Professional Documents

Culture Documents

Besmak Components PVT

Uploaded by

Sadham BabuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Besmak Components PVT

Uploaded by

Sadham BabuCopyright:

Available Formats

BESMAK COMPONENTS Pvt. Ltd.

AN ORGANIZATION STUDY ON DYNADIS BIOTECH INDIA PVT LTD By J.VIDHYA Roll no: 201011113 Registration number: 1065238

A PROJECT REPORT

Submitted to the

DEPARTMENT OF MANAGEMENT STUIDES in partial fulfillment of the requirements of

MASTER OF BUSINESS ADMINISTRATION

DEPARTMENT OF MANAGEMENT STUDIES RAJALAKSHMI ENGINEERING COLLEGE CHENNAI-602102

ANNA UNIVERSITY OF TECHNOLOGY

JUNE-2011

AN ORGANIZATION STUDY ON DYNADIS BIOTECH INDIA PVT LTD By J.VIDHYA Roll no: 201011113 Registration number: 1065238

A PROJECT REPORT

Submitted to the

DEPARTMENT OF MANAGEMENT STUIDES

in partial fulfillment of the requirements

of

MASTER OF BUSINESS ADMINISTRATION

DEPARTMENT OF MANAGEMENT STUDIES RAJALAKSHMI ENGINEERING COLLEGE CHENNAI-602102

ANNA UNIVERSITY OF THECHNOLOGY

JUNE-2011

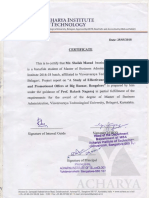

BONAFIDE CERTIFICATE

Certifies that the project report titled AN ORGANIZATION STUDY ON DYNADIS BIOTECH INDIA PVT LTD is the bonafide work of Ms.J.VIDHYA who carried out the work under my supervision. Certifies further that to the best of my knowledge the work reported here in does not form part of any other project report or dissertation on the basis of which a degree or a award was conferred on an earlier occasion on this or any other candidate.

Signature of the Guide Dept of Management Studies Rajalakshmi engineering college

Signature of the HOD Dept of Management Studies Rajalakshmi engineering college

DECLARATION

I J.VIDHYA hereby declare that the project work entitled AN ORGANIZATION STUDY ON DYNADIS BIOTECH INDIA PVT LTD submitted to the Anna University in partial fulfillment of the requirements for the degree in MASTER OF BUSINESS ADMINISTRATION is an authentic record of work carried out by me under the guidance of Mrs.S.GOMATHIE PRIYA Faculty, MBA Department, RAJALAKSHMI ENGINEERING COLLEGE, DR.JAGHAN MOHAN Of DYNADIS BIOTECH INDIA PVT LTM.

PLACE: CHENNAI DATE:

( J.VIDHYA )

ACKNOWLEDGEMENT I take the pleasure in conveying my gratefulness to all those who stood by my side for completing the project successfully. I extend my immense gratitude to our honorable chairpersonDr.(Mrs.)

ThangamMeganathan, M.A.,M.Phil., PhD. for her sincere endeavor in educating us in her premier institution. I thank our principal Dr.Renganarayan for providing all the required facilities for completing the project work. I would like to express my heartfull gratitude to our Head of the Department Mr.T.C.Thomas, who is responsible for molding my thinking to complete this project, I deem it as pleasure to take this opportunity to express my heartfelt thanks and profound gratitude to Mrs.GOMATHIfaculty guide, her whole hearted support and valuable guidance during the period of research. I wish to express my thanks to all our Department staffs, for their valuable suggestion during the period of my project work. I would like to place my thanks to DIRECTORMr.P.S.Pandyan, B.Tech., B.L.,MBA.,I.A.S (Retd), for allowing me to carry out the study and I also place my sincere thanks to DEAN Mr.S.Shankar,PGDM(IIM-C) for his keen involvement and constant

encouragement in the successful completion of the project work and express my heartiest thanks to DR.JAGHAN MOHAN Of DYNADIS BIOTECH INDIA PVT LTM. I take this opportunity to thank my parents, family members and friends, who have helped me to complete

this project by giving co-operation and encouragement towards the initialization development and the success of the project.

