Professional Documents

Culture Documents

Trouble Ev e

Uploaded by

Sylvester SullivanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Trouble Ev e

Uploaded by

Sylvester SullivanCopyright:

Available Formats

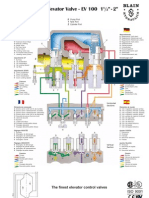

Hydraulic Elevators Technical Info No.

E11a

EV 100 Elevator Control Valve

Trouble Shooting Up Travel

Jan. 2000

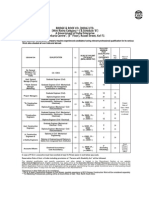

I Valves are fully adjusted at the factory. Check electrical operation before changing valve setting. II For checking operation of the solenoids, remove the top nuts. By lifting the solenoids a few millimeters the magnetic pull of the solenoid can be felt as well as the operation of the elevator car. Problem Possible cause 1) Solenoid A not energised or voltage too low. 2) Solenoid A tube not screwed down tight. 3) Solenoid valve A dirt between needle and seat. 4) Adjustment 2 (Up Accel.) not open enough. 5) Adjustment 1 is too far back (not enough pilot pressure, minimum 5 bar) or bypass flow guide too large (slots too wide). 6) Relief valve set too low. 7) The down valve is open because adjustment 8 is closed off. 8) Pump running in the wrong direction. 9) The pump is undersize or worn. 10) The pump connection flange is leaking excessively. 11) See 9) and 10) above. 12) Solenoid B not energised or voltage too low. 13) Dirt in solenoid B or solenoid tube not pulled up tight. 14) Adjustment 1 turned in too far. 15) Adjustment 2 open too far. 16) Star to delta motor switch period is too long. 17) UO O-ring on the bypass valve U is leaking or front O-ring on flange 4F leaking (unlikely). 18) Excessive friction on the guide rails or in the cylinder head. 19) Solenoid B (Up Deceleration) does not de-energise. 20) Adjustment 3 not open enough. 21) UO O-ring on bypass valve U leaking. (If this is the cause, the car will still accelerate up with 2 fully closed). 22) Up Leveling speed 4 too fast. 23) Solenoid A not energised (possibly solenoid A and B reversed) or dirt. 24) Solenoid A tube not screwed down tight. 25) Up Leveling speed adjustment 4 too far in. 26) Relief Valve set too low. 27) Middle O-ring of middle flange 4 leaking. Recommended See note II at top of page. Turn adjustment 5 all the way in. If the elevator now starts upwards the problem is at solenoid A, 1), 2) or 3). Open further. With the pump running, turn adjustment 1 in, or if already too far, insert smaller bypass flow guide. Set higher Open adjustment 8. If by turning adjustment 1 with the pump running the pressure does not rise above 5 bar, even with a smaller bypass valve inserted, the problem should be sought under 8), 9) or 10). --See note II at top of page. Turn restriction 3 all the way in. If the elevator now travels with full speed, the cause is 12) or 13). Open adjustment 1. Close in adjustment 2. 0,2 - 0,3 secs. is sufficient. Close adjustment 2 completely. If the elevator still goes into full speed, change O-rings. Can not be eliminated through valve adjustment. See note II at top of page. Possibly elevator slow down switch too high. Open 3 further. Turn in 2 further. Replace O-ring: EV 3/4 = 26,0 x 2,0 EV 1 1/2 + 2 = 39,3 x 2,6 EV 2 1/2 = 58,0 x 3,0 Adjust 4 to between 6 and 10 cm/sec. See note II at top of page. If with adjustment 5 fully closed the car now up levels, the problem is solenoid A. Between being level with the flange and 2 mm out is a normal setting for 4. Set higher. Replace O-ring: EV 3/4 26,0x2,0 EV 1 1/2 + 2 47,0x2,5 EV 2 1/2 67,0x2,5 See note II at top of page. Open further. Adjust to between 6 and 10 cm/sec.

No Up-Start (Elevator remains at floor)

Up Start but no Full Speed

Up Start too hard

Elevator does not decelerate into Up-Leveling (continues at full speed)

No Up-Leveling

No Re-Leveling

Elevator slows

28) Solenoid A (Up stop) is de-energised too late. 29) Adjustment 5 (Soft Stop) not far enough down but travels open. 30) Up Leveling adjustment 4 is too far out passed the upper(too fast).

floor level. Elevator stops before reaching the floor.

31) Adjustment 1 Bypass not far enough open and pump flow does not completely by-pass. 32) Up-Leveling too slow. 33) Solenoids A and B wrong way round. 34) Middle O-ring FO on flange 4F leaking.

Open adjustment 1 two turns further out.Jan. 2000 Open adjustment 4 further. See note II at top of page. Change O-ring.

Hydraulic Elevators Info No. E11a

EV 100 Elevator Control Valve

Trouble Shooting Down Travel Possible cause Recommended 51) Solenoid D not energised or voltage too low. See note II at top of page 1. 52) Adjustment 6 not open enough or adjustment 8 too far open. 53) O-ring UO on down valve leaking.

