Professional Documents

Culture Documents

Consolidated Farming LTD Report

Uploaded by

MutetoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Consolidated Farming LTD Report

Uploaded by

MutetoCopyright:

Available Formats

1.

0 EXECUTIVE SUMMARY

Consolidated Farming Limited (CFL) is negotiating a Power Purchase Agreement (PPA) with ZESCO Limited the electricity service provider. In the PPA, there are conditions which attract penalties for non-compliant that CFL will have to adhere to such as efficient use of electricity for their operations. Consolidated Farming Limited (CFL) has complained of huge voltage drops on the 11kV lines that transverse the estate. Low voltages at the pump stations (360V instead of 400V) have been recorded. Yala Zambia Limited was requested to carry out a study of the farm s electricity distribution network and make appropriate recommendations on how to deal with the problem. Further, CFL is negotiating a Power Purchase Agreement (PPA) with ZESCO Limited the electricity service provider. In the PPA, there are conditions which attract penalties for noncompliant that CFL will have to adhere to such as efficient use of electricity for their operations. This report looks in detail at the electricity distribution network for CFL at their Kafue Flats farm. It starts by analyzing the electricity distribution network from the uptake substations i.e. where CFL gets supply from ZESCO Limited. CLF gets supply from ZESCO Limited at 33kV at three substations. The 11kV distribution network up to each pumping station on the farm was studied in detail.

2.0 METHODOLOGY The methodology used in this report involved site visits to carry out physical inspections of the electricity distribution network and visiting each pumping station with a view of establishing visible weak points. Discussions were held with the Chief Engineer and Factory Electrical Engineer on their experiences with the operations of the network especially the electricity supply to the pumping stations as the voltages at these sites was of major concern. No voltage measurements could be established or carried out as at the time of the site visit, pumping had not yet commenced and most transformers at the pump stations were on either off or on no load.

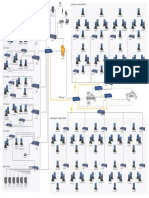

3.0 STATE OF EXISTING ELECTRICITY DISTRIBUTION NETWORK Consolidated Farming Limited Kafue Flats sugar estate is supplied at 33,000V by ZESCO Limited from three sources. These are t-offs from ZESCO 33kV lines and CFL has established their own three 33/11 substations one at each uptake point. These substations are: Nampundwe, Main

and K6. ZESCO Limited has tariff metering installed on 33kV at each of the three substations. From each substation, there is one 11kV line going to supply various irrigation pumping stations on the farm, the factory and domestic houses on the estate. CFL has it s own generation using bagasse and this is what is used for production in the factory. This is attainable when cane harvesting and crushing starts. The supply from ZESCO is used mainly for irrigation on the estate. As a starting point, this report will look at the electricity network from each of the three substations. 3.1 Substations The major load on the estate consists mainly of induction motors running the irrigation pumps. The load is therefore highly inductive with a lagging power factor. The primary voltage control is by means of the OLTCs (on load tap changers) on Nampundwe and Main substations. 3.1.1 Nampundwe 33/11kV substation This substation is located near Nampundwe Township. The following equipment is installed at Nampundwe substation: o o o o o o o o o 1x33,000/110V voltage transformer (VT) 1x33kV isolator 1x33kV circuit breaker (make - Geleistamme) 33kV surge divertors on the main transformer 1x5MVA 33/11kV transformer (make Brush) o Vector group DYn11 Current transformers: CT ratio 200/1 11kV autorecloser (make Westcorp, ABB) 1x500kVA 11/0.4kV ground mounted transformer (no name plate) as a local transformer 2x120mm2 XPLE 3C 11kV cables connect from the power transformer: one to the 11kV line through the autorecloser and the other to the 500kVA station transformer

From Nampundwe substation, there is a 50mm2 Aluminum Conductor Steel Reinforced (ACSR) 11kV line into the estate and supplying pumping stations with a total installed capacity of ..the total length of the 11kV is .. Comments o Poor house substation keeping o The fence needs replacement to improve security and safety o The power control device on the 11kV ABB autorecloser does not work and hence unable to record any events and show readings of important line parameters

o Poor access to the substation this can make restoration works difficult in emergency cases o The 500kVA 11/0.4kV local transformer be recovered and replaced with a 25kVA 11/0.4kV pole mounted unit. The 500kVA can be used as a spare unit on the estate

