Professional Documents

Culture Documents

Book 1

Uploaded by

Himanshu JethaniOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Book 1

Uploaded by

Himanshu JethaniCopyright:

Available Formats

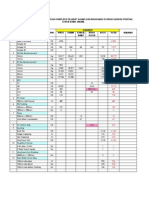

Items Qty Unit Rate Amount Schedule A part I building for roog facilities 1 Block Parking Shed for

2 cars 1 Block Parking Shed for 10 scooters 1 Block RCC water Tank of 25000gal 1 Block Schedule A part II M&L For gun metal valve 20mm 2 each M&L For gun metal valve 15mm 3 each M&L for GI tubing of 20mm 10 RM All as pwe above item but fixed to wall and ceiling 12 RM All as pwe above item but fixed to wall and ceiling 15mmRM 12 bore tap class copper allooy with crutch or butter fly handle 15mm bore 1 each Schedule A PartIII M&L for GI tubing of 25mm 20 RM M&L for mounting the condensing evaporating unit 1.5 QTL S&F plain black sheet 1.6mm thick as in canopy 4 SQM Schedule A partIV Excavation over areas n exc 1.50m deep 1700 CUM Excavation in trenches not exc 1.5m 40 CUM M&L for moorum filling 15cm thick 1000 CUM M&L for soiling base 200mm spread thickness by using power roller 260 X SQM WBM 150mm thick in 2 layers 250 X SQM Embankments including raising or lowering earth 30cm thick ht 1.5m 200 CUM Prepration of unsurfaced WBM 250 X SQM Bituminous premix asphaltic dense concrete 40mm thick X SQM 250 PCC 1:3:6 using 40mm stone 18 CUM Brick work 27 CUM 15mm thick rendering in cm 1:4 on brick or concrete 40 SQM PCC 1:2:4 4 CUM RCC M25 Design mix using 20mm stone 5 CUM TMT bars 10mm 750 KG Sand Filling 240 CUM Removing excavated soil 1740 CUM Use and waste of from work for rough finished surfaces of soffits of suspended slabs 27 SQM Supply only water proofing compound 12 KG Schedule A part V excavation 185 CUM returning, filling 165 CUM Removing excavated soil 20 CUM CI pipe of 80mm 130 RM CI fittings 50 KG Rubber gasket joints for 80mm pipe 20 each Lead joint 5 each Cutting down existing CI pipe 1 each Galvanized Iron pipe 25mm bore 20 RM 40mm bore 290 RM Schedule A part VI Excavation 345 CUM

returning, filling 240 CUM Removing excavated soil 105 CUM Sand cushioning 95 CUM Unreinforced precast concrete cable LV 250*150*40 7800 each Steel tublar swagged poles 410 SP-22 8.5 mt long 20 each GI tubing 40mm 50 RM 4 way SPN with 20amp rated bus bar 240v 2 each MCB TPN for 35 to 60A 240v 2 each PCC 1:4:8 10 CUM PCC 1:2:4 5 CUM Schedule A part VII Excavation 35 CUM PCC 1:4:8 as in foundation filling 2 CUM PCC 1:4:8 as in concrete bed 74 CUM 150mm bore salt gazed stone 80 RM Brick work 3 CUM Concrete 1:2:4 1 CUM Extra for finished surface 3 RM Rendering 10mm thick on brick 10 SQM PCC 1:2:4 using 12.5mm stone 1 CUM PCC 1:2:4 using 20mm stone 1 CUM TMT bars 8mm 11 KG returning, filling 15 CUM Removing excavated soil 20 CUM Schedule A part VIII Excavation 160 CUM PCC 1:3:6 using 40mm stone 23 CUM hard core guage 63mm 23 CUM Brick work 41 CUM 15 mm thick rendering in cm 1:4 187 SQM 1:2:4 in coping 4 CUM PCC 1:2:4 in drain 6 CUM Extra for finished drain or channel 30cm inner girth 200 RM Removing excavated soil 182 CUM Supply only water proofing compound 53 KG Schedule A part IX Excavation in trenches not exc 1.5m 370 CUM 1:4:8 in foundation 370 CUM Reinforced cement concrete M-25 in column footing 84 CUM TMT bars 10mm dia 6320 KG TMT bars 8mm dia 410 KG TMT 8to10mm dia as in stirrups, spacers 4340 KG Rough finished sides of columns,pillars 572 SQM Brick work 220 CUM 1:2:4 as in coping 10 CUM Rendering 15mm thick on brick 1170 SQM Rendering 15mm thick on brick other than fair faces 1240 SQM 3coats of white wash 2410 SQM Cement pipes of 100m 41 RM returning, filling 230 CUM

