecm Electronically Commutated Motor Iec Market 50076406 Brochure English WebDocument12 pagesWEG WMO Wecm Electronically Commutated Motor Iec Market 50076406 Brochure English Weboliveira.fr3No ratings yet

- PC Lexan 104Document4 pagesPC Lexan 104countzeroaslNo ratings yet

- Chapter 4-Force VibrationDocument30 pagesChapter 4-Force VibrationAyub Abd RahmanNo ratings yet

- Prueba 2 Conceptos T RmicosDocument26 pagesPrueba 2 Conceptos T RmicosjosueNo ratings yet

- Amp Classe Ab 2w - Ts4871Document46 pagesAmp Classe Ab 2w - Ts4871Rodrigo BonfanteNo ratings yet

- Fiitjee Aits 2023 Megred Yash PatilDocument845 pagesFiitjee Aits 2023 Megred Yash PatilPRIYANSHU 22117110No ratings yet

- Problem Sheet 6,7Document1 pageProblem Sheet 6,7rohanNo ratings yet

- 1.1.1.4 Lab - Ohms LawDocument1 page1.1.1.4 Lab - Ohms LawDenis IvicNo ratings yet

- Circuit Breaker Switching Transients Causing Transformer FailuresDocument41 pagesCircuit Breaker Switching Transients Causing Transformer Failuresbrockwell496No ratings yet

- 213 Spring07 Relativity PDFDocument42 pages213 Spring07 Relativity PDFJohnConnerNo ratings yet

- Equilibrium of Bodies in Liquids Density and Relative DensityDocument16 pagesEquilibrium of Bodies in Liquids Density and Relative DensityAdegoke TofunmiNo ratings yet

- Display Devices LuminescenceDocument18 pagesDisplay Devices LuminescenceKush SharmaNo ratings yet

- 4MW ROOFTOP SOLAR PLANT TEST FORMDocument1 page4MW ROOFTOP SOLAR PLANT TEST FORMRhey NaturalNo ratings yet

- Maxwell's Equations Form Basis of Electromagnetic WavesDocument31 pagesMaxwell's Equations Form Basis of Electromagnetic WavesDenzel Ivan PalatinoNo ratings yet

- Dynamic, Absolute and Kinematic ViscosityDocument6 pagesDynamic, Absolute and Kinematic ViscosityLalo PalaciosNo ratings yet

- Midterm Exam - HydraulicsDocument1 pageMidterm Exam - HydraulicsGhiovani DayananNo ratings yet

- Compact Power Pack Type HC: 1. Design and General InformationDocument17 pagesCompact Power Pack Type HC: 1. Design and General InformationCesar MessiasNo ratings yet

- NCE1507AK: Enhancement Mode Power MOSFETDocument7 pagesNCE1507AK: Enhancement Mode Power MOSFETAdin Javier Rizo RamosNo ratings yet