Professional Documents

Culture Documents

Safe

Uploaded by

Bijendra PrajapatiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Safe

Uploaded by

Bijendra PrajapatiCopyright:

Available Formats

INTERPLANT STANDARDS STEEL INDUSTRY

GUIDELINES FOR SAFETY IN EOT CRANES (First Revision) IPSS Corresponding IS does not exist 0. 0.1 FOREWORD

IPSS:2-02-007-01 Formerly: IPSS:2-02-007-85

This Inter Plant Standard has been prepared by the Standards Committee on EOT Cranes, IPSS 2:2 with the active participation of the representatives of all the steel plants, established manufacturers and leading consultants and was adopted in June 2001. Inter Plant Standards for steel industry primarily aim at achieving rationalization and unification of parts and assemblies used in steel plant equipment and accessories, for guidance in indenting stores or equipment by individual steel plants. It is not desirable to make deviations in technical requirements. EOT Cranes in steel plants are used for handling hot metal, liquid steel, red hot ingots and slabs etc. Any failure or malfunctioning of the crane, therefore, results in serious accident causing loss of life and big breakdowns. As there is no Indian Standard on safety for EOT Cranes, need for making an Inter Plant Standard on this subject is considered of utmost importance. This standard deals with safety aspects related to EOT Cranes.

0.2

0.3

0.4

Many of the safety aspects relating to EOT Cranes have already been covered in the following Interplant Standards. This interplant standard should be read in conjunction with the following standards: IPSS:2-02-001-85 Design parameters for EOT Cranes (with Amendment 1) IPSS:2-02-002-01 Acceptance norms for EOT Cranes (first revision) IPSS:2-02-003-97 General code of practice for design parameters for EOT Cranes (mechanical aspects) (first revision) IPSS:2-02-004-97 Code of practice for design parameters for EOT Cranes (electrical aspects) (first revision) IPSS:2-02-005-97 Code of practice for selection of electric cables for use on EOT Cranes (first revision) IPSS:2-02-006-01 Code of practice for laying of electric cables on EOT Cranes (first revision)

a) b) c) d) e) f)

Page 1 of 4

IPSS:2-02-007-01 0.5 Various Indian and IPSS standards referred to in this standard, have undergone revision over a period of time. This revision has been carried out to incorporate these changes. SCOPE This interplant standard covers the safety in the design layout and general safety arrangements required in EOT Cranes for use in steel plants. SAFETY FOR HOIST MECHANISM For cranes handling hot metals, there shall be two drive motors. Each input line shall have two brakes, each independently capable of holding the full load. Adequate provision shall be inbuilt in design to arrest the fall of the load in case of failure of any component, like gearing, output and rope drum shafts. SAFETY RELATING TO CRANE STRUCTURE Safe access for maintenance and removal of all mechanical and electrical parts shall be ensured without any additional scaffolding or necessitating dismantling of other equipment or structures. Safe access to the crane bridge and trolley from the LT walkway platform shall be provided. Access to the cabin from the bridge girder platform shall be via a staircase. Minimum width of staircase shall be 600 mm and inclination to the horizontal shall not be more that 60o. Full length chequered plate platforms with hand railing wherever possible shall be provided on the top for both bridge girders in order to have easy access to the operators cabin, long travel drive, current collectors, trolleys, etc. The width of the chequered plate covering shall not be less than 500 mm. In case of lattice construction, at least 500 mm wide full length chequered plate platforms shall be provided at the bottom chord level of all the bridge girders for periodical checking of all rivets, bolts, lamps, etc. Full length toe boards shall be provided along with the chequered plate platforms. 3.4 All opening in the foot walks flooring for access to the bottom chord platform and inspection platforms shall be provided with strong hinged covers. These covers in the maximum open position shall be inclined at an angle slightly more than 90o to the horizontal. They shall be so located that they do not foul in their open position with any moving part of the crane. Minimum size of the opening shall be 600 mm x 600 mm. (a) When down shop leads are located below the runway rails, a guard shall be provided on the crane to prevent the hoist ropes from coming in contact with down shop leads. When the crane cabin is Page 2 of 4