Removing excavated soil 140 CUM Angle 65*65*6 2560 KG 2 strand steel barbed wire 2.24mm dia with 2mm dia barbs atRM 68 100 75mm spacing 2 coats of synthatic enamel over a coat of red oxide priemer on new steel surfaces 110 SQM Treating small articles with tar or coal tar 2 100 NOS Schedule A part X Flame proof one light point 20 All as per above item but with 205sq mm cable for power plug 16a 8 Flame proof switch of cast alluminium alloy SP 16A,230V each 20 Switch socket combination with plug 2 pole and 1earth ineach 250V,16A 8 LM6 Flame proof tube light fitting 2*40w 16 each Flame proof ceiling fan 1200mm sweep 3 each ceiling fan regulator 3 each Flame proof distribution board TPN 4way MCB type with1 each 40A Flame proof exhaust fan 305mm sweep 1400RPM 1 each G.I. Earthing with earth plate 60*60*6 thick 2 each Hot crane 2ton cap span apprx 7.0mt centre to centre single girder 1 each water cooler 1 each Wall mounted Automatic boost buck transformer with electronic transistorised relay 1 each Air cooled ceiling mounted Concealed type ductable split each job 1 air conditioner having cap 5.5TR Copper refrigerant tubing 5/8" for discharge and 7/8" for suction 25 RM Air duct of 22guage SWG GI sheet with 25mm fibre glass SQM 30 wrapped externally All as per above item but sheet of 24 SWG 20 SQM All as per above item but sheet of 20 SWG 5 SQM Duct damper fixed inside the duct 0.5 SQM Fire damper with fusible link fixed inside the duct 0.5 SQM Fix diffuser fabricated out of MS sheet with vol control damper duly powder coated 1 SQM return air grill duly fabricated of 22SWG of power coated finish 1.5 SQM Sluice valve 80mm 1 each const of valve pit of 120*120*120 1 each Instant patch perfact ready mix bitumen polymer 20 KG Street light fittings HPSV 70W inclusive of lamp 20 each 4pole MCCB 250A 415V with rupturing cap 35KA 1 Each Aluminium cable 3.5core 35sqmm 200 RM Aluminium cable 4core 10sqmm 1000 RM G.I. Earthin with 600*600*6 5 Each LT panel board made out of CRCA sheet of 3.15mm thick Each 1 Earth continuity conductor with GI strip of 25*4mm 15 RM Septic tank for 10 users 1 Each Soakage well complete of size 1.2m dia 3m depth 1 Each Steel gates of 6m span 1 Each Steel gates of 4m span 2 Each

You might also like

- Item Rate Boq: Validate Print HelpDocument22 pagesItem Rate Boq: Validate Print HelpShabir TrambooNo ratings yet

- BoQ % Work Progress 26.4.2016Document8 pagesBoQ % Work Progress 26.4.2016Ahmad Nadeem EzzatNo ratings yet

- 2266 DC On 5522222222Document1 page2266 DC On 5522222222koklenderNo ratings yet

- NITSCHEDULEDocument7 pagesNITSCHEDULEmarcNo ratings yet

- NIT Schedule For Balance Work For Construction of New High School Building at Hardi (Bolck Nawagarh) I/c Water Supply & Sanitary PAC Rs.-38.89 LakhsDocument12 pagesNIT Schedule For Balance Work For Construction of New High School Building at Hardi (Bolck Nawagarh) I/c Water Supply & Sanitary PAC Rs.-38.89 LakhsAri RangelNo ratings yet