Technical

Problem No Down Start

(Elevator remains at floor) Down start but no full speed Down full speed but no Down leveling Elevator travels

54) 55) 56) 57) 58) 59) 60)

Open 6. Turn in 8 cautiously (Danger of travelling through). Change: EV 3/4 = 26,0x2,0 EV 1 1/2 + 2 = 39,3x2,6 EV 2 1/2 = 58,0x3,0 Solenoid C not energised or voltage too low. See note II at top of page 1. Adjustment 7 (Full speed down) not far Open 7 further. enough open. Solenoid D not energised (possibly See note II at top of page 1. solenoids C and D reversed). Adjustment 9 (Down Leveling speed) Between being level with the flange and two turns not far enough open. further out is a normal setting. Spring 9F in adjustment 9 broken. Replace spring. Adjustment 8 (Down Deceleration) not far Open turn further. enough open. Down Leveling speed 9 too fast. Adjust to between 6 and 10 cm/sec. Clean or change needle and seat. Change: EV 3/4 = 26,0x2,0 EV 1 1/2 + 2 = 47,0x2,5 EV 2 1/2 = 58,0x3,0 Replace and test in sequence. Where possible, isolate and check. Consider oil cooler.

Page 2/2

through the lower floor. 61) Solenoid Valve C leaking at needle. 62) O-ring FO on flange 7F leaking.

63) Leak at DN, XO, VO, WO, FO or HO. Leakage (Elevator sinks away from floor). 64) Other valve or handpump in system leaking. 65) Contraction of oil during cooling especially from above 35C.

Pfaffenstrasse 1 Boellinger Hoefe 74078 Heilbronn Germany

Tel. 07131 21016 Fax 07131 485216 http://www.blain.de e-mail:info@blain.de

GmbH

Manufacturer of the Highest Quality: Control Valves for Elevators Tank Heaters - Hand Pumps Pipe Rupture Valves - Ball Valves

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Full KV Valves InfoDocument6 pagesFull KV Valves InfoSylvester Sullivan100% (1)

- Mil STD 756bDocument85 pagesMil STD 756bgeoffxyz0No ratings yet

- Blain Sys Leak KVDocument1 pageBlain Sys Leak KVSylvester SullivanNo ratings yet

- Blain Sys Leak EVDocument1 pageBlain Sys Leak EVSylvester SullivanNo ratings yet

- Troubleshooting GuideDocument8 pagesTroubleshooting GuideSylvester SullivanNo ratings yet

- Trouble KV eDocument2 pagesTrouble KV eSylvester SullivanNo ratings yet

- EV Spare Parts List: Down Leak Solenoid Valves AdjustmentsDocument1 pageEV Spare Parts List: Down Leak Solenoid Valves AdjustmentsSylvester SullivanNo ratings yet

- Slack Rope Valve KS For BLAIN EV, KV Down Valve and L10Document1 pageSlack Rope Valve KS For BLAIN EV, KV Down Valve and L10Sylvester SullivanNo ratings yet

- RL RL RL RL RL: R R R R R Amloc Amloc Amloc Amloc AmlocDocument5 pagesRL RL RL RL RL: R R R R R Amloc Amloc Amloc Amloc AmlocSylvester SullivanNo ratings yet

- Sys Leak EVDocument1 pageSys Leak EVSylvester SullivanNo ratings yet

- Blain Spare Parts EV KVDocument2 pagesBlain Spare Parts EV KVSylvester SullivanNo ratings yet

- HPDocument2 pagesHPSylvester SullivanNo ratings yet

- MD eDocument4 pagesMD eSylvester SullivanNo ratings yet

- Ev eDocument6 pagesEv eSylvester SullivanNo ratings yet

- Quick Adj Ev eDocument2 pagesQuick Adj Ev eSylvester SullivanNo ratings yet

- Slack Rope Valve KS For BLAIN EV, KV Down Valve and L10Document1 pageSlack Rope Valve KS For BLAIN EV, KV Down Valve and L10Sylvester SullivanNo ratings yet

- Flow - Pressure Chart (US and Metric)Document4 pagesFlow - Pressure Chart (US and Metric)Sylvester SullivanNo ratings yet

- Blain BVDocument2 pagesBlain BVSylvester SullivanNo ratings yet

- EV Poster34Document1 pageEV Poster34Sylvester SullivanNo ratings yet

- Blain CX-EDocument1 pageBlain CX-ESylvester SullivanNo ratings yet

- Blain Sys Leak KVDocument1 pageBlain Sys Leak KVSylvester SullivanNo ratings yet

- Blain Service Manual LowDocument15 pagesBlain Service Manual LowSylvester SullivanNo ratings yet