1. 1.1

2. 2.1

3. 3.1

3.2

3.3

3.5

IPSS:2-02-007-01 located by the side of the down shop leads, it shall be protected by providing suitable guards/wire mesh structure for safety of the crane operator or other people. (b) Suitable wire mesh guard shall be provided on down shop leads inspection cage to protect the maintenance personnel. and The mm The has

3.6

Enclosed cabins shall have a water tight plate roof sloping to the rear provided with sliding or hinged windows on three sides and door. window shall be provided with toughned safety glass of minimum 6 thickness and installed from inside so that it can be changed easily. glasses shall be installed in such a way that the crane operator sufficient view for safe operation of the crane.

3.7

Crane cabin subjected to heat from below shall have 5 mm thick bright steel plate shield suitably bolted 150 mm below the bottom of floor. The glasses provided in such cabins shall also be heat resistant and of double walled construction in case of air conditioned cabins. Operators cabin shall be provided with suitable warning signal device and shall be so installed that it is easily accessible by the operator and maintenance personnel. Adequate means, independent of controlled brakes shall be provided for securely anchoring the crane to the gantry when not in use for locking of outdoor cranes. Minimum head room of 2000 mm shall be provided on all walkways, trolley platform and inside the operators cabin. If glasses are provided at the bottom in the cabin for better visibility, it is essential to fix removable steel grating over the glasses to support the weight of the personnel. Bridge drive floating shafts shall be provided with platforms below it. End carriage shall have a minimum clearance of 450 mm for walking when trolley is in extreme end position, provided the hook approach is not critical. The painted letters and figures indicating the safe working load of the crane and other data of the crane shall always be prominently displayed. Proper type of fire extinguisher shall be provided in the crane operators cabin. Coupling guards on all the drives should be provided. Insulating rubber mats shall be provided on the cabin floor and in front of all electrical panels. Page 3 of 4

3.8

3.9

3.10

3.11

3.12 3.13

3.14

3.15

3.16 3.17

IPSS:2-02-007-01

4. 4.1

SAFETY RELATING TO ELECTRICAL SYSTEM All electrical cables shall be so laid that they can be easily inspected or maintained. A space of 500 mm in front of the panel and resistors shall be provided. Similar space shall be provided at the back in case of panels requiring maintenance from the back. A space of 500 mm in front and back of the panels shall be provided for dc cranes. The arrangements for disconnecting the cranes from the main power supply shall be provided by means of either an isolator on the bridge or a switch lockable in open position. Safety switches shall be provided on four corners of the crane which can be operated from either gantry or bridge platform. In addition, one such switch shall be provided in the cabin also. Indicating lamps (red and green) shall be provided in the operators cabin. Incoming 415 V ac terminal fixed in crane cabin shall be properly insulated and shrouded for electrical safety. LIGHTING Cabin shall be provided with light fitting in such a way that operator can see properly the controls and the inside of the cabin but the light shall not obstruct the vision of the man below giving signal to the operator. The crane shall be provided with sufficient lights, hung from the girder of the crane so that the working area under the crane is properly illuminated. There shall be more than two plug points of 24 V dc fitted on the girder of the crane to provide hand lamp for maintenance jobs.

4.2

4.3

4.4

4.5 4.6

5. 5.1

5.2

5.3

__________________

Page 4 of 4

You might also like

- Guidelines For Safety in E O T Cranes: IPSS: 2-02-007-18 (First Revision)Document4 pagesGuidelines For Safety in E O T Cranes: IPSS: 2-02-007-18 (First Revision)Mohammad Safdar SadatNo ratings yet

- EotDocument16 pagesEotMayuresh GoregaonkarNo ratings yet

- Specification KONE ECO3000 EscalatorDocument5 pagesSpecification KONE ECO3000 EscalatorRohit JainNo ratings yet