- 3 Electrical Esatimate LakeDocument29 pages3 Electrical Esatimate LakehiyogsNo ratings yet

- Madurai MCN - Engineering & Face Lift Balance/Pending Work - SOQDocument33 pagesMadurai MCN - Engineering & Face Lift Balance/Pending Work - SOQmohamed rafiNo ratings yet

- Labour Rate RecommendedDocument106 pagesLabour Rate RecommendedDhiyanesh Waran78% (18)

- DTP Sy 43 Mudbal BDocument18 pagesDTP Sy 43 Mudbal BshivapannaleNo ratings yet

- C C C CDocument11 pagesC C C Ckalpana_8912No ratings yet

- TSP Work - Estimate - Template 330Document6 pagesTSP Work - Estimate - Template 330shivapannaleNo ratings yet

- DTP 254 MudbalDocument12 pagesDTP 254 MudbalshivapannaleNo ratings yet

- Harga Material - PurchasingDocument2 pagesHarga Material - PurchasingPanji NurdyantoNo ratings yet

- Material Takeoff SheetDocument14 pagesMaterial Takeoff SheetAssem ElhajjNo ratings yet

- Boq 1326 8707Document5 pagesBoq 1326 8707Muhammad RizwanNo ratings yet

- PE RT PIPE KavitaDocument11 pagesPE RT PIPE KavitaaasifNo ratings yet

- BoQ DEW DROPS - Sundhar MailDocument8 pagesBoQ DEW DROPS - Sundhar MailAtul ShrivastavaNo ratings yet

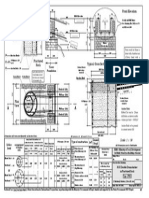

- Front Elevation Section A-A: Tower FoundationDocument1 pageFront Elevation Section A-A: Tower FoundationkoklenderNo ratings yet

- Bought Out Itms Tracking SheetDocument32 pagesBought Out Itms Tracking Sheetvinoth madhavanNo ratings yet

- AI Quote - Labour Rate AnalysisDocument29 pagesAI Quote - Labour Rate AnalysisKarthi KesanNo ratings yet

- Mula BreakdownDocument8 pagesMula BreakdownSisay chaneNo ratings yet

- Atdp Es 000212Document35 pagesAtdp Es 000212peetholNo ratings yet

- D DFGFS HFon PDFDocument1 pageD DFGFS HFon PDFkoklenderNo ratings yet

- Drilling of 1 No Bore Well at SRS, NDRI, Adugodi, Bangalore. SH:-Pdg. Pump SetsDocument5 pagesDrilling of 1 No Bore Well at SRS, NDRI, Adugodi, Bangalore. SH:-Pdg. Pump SetsRatnakar SeethiniNo ratings yet

- Towards Bridge: Standard QuantitiesDocument1 pageTowards Bridge: Standard QuantitieskoklenderNo ratings yet

- EstimateDocument207 pagesEstimategvgbabu100% (1)

- 8 LSDocument2 pages8 LSannapurnastore66No ratings yet

- Samudayik BhawanDocument13 pagesSamudayik BhawanManish PatelNo ratings yet

- Dharmagiri - 2 BOQ For RefDocument4 pagesDharmagiri - 2 BOQ For RefNani JupallyNo ratings yet

- Boq of Solu Hydro Power Project PKG 1Document37 pagesBoq of Solu Hydro Power Project PKG 1vijayNo ratings yet

- Estimate of Labs& Multipurpose Hall GEC GirlsDocument32 pagesEstimate of Labs& Multipurpose Hall GEC GirlsBryan OscoNo ratings yet

- 120kl OhsrDocument21 pages120kl OhsrSrinivasa_DRao_6174100% (1)

- No. Items Description: (Without Supply)Document2 pagesNo. Items Description: (Without Supply)Rizwan HameedNo ratings yet

- Front Elevation Section A-A: Hard Rock Tower FoundationDocument1 pageFront Elevation Section A-A: Hard Rock Tower FoundationkoklenderNo ratings yet

- 2-Volume I Part IIDocument48 pages2-Volume I Part IIBasava NNo ratings yet

- Final GI Pipe Earth 2013Document8 pagesFinal GI Pipe Earth 2013Thirukandiyur Sudarsana Sri RamanNo ratings yet

- Animal Feed EFFORTDocument16 pagesAnimal Feed EFFORTHaftamu Tekle100% (1)

- Dharmagiri - 2 BOQDocument20 pagesDharmagiri - 2 BOQNani JupallyNo ratings yet

- Date-070209 SR - No. Description Unit Rate A Rcc. WorkDocument6 pagesDate-070209 SR - No. Description Unit Rate A Rcc. WorkAjay SinghNo ratings yet

- Store Office EstimationDocument1 pageStore Office Estimationmonarch_007No ratings yet

- To The Project Manager NKC Humhama SrinagarDocument2 pagesTo The Project Manager NKC Humhama Srinagarshubhankar sharmaNo ratings yet

- Papa Document 8Document10 pagesPapa Document 8krishansoni1965No ratings yet

- Section A-A Front Elevation: Hard Rock Tower FoundationDocument1 pageSection A-A Front Elevation: Hard Rock Tower FoundationkoklenderNo ratings yet

- Boqcomparativechart - 2023-05-27T095500.235Document17 pagesBoqcomparativechart - 2023-05-27T095500.235Abode ArtisanNo ratings yet

- Green Atom ScopeDocument107 pagesGreen Atom ScopeadihindNo ratings yet

- Refractory Stock SheetDocument9 pagesRefractory Stock SheetJunaid MazharNo ratings yet

- Maintanence and Repairs of Existing Community Toilet at Keelalakhsmipuram in Kayalpatnam MunicipalityDocument5 pagesMaintanence and Repairs of Existing Community Toilet at Keelalakhsmipuram in Kayalpatnam MunicipalitykayalonthewebNo ratings yet

- Quotation: M/S. North East Construction HosurDocument9 pagesQuotation: M/S. North East Construction HosurramalingammNo ratings yet

- Fire Fighting Works: S.No. Description Unit Qty 1.0 Fire Hydrant SystemDocument7 pagesFire Fighting Works: S.No. Description Unit Qty 1.0 Fire Hydrant SystemRakesh Karan SinghNo ratings yet

- Bill of Materials and Cost Estimate: Material/Description Quantity Unit I. Earth WorksDocument8 pagesBill of Materials and Cost Estimate: Material/Description Quantity Unit I. Earth WorksJaymar Palomares Orillo100% (1)

- Labour and Material Calculation SheetDocument6 pagesLabour and Material Calculation SheetKarthimeena MeenaNo ratings yet

- Proposed Niper Campus at Guwahati, Assam. Admin BlockDocument7 pagesProposed Niper Campus at Guwahati, Assam. Admin Blockkiran raghukiranNo ratings yet

- UntitledDocument9 pagesUntitledGada RobaleNo ratings yet

- MS For Fire StoppingDocument22 pagesMS For Fire Stoppingtvpham123No ratings yet

- Civil Mgineershould Inow The Following Details1Document25 pagesCivil Mgineershould Inow The Following Details1Srinivasan RanganathanNo ratings yet

- BOQ For Plumbing, Sanitary Works: SR - No Item Description Quantity Unit Rate Amount (RS.)Document6 pagesBOQ For Plumbing, Sanitary Works: SR - No Item Description Quantity Unit Rate Amount (RS.)Paran GogoiNo ratings yet

- AbstratctDocument6 pagesAbstratctHemant PanpaliyaNo ratings yet

- Shivamogga Smart City - 2aDocument29 pagesShivamogga Smart City - 2aVarun HmNo ratings yet

- Alternate To Ghat-Ki-Guni by Construction of Tunnel in Jhalana Hills JaipurDocument46 pagesAlternate To Ghat-Ki-Guni by Construction of Tunnel in Jhalana Hills JaipurDevendra SharmaNo ratings yet

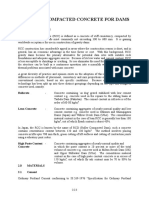

- Roller Compacted Concrete For DamsDocument16 pagesRoller Compacted Concrete For Damsabhineet srivastavaNo ratings yet

- Carbonization of Pitch and Resin PDFDocument8 pagesCarbonization of Pitch and Resin PDFWagnerdeLagesNo ratings yet

- Pferd - Limas Rotativas Cat. 202Document64 pagesPferd - Limas Rotativas Cat. 202MinatelNo ratings yet

- CTD-101K Datasheet 2003Document3 pagesCTD-101K Datasheet 2003tsram90No ratings yet

- Self Compacting ConcreteDocument33 pagesSelf Compacting Concreteapi-252700561100% (1)

- Technology and Concepts For Joint Sealing PDFDocument32 pagesTechnology and Concepts For Joint Sealing PDFyvanmmuNo ratings yet

- Gift From The Aluminum GodDocument38 pagesGift From The Aluminum GodStephane CaronNo ratings yet

- Glazing Compatibility6 PDFDocument3 pagesGlazing Compatibility6 PDFpandey008No ratings yet

- Hiq CatalogDocument8 pagesHiq CatalogAbdur RahmanNo ratings yet

- WNT Catalogue 2016 - 07 Thread Turning PDFDocument47 pagesWNT Catalogue 2016 - 07 Thread Turning PDFMani StoqnovaNo ratings yet

- Hand RailDocument5 pagesHand RailpandiangvNo ratings yet

- EU FlowerDocument2 pagesEU FlowerabeesNo ratings yet

- TDS - Masterflow 648CPDocument3 pagesTDS - Masterflow 648CPVenkata RaoNo ratings yet

- Apro Introduction 2015Document20 pagesApro Introduction 2015urtzilegorburuNo ratings yet

- Wrought AlloysDocument33 pagesWrought AlloysKanjiMasroorNo ratings yet

- An Introduction To FRP Composites For Construction: ISIS Educational Module 2Document27 pagesAn Introduction To FRP Composites For Construction: ISIS Educational Module 2Shital ChaudhariNo ratings yet

- Basalt FiberDocument19 pagesBasalt FiberShariqKhanNo ratings yet

- Aqua StopDocument2 pagesAqua Stoppravi3434No ratings yet

- Aluminium Packaging ApplicationsDocument8 pagesAluminium Packaging ApplicationsedelapolloNo ratings yet

- Casting DefectsDocument2 pagesCasting DefectsLanky IloveuNo ratings yet

- GRP Product GuideDocument20 pagesGRP Product Guidedp75No ratings yet

- Advanced Concrete TechnologyDocument2 pagesAdvanced Concrete TechnologyNarasimha Prasad Kikeri NarasimhaNo ratings yet

- RE TEC 008 Mechanical Compliance Sheet HVACDocument3 pagesRE TEC 008 Mechanical Compliance Sheet HVACramis0007No ratings yet

- Halfen Natural Stone Support Systems: Faç A D EDocument40 pagesHalfen Natural Stone Support Systems: Faç A D ElavovNo ratings yet

- Paint AdditivesDocument3 pagesPaint AdditivesAnonymous yy8In96j0rNo ratings yet

- Effect of Waste Polymer Modifier On The Properties of Bituminous Concrete MixesDocument8 pagesEffect of Waste Polymer Modifier On The Properties of Bituminous Concrete MixesluanaheresNo ratings yet

- Mechanical Pipe Spacing 1",2",3"Document6 pagesMechanical Pipe Spacing 1",2",3"shankarniceguyNo ratings yet

- F607RWDocument1 pageF607RWEli Antonio Cruz FloresNo ratings yet

- Masonary Example Calculations - ShearDocument8 pagesMasonary Example Calculations - ShearJohn Van RooyenNo ratings yet

- Governm Ntofandhrapradesh: o 146 CemDocument2 pagesGovernm Ntofandhrapradesh: o 146 Cemvarma369vinaNo ratings yet