3.1.2 Main 33/11kV substation The following equipment is installed at Main substation: 1x25kVA 33/0.4kV local transformer for the station auxiliaries 1x33kV isolator 1x33kV circuit breaker (make - Dimako) 33kV surge divertors on the main transformer 1x4MVA 33/11kV transformer (make Dimako) o Vector group DYn11 o Current transformers: CT ratio . o 11kV autorecloser (make ABB) o 1x120mm2 XPLE 3C 11kV cable connect from the power transformer to the 11kV line through the autorecloser. o o o o o From the Main substation, there is a 50mm2 Aluminum Conductor Steel Reinforced (ACSR) 11kV line into the estate and supplying pumping stations with a total installed capacity of ..the total length of the 11kV is .. Comments o Poor house substation keeping o Poor access into the substation as the repaired 33/11kV transformer is in the substation access gate needs to be repositioned. This can make restoration works difficult in emergency cases as access will be restricted o There is leakage which needs attention on the red phase HT bushing on the main transformer

3.1.3 K6 33/11kV substation The following equipment is installed at K6 substation: o 2x33kV isolator (one with an earthing switch) o 1x33kV Nulec autorecloser for transformer protection

o 33kV and 11kV surge divertors on the main transformers o 2x2.5MVA 33/11kV transformers (make 1x Dimako & 1xPower Transformers) o Vector group DYn11 o Current transformers: CT ratio o 11kV autorecloser (make ABB) o 1x120mm2 XPLE 3C 11kV cable connect from the power transformer to the 11kV line through the autorecloser. o 1x33kV cable creating a 33kV busbar from which the power transformers are connected From the Main substation, there is a 50mm2 Aluminum Conductor Steel Reinforced (ACSR) 11kV line into the estate and supplying eight (08) pumping stations with a total installed capacity of 6,460kVA. The total length of the 11kVin operation including t-offs is eight (08) km. There is a new t-off from Ganga pumping station on 100mm2 ACSR which is not yet in operation. This is new line will off-load some pumping stations from Main substation. Comments o Poor house substation keeping o The substation gate needs to be replaced to improve safety and security of the substation 3.2 11kV overhead lines From each of the three 33/11kV substations, there is one 11kV overhead line feeding several pumping stations. All the lines are constructed using 12m wood poles, 50mm2 ACSR, with steel cross-arms and pin insulators in a flat configuration. There are normally open points on the lines separating the three 33/11kV substations thereby facilitating the transfer of load from one substation to another should need arise. The structural construction of the lines meets the required standards. However, the following were observed: o At the t-off points, terminal and some section structures to join two pieces of conductor, binding has been used instead of using PG clamps o There are no isolating points (drop-out fuse assemblies or solid links) at all the t-offs meaning all these points are directly connected The total length of the 11kV overhead lines including t-offs on the estate is table indicating the line lengths. Below is a

Table 3.1 11kV lines from Main 33/11kV substation S/N FROM TO LENGTH, COMMENTS

km 1 2 3 4 5 6 7 8 Main 33/11kV substation Main line Main line Main line Main line Main line Main line Main line Sigma 2 pumping station AO pumping station CV pumping station Tala pumping station Factory Shada pumping station Sigma 1 pumping station Airtel New pumping station (not yet operational) 13.6 1.25 1.2 1.4 0.7 0.06 0.05 0.15 1.1 This is the main line T-off from main line T-off from main line T-off from main line T-off from main line T-off from main line T-off from main line T-off from main line T-off from main line

TOTAL

19.51

3.3 Distribution transformer substations Each pumping station has at least one step down ground mounted transformer (GMT) supplying the motors which drive the pumps. Bigger pumping stations have two or three transformer. These units step down from 11,000V to mainly 400V and in some cases to 3,300V or 3,345V depending on the intended operation of the particular pumping station. The transformers vary in capacity depending on the capacity of the pumping station. On these substations, the following were observed: o No lugs have been used on some HT transformer terminations on the 11/0.4kV transformers on the pumping stations o On two pumping stations namely CV and , the drop-out fuses on the transformers have been by-passed o Earth connection on some transformers is poor (no lug used for connection to the earthing bolt on the transformer tank) and on the 800kVA transformer at CV, the earth has been vandalized. On transformers on other pump station like Sigma1, a 16mm2 bare copper conductor has been used as earth wire

4.0 Pumping stations operations

As stated in 3.3, each pumping station has at least one ground mounted transformer supplying the motors for pumping. At the time of the site visits, pumping had not yet started and hence most of the transformers on these stations were either soak (no load) or disconnected. The motors and pumps on these stations vary in capacity. The main protection on the motors is .. These pumping stations are manned on a have cellular phones for communication. hrs basis by pump operators or pump men. These

