Professional Documents

Culture Documents

Blain KV Trouble-Gb

Uploaded by

Sylvester SullivanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Blain KV Trouble-Gb

Uploaded by

Sylvester SullivanCopyright:

Available Formats

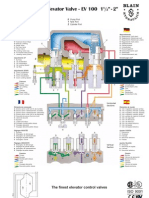

KV Elevator Control Valve Trouble Shooting (2007)

UP Travel

Valves are fully adjusted and tested in the factory. Check electrical operation before changing valve setting.

Problem

No Up-Start (Elevator remains at oor).

Possible cause

Recommended

Test for KV1S and KV2S: Turn adjustment 5 all the way in, if the elevator now starts upwards the problem is at solenoid A. Solenoid A not energised or voltage too low. Solenoid A tube not screwed down tight. Solenoid valve A: Dirt or damage between needle and seat. Orice in bypass valve blocked. Adjustment 1 too far back (open). Not enough pilot pressure (minimum 5 bar) or bypass ow guide too large (slots too wide). see* Pressure relief valve, S is set too low. Down valve 7 or 9 are open due to contamination in their orices. (Especially if the elevator settles back on the buffers. Solenoid D is leaking. Pump running in the wrong direction. The pump connection ange is leaking excessively. The pump is undersize or worn. See A below. Tighten Solenoid A tube. Clean or change needle and seat. Clean or change bypass valve, U. With the pump running, turn adjustment 1 in, or if already too far in, insert smaller bypass ow guide (see the diagramm in KV literature). Set relief valve higher. Preadjustment all the way in and then 1 turn out. Clean or replace down valves 7 (KV2 only) and 9. Clean solenoid D. Install the pump correctly. Seal the pump connection. Select a bigger pump or replace the pump.

* Test: If by turning adjustment 1 with the pump running the pressure does not rise above 5 bar, even with a smaller bypass valve inserted, the problem should be sought at the pump. Adjustment 1 turned in too far. Up-Start too hard. Bypass ow guide U too small (slots too narrow). Star to delta motor switch period is too long. O-ring UO on the bypass valve U is leaking. Excessive friction on the guide rails or in the cylinder head. Elevator slows down but over travels the oor level. Solenoid A (Up-stop) is de-energised too late. Adjustment 5 (Soft Stop) not far enough open (KV1S and KV2S). Adjustment 1 Bypass not far enough open and pump ow does not completely by-pass. Adjustment 1 too far in. pipe thread connection in return line T should not exceed 14 mm. Turn out adjustment 1. Change to ow guide with wider slots. 0.2-0.3 sec. is sufcient. Change O-Ring see KV Spare Parts List. Can not be eliminated through valve adjustment. See A below. Open further out. Open adjustment 1 two turns further out. Open adjustment 1 further out. With tape threads, 4-6 threads of engagement is sufcient.

Relief-Valve not adjustable to lower value. Elevator doesnt reach full speed.

By-pass piston doesnt close. Dirt/foreign particeles in by-pass piston orice.

Clean the dirt / foreign particels in the by-pass piston orice or change the piston and turn adjustment 1 out.

A For checking the operation of the solenoids, remove the top nuts. By lifting the coils a few millimeters, the magnetic pull of the coil can be felt.

For testing, the operation of the elevator car can also be controlled by lifting and replacing the coil. If the coil gets too hot, the coil has to be mounted onto the solenoid and the following adjustments have to be carried out on normal travels from oor to oor. Nominal Settings: Adjustment 1 level with ange faces. Adjustment 5 (KV1S & KV2S) level with ange faces.

mar 07

Pfaffenstrasse 1 Boellinger Hoefe 74078 Heilbronn Germany

Tel. 07131 2821-0 Fax 07131 485216 http://www.blain.de e-mail:info@blain.de

GmbH

Manufacturer of the Highest Quality: Control Valves for Elevators Tank Heaters - Hand Pumps Pipe Rupture Valves - Ball Valves

KV Elevator Control Valve Trouble Shooting (2007)

Down Travel

Valves are fully adjusted and tested in the factory. Check electrical operation before changing valve setting.

Problem

No Down Start (Elevator remains at oor). KV2 only: Down start but no full speed KV2 only: Down full speed but no down leveling.

