Professional Documents

Culture Documents

ADL 65 ObjectiveType

Uploaded by

Selva Raj PillaiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ADL 65 ObjectiveType

Uploaded by

Selva Raj PillaiCopyright:

Available Formats

ADL- 65: Production Planning and Control Assignment 'C 1.

If the order winner is delivery speed to customer, then the production planning and control system must focus on: a) b) c) d) Cost Lead time Quality Coordination with Marketing

2. A firm uses simple exponential smoothing to forecast demand with a = 0.2. The forecast for the month of March was 500 units whereas the actual demand turned out to be 460 units. What is the forecast for the month of April? a) b) c) d) 489.6 492 480 490

3. Bias as a measure of forecast error is used to determine: a) b) c) d) The total magnitude of error The direction of error Absolute value Weighted average

4. Aggregate output planning generally consists of planning a desired output over a period of: a) b) c) d) one week five years daily three months to 1 year

5. Optimum inventory level as per EOQ system will increase: a) b) c) d) in direct proportion to increase in holding cost inversely with setup cost in proportion to square root of demand for the year in direct proportion to square root of holding cost

6. Product structure tree is: a) diagram explaining the features of a product b) used to display the total makeup of a particular product c) is representation of a tree d) identical to decision tree 7. Kit numbers are used in MPS: a) when there are many small, loose parts - such as fasteners, nuts and bolts - at level 1 in the product structure b) to identify related items c) to add complexity to planning d) as a quick aid to forecasting

8. MRP takes the output from the master schedule, combines that with information from inventory records and product structure records and determines: a) the volume of production in each period b) the schedule of timing and quantities for each item to get the right materials to the right place at the right time c) closing inventory d) whether customer demand can be met 9. Manufacturing Resource Planning is: a) the planning of resources in the manufacturing environment using the closed loop system b) another term for rough cut capacity planning c) is also known as MRP I or little d) is a quicker way to MRP 10. A classification system has been devised to determine how well an MRP system has been implemented. Class C company is: a) b) c) d) one which has MRP II in full use and the closed loop is working one in which MRP system is working only in the computing department one which may have MRP, capacity planning and shop floor controls working one which uses MRP for inventory ordering but not for scheduling

11. MRP logic uses the following relationships: a) b) c) d) Net requirements = total requirements - available inventory Net requirements = scheduled receipts + inventory on hand Net requirements = gross requirements - allocations Net requirements = gross requirements - on hand inventory

12. Lot-for-Lot technique in MRP yields: a) b) c) d) high holding cost low setup cost zero holding cost zero setup cost

13. The simulation studies on many of the lot sizing rules show: a) b) c) d) good performance of L-4-L rule good performance of EOQ rule poor performance of PPB, GR and MCP rules poor performance of L-4-L and EOQ rules

14. Time fence is a designated length of time a) to create system nervousness in MRP system b) that is the longest lead time from raw material to finished production for an end item c) that must pass without changing the MPS, to stabilise the MRP system; afterward the MPS is allowed to change d) around which the system is upgraded

15. Pegging is used in MRP system for: a) b) c) d) identifying which components are affected by disruptions in material plans pausing the system showing old records showing current records with updated status

16. Route sheet used in production planning and control is: a) used to indicate the location of each department b) a document to show the routing of a component, including the work centers and operation times, through its production processes c) a flow process chart used for process change d) a document showing the daily production schedule 17. The Master Production Schedule (MPS) is a schedule of: a) weekly production plan for each product according to customer orders and demand forecasts b) aggregate production plan in product groups c) daily production plan for shop floor control d) business activity expressed in money value 18. A good strategy to meet short term overload for a month can be: a) b) c) d) buy a new equipment invest in a new project subcontract work telling marketing that the job cannot be done

19. Infinite loading is: a) b) c) d) assigning jobs to work centers without considering the work center's capacity using Gantt chart for loading using visual load profile for showing load considering loading of planned orders only

20. Final Assembly Schedule can serve as MPS: a) b) c) d) when the number of end products manufactured is small when the number of end products is large when there is a need to disaggregate when M-bills have to be used

21. An aluminium extruder forecasted the demand for pipe extrusions to be 500 units per month for each of three months. The actual demands turned out to be 400, 560 and 700. The forecast error in terms of MAD(Mean Absolute Deviation) is: a) b) c) d) -50 units 125 units 120 units 53 units

22. Frigerware has experienced demand for ice coolers at 400 units for April, 500 units for May and 600 units for June. The forecast of demand for July using a three period model with the most recent period's demand weighted twice as heavily as each of the previous two period's demand is:

a) b) c) d)

425 525 625 400

23. In the regression model for forecasting, the forecast of the period's demand F is expressed as F = a + bX, where: a) b) c) d) F is the independent variable X is the dependent variable X is the independent variable a is the slope of the line

24. Capacity is a facility's productive capability, usually expressed as volume of: a) b) c) d) input in case of automobiles output in case of steel producer likely business as per marketing output in case of hospital

25. For short term periods of up to one year, fundamental capacity is fixed. However, short term adjustments of capacity are possible by: a) b) c) d) building inventories during slack periods to meet later demand subcontracting during slack periods building inventories during peak periods to meet demand in slack periods wishing that some customers may cancel the order

26. Steel manufacturing is an example of : a) b) c) d) Job manufacturing process Continuous manufacturing flow process Assembly line process None of the above

27. Visual Load profile is: a) b) c) d) a graph comparing work loads and capacities on a time scale identical to Gantt load chart used for forward scheduling process used for job sequencing