GUIDE: Mrs.Gomathi NAME: J.VIDHYA

TABLE OF CONTENTS

CHAPTER 1 2 3 4

TITLE INTRODUCTION INDUSTRIAL PROFILE COMPANY PROFILE NYTRACEUTICALS AND CAROTENOIDS 11

PAGE 8 9

13

5PRODUCT 6 7 8

16 ORGANIZATION STRUCTURE THE PROJECT LEARNING EXPERIENCE 31 18 19

REFERENCE

ABSTRACT

Organizational Functioning is an important factor for any Organization to achieve the desired goals and Objectives. This requires Co-ordination at all levels for smooth functioning. This report aims to understand the overview of the organization. The main purpose of doing the organization study was to study the various departments of the organization and understand their basic functions, their purpose, achievements and the mission and vision of the company and their progress towards that. It is very important to know the overall structure of an organization. The actual professionalism can be studied only through experience.

WHAT WE DO:

Equipped with State of the art tool room facilities including 3D model designing, supported by a team of highly skilled employee base for both designing and manufacture of tools, in India, we also have excellent mastery over the manufacturing of multi cavity injection moulded plastic components. We are an accredited company certified ISO/TS 16949 : 2002 and a leading supplier of Plastic Components of various types, material, specification and requirements to the automotive and non automotive sector globally. ABOUT COMPANY:

BESMAK COMPONENTS PVT LTD was incorporated in October 1994. The company is engaged in the manufacture of Plastic components, supporting the Automotive Wiring Harness Industry for all kinds of vehicles.

A team consisting of Technocrats, lead by LATE. C.N.HARI, Our founder Chairman and Managing Director, promoted this company as a captive unit to cater to Wiring harness Units, which inturn are ancillary facilities of all leading Vehicle Manufacturing Plants located globally. Infact, our components became an Import substitution to many CUSTOMERS for connector application in the automotive sector. The technocrats were dedicated team of Tool and Die engineers who had decades of experience behind them in the manufacture of automotive plastic components.

GROWTH Since its inception in 1994 with 15 CUSTOMERS, we at BESMAK currently cater to more than 50 regular customers worldwide.

FACILITIES BESMAK has rich experience in 3D model design and development capablities, tools for plastic mould manufacturing and injection moulding. We have the latest high precision CNC controlled machineries with the latest technology available and well experienced employees in the field of manufacturing of high precision engineered plastic components.

DESIGN & DEVELOPMENT

Equipped with latest versions of AUTOCAD, UNIGRAPHICS AND IDEAS Technology, our Design and Development Department has an edge over other facilities to cope up with the increasing demands of the customers. We make our Standards to meet International quality specifications and have been accredited with ISO/TS - 16949 : 2002 Certifications for the systems maintained.

MANUFACTURING:

TOOL & DIE MAKING

We have State of the art captive Tool room with the capacity to deliver high precision tools and moulds. Our tool room is equipped with CNC Wire cut, Spark Erosion Machine, CNC Surface grinding and NC Cylindrical & Surface Grinding Machines.

INJECTION MOLDING

BESMAK has its manufacturing facility with covered space of about 15000 sq. ft. and has 13 nos of fully automatic Injection moulding machines with capacity ranging between 50 to 120 tons. We are currently producing around 7.5 million quality components every month by operating at three shifts per day. We have the capacity to produce 9 million parts per month.

QUALITY SYSTEMS

To assure product and process quality, BESMAK is equipped with latest equipments like height master, Quick vision (CNC vision measuring system), Push pull tester, hardness tester, water proof testing rig, Profile projector etc....

COSTOMERS: BESMAK has made its presence in the market with the over whelming support of its CUSTOMERS from its inception. Our Company has extended its operations over the length and breadth of India keeping in mind the major four and two wheeler automotive industry in India and made a humble presence in Malaysian automotive sector too. Today we supply the best

quality products and service to our ESTEEMED CUSTOMERS and have attained a significant position in the Automotive Wiring Harness Industry by being dedicated suppliers of Plastic Components / Connectors / Housings.

BESMAK is currently catering mainly to

y y y y y y y y y y y y y y y

MARUTI TATA MOTORS HYUNDAI MOTORS TOYOTA FORD GM HONDA SUZUKI HERO HONDA BAJAJ AUTO LTD KINETIC ENGINEERING TVS MOTOR CO. LTD YAMAHA SUZUKI MOTOR INDIA PVT. LTD. AND TAFE [TRACTORS]

through their 1st tier vendors like y y y y y DELPHI AUTOMOTIVE DHOOT Transmission TATA YAZAKI TYCO Electronics NAPINO Auto Electric and other ESTEEMED CUSTOMERS.