Possible cause

Solenoid D not energised or voltage too low. Adjustment 6 turned in too far. O-ring XO on down valve, leaking. Solenoid C not energised or voltage too low. Adjustment 7 (Full speed down) turned in too far. Solenoids C and D reversed. Adjustment 9 (Down leveling speed) turned out too far. Down ow guide too small (slots too narrow).

Recommended

Lift coil to check magnetic pull. See A below. Turn out adjustment 6. Replace O-ring XO. Lift coil to check magnetic pull. See A below. Turn out adjustment 7. See A below. Swap solenoid C and D. Turn in adjustment 9. Change ow guide (use next bigger insert size). Adjust to 0.05 m/s. Clean or change needle and seat. Replace ow guide. Replace and test in sequence. Where possible, isolate and check.

Elevator travels through the oor level.

Down leveling speed 9 too fast. Solenoid Valve D leaking at the needle. Orice in ow guide contaminated.

Leakage (Elevator sinks away from oor).

Leak at N6, S6, XO, VO, WO or HO. Other valves (ex. handpump) in the system, leaking.

Contraction of oil during cooling, especially from 35C or above. Consider oil cooler to keep oil temperatures down.

A For checking the operation of the solenoids, remove the top nuts. By lifting the coils a few millimeters, the magnetic pull of the coil can be felt.

For testing, the operation of the elevator car can also be controlled by lifting and replacing the coil. If the coil gets too hot, the coil has to be mounted onto the solenoid and the following adjustments have to be carried out on normal travels from oor to oor. Nominal Settings: Adjustments 7 & 9, screwheads level with the hexagon heads.

mar 07

Pfaffenstrasse 1 Boellinger Hoefe 74078 Heilbronn Germany

Tel. 07131 2821-0 Fax 07131 485216 http://www.blain.de e-mail:info@blain.de

GmbH

Manufacturer of the Highest Quality: Control Valves for Elevators Tank Heaters - Hand Pumps Pipe Rupture Valves - Ball Valves

You might also like

- Rtaa Svd01a en - 01012004Document10 pagesRtaa Svd01a en - 01012004alcomech100% (3)

- TLB890 Hydraulic Pressure Testing PDFDocument13 pagesTLB890 Hydraulic Pressure Testing PDFjwd50% (2)

- Full KV Valves InfoDocument6 pagesFull KV Valves InfoSylvester Sullivan100% (1)

- Rtaa SB 4 - 10011991Document6 pagesRtaa SB 4 - 10011991alcomech100% (3)

- Full KV Valves InfoDocument6 pagesFull KV Valves InfoSylvester Sullivan100% (1)

- CH 04Document19 pagesCH 04Charmaine Bernados BrucalNo ratings yet

- Blain EV Troubleshooting Ev - Trouble-GbDocument2 pagesBlain EV Troubleshooting Ev - Trouble-GbSylvester SullivanNo ratings yet

- KV Trouble GBDocument2 pagesKV Trouble GBtojoNo ratings yet

- EV 100 Trouble Shooting (2013) : UP TravelDocument2 pagesEV 100 Trouble Shooting (2013) : UP TravelAnonymous Ih1EEENo ratings yet

- Ev-Trouble GBDocument2 pagesEv-Trouble GBJean Luis SaviñónNo ratings yet

- Ev-Trouble GBDocument2 pagesEv-Trouble GBNevenko ArlovNo ratings yet

- Valves 4Document78 pagesValves 4Gurmeet MehmaNo ratings yet

- Blain Ev100 - GBDocument6 pagesBlain Ev100 - GBSylvester SullivanNo ratings yet

- Blain EV100Document6 pagesBlain EV100Sylvester SullivanNo ratings yet

- TroubleshootingDocument7 pagesTroubleshootingg665013No ratings yet

- Troubleshoooting Hydraulic System71742 - 10Document7 pagesTroubleshoooting Hydraulic System71742 - 10honeyvish92No ratings yet

- Solenoid ValveDocument3 pagesSolenoid ValveHasanka MadhurangaNo ratings yet

- Mustang Series M116-31 or M6116-31 (Globe), M1116-31 or M61116-31 (Angle) Installation InstructionsDocument1 pageMustang Series M116-31 or M6116-31 (Globe), M1116-31 or M61116-31 (Angle) Installation InstructionsWattsNo ratings yet