- Spec of High Mast Tower 30 MtrsDocument11 pagesSpec of High Mast Tower 30 MtrsNagesh Rao0% (1)

- High Mast SpecsDocument10 pagesHigh Mast SpecsBhanu PratapNo ratings yet

- CraneDocument19 pagesCranedeua2004No ratings yet

- Specifications for 750kg passenger liftDocument19 pagesSpecifications for 750kg passenger liftlahiruNo ratings yet

- Tender For High Mast Lighting SystemDocument8 pagesTender For High Mast Lighting SystemArchishman BhattacharyaNo ratings yet

- C-2107499 - KONE - ESCALATOR - TM110 - Technical - Specification en - USDocument13 pagesC-2107499 - KONE - ESCALATOR - TM110 - Technical - Specification en - USSabeeh KhanNo ratings yet

- Cabloc Vertical Fall ArrestDocument10 pagesCabloc Vertical Fall ArrestTunaru GabrielNo ratings yet

- Document No PCPL-0532-4-407-04-08 MV Switchgear Section - 4 PAGE: 1 of 13 ScopeDocument13 pagesDocument No PCPL-0532-4-407-04-08 MV Switchgear Section - 4 PAGE: 1 of 13 ScopetceterexNo ratings yet

- EOT Crane SpecificationDocument24 pagesEOT Crane SpecificationArvind Sharma100% (1)

- CEM PT HandbookDocument44 pagesCEM PT Handbook翹翹九九100% (2)

- Double Girder EOT Crane EnquiryDocument3 pagesDouble Girder EOT Crane EnquiryvkNo ratings yet

- EOT CRANE - Rev 2Document6 pagesEOT CRANE - Rev 2Koushik BhaumikNo ratings yet

- Technical Requirements - Commercial Escalators 1.00 Scope of WorkDocument8 pagesTechnical Requirements - Commercial Escalators 1.00 Scope of WorkAbd Malek RosediNo ratings yet

- DC Poweer Distribution Switch BoardDocument9 pagesDC Poweer Distribution Switch BoardpvenkyNo ratings yet

- KT - Specs High Power Busbar Trunking Metal Enclosure 1000 To 6300A Cu V20180607Document5 pagesKT - Specs High Power Busbar Trunking Metal Enclosure 1000 To 6300A Cu V20180607N_LocusNo ratings yet

- Fixed Access Ladders Engineering Data SheetDocument7 pagesFixed Access Ladders Engineering Data SheetEd CortesNo ratings yet

- GangwayDocument26 pagesGangwayegyinspectoryahoo100% (2)

- Electrically Operated Travelling Crane: Engineering DepartmentDocument6 pagesElectrically Operated Travelling Crane: Engineering DepartmentJOYDEEP DASGUPTA33% (3)

- QCS 2014 - 3.7 Roller Shutter FIre DoorsDocument3 pagesQCS 2014 - 3.7 Roller Shutter FIre DoorsthomsonNo ratings yet

- Item 683.03105008 - 50 Foot Camera Pole With 1 Lowering DeviceDocument8 pagesItem 683.03105008 - 50 Foot Camera Pole With 1 Lowering DeviceWaheed AhmadNo ratings yet

- Sandwhich BusductDocument5 pagesSandwhich BusductHarmandeep Ahluwalia100% (1)

- Ced22 (7571) PDFDocument24 pagesCed22 (7571) PDFskilmagNo ratings yet

- SH1 RFP - P4 OTR - Ch8 Balance of Plant - p13-16Document4 pagesSH1 RFP - P4 OTR - Ch8 Balance of Plant - p13-16SonNguyenNo ratings yet

- Fan - SpecsDocument24 pagesFan - SpecsAnonymous 5ffEIfWIM2No ratings yet

- Cable Pulling and Connections MethodDocument6 pagesCable Pulling and Connections MethodUbah ChigozieNo ratings yet

- Technical Specification For 12MTR High Mast Pole PDFDocument5 pagesTechnical Specification For 12MTR High Mast Pole PDFthirumalNo ratings yet