Our components have found their presence in the PROTON CARS of MALAYSIA for the last 8 years.

PRODUCTS: y Automobile Connectors o Wire connectors o Fuse deck o Fuse connectors o Door sealers o Engine assembly parts o Valve sealers and joiners Exterior components o Towing hook sealers(Nissan) o Bumper bracket o Other nylon items

COMPANY STUDY: PRODUCTION UNIT In this production plant people are using 5s principle and kaizen model of quality standardization. They partly achieved the 5s principles and they are very conscious about zero wastage. RAW MATERIALS: y y y y y Nylon 66 (20 tons per month) Nylon 6 (5 tons per month) PBT [poly butylene terephthalate] (3 tons per month) PPCP [poly propylene co polymer] (1 ton per month) PPHP [poly propylene homo polymer] (1 ton per month)

ASSEMBLY: y y y y Rubber items Bronze Wood Wires

MACHINERY IN PRODUCTION UNIT:

y y y y y Servo injection machines (4 Nos) Mitsubishi injection machines (4 Nos) Streamers GC (2 Nos) Coolers GC (2 Nos) Water pumps CRI (2 Nos)

PRODUCTION METHOD: y y y y y y

Temperature setting Water cooling Clamping Ejection Injection & holding Ejection of finished products

PRODUCT REJECTION AND ACCEPTENCE:

It has an hypothesis level where the defects can go up to +3 or -3 pts .If it exceeds or below then both the mold and components will be rejected.

COMPANY OUTLOOK: y Raw materials store o General o Temporary y Incoming inspection y Injection molding shop y Mold storage y Press shop y Visual inspection y Rejection review area y Design and development y Production y Quality control y Admin

y Tools o Tool room machinery o Tool fitting shops o CNC shops o Tool store rooms y Final inspection y Packing area y Finished goods stores y Dispatch y Gen set room y Electrical maintenance y Cooling tower y Scrap grinding y Humidification area y ERP section

TOOL STORE: y It is a manufacturing plant which is a slow process y In manufacturing process we will manufacture production equipment y This part is very technical where the machines can be operated only by specialized

technicians

MACHINES IN TOOL ROOM: y y y y 5 CNC machines

Grinding machines Sharping machines Mold maintenance machine CNC machines cost is around 45 lakhs each, 1.5/nv input 30 kv2 Mitsubishi Japan , 10 kv2 sodick cost around 40 lakhs. These machines are used to manufacture the components of production mold die machines. The CNC machines should be kept in the cool place where the temperature should not exceed 22 degree Celsius.

POWER CONSUMPTION: y Tool room

y y y y Mitsubishi Japan 2 units per hour o 2x2x24=96 units per day Kv2 sodick 3 units per hour o 3x2x24=144 Other lath machines will consume 103 units per day Total tool room electricity consumption is around 350 units per day and 10500 units per month

Production unit electricity consumption y Total machines 14 o 3x7= 21 o 3x7= 21 o 4x10=40 o 4x18=32 y Total units per hour 114 y 2736 units per day y 84816 units per month y Units used through power 30000 y Diesel used per month is around 300000rs

PURCHASE y Raw materials

You might also like

- Need of The StudyDocument5 pagesNeed of The StudyMeena SivasubramanianNo ratings yet

- Advertising Activities - Bajaj MotorsDocument44 pagesAdvertising Activities - Bajaj MotorsL. V B ReddyNo ratings yet

- Sathyabama: A Study of Customer Satisfaction AT Hyundai Motors LimitedDocument44 pagesSathyabama: A Study of Customer Satisfaction AT Hyundai Motors Limitedpower star rajkumarNo ratings yet

- A Study On Customer Satisfaction at Rubber General Industry India PVT - LTD, CoonoorDocument9 pagesA Study On Customer Satisfaction at Rubber General Industry India PVT - LTD, CoonoorNavaneeth Vroon0% (1)

- Final Research ProjectDocument86 pagesFinal Research Projectranjha8988% (8)

- Customer Relationship ManagementDocument8 pagesCustomer Relationship ManagementdibeeshNo ratings yet

- 152c1e00d5 Consumer SatisfactionDocument57 pages152c1e00d5 Consumer SatisfactionAvinash AviiNo ratings yet

- Final Sip ReportDocument72 pagesFinal Sip ReportMohammad ShoebNo ratings yet

- Synopsis Report On Organic Cosmetics by PCTEDocument10 pagesSynopsis Report On Organic Cosmetics by PCTESingh GurpreetNo ratings yet