- Fluidbasics Chapter14Document11 pagesFluidbasics Chapter14asNo ratings yet

- Handling of Turbine During Emergency: Emergencies in Turbine and AuxiliariesDocument3 pagesHandling of Turbine During Emergency: Emergencies in Turbine and Auxiliariesron1234567890No ratings yet

- Maintenance and Service Manual For Elevator Control Valve EV 100 BlainDocument13 pagesMaintenance and Service Manual For Elevator Control Valve EV 100 BlainCristian Liviu CiovicaNo ratings yet

- Ev Quick-GbDocument2 pagesEv Quick-GbGul Nawab KhanNo ratings yet

- Maintenance and Service Manual For Elevator Control Valve: EV 100 BlainDocument13 pagesMaintenance and Service Manual For Elevator Control Valve: EV 100 Blainsuk2010No ratings yet

- Ev100manual en PDFDocument13 pagesEv100manual en PDFdragishabl100% (1)

- Control Valve PresentDocument120 pagesControl Valve PresentShoeb Ali KhanNo ratings yet

- Preventive Maintenance of Hydraulic Pumps and Motors: Induction/Refresher Drilling Training Programme Foreman (Drilling)Document25 pagesPreventive Maintenance of Hydraulic Pumps and Motors: Induction/Refresher Drilling Training Programme Foreman (Drilling)mukesh ojhaNo ratings yet

- Mep Oral AnswersDocument28 pagesMep Oral AnswersAshjo Gamer100% (1)

- Group 2 Operational Checks and TroubleshootingDocument7 pagesGroup 2 Operational Checks and TroubleshootingPriscila RodriguesNo ratings yet

- Sequence ValveDocument8 pagesSequence Valvemr3478No ratings yet

- Setting The HYDRAULIC VALVE BANKDocument6 pagesSetting The HYDRAULIC VALVE BANKAlex RamirezNo ratings yet

- Sur - Flo Turbine MeterDocument40 pagesSur - Flo Turbine MeterCheng HuangNo ratings yet

- Defect List CommentDocument2 pagesDefect List Commentmohammed TabrezNo ratings yet

- Installation and OperationDocument9 pagesInstallation and Operationabdullatif_asNo ratings yet

- Control Valves: Fluid Mechanics, Hydraulics & PneumaticsDocument28 pagesControl Valves: Fluid Mechanics, Hydraulics & Pneumaticsshahzaibkhan ccpNo ratings yet

- Manual de Fallas TDS 11 PDFDocument68 pagesManual de Fallas TDS 11 PDFvegeta1984100% (2)

- Blain EV 100 Ev - Quick-GbDocument2 pagesBlain EV 100 Ev - Quick-GbSylvester SullivanNo ratings yet

- RJSINGLEDocument88 pagesRJSINGLEAbhishek TiwariNo ratings yet

- Hydraulic MaintenanceDocument27 pagesHydraulic Maintenancekhumiso100% (1)

- Setting The Hydraulic Block ManifoldDocument6 pagesSetting The Hydraulic Block ManifoldJuan Pablo Villazon RichterNo ratings yet

- Section: Illustrated Sou Rcebook Mechanical ComponentsDocument15 pagesSection: Illustrated Sou Rcebook Mechanical ComponentsparamontNo ratings yet

- Hydraulic Troubleshooting GuideDocument3 pagesHydraulic Troubleshooting GuideRamon PeyegrinNo ratings yet

- 5r55n How-To-Fix-ItDocument87 pages5r55n How-To-Fix-ItDavid Chalker100% (14)

- Boiler Safety ValveDocument11 pagesBoiler Safety ValveAayush Agrawal100% (1)

- Group 2 Operational Checks and TroubleshootingDocument11 pagesGroup 2 Operational Checks and TroubleshootingPriscila RodriguesNo ratings yet

- Vacuum Pumps Common Problems and TroubleshootingDocument5 pagesVacuum Pumps Common Problems and TroubleshootingTânia RomanholiNo ratings yet

- Chapter 4Document46 pagesChapter 4Thành CôngNo ratings yet

- 1Ø Service Manual: Engineered For LifeDocument76 pages1Ø Service Manual: Engineered For LifejewettwaterNo ratings yet

- Hydraulic SystemDocument81 pagesHydraulic SystemMaritza Gabriela Arizabal MedinaNo ratings yet

- Additel 918 ManualDocument2 pagesAdditel 918 ManualAnonymous ffje1rpaNo ratings yet

- Bucholz RelayDocument4 pagesBucholz RelayMonish Nawal100% (1)