- Annexure I Technical Specifications For Lighting High MastDocument5 pagesAnnexure I Technical Specifications For Lighting High MastManish Gupta100% (1)

- Cable LayingDocument6 pagesCable LayingPramod B.WankhadeNo ratings yet

- MV Switchgear 11 KV VCB Rev-0Document16 pagesMV Switchgear 11 KV VCB Rev-0ISHA SINGHNo ratings yet

- Busbar Trunking System 800A Sandwich ConstructionDocument3 pagesBusbar Trunking System 800A Sandwich Constructionsajeevi piumikaNo ratings yet

- CablocDocument4 pagesCabloccokiaaNo ratings yet

- Spec-High MastDocument18 pagesSpec-High MastHarmandeep AhluwaliaNo ratings yet

- MNS-MCC LV SpecificationDocument16 pagesMNS-MCC LV SpecificationRaju MbkNo ratings yet

- Specifications For Motor Control CentersDocument5 pagesSpecifications For Motor Control CentersNATHANNo ratings yet

- Live Line TransmissionDocument8 pagesLive Line TransmissionPraveen KumarNo ratings yet

- Ladders Engineering Data Sheet Ontario - 2014Document5 pagesLadders Engineering Data Sheet Ontario - 2014Eric0% (1)

- RFP For LT PanelDocument13 pagesRFP For LT Panelsourendra prasad karan100% (1)

- Passenger ElevatorDocument17 pagesPassenger ElevatorAnant NimjeNo ratings yet

- SS Screen SpecsDocument2 pagesSS Screen SpecsusmanaliNo ratings yet

- Technical Specification Rolling Shutter ACDFSDocument10 pagesTechnical Specification Rolling Shutter ACDFSnikkiNo ratings yet

- Circotech SystemDocument2 pagesCircotech Systempcorreia_81No ratings yet

- Type Tested LV Panel For Industry (IEC 61439)Document19 pagesType Tested LV Panel For Industry (IEC 61439)nihar039255No ratings yet

- Tech Spec. of EOT CraneDocument7 pagesTech Spec. of EOT CraneSuresh MuttaNo ratings yet

- CEM PT HandbookDocument44 pagesCEM PT HandbookThomas OrNo ratings yet

- Busway SpecificationDocument6 pagesBusway SpecificationNATHANNo ratings yet

- Lift hoisting equipment and safety requirementsDocument2 pagesLift hoisting equipment and safety requirementsleekeanyewNo ratings yet

- Is 12466 2012 PDFDocument11 pagesIs 12466 2012 PDFlokeshras12No ratings yet

- HFY3-3720-ELE-PD-0002 - 0 OHTL Installation and Test ProcedureDocument10 pagesHFY3-3720-ELE-PD-0002 - 0 OHTL Installation and Test ProcedureAli SalehNo ratings yet

- Overhead CraneDocument11 pagesOverhead CraneGie Mak100% (2)

- Site-Specific Steel Erection Plan SummaryDocument3 pagesSite-Specific Steel Erection Plan SummaryQi ZengNo ratings yet

- LT Switchgear Technical SpecificationDocument28 pagesLT Switchgear Technical SpecificationUday Sankar YadavNo ratings yet

- Guidelines For The Construction and Maintenance of Transmission LinesDocument8 pagesGuidelines For The Construction and Maintenance of Transmission LinesPierre Enrique Carrasco FuentesNo ratings yet

- Method Statement For Mock-Up InstallationDocument17 pagesMethod Statement For Mock-Up InstallationshareyhouNo ratings yet

- DLT Strand Jack and Climbing Jack SystemsDocument28 pagesDLT Strand Jack and Climbing Jack SystemsUhrin ImreNo ratings yet

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- A Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsFrom EverandA Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsNo ratings yet