28. SPT rule in scheduling: a) b) c) d) assigns highest priority to the slowest job prioritises on basis of setup time prioritises on basis of delivery times assigns highest priority to the job order whose processing time is shortest

29. Which sequencing rule will you prefer for minimising average job lateness: a) b) c) d) Shortest processing time rule Longest processing time rule Earliest Due Date rule First cum first served rule

30. For scheduling N jobs through two machine centers in series, you will use: a) b) c) d) Johnson rule to decide the sequence and then schedule on a Gantt chart McLaren's Order Moment Groff's Algorithm None of the above

31. If a machining center has a machine utilisation of 95% and operator efficiency of 80%, what is the effective work centre capacity in July assuming 26 working days and 3 shifts running each day: a) b) c) d) 472.24 hours 472 hours 158.08 hours 59.28 hours

32. Critical Ratio used in Capacity Planning and Control is: a) b) c) d) Time to due date divided by required time for remaining operations Time for first job divided by time for second job Capacity consumed by the job divided by total capacity of the plant Capacity of output divided by capacity of input

33. Job A and B are waiting to be released. Both will go to work center 1. Then A will continue on to work center 3 while B will go to work center 4. Suppose that A has high priority on the first work center and center 4 is backlogged and center 4 is idle. Which order should be released first? a) b) c) d) Job A Job B Both Job A and Job B together Toss a coin and if its heads, go for Job A otherwise Job B.

34. Cycle time as used in assembly line manufacturing is: a) b) c) d) the time taken in last work station the productive time divided by demand the time taken by the bottleneck operation both b) and c) are considered and the higher value taken

35. In an assembly line the total processing time per, unit is 380 seconds, and the cycle time for the line is 90 seconds. What is the minimum number of workstations required in the assembly line? a) b) c) d) 4 stations 4.22 stations 5 stations 4.2 stations

36. Runout Time (ROT) used in batch processing is: a) b) c) d) the time taken to complete the batch the current inventory of an item divided by the demand per period for that item the demand for the item divided by the opening inventory level time for setup plus processing time

37. JIT is: a) b) c) d) another management jargon a philosophy of waste reduction and techniques for reducing inventory and waste applicable only to job shop units none of the above

38. If the setup cost is Rs 10,000 per setup, annual demand is 100,000 units and holding cost is Rs 200 per unit per year the optimal batch quantity in production should be (rounded off): a) 3162 b) 316

c) 31623

d) 3000 39. Kanban is: a) b) c) d) a push production system another word for MRP system a pull system based on a 'visible record' or 'card' input output system

40. If D is the demand per unit of time, L is the lead time, A is the container capacity and S the safety stock factor,the number of Kanbans N will be : a) b) c) d) DL(1+S)/A A(l+S)/D LAS(l + D)/24 (D/A) + L+S

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Cut Business PlanDocument3 pagesCut Business PlanSelva Raj Pillai0% (3)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Cloud Computing Based On UBanto Cloud Enterprise - SelvarajDocument9 pagesCloud Computing Based On UBanto Cloud Enterprise - SelvarajSelva Raj PillaiNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

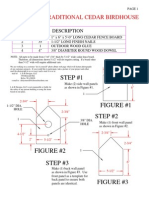

- Bird HouseDocument3 pagesBird Housekhunchaiyai100% (3)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Android 2.2 CDDDocument20 pagesAndroid 2.2 CDDCrhistian Eduardo VillarrealNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Perception - 9Document21 pagesPerception - 9Selva Raj PillaiNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Consumer As An IndividualDocument27 pagesConsumer As An IndividualSelva Raj PillaiNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Consumer As An IndividualDocument27 pagesConsumer As An IndividualSelva Raj PillaiNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Proposed Inclement Weather PolicyDocument2 pagesProposed Inclement Weather Policyapi-314308961No ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Long Test Science8 Module 1-3Document2 pagesLong Test Science8 Module 1-3Aizelle Taratara FaderoNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Chirstmas SongsDocument6 pagesChirstmas SongsIrina DrugeaNo ratings yet

- Matter in Our Surroundings July 2Document3 pagesMatter in Our Surroundings July 2Fullmarks EducareNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- 1 s2.0 S2772424721000111 MainDocument14 pages1 s2.0 S2772424721000111 MainestefanyNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Experiencing AntarcticaDocument4 pagesExperiencing AntarcticaLinh Dương KhánhNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 900 Ohb UkDocument120 pages900 Ohb UkSemifallenNo ratings yet

- Facing Down Armageddon: Our Environment at A CrossroadsDocument8 pagesFacing Down Armageddon: Our Environment at A CrossroadsQuibus_LicetNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Design of 10MW Generation For Calaguas Group of IslandDocument236 pagesDesign of 10MW Generation For Calaguas Group of IslandNina SakuraNo ratings yet

- PDS Hempe's Galvosil 15780 en-GBDocument2 pagesPDS Hempe's Galvosil 15780 en-GBRaghu VamshiNo ratings yet

- Maaseh BereshitDocument15 pagesMaaseh BereshitLordswitchNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Carta Psicrométrica (1atm)Document1 pageCarta Psicrométrica (1atm)alexoutbreakNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- English Sem 2 - Cls 8 - 17Document27 pagesEnglish Sem 2 - Cls 8 - 17Jamal UdinNo ratings yet

- Interview With Andrejs LandsmanisDocument2 pagesInterview With Andrejs LandsmanisForsta AP-fondenNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Duxbury Clipper 01 - 21 - 2009Document44 pagesDuxbury Clipper 01 - 21 - 2009Duxbury ClipperNo ratings yet