- I & M Mark 57: Ideal InstallationDocument4 pagesI & M Mark 57: Ideal Installationbenzerga karimNo ratings yet

- Sequencing of CylindresDocument5 pagesSequencing of CylindreschtganduNo ratings yet

- Safety Valve SettingDocument26 pagesSafety Valve SettingLalit MeenaNo ratings yet

- Turbine Emergency - Thermal Power Plant A-ZDocument5 pagesTurbine Emergency - Thermal Power Plant A-ZSiva Kulanji100% (1)

- HTTP WWW - Hydraulicspneumatics.com Classes Article Article Draw P17Document6 pagesHTTP WWW - Hydraulicspneumatics.com Classes Article Article Draw P17jorsueNo ratings yet

- Claval PRV TM-90-01Document30 pagesClaval PRV TM-90-01DuxToyNo ratings yet

- Stainless Series S116-52 or S6116-52 (Globe), S1116-52 or S61116-52 (Angle) Installation InstructionsDocument2 pagesStainless Series S116-52 or S6116-52 (Globe), S1116-52 or S61116-52 (Angle) Installation InstructionsWattsNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- RL RL RL RL RL: R R R R R Amloc Amloc Amloc Amloc AmlocDocument5 pagesRL RL RL RL RL: R R R R R Amloc Amloc Amloc Amloc AmlocSylvester SullivanNo ratings yet

- Flow - Pressure Chart (US and Metric)Document4 pagesFlow - Pressure Chart (US and Metric)Sylvester SullivanNo ratings yet

- Slack Rope Valve KS For BLAIN EV, KV Down Valve and L10Document1 pageSlack Rope Valve KS For BLAIN EV, KV Down Valve and L10Sylvester SullivanNo ratings yet

- Sys Leak EVDocument1 pageSys Leak EVSylvester SullivanNo ratings yet

- EV Poster1-12Document1 pageEV Poster1-12Sylvester SullivanNo ratings yet

- EV Poster34Document1 pageEV Poster34Sylvester SullivanNo ratings yet

- Flow - Pressure Chart (US and Metric) : (57,3 L/MTR.)Document4 pagesFlow - Pressure Chart (US and Metric) : (57,3 L/MTR.)Sylvester SullivanNo ratings yet

- EV Spare Parts List: Down Leak Solenoid Valves AdjustmentsDocument1 pageEV Spare Parts List: Down Leak Solenoid Valves AdjustmentsSylvester SullivanNo ratings yet

- Blain Sys Leak KVDocument1 pageBlain Sys Leak KVSylvester SullivanNo ratings yet

- Blain Spare Parts EV KVDocument2 pagesBlain Spare Parts EV KVSylvester SullivanNo ratings yet

- Blain Price List 300 Euro 2008Document1 pageBlain Price List 300 Euro 2008Sylvester SullivanNo ratings yet

- Blain MD - GBDocument4 pagesBlain MD - GBSylvester SullivanNo ratings yet

- Blain KV-GBDocument6 pagesBlain KV-GBSylvester SullivanNo ratings yet

- Blain HP - 4spDocument2 pagesBlain HP - 4spSylvester SullivanNo ratings yet

- Blain EV100Document6 pagesBlain EV100Sylvester SullivanNo ratings yet

- Blain EV 100 Ev - Quick-GbDocument2 pagesBlain EV 100 Ev - Quick-GbSylvester SullivanNo ratings yet

- Blain CX-EDocument1 pageBlain CX-ESylvester SullivanNo ratings yet

- Adj Proc KVDocument2 pagesAdj Proc KVSylvester SullivanNo ratings yet

- Blain Electronic Servo Valve - Sev - GB - 07Document34 pagesBlain Electronic Servo Valve - Sev - GB - 07Sylvester SullivanNo ratings yet

- Blain Service Manual LowDocument15 pagesBlain Service Manual LowSylvester SullivanNo ratings yet

- Blain EV 0-1-10-100 Adj-proc-EVDocument2 pagesBlain EV 0-1-10-100 Adj-proc-EVSylvester SullivanNo ratings yet

- Adjust 9Document1 pageAdjust 9Sylvester SullivanNo ratings yet

- Blain BVDocument2 pagesBlain BVSylvester SullivanNo ratings yet

- Blain Sys Leak EVDocument1 pageBlain Sys Leak EVSylvester SullivanNo ratings yet