5.0 Analysis and discussion After the site visits to the estate, a number of points were established: 5.1 11kV overhead lines o The non application of PG clamps on the t-offs is of serious concern. The binding that has been used instead of PG clamps may not be firm enough and as a result, these become high resistance points or hot spots leading to significant voltage drops. o Since all the t-offs are directly connected or solid, there is no isolating point. A fault on any of the t-offs will result in the 11kV autorecloser at the 33/11kV substation to operate (trip) thereby cutting off electricity supply to all the pumping stations fed from the particular substation. With what has already been mentioned regarding the motor starting procedures, this will result in unnecessarily high maximum demand. A fault on any t-off is supposed to isolate that particular t-off and not affected the entire line. During planned or breakdown maintenance/repair works on a particular t-off, the whole line will have to be shut down thereby shutting down all the other pumping stations not affected by the maintenance/repair works. This will no doubt affect productivity on the estate. o The lines especially from Nampundwe and Main substations seem to be overloaded. The rated current carrying capacity of the conductor (50mm2 ACSR) under the ambient conditions obtaining on the estate is .. With the estimated load on Nampundwe substation of .. and Main substation of .., clearly these lines are overloaded. This will result in significant line voltage drops and distribution line losses especially when pumping is at it s peak. Upgrading of the line conductor from 50mm2 to 100m2 should be considered. o

6.0 Recommendations Several options to mitigate the situation both in the short and medium terms have been proposed. The following is therefore being recommended: 6.1 System clean up The first actions that have been recommended to be undertaken do not need a lot of investments. System clean up is essential in dealing with potential hot spots which are contributing to voltage drops as well as 6.1.1 Procurement and application of PG clamps As an immediate action, CFL must procure 50mm2 PG clamps and apply them on all the t-off points and some terminal and section structures where binding has been used instead of PG clamps. On the local market, a 50mm2 PG clamp costs on the average about K A total of .. PG clamps will be required immediately. Some PG clamps should be stocked for expansion works that are planned on the farm. 6.1.2 Procurement and installation of 11kV drop-out fuse assemblies 11kV drop-out fuse assemblies need to be procured and installed on all line t-off points. This will facilitate easy isolation of sections of the network during faulty and planned operations like maintenance thereby leaving the healthy parts uninterrupted. A fault on a t-off supplying a particular pumping station will on isolate that pump station leaving the rest of the pumping stations unaffected. This will avoid starting all stations after a fault on just one section or t-off and ultimately the unnecessarily high maximum demand associated with this will be addressed. Further, it will be easier to locate the fault as only the affected part will be isolated. 6.1.3 Carry out thermographic scanning/survey Thermographic scanning with a thermographic camera is essential in determining hot spots that can lead to premature or early failure of part of the network or a piece of equipment. Hot spots are usually found on equipment terminal connection points (transformers, isolators, circuit breakers etc) and overhead lines terminal and section structures as well as line t-off points. Apart from resulting in pre-mature network failure or faults, hot spots are high resistance points which result in voltage drops.

Hot spots develop among reasons due to loose contacts, corrosion to atmospheric weathering etc. Determining these hot spot points on the network and taking corrective measures is highly recommended. Organisations that have thermographic cameras that can be hired are SKF in Kitwe and ZESCO Ltd. 6.2 Upgrading of the main 11kV lines from Nampundwe and Main 33/11kV substations As indicated, the 11kV lines from Nampundwe and Main 33/11kV sub stations are over loaded when pumping is at peak and as a result, significant voltage drops are experienced. Voltages of .v at the pump stations are recorded. To improve the voltage profile, the 50mm2 ACSR conductor on these lines should be replaced with 100mm2 ACSR. Only the t-offs should remain on 50mm2. The other line structures will remain the same as they are able to take 100mm2. For the line from Main substation, the conductor upgrade is proposed from the substation to the factory a distance of ..km. For the Nampundwe line, the conductor upgrade is to be from the substation to ..- a distance of ..km. the estimated costs of these are : o Nampundwe line: . o Main line: However, the disadvantage that this has is that it will lead to a prolonged outage of the line during the time when the conductor replacement will be done. CFL has an in-house construction team who are capable of carrying out this work 6.3 Shifting of Main and Nampundwe 33/11kV substations Shifting of the two substations from their present locations to closer to the load centres will reduce the voltage drop on the 11kV line. This will mean construction of 33kV lines from the current substation locations. As indicated earlier, CFL has an inhouse construction team who are capable of carrying out this work. Shifting of the substations will utilize the same equipment existing such as isolators, power transformers, circuit breakers etc. Control cabling may have to be replaced. It will entail first construction of the 33kV lines and the new substation civil works before actually shifting the equipment. The actual shifting, installation and commissioning of the equipment can be done during the off-peak season when there is reduced demand for pumping.