- Dipentene 1Document12 pagesDipentene 1girish19No ratings yet

- GPS2BDocument40 pagesGPS2Bgirish19No ratings yet

- Kok Kinos 2011Document6 pagesKok Kinos 2011girish19No ratings yet

- Downlighter Trade - Web Ready - July 2012Document8 pagesDownlighter Trade - Web Ready - July 2012girish19No ratings yet

- PwsDocument1 pagePwsgirish19No ratings yet

- LLG FaultDocument8 pagesLLG Faultranjish_007No ratings yet

- (Gary Dunning) Introduction To Programmable LogicDocument69 pages(Gary Dunning) Introduction To Programmable LogictestfbNo ratings yet

- PwsDocument1 pagePwsgirish19No ratings yet

- Earlier StreamerDocument6 pagesEarlier Streamergirish19No ratings yet

- CEA AmmendmentsDocument18 pagesCEA Ammendmentsgirish19No ratings yet

- Pages From Legrand Catalogue 2010-14-27Document14 pagesPages From Legrand Catalogue 2010-14-27girish19No ratings yet

- 2006 18 Spring Wiring Matters Power Factor Correction PFCDocument3 pages2006 18 Spring Wiring Matters Power Factor Correction PFCArsyad Harus SemangattNo ratings yet

- Hand ToolDocument5 pagesHand ToolHamza NoumanNo ratings yet

- Collection A/c No. 31519633821 Collection A/c No. 31519633821Document1 pageCollection A/c No. 31519633821 Collection A/c No. 31519633821girish19No ratings yet

- Nfpa Dust 1957Document85 pagesNfpa Dust 1957girish19No ratings yet

- Industrial Plug Socket NewDocument12 pagesIndustrial Plug Socket Newgirish19No ratings yet

- ResultDocument7 pagesResultgirish19No ratings yet

- 6488689Document230 pages6488689girish19No ratings yet

- Phast7.0 ReleaseLetter&NoteDocument46 pagesPhast7.0 ReleaseLetter&Notegirish19No ratings yet

- Instruction Manual NewDocument253 pagesInstruction Manual NewManoj Garg100% (1)

- SMPV Rules 1981Document47 pagesSMPV Rules 1981Pukhraj DagaNo ratings yet

- 1077-2618/03/$17.00©2003 IeeeDocument6 pages1077-2618/03/$17.00©2003 Ieeegirish19No ratings yet

- Hac ModelDocument16 pagesHac Modelgirish19No ratings yet

- Lecture NotesDocument255 pagesLecture NotessonuNo ratings yet

- Thermal Imaging Camera - Ti32Document42 pagesThermal Imaging Camera - Ti32rajpre1213No ratings yet

- Arc FlashDocument17 pagesArc Flashleo_j9No ratings yet

- On Site Ignition Probabilities - HSE UKDocument192 pagesOn Site Ignition Probabilities - HSE UKgirish19No ratings yet

- Arc Flash HazardDocument8 pagesArc Flash HazardSJS68No ratings yet

- Sulphur MsdsDocument28 pagesSulphur Msdsgirish19No ratings yet

- Sting o LightsDocument2 pagesSting o Lightsgirish19No ratings yet

- BOQ For Repair Work of 40'X20' Building at A/Selesthimaduwa VidyalayaDocument9 pagesBOQ For Repair Work of 40'X20' Building at A/Selesthimaduwa VidyalayaAnuranga SahampathNo ratings yet

- DMCCW PROTOCOL 1 (Autosaved) (1) .Document7 pagesDMCCW PROTOCOL 1 (Autosaved) (1) .Raktima MisraNo ratings yet

- Steam Room Construction & Generator Sizing GuideDocument2 pagesSteam Room Construction & Generator Sizing GuideasdthuNo ratings yet

- MDT Geotech Manual Covers Roadway Slope and Embankment DesignDocument40 pagesMDT Geotech Manual Covers Roadway Slope and Embankment DesignAlhaz UddinNo ratings yet

- Industrial Enclosures Catalogue Oct 10 Complete - 2Document88 pagesIndustrial Enclosures Catalogue Oct 10 Complete - 2Harsha Jayanath GajanayakaNo ratings yet

- Catalogue Pipe Hangers SupportsDocument111 pagesCatalogue Pipe Hangers SupportsIlija Runjajic100% (1)

- Highway Materials Manual: Kingdom of Saudi Arabia Ministry of CommunicationsDocument75 pagesHighway Materials Manual: Kingdom of Saudi Arabia Ministry of CommunicationsAyman KandeelNo ratings yet

- Engineering Materials by RK RajputDocument528 pagesEngineering Materials by RK Rajputmv599766No ratings yet

- Imperial Bungalows PDFDocument2 pagesImperial Bungalows PDFPrajitha Jinachandran T KNo ratings yet

- A Place To Put Down Your Roots.: Stock Image For Representation OnlyDocument8 pagesA Place To Put Down Your Roots.: Stock Image For Representation OnlyKartick PaiNo ratings yet

- Csyc12mkf Service ManualDocument71 pagesCsyc12mkf Service ManualcoronaqcNo ratings yet

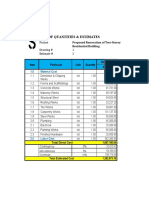

- Bill of Quantities & Estimates: Proposed Renovation of Two-Storey Residential BuildingDocument5 pagesBill of Quantities & Estimates: Proposed Renovation of Two-Storey Residential BuildingLesnah BelderolNo ratings yet

- Pearl Academy Jaipur Adapts Traditional ArchitectureDocument4 pagesPearl Academy Jaipur Adapts Traditional ArchitectureDivakar AgarwalNo ratings yet

- Estimating & TenderingDocument13 pagesEstimating & TenderingRoshan de Silva80% (5)

- Valvula FM 8pol ZSFZ PDFDocument8 pagesValvula FM 8pol ZSFZ PDFglobaldisNo ratings yet

- UCSanDiegoBEPTemplate v1.1 CompleteSampleDocument26 pagesUCSanDiegoBEPTemplate v1.1 CompleteSampleMarvvvNo ratings yet

- Introduction To TrackDocument81 pagesIntroduction To TrackiritmspceNo ratings yet

- Finite Element Analysis of Fiber Reinforced Polymer (FRP) Bridge Deck StructuresDocument9 pagesFinite Element Analysis of Fiber Reinforced Polymer (FRP) Bridge Deck StructuresVietnhut PhanNo ratings yet

- Volume Loss in Shallow TunnellingDocument14 pagesVolume Loss in Shallow TunnellingAida RafrinNo ratings yet

- Tree Cutting MethodDocument14 pagesTree Cutting MethodBienSabadoNo ratings yet

- Hk42fz017 Carrier 58cta 58ctx FurnaceDocument56 pagesHk42fz017 Carrier 58cta 58ctx FurnaceJerry Han100% (1)

- Bolt Joint Design and SpecificationsDocument29 pagesBolt Joint Design and SpecificationsPablo GalindosNo ratings yet

- Guide To Standards-Pools and SpasDocument15 pagesGuide To Standards-Pools and SpasMIguel HazNo ratings yet

- Soil Permeability LectureDocument34 pagesSoil Permeability LectureSheikh AnikNo ratings yet

- Concrete Construction Article PDF - Evaluating Cracks PDFDocument4 pagesConcrete Construction Article PDF - Evaluating Cracks PDFEmad KhanNo ratings yet

- Standard CMU CatalogueDocument4 pagesStandard CMU CatalogueAnthony AngNo ratings yet

- Aisc TearoutsDocument11 pagesAisc Tearoutsclam2014No ratings yet

- Portals - 0 - Checklist For Internal Plumbing WorkDocument2 pagesPortals - 0 - Checklist For Internal Plumbing Workrahul kumarNo ratings yet

- Water's Edge BrochureDocument15 pagesWater's Edge BrochureAndrew Ahmed50% (2)

- MAKAUT Tribology SyllabusDocument2 pagesMAKAUT Tribology SyllabusTamonash JanaNo ratings yet