- User Manual PM3250Document80 pagesUser Manual PM3250otavioalcaldeNo ratings yet

- C4 Vectors - Vector Lines PDFDocument33 pagesC4 Vectors - Vector Lines PDFMohsin NaveedNo ratings yet

- Retail Banking Black BookDocument95 pagesRetail Banking Black Bookomprakash shindeNo ratings yet

- Regional Manager Business Development in Atlanta GA Resume Jay GriffithDocument2 pagesRegional Manager Business Development in Atlanta GA Resume Jay GriffithJayGriffithNo ratings yet

- (Campus of Open Learning) University of Delhi Delhi-110007Document1 page(Campus of Open Learning) University of Delhi Delhi-110007Sahil Singh RanaNo ratings yet

- Csu Cep Professional Dispositions 1Document6 pagesCsu Cep Professional Dispositions 1api-502440235No ratings yet

- Numerical Modelling and Design of Electrical DevicesDocument69 pagesNumerical Modelling and Design of Electrical Devicesfabrice mellantNo ratings yet

- Mahesh R Pujar: (Volume3, Issue2)Document6 pagesMahesh R Pujar: (Volume3, Issue2)Ignited MindsNo ratings yet

- Odisha State Museum-1Document26 pagesOdisha State Museum-1ajitkpatnaikNo ratings yet

- Module6 Quiz1Document4 pagesModule6 Quiz1karthik1555No ratings yet

- Frellwits Swedish Hosts FileDocument10 pagesFrellwits Swedish Hosts FileAnonymous DsGzm0hQf5No ratings yet

- International Security Notes International Security NotesDocument34 pagesInternational Security Notes International Security NotesBEeNaNo ratings yet

- MEd TG G07 EN 04-Oct Digital PDFDocument94 pagesMEd TG G07 EN 04-Oct Digital PDFMadhan GanesanNo ratings yet

- Mozal Finance EXCEL Group 15dec2013Document15 pagesMozal Finance EXCEL Group 15dec2013Abhijit TailangNo ratings yet

- Bba VDocument2 pagesBba VkunalbrabbitNo ratings yet

- Design and Analysis of Modified Front Double Wishbone Suspension For A Three Wheel Hybrid VehicleDocument4 pagesDesign and Analysis of Modified Front Double Wishbone Suspension For A Three Wheel Hybrid VehicleRima AroraNo ratings yet

- 2-1. Drifting & Tunneling Drilling Tools PDFDocument9 pages2-1. Drifting & Tunneling Drilling Tools PDFSubhash KediaNo ratings yet

- Math 9 Quiz 4Document3 pagesMath 9 Quiz 4Lin SisombounNo ratings yet

- A Medium-Rise Residential Building: A B C E D F G HDocument3 pagesA Medium-Rise Residential Building: A B C E D F G HBabyjhaneTanItmanNo ratings yet

- Previous Year Questions - Macro Economics - XIIDocument16 pagesPrevious Year Questions - Macro Economics - XIIRituraj VermaNo ratings yet

- Walking in Space - Lyrics and Chord PatternDocument2 pagesWalking in Space - Lyrics and Chord Patternjohn smithNo ratings yet

- Gaming Ports MikrotikDocument6 pagesGaming Ports MikrotikRay OhmsNo ratings yet

- The Wayland News October 2014Document16 pagesThe Wayland News October 2014Julian HornNo ratings yet

- 1916 South American Championship Squads - WikipediaDocument6 pages1916 South American Championship Squads - WikipediaCristian VillamayorNo ratings yet

- UM-140-D00221-07 SeaTrac Developer Guide (Firmware v2.4)Document154 pagesUM-140-D00221-07 SeaTrac Developer Guide (Firmware v2.4)Antony Jacob AshishNo ratings yet

- Grid Pattern PortraitDocument8 pagesGrid Pattern PortraitEmma FravigarNo ratings yet

- The Privatization PolicyDocument14 pagesThe Privatization PolicyRIBLEN EDORINANo ratings yet

- Ajmera - Treon - FF - R4 - 13-11-17 FinalDocument45 pagesAjmera - Treon - FF - R4 - 13-11-17 FinalNikita KadamNo ratings yet

- DS Agile - Enm - C6pDocument358 pagesDS Agile - Enm - C6pABDERRAHMANE JAFNo ratings yet