- EV Poster1-12Document1 pageEV Poster1-12Sylvester SullivanNo ratings yet

- Blain Spare Parts EV KVDocument2 pagesBlain Spare Parts EV KVSylvester SullivanNo ratings yet

- Blain RL-EDocument4 pagesBlain RL-ESylvester SullivanNo ratings yet

- Blain Price List 300 Euro 2008Document1 pageBlain Price List 300 Euro 2008Sylvester SullivanNo ratings yet

- Blain MD - GBDocument4 pagesBlain MD - GBSylvester SullivanNo ratings yet

- Blain KV-GBDocument6 pagesBlain KV-GBSylvester SullivanNo ratings yet

- Blain HP - 4spDocument2 pagesBlain HP - 4spSylvester SullivanNo ratings yet

- Blain KV Trouble-GbDocument2 pagesBlain KV Trouble-GbSylvester Sullivan100% (1)

- User Guide: Emergency Response Planning ModuleDocument19 pagesUser Guide: Emergency Response Planning ModulebfibingierNo ratings yet

- Chenchu Ramaiah Neti: Phone: +91-8970888117Document3 pagesChenchu Ramaiah Neti: Phone: +91-8970888117chaitumdsNo ratings yet

- FIRST SEMESTER 2022-2023: of Programming Languages 10 Edition, Pearson, 2012.Document3 pagesFIRST SEMESTER 2022-2023: of Programming Languages 10 Edition, Pearson, 2012.Shivam KediaNo ratings yet

- Mercruiser 860168051Document102 pagesMercruiser 860168051JorjNo ratings yet

- Pipe 2D Autocad: Compared WithDocument8 pagesPipe 2D Autocad: Compared WithThiruvengadamNo ratings yet

- IBM SkillsBuild Intern OfferDocument2 pagesIBM SkillsBuild Intern OfferMuhammed AkramNo ratings yet

- OpticalDocument3 pagesOpticalAshok Pradhan100% (1)

- Types of Transmission WiresDocument15 pagesTypes of Transmission WiresGamal AymanNo ratings yet

- Master Coursework UmpDocument6 pagesMaster Coursework Umpf67m6abx100% (2)

- HPE - A00104922en - Us - ClearPass Policy Manager Scaling and Ordering GuideDocument17 pagesHPE - A00104922en - Us - ClearPass Policy Manager Scaling and Ordering Guide陳建和No ratings yet

- B&R Construction Company Job OpeningsDocument9 pagesB&R Construction Company Job OpeningsroopavijaykumarNo ratings yet

- L00161 1121Document29 pagesL00161 1121aboofazilNo ratings yet

- Method of Statement For The Construction and Completion of Structural Worksfor Entrances and Station Box at Conlay Station - 8.11.2018Document39 pagesMethod of Statement For The Construction and Completion of Structural Worksfor Entrances and Station Box at Conlay Station - 8.11.2018Mamat XNo ratings yet

- ITGS Paper 2 Question Booklet HLSLDocument8 pagesITGS Paper 2 Question Booklet HLSLMohammad HamdanNo ratings yet

- Kemppi BrochureDocument14 pagesKemppi BrochureRAJIV GandhiNo ratings yet

- Thor Hanks ResumeDocument1 pageThor Hanks ResumethorhanksNo ratings yet

- How industrial engineering can optimize mining operationsDocument6 pagesHow industrial engineering can optimize mining operationsAlejandro SanchezNo ratings yet

- Prefabricated BuildingDocument8 pagesPrefabricated BuildingAnubhav GargNo ratings yet

- Bus Network Topology GuideDocument8 pagesBus Network Topology GuideMjjames Manalo100% (1)

- 05 DistanceProt-7SA8 Principles V02 PDFDocument23 pages05 DistanceProt-7SA8 Principles V02 PDFOliver RisteskiNo ratings yet

- Mastering ROS For Robotics Programming - Sample ChapterDocument65 pagesMastering ROS For Robotics Programming - Sample ChapterPackt PublishingNo ratings yet

- Scorpius SRT 60 ROW Tracker DatasheetDocument4 pagesScorpius SRT 60 ROW Tracker DatasheetPhani ArvapalliNo ratings yet

- Data WranglingDocument30 pagesData WranglingYashwanth YashuNo ratings yet

- List of Essential Books For Civil EngineeringDocument1 pageList of Essential Books For Civil Engineeringraju_420034520100% (1)

- Jakarta MCU Participants ListDocument20 pagesJakarta MCU Participants ListBeny FirmansyahNo ratings yet

- bbs145 PDFDocument2 pagesbbs145 PDFnageshwariNo ratings yet

- Validation Based ProtocolDocument7 pagesValidation Based ProtocolTerimaaNo ratings yet

- Syllabus C60 0001Document11 pagesSyllabus C60 0001christy smartNo ratings yet

- Smart Social Networking: 21St Century Teaching and Learning SkillsDocument6 pagesSmart Social Networking: 21St Century Teaching and Learning SkillsJaz Cedric SibuloNo ratings yet