Professional Documents

Culture Documents

RedBrand Answers 1

Uploaded by

Adarsh Manish TiggaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RedBrand Answers 1

Uploaded by

Adarsh Manish TiggaCopyright:

Available Formats

Answers to Red Brand Canners Case Part I 1.

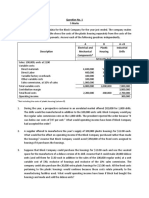

Based on the availability of 600,000 pounds of grade A tomatoes (grade 9), one can mix in some grade B tomatoes (grade 5) to generate a mix of grade 8. Let X denote the pounds of grade B tomatoes that can be mixed in. Then: (600,000*9+X*5)/(600,000+X)=8. Solving this, yields X=200,000 lbs for a total weight of 800,000 lbs. 2. Coopers suggestion restricts the usage of tomatoes to merely 800,000 lbs (as shown in 1). The leftover tomatoes could be used profitably to at least make tomato paste. It might also be more profitable to make use of the A tomatoes to produce some tomato juice as well, and end up with a mix products that together produce the most profit. 3. In Exhibit 3, Myers attempt to prorate the unit cost per tomato (18 cents) based on the quality of tomato (grade A or B). The first equation (1) indicates that the sum of 600,000 lb multiplied by the unit cost per lb for grade A tomatoes (Z) and 2,400,000 lb multiplied by the unit cost per lb for grade B tomatoes (Y) equals the total cost paid (3,000,000 lbs multiplied by 18 cents per lb). The second equation (2) defines the relative relationship between the unit prices for grade A and B tomatoes based on the relative quality points for the two grades. Solving the two equations yields the values for the unit prices for the two grades. Based on this one can state that the unit cost per lb for tomatoes of quality of 1 is equal to the value of Z/9 or Y/5. This is then used to find the adjusted fruit cost. For example, the cost per case of whole tomatoes would be: (Z/9) $/lb *8*18 lb/case or $4.47 per case. Similarly, for tomato juice the cost per case would be: (Z/9) $/lb * 6 * 20 lb/ case = $3.72 per case. Since Myers believes that tomato paste is the most profitable option, he would like to sell as much tomato paste that demand allows, which is 80,000 cases or 2,000,000 lbs (80,000 cases*25lb per case). Beyond that Myers ranks tomato juice as the next profitable item and so the remaining 400,000 lbs of grade B tomatoes and 600,000 lbs of grade A tomatoes should be used for making tomato juice. A fundamental shortcoming in the analysis is that the fact that the grade A tomatoes implicitly cost the company more than the grade B tomatoes has nothing with the current task at hand which is to maximize the operating profit for the season given the resources (tomatoes) at hand. Indeed, tomatoes have already been purchased and, hence, their purchase price is a sunk cost. It does not make sense to penalize the production of whole tomatoes because of the cost already incurred in purchasing grade A tomatoes. 4. Let wA= weigh of tomato grade A allocated to produce whole tomatoes (lbs), wB=weight of tomato grade B allocated to produce whole tomatoes (lbs), jA=weight of tomato grade A allocated to produce whole tomatoes (lbs), jB=weight of tomato grade B allocated to produce whole tomatoes (lbs), pA=weight of tomato grade A allocated to produce whole tomatoes (lbs),