o Main substation: shift to a location near the factory or administration area. There is ample space for a 33kV line way leave from the substation to the proposed site. At the new site, two 11kV feeders will be established: one to supply pumping stations towards .. and the other to supply pumping stations up to Sigma1. These feeders should be through individual 11kV autoreclosers. o Nampundwe substation: shift to a location .. There is adequate space for a 33kV line way leave from Nampundwe substation to the proposed site. The length of the new 33kV line will be . o Estimated costs: The estimated costs of shifting the substations are indicated below: Table S/N 1 2 3 4 5 Costs of shifting substations ITEM DESCRIPTION Construction of 33kV line Substation civil works 2x11kV autoreclosers Control cabling Labour TOTAL NAMPUNDWE MAIN

You might also like

- 400kv Nelamangana SubstationDocument4 pages400kv Nelamangana Substationtanwar_anuj199067% (3)

- Field Visits PDFDocument7 pagesField Visits PDFAdarsh ShettyNo ratings yet

- Distribution SubstationDocument16 pagesDistribution SubstationKunal PahariNo ratings yet

- KSCB It ReportDocument52 pagesKSCB It ReportShalu ShaluNo ratings yet

- Parallel Operation of Transformers With Non-Identical TapsDocument13 pagesParallel Operation of Transformers With Non-Identical TapsRohini DesaiNo ratings yet

- Mannam Substation Visit ReportDocument8 pagesMannam Substation Visit ReportJeseemNo ratings yet

- 400kv Final PPT by MayankDocument20 pages400kv Final PPT by MayankMayank Mishra83% (12)

- Vocational Training ReportDocument15 pagesVocational Training ReportSaroj KumarNo ratings yet

- 11 KV Network ElementDocument11 pages11 KV Network ElementKuldip PrasadNo ratings yet

- Chapter MistakesDocument12 pagesChapter MistakesEr Umar RashidNo ratings yet

- 1.1 About 33/11Kv Substation, Midc, ButiboriDocument20 pages1.1 About 33/11Kv Substation, Midc, ButiboriParitoshik KharadNo ratings yet

- 5204 Assign 16 ADocument6 pages5204 Assign 16 AbashabddhkNo ratings yet

- Vocational Training Report at C.S.E.B. Raipur 15 June To 14 JulyDocument29 pagesVocational Training Report at C.S.E.B. Raipur 15 June To 14 JulyMãñyä ShârmåNo ratings yet

- 132 KV Substation Traning Report at HaldiaDocument31 pages132 KV Substation Traning Report at Haldiababli91No ratings yet

- Vocational Training Report at C.S.E.B. Raipur 15 June To 14 JulyDocument28 pagesVocational Training Report at C.S.E.B. Raipur 15 June To 14 JulyBabar SaleemNo ratings yet

- Diesel Locomotive Works: A Industrial Trainingreport OnDocument19 pagesDiesel Locomotive Works: A Industrial Trainingreport OnVimod kumarNo ratings yet

- 2020 Mid-Semester Assignment - Design of An Urban HV Distribution NetworkDocument6 pages2020 Mid-Semester Assignment - Design of An Urban HV Distribution NetworkMuhammad Raza RafiqNo ratings yet

- 1 - (33 - 11 KV Substations)Document12 pages1 - (33 - 11 KV Substations)sajd abbasNo ratings yet

- 220kv ShornurDocument102 pages220kv ShornurAhamed Shahin CkNo ratings yet

- 33kV Substation Costruction ManualDocument4 pages33kV Substation Costruction Manualkunwarsingh27100% (2)

- Swyd NewDocument39 pagesSwyd NewMrityunjayChauhanNo ratings yet

- Intoduction To 400Kv Switchyard: Single Line Diagram of 400kV SubstationDocument3 pagesIntoduction To 400Kv Switchyard: Single Line Diagram of 400kV SubstationPratik LahaneNo ratings yet

- SGP 1Document20 pagesSGP 1BantiNo ratings yet

- Presentation On Substation 220 KVDocument37 pagesPresentation On Substation 220 KVPiyush Bansal75% (12)

- INTRODUCTION-WPS OfficeDocument6 pagesINTRODUCTION-WPS OfficeAbdulrahaman AbdulraheemNo ratings yet

- ABSTRACTDocument14 pagesABSTRACTanilNo ratings yet

- A Report On IIUC Substation-3 (Beside FSE)Document8 pagesA Report On IIUC Substation-3 (Beside FSE)Sajjadul IslamNo ratings yet

- Switchyard O&m FinalDocument73 pagesSwitchyard O&m FinalAmit Biswas100% (2)

- Presentation On: By-Er Rajinder Kumar Lecturer Electrical Engg. Govt Polytechnic College AmritsarDocument70 pagesPresentation On: By-Er Rajinder Kumar Lecturer Electrical Engg. Govt Polytechnic College AmritsarAnonymous ExWAN2xjFJ100% (1)

- Unit 6: Substations: Prepared By: Er. Madhav P. Nagarkoti (Visiting Faculty)Document43 pagesUnit 6: Substations: Prepared By: Er. Madhav P. Nagarkoti (Visiting Faculty)Dipesh YadavNo ratings yet

- Transformers - Three Phase TransformersDocument25 pagesTransformers - Three Phase TransformersDeepakDeep100% (1)

- Single Line Diagrams PDFDocument14 pagesSingle Line Diagrams PDFBattinapati Shiva60% (5)

- An Investigation of Ferroresonance On 13-kV Delta Ungrounded Tertiaries Using EMTPDocument25 pagesAn Investigation of Ferroresonance On 13-kV Delta Ungrounded Tertiaries Using EMTPCinar InalNo ratings yet

- Objective of The TrainingDocument35 pagesObjective of The TrainingRishiNo ratings yet

- Kota RailwayDocument40 pagesKota RailwayMulayam Singh Choudhary0% (1)

- T&D Supply SystemDocument93 pagesT&D Supply SystemAnil PalamwarNo ratings yet

- Intern Ship Report of 132Kv Grid StationDocument81 pagesIntern Ship Report of 132Kv Grid Stationdarkroom92% (25)

- Loki ReportDocument45 pagesLoki ReportNaveenVaddeNo ratings yet

- Design of 400 220 132 KV 1316 MW Power SubstationDocument117 pagesDesign of 400 220 132 KV 1316 MW Power SubstationAHMED YOUSEF100% (1)

- Power SystemDocument5 pagesPower Systemcaedv77No ratings yet

- Guideline To Design Electrical Network For Building Small AreaDocument3 pagesGuideline To Design Electrical Network For Building Small AreaAnonymous ufMAGXcskMNo ratings yet

- Upcl Report - Nitesh3Document28 pagesUpcl Report - Nitesh3Vaibhav SharmaNo ratings yet

- Six Week Industrial Training Report ON 66 KV Substation LatialaDocument48 pagesSix Week Industrial Training Report ON 66 KV Substation LatialaDdumbaNo ratings yet

- Power System in VSP NEWDocument35 pagesPower System in VSP NEWpruddvi100% (1)

- Substations ModifiedDocument60 pagesSubstations Modifiedarjuna4306No ratings yet

- Earthing Transformers For Power SystemsDocument11 pagesEarthing Transformers For Power Systemsanoopk222100% (1)

- Experiment No 09 Fault Scenario Simulation in A Feeder-1Document4 pagesExperiment No 09 Fault Scenario Simulation in A Feeder-1Kaustubh PatilNo ratings yet

- Nomi Internship ReportDocument13 pagesNomi Internship Reportبلال شبیرNo ratings yet

- Power Grid Training ReportDocument43 pagesPower Grid Training ReportJanmejey BarikNo ratings yet

- JunaidDocument2 pagesJunaidhamzadaud032No ratings yet

- Chambal Power House (C.P.H) YardDocument50 pagesChambal Power House (C.P.H) YardDevendra Sharma100% (1)

- Indian RailwayDocument37 pagesIndian RailwayAnonymous 3BGW2XaXZeNo ratings yet

- Farhan ADocument32 pagesFarhan ANikhil BoothpurNo ratings yet

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsFrom EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsRating: 3 out of 5 stars3/5 (2)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Catalogo Kaeser PDFDocument7 pagesCatalogo Kaeser PDForlando_ubaldoNo ratings yet

- Release Notes ABI 2009Document3 pagesRelease Notes ABI 2009Jesus Omar Hilario CercadoNo ratings yet

- Air PollutuionDocument3 pagesAir PollutuionMalvikasingh93No ratings yet

- Oracle® Application Express: Accessibility GuideDocument49 pagesOracle® Application Express: Accessibility GuideKrunal MakwanaNo ratings yet

- Spe 77-101 Steel Gate Globe and Check Valves To Iso 15761Document13 pagesSpe 77-101 Steel Gate Globe and Check Valves To Iso 15761zeke2611100% (1)

- Mobile Crane Inspector & CertificationDocument3 pagesMobile Crane Inspector & CertificationgptothNo ratings yet

- CHP556 - FOX660 Multiservice Utility MUX For TDM TransportDocument2 pagesCHP556 - FOX660 Multiservice Utility MUX For TDM TransportMichael Parohinog GregasNo ratings yet

- Welder Sample Resume: Professional ExperienceDocument1 pageWelder Sample Resume: Professional ExperiencePhilip KrebsNo ratings yet

- S7700 and S9700 V200R008C00 Configuration Guide - Ethernet SwitchingDocument1,277 pagesS7700 and S9700 V200R008C00 Configuration Guide - Ethernet SwitchingRahat MehmoodNo ratings yet

- TS 103 190 - V1.1.1 - Digital Audio Compression (AC-4) Standard PDFDocument295 pagesTS 103 190 - V1.1.1 - Digital Audio Compression (AC-4) Standard PDFHien Ly cong minhNo ratings yet

- 2003 Nissan Altima 2.5 Serivce Manual PBDocument8 pages2003 Nissan Altima 2.5 Serivce Manual PBAndy DellingerNo ratings yet

- Holdpeak 1356 enDocument39 pagesHoldpeak 1356 enGabrielyNoelia GarayNo ratings yet

- TLT-501 (02) Mix Design Method For Soil-Cement Mixtures 1.0 SCOPEDocument9 pagesTLT-501 (02) Mix Design Method For Soil-Cement Mixtures 1.0 SCOPEagus wahyudiNo ratings yet

- Instruction Manual Remote Control: 1. Product Presentation and Application AreasDocument7 pagesInstruction Manual Remote Control: 1. Product Presentation and Application AreasRajkumar MudaliarNo ratings yet

- 23xrv 4ssDocument154 pages23xrv 4ssLouie DupayaNo ratings yet

- 07-IsY10221 Meetings Agendas & MinutesDocument4 pages07-IsY10221 Meetings Agendas & Minutesjohn paroNo ratings yet

- Fisher EWN Series and EW 1 Series Valves: Scope of ManualDocument24 pagesFisher EWN Series and EW 1 Series Valves: Scope of ManualMOUWAKILNo ratings yet

- Free Video To Flash Converter LogDocument12 pagesFree Video To Flash Converter LogThomas HillNo ratings yet

- House and Home - Enterprise Network DesignDocument1 pageHouse and Home - Enterprise Network DesignfpnjieNo ratings yet

- Ict 7-8Document2 pagesIct 7-8Jeramy BallesterosNo ratings yet

- Anytone At-5189 ManualDocument38 pagesAnytone At-5189 Manual9w2nrNo ratings yet

- Digital HV Insulation Tester 10KV KM 2804 inDocument1 pageDigital HV Insulation Tester 10KV KM 2804 inindustrialindiaNo ratings yet

- ProjectWorks DetailingDocument9 pagesProjectWorks DetailingsankalpaNo ratings yet

- Atmoscope: Self-Contained SMD Hot Air Work StationDocument12 pagesAtmoscope: Self-Contained SMD Hot Air Work StationFabian ZambranoNo ratings yet

- Risks Assessment - Al Khor ProjectDocument4 pagesRisks Assessment - Al Khor Projectloveson709No ratings yet

- Deepam PDFDocument2 pagesDeepam PDFg_jayaram5829No ratings yet

- Communication Protocol For Carscop CCTR-800 GPS - enDocument13 pagesCommunication Protocol For Carscop CCTR-800 GPS - enJoãoBatistaBenDavidNo ratings yet

- 1987 Right To Environment and Sustainable DevelopmentDocument26 pages1987 Right To Environment and Sustainable DevelopmentAbhishek CharanNo ratings yet

- Final Exam Semester 1Document16 pagesFinal Exam Semester 1BarbaraBarNo ratings yet

- 53258-03 (Mach 2.1), GL2-GL2000-RCA-3.0kDocument7 pages53258-03 (Mach 2.1), GL2-GL2000-RCA-3.0kBalboaWaterNo ratings yet