- 7P of ICICI Bank Marketing ProjectDocument9 pages7P of ICICI Bank Marketing ProjectRoyal ProjectsNo ratings yet

- Customer Satisfaction Towards Idea SimDocument62 pagesCustomer Satisfaction Towards Idea SimSunaina KhoslaNo ratings yet

- A Study On Customer Satisfaction Towards Shri Kannan Departmental Stores With Special Reference in Namakkal TownDocument3 pagesA Study On Customer Satisfaction Towards Shri Kannan Departmental Stores With Special Reference in Namakkal Townselmuthusamy100% (2)

- Marketing - COMPARATIVE STUDY OF CUSTOMERS PERCEPTION FOR HONDA & YAMAHA BIKESDocument56 pagesMarketing - COMPARATIVE STUDY OF CUSTOMERS PERCEPTION FOR HONDA & YAMAHA BIKESShailabh KhandelwalNo ratings yet

- Infowiz ReportDocument54 pagesInfowiz ReportAjit SharmaNo ratings yet

- A Study On Rural Consumer Behaviour Towards Selected Fast Moving Consumer Goods in Karur DistrictDocument9 pagesA Study On Rural Consumer Behaviour Towards Selected Fast Moving Consumer Goods in Karur DistrictpecmbaNo ratings yet

- My3 Final Report BSNLDocument38 pagesMy3 Final Report BSNLPavan PaviNo ratings yet

- Biswajit Rcem Bigbazzar ProjectDocument50 pagesBiswajit Rcem Bigbazzar Projectbibek beheraNo ratings yet

- Customer Relationship Management Project Report MBA, Customer Retention Project Report, Loyalty Services According To CustomerDocument9 pagesCustomer Relationship Management Project Report MBA, Customer Retention Project Report, Loyalty Services According To CustomerSameerNo ratings yet

- A Study On Consumer Buying Behaviour in KKP Spinning Mills Private LimitedDocument12 pagesA Study On Consumer Buying Behaviour in KKP Spinning Mills Private LimitedRK FeaturesNo ratings yet

- Finaly Project Over PDFDocument81 pagesFinaly Project Over PDFSunil Kumar Mahato0% (1)

- Customer PerceptionDocument90 pagesCustomer PerceptionOmsi Latha100% (1)

- Summer Training Report Diya 1Document40 pagesSummer Training Report Diya 1navdeep2309No ratings yet

- Customer Satisfaction in Big BazaarDocument76 pagesCustomer Satisfaction in Big BazaarAditya VermaNo ratings yet

- Project ReportDocument63 pagesProject Reportdeepak singhNo ratings yet

- LG and Its CompetitorsDocument50 pagesLG and Its CompetitorsBillGates BNo ratings yet

- A Training Project Report On Market Survey of Various Zones BDocument105 pagesA Training Project Report On Market Survey of Various Zones Bhanu11No ratings yet

- Big BazarDocument90 pagesBig BazarAnonymous g3lny8ux50% (2)

- Project Report On Total Quality Management: ConceptualizationDocument155 pagesProject Report On Total Quality Management: ConceptualizationNeha Sable DeshmukhNo ratings yet

- A Study of Effectiveness On Advertisement and Promotional Offers at Big Bazaar, BangaloreDocument78 pagesA Study of Effectiveness On Advertisement and Promotional Offers at Big Bazaar, BangaloreManu B100% (1)

- Big Bazaar ProjectDocument74 pagesBig Bazaar Projectghoshsubhankar1844No ratings yet

- Neeraj Solanki BBA Final YearDocument72 pagesNeeraj Solanki BBA Final YearNeeraj solankiNo ratings yet

- Project Report BajajDocument88 pagesProject Report BajajPramod KumarNo ratings yet

- A - Study - of - Recruitment - and - Selection - Pro (1) 2Document75 pagesA - Study - of - Recruitment - and - Selection - Pro (1) 2Munna MunnaNo ratings yet

- Employee Satisfaction and Perception Towards InfowizDocument34 pagesEmployee Satisfaction and Perception Towards InfowizShubham kumarNo ratings yet

- GopiDocument63 pagesGopipriyaNo ratings yet

- "A Study On Customer Expectation From On-Line Marketing WithDocument89 pages"A Study On Customer Expectation From On-Line Marketing Withprathamesh kaduNo ratings yet

- Organization Study IIDocument84 pagesOrganization Study IIAnshid Elamaram0% (1)

- Mini ProjDocument27 pagesMini ProjMekhajith MohanNo ratings yet

- Summer Internship Project ReportDocument46 pagesSummer Internship Project Reportanup_agarwal100% (1)

- Customer Satisfaction in Hyundai 2019Document89 pagesCustomer Satisfaction in Hyundai 2019Anshu KNo ratings yet

- To Study The Students Buying Behaviour Towards Laptops: Harshit Gupta Harshit - Gupta@lbsim - Ac.inDocument39 pagesTo Study The Students Buying Behaviour Towards Laptops: Harshit Gupta Harshit - Gupta@lbsim - Ac.inMegha MattaNo ratings yet

- Customer Satisfaction Towards Raymonds Fashion WearDocument39 pagesCustomer Satisfaction Towards Raymonds Fashion WearChandan SrivastavaNo ratings yet

- For SPSS AnalysisDocument22 pagesFor SPSS AnalysisUvasre SundarNo ratings yet

- A Study On Customer Satisfaction Towards Bajaj Pulsar, ChennaiDocument90 pagesA Study On Customer Satisfaction Towards Bajaj Pulsar, Chennaipriya kumarNo ratings yet

- Customer Retention in Retail Setor by NonameDocument69 pagesCustomer Retention in Retail Setor by NonameMonalisa MunniNo ratings yet

- 444-Rcu Business Communication Notes Aug 2018 PDFDocument87 pages444-Rcu Business Communication Notes Aug 2018 PDFPride Nechishanyi0% (1)

- Customer Satisfaction and Brand Loyalty in Big BasketDocument73 pagesCustomer Satisfaction and Brand Loyalty in Big BasketUpadhayayAnkurNo ratings yet

- 007 - Review of LiteratureDocument15 pages007 - Review of LiteratureNamrata SaxenaNo ratings yet

- Customer Satisfaction Sujala PipesDocument87 pagesCustomer Satisfaction Sujala PipesVenkateshNo ratings yet

- Arpit's SIP Project On "Retailer's Satisfaction"Document63 pagesArpit's SIP Project On "Retailer's Satisfaction"Arpit GargNo ratings yet

- Customer Satisfaction Regarding HDFC BankDocument104 pagesCustomer Satisfaction Regarding HDFC BankAmarkant0% (1)

- A Project Report ON A Study On Consumer Perception Towards Branded Clothes in Central Future Lifestyle Fashion atDocument6 pagesA Project Report ON A Study On Consumer Perception Towards Branded Clothes in Central Future Lifestyle Fashion atjassi nishadNo ratings yet

- Amway Corporation in India (Marketing Research)Document81 pagesAmway Corporation in India (Marketing Research)Ankit JainNo ratings yet

- Project Sneha WordDocument68 pagesProject Sneha WordBasically EverythingNo ratings yet

- Vamsi Project 58Document82 pagesVamsi Project 58Anil Kumar GudigantiNo ratings yet

- The Study of Rural Marketing Strategies of Mahindra TractorsDocument5 pagesThe Study of Rural Marketing Strategies of Mahindra TractorsAman PatelNo ratings yet

- Green Products A Complete Guide - 2020 EditionFrom EverandGreen Products A Complete Guide - 2020 EditionRating: 5 out of 5 stars5/5 (1)

- It’S Business, It’S Personal: From Setting a Vision to Delivering It Through Organizational ExcellenceFrom EverandIt’S Business, It’S Personal: From Setting a Vision to Delivering It Through Organizational ExcellenceNo ratings yet

- Chilere - Unitatile de Racire - Technical - Brochures - NX - 0152P - 0812P - EN PDFDocument72 pagesChilere - Unitatile de Racire - Technical - Brochures - NX - 0152P - 0812P - EN PDFDaniel MilosevskiNo ratings yet

- Lithospheric Evolution of The Pre-And Early Andean Convergent Margin, ChileDocument29 pagesLithospheric Evolution of The Pre-And Early Andean Convergent Margin, ChileAbdiel MuñozNo ratings yet

- Avinash Uttareshwar MeherDocument6 pagesAvinash Uttareshwar MeheravinashNo ratings yet

- I. You'll Hear A Conversation Between Two People. Listen and Fill in The Blanks (10 PTS) This Is The VOA Special English Agriculture ReportDocument7 pagesI. You'll Hear A Conversation Between Two People. Listen and Fill in The Blanks (10 PTS) This Is The VOA Special English Agriculture ReportTHỌ NGUYỄN VĂNNo ratings yet

- INT PL 2020 Web 01-20 PDFDocument320 pagesINT PL 2020 Web 01-20 PDFAndriana Vilijencova100% (1)

- Makaut Grade Card Collection Notice 2018-19Document1 pageMakaut Grade Card Collection Notice 2018-19Sourav PandaNo ratings yet

- H&M Case Study AssignmentDocument7 pagesH&M Case Study AssignmentwqvyakNo ratings yet

- CASBA Directive 2074Document17 pagesCASBA Directive 2074vijaycool85No ratings yet

- SOL-Logarithm, Surds and IndicesDocument12 pagesSOL-Logarithm, Surds and Indicesdevli falduNo ratings yet

- Pitch Analysis PaperDocument7 pagesPitch Analysis PaperMunib MunirNo ratings yet

- Critique of Violence - Walter BenjaminDocument14 pagesCritique of Violence - Walter BenjaminKazım AteşNo ratings yet

- NEC G266 Quick Reference GuideDocument3 pagesNEC G266 Quick Reference GuideIonut Gabriel DascaluNo ratings yet

- Compressor-Less: Historical ApplicationsDocument70 pagesCompressor-Less: Historical Applicationssuryakantshrotriya100% (1)

- 1.rle Rubrics For Case PresentationDocument2 pages1.rle Rubrics For Case PresentationKhristine EstosoNo ratings yet

- IMG - 0009 Thermodynamic Lecture MRCDocument1 pageIMG - 0009 Thermodynamic Lecture MRCBugoy2023No ratings yet

- Of Personality Traits of Only and Sibling School Children in BeijingDocument14 pagesOf Personality Traits of Only and Sibling School Children in BeijingMuhammad Hamza AsgharNo ratings yet

- Ground Architecture (Mourad Medhat)Document146 pagesGround Architecture (Mourad Medhat)Aída SousaNo ratings yet

- Jimma UniversityDocument99 pagesJimma UniversityBekan NegesaNo ratings yet

- Ground Vehicle Operations ICAODocument31 pagesGround Vehicle Operations ICAOMohran HakimNo ratings yet

- THE REFUND - Frigyes Karinthy: AuthorDocument6 pagesTHE REFUND - Frigyes Karinthy: AuthorMilind JamnekarNo ratings yet

- Prof Ed 9-A - Module 6 - Tumacder, DHMLDocument6 pagesProf Ed 9-A - Module 6 - Tumacder, DHMLDanica Hannah Mae TumacderNo ratings yet

- Book - Sefer Yetzira - Book of Creation - Free KabbalahDocument3 pagesBook - Sefer Yetzira - Book of Creation - Free KabbalahJoshuaNo ratings yet

- Cable Systems For High and Extra-High Voltage: Development, Manufacture, Testing, Installation and Operation of Cables and Their AccessoriesDocument1 pageCable Systems For High and Extra-High Voltage: Development, Manufacture, Testing, Installation and Operation of Cables and Their AccessorieseddisonfhNo ratings yet

- Power Distribution & Utilization: Total Power Generation of Last 10 Years and Forecast of 20 YearsDocument12 pagesPower Distribution & Utilization: Total Power Generation of Last 10 Years and Forecast of 20 YearsSYED ALIYYAN IMRAN ALINo ratings yet

- 3-Storeyed 31-3-2015-Schedule PDFDocument1 page3-Storeyed 31-3-2015-Schedule PDFSi Thu AungNo ratings yet

- pm2 5 Sensor 201605Document6 pagespm2 5 Sensor 201605Vennela NandikondaNo ratings yet

- 6000 Most Common Korean Words - For All TOPIK Levels PDFDocument232 pages6000 Most Common Korean Words - For All TOPIK Levels PDFZac67% (3)

- The Aerodynamics of ParachutesDocument78 pagesThe Aerodynamics of Parachutesstevehuppert50% (2)

- Ficha Tecnica Reflector 2000W Led Lluminacion de Campos de Futbol Estadios Goled Philips Osram Opalux LedDocument5 pagesFicha Tecnica Reflector 2000W Led Lluminacion de Campos de Futbol Estadios Goled Philips Osram Opalux Ledluis perdigonNo ratings yet