pB=weight of tomato grade B allocated to produce whole tomatoes (lbs). The formulation that maximizes net income for the tomato manufacturing operation is given below. First, the objective function is to maximize the generated income from selling the various tomato products. The income from selling a case of a product type is the contribution shown in Exhibit 2 plus the fruit cost. For each product type the income per pound is obtained by dividing the income per case by the weight (lb) per case. Then the total income for the product is the unit income per lb multiplied by the weight (in lbs) of tomatoes used in producing the product type. The objective function is then: Maximize ((1.20+3.24)*100)/18)*(wA+ wB) + ((0.36+3.60)*100)/20)*( jA+ jB) + ((1.05+4.50)*100)/25)*( pA+ pB) The first type of constraint is that the mix of tomato grades used should ensure the required scores for the whole tomatoes and the tomato juice products. No constraint is necessary for the tomato paste product as using either tomato grade A or B would meet the score required for tomato paste. For the whole tomatoes product, the combined score is 9*wA + 5* wB should be 8*(wA+ wB) or wA- 3wB 0. Similarly, for the tomato juice product, 9*jA + 5* jB should be 6*(jA+ jB) or 3jA - jB 0. Another set of constraints is needed to limit production of each type of tomato product so as to not to exceed demand. Finally, the usage of tomatoes should be limited to the amounts available of each grade. The complete formulation is then: Maximize ((1.20+3.24)*100)/18)*(wA+ wB) + ((0.36+3.60)*100)/20)*( jA+ jB) + ((1.05+4.50)*100)/25)*( pA+ pB) wA- 3wB 0 (whole tomatoes quality constraint) 3jA - jB 0 (tomato juice quality constraint) wA+ wB 800,000*18 (whole tomatoes production less than demand) jA+ jB 50,000*20 (tomato juice production less than demand) pA+ pB 80,000*25 (tomato paste production less than demand) wA+ jA+ pA 600,000 (grade A tomatoes usage less than available amount) wB+ jB+ pB 2,400,000 (grade B tomatoes usage less than available amount) wA, wB, jA, jB, pA, pB 0 5. In order to capture the possibility of ordering more grade A tomatoes, let eA denote the extra weight of grade A tomatoes to be purchased. The formulation can be modified to capture the cost (in the objective function) of purchasing the extra grade A tomatoes and the corresponding increased availability of such tomatoes (grade A tomatoes usage constraint). The new formulation is: Maximize ((1.20+3.24)*100)/18)*(wA+ wB) + ((0.36+3.60)*100)/20)*( jA+ jB) + ((1.05+4.50)*100)/25)*( pA+ pB) 0.255eA wA- 3wB 0 (whole tomatoes quality constraint) 3jA - jB 0 (tomato juice quality constraint) wA+ wB 800,000*18 (whole tomatoes production less than demand) jA+ jB 50,000*20 (tomato juice production less than demand)

pA+ pB 80,000*25 (tomato paste production less than demand) wA+ jA+ pA - eA 600,000 (grade A tomatoes usage less than available amount) wB+ jB+ pB 2,400,000 (grade B tomatoes usage less than available amount) 0 eA 80,000 (maximum amount of extra grade A tomatoes available) wA, wB, jA, jB, pA, pB, eA 0

You might also like

- Red Brand SolDocument13 pagesRed Brand Solmanu_130381No ratings yet

- Red Brand Canners: Case Analysis by Group 10, Section EDocument3 pagesRed Brand Canners: Case Analysis by Group 10, Section EKaran Barua100% (1)

- RedBrand Answers 2Document2 pagesRedBrand Answers 2alfonsorosNo ratings yet

- RedBrand Canners SolutionDocument2 pagesRedBrand Canners SolutionWooly JumperNo ratings yet

- Red Brand Canners Case StudyDocument8 pagesRed Brand Canners Case Studyvamshi0% (1)

- Red Brand CannersDocument5 pagesRed Brand CannersKazi MahimNo ratings yet

- Red Brand Canners SummaryDocument6 pagesRed Brand Canners SummaryMalgorzata Pankowska0% (1)

- Red Brand Canners 1Document7 pagesRed Brand Canners 1Marcel TanNo ratings yet

- RBCDocument2 pagesRBCHeber RuizNo ratings yet

- Introduction To Quantitative Decision Making Assignment - 1: Submitted By: Razal Faizal Section - A PGP - 1Document5 pagesIntroduction To Quantitative Decision Making Assignment - 1: Submitted By: Razal Faizal Section - A PGP - 1MukulNo ratings yet

- 1 - REV - Case Red Brand CannersDocument6 pages1 - REV - Case Red Brand CannersArun AhirNo ratings yet

- Red Brand CannersDocument3 pagesRed Brand CannersGauthamNo ratings yet

- Red Brand CannersDocument3 pagesRed Brand CannersRodrigo IguasniaNo ratings yet

- Red Brand Canner: Tomato PurchasedDocument4 pagesRed Brand Canner: Tomato PurchasedswagonswagonswagNo ratings yet

- Red Brand Canner: Tomato PurchasedDocument2 pagesRed Brand Canner: Tomato PurchasedRuthra KumarNo ratings yet

- Red Brand CannersDocument9 pagesRed Brand CannerssabyavgsomNo ratings yet

- Red Brand CannersDocument4 pagesRed Brand CannersRationallyIrrationalSamikshaNo ratings yet

- Case Study Red Brand Canners: A A B B C D DDocument5 pagesCase Study Red Brand Canners: A A B B C D DAmol KatkarNo ratings yet

- Red Brand Canners CaseDocument4 pagesRed Brand Canners CaseNabanita GhoshNo ratings yet

- CA So Red Brand CannersDocument13 pagesCA So Red Brand CannersDerly Angel Lizarraga RamosNo ratings yet

- Case Analysis Operations Research Red Brand Canners (Download To View Full Presentation)Document12 pagesCase Analysis Operations Research Red Brand Canners (Download To View Full Presentation)mahtaabk83% (12)

- Case Fast Gro FertilizersDocument5 pagesCase Fast Gro FertilizersnishanthNo ratings yet

- Red Brand CannersDocument2 pagesRed Brand Cannersprateek_goyal20910% (1)

- Red Brand CannersDocument8 pagesRed Brand Cannersmystique4686No ratings yet

- Red Brand CannersDocument7 pagesRed Brand CannersAnshuman AgarwalNo ratings yet

- Krugman2e Solutions CH15Document12 pagesKrugman2e Solutions CH15Joel OettingNo ratings yet

- CHE 461 Ass1 q3Document5 pagesCHE 461 Ass1 q3Para DiseNo ratings yet

- MCQ 8Document9 pagesMCQ 8Pines Macapagal100% (1)

- Industrial Organization & Perfect CompetitionDocument71 pagesIndustrial Organization & Perfect CompetitionRoni SuhandaniNo ratings yet

- Red Brand CannersDocument3 pagesRed Brand CannersAnoop SlathiaNo ratings yet

- Chapter 11 PracticeDocument22 pagesChapter 11 PracticeBreanna WolfordNo ratings yet

- Chapter - EightDocument10 pagesChapter - Eight3ooobd1234No ratings yet

- Man Kiw Chapter 07 Solutions ProblemsDocument11 pagesMan Kiw Chapter 07 Solutions ProblemsMariya Abdul GhafoorNo ratings yet

- Gross Margin AnalysisDocument12 pagesGross Margin AnalysisRashe FasiNo ratings yet

- AnswerDocument1 pageAnswerEevan SalazarNo ratings yet

- Evaluating Willingness To PayDocument25 pagesEvaluating Willingness To PaySeptian abbiyyah GaniNo ratings yet

- ECON 303 Homework 01 Microeconomics: Real Price of ButterDocument2 pagesECON 303 Homework 01 Microeconomics: Real Price of Butteralexsheep17No ratings yet

- Sensitivity AnalysisDocument8 pagesSensitivity AnalysisFarhan Ahmed SiddiquiNo ratings yet

- Sithkop002 Short QuestionDocument23 pagesSithkop002 Short QuestionMukta AktherNo ratings yet

- ECON 2113 - Homework GroupDocument7 pagesECON 2113 - Homework GroupNamanNo ratings yet

- PT - 2Document6 pagesPT - 2Devabn NirmalNo ratings yet

- ACCY 115 Tutorial 7Document5 pagesACCY 115 Tutorial 7kennedy othoroNo ratings yet

- Efficiency and Cost of Tax ExercisesDocument23 pagesEfficiency and Cost of Tax ExercisesLuis Emmanuel FletaNo ratings yet

- Microeco HW Answers Ch. 3, 4Document7 pagesMicroeco HW Answers Ch. 3, 4pheeyona100% (3)

- CA2 Indicative SolutionsDocument4 pagesCA2 Indicative SolutionsAkshat AnandNo ratings yet

- Bab 8 Costing by Product and Joint ProductDocument4 pagesBab 8 Costing by Product and Joint Productammara_786No ratings yet

- Aquaponics 1700sftDocument6 pagesAquaponics 1700sftIcky IckyNo ratings yet

- CH 4 Cost IIDocument6 pagesCH 4 Cost IIfirewNo ratings yet

- L2 HW 2Document9 pagesL2 HW 2Carlos Andrés Valverde50% (2)

- Practice Exam ADocument11 pagesPractice Exam Aaksi_28No ratings yet

- Risk Uncertainty and Decision MakingDocument14 pagesRisk Uncertainty and Decision Makingkevior2No ratings yet

- Question No. 1 5 Marks: Not Including The Costs of Plastic Housing (Column B)Document13 pagesQuestion No. 1 5 Marks: Not Including The Costs of Plastic Housing (Column B)Mawaz Khan MirzaNo ratings yet

- Consumers, Producers and The Efficiency of Markets: Solutions To Text ProblemsDocument13 pagesConsumers, Producers and The Efficiency of Markets: Solutions To Text ProblemsterrancekuNo ratings yet

- Bus ID No.: E-2071: Passenger InformationDocument1 pageBus ID No.: E-2071: Passenger InformationKarthikeyan VelusamyNo ratings yet

- ResearchDocument92 pagesResearchKarthikeyan VelusamyNo ratings yet

- 1Document1 page1Karthikeyan VelusamyNo ratings yet

- 1Document1 page1Karthikeyan VelusamyNo ratings yet

- Book 1Document1 pageBook 1Karthikeyan VelusamyNo ratings yet

- LICENSES Full Documentation STDDocument511 pagesLICENSES Full Documentation STDffssdfdfsNo ratings yet

- POM TopicsDocument2 pagesPOM TopicsAnkit SankheNo ratings yet

- Hire Purchase and LeasingDocument30 pagesHire Purchase and LeasingShreyas Khanore100% (1)

- Casey Loop's Whistleblower Lawsuit vs. The CTADocument18 pagesCasey Loop's Whistleblower Lawsuit vs. The CTAChadMerdaNo ratings yet

- United States Court of Appeals For The Second CircuitDocument19 pagesUnited States Court of Appeals For The Second CircuitScribd Government DocsNo ratings yet

- A Minor Project Report: Product Analysis of ItcDocument83 pagesA Minor Project Report: Product Analysis of ItcDeep SinghNo ratings yet

- Supply Chain Management - Darden's RestaurantDocument26 pagesSupply Chain Management - Darden's RestaurantShameen Shazwana0% (1)

- Chapt Er: Nature and Scope of Investment DecisionsDocument21 pagesChapt Er: Nature and Scope of Investment DecisionschitkarashellyNo ratings yet

- Digital Banking, Customer PDFDocument27 pagesDigital Banking, Customer PDFHafsa HamidNo ratings yet

- Aon Corp Identity Standards-RevDec2004Document22 pagesAon Corp Identity Standards-RevDec2004ChiTownITNo ratings yet

- Sample Company Presentation PDFDocument25 pagesSample Company Presentation PDFSachin DaharwalNo ratings yet

- Importance of Managerial EconomicsDocument3 pagesImportance of Managerial EconomicsRohit RaviNo ratings yet

- UntitledDocument2 pagesUntitledHarikrishnan SivajiNo ratings yet

- A Project Report ON A Study of Promotion Strategy and Customer Perception of MC Donalds in IndiaDocument18 pagesA Project Report ON A Study of Promotion Strategy and Customer Perception of MC Donalds in IndiaShailav SahNo ratings yet

- Primary and Secondary Data (UNIT III)Document12 pagesPrimary and Secondary Data (UNIT III)shilpeekumariNo ratings yet

- Executive SummaryDocument3 pagesExecutive SummaryBenchinoune Abderrahim0% (1)

- Wipro WInsights Sustainability ReportingDocument3 pagesWipro WInsights Sustainability ReportingHemant ChaturvediNo ratings yet

- Four Fold TestDocument19 pagesFour Fold TestNeil John CallanganNo ratings yet

- Business in Inf Age1newDocument13 pagesBusiness in Inf Age1newarchana_sree13No ratings yet

- Interoffice Legal MemoDocument8 pagesInteroffice Legal MemoArvin Antonio Ortiz100% (1)

- Textured Soy Protein ProductsDocument13 pagesTextured Soy Protein ProductsAmit MishraNo ratings yet

- Devops Case StudiesDocument46 pagesDevops Case StudiesAlok Shankar100% (1)

- Mt2000 Series Isv GuideDocument17 pagesMt2000 Series Isv GuideKlever MadrizNo ratings yet

- 101 Win Themes For All OccasionsDocument6 pages101 Win Themes For All OccasionstausarpaoNo ratings yet

- A Study On Customer Satisfaction of Santoor Soap Virudhunagar TownDocument2 pagesA Study On Customer Satisfaction of Santoor Soap Virudhunagar Townvishnuvishnu07100No ratings yet

- The Ideal Essay ST Vs PLTDocument1 pageThe Ideal Essay ST Vs PLTAlisha HoseinNo ratings yet

- Acca F2 Management Accounting Mock Test Dec 2008 Prepared By: Ben LeeDocument17 pagesAcca F2 Management Accounting Mock Test Dec 2008 Prepared By: Ben Leesomica100% (4)

- Present and The Past Behavior of The Garment Industry in Sri LankaDocument7 pagesPresent and The Past Behavior of The Garment Industry in Sri Lankanalaka.sampath100% (1)

- ASSIGNMENT 407 - Audit of InvestmentsDocument3 pagesASSIGNMENT 407 - Audit of InvestmentsWam OwnNo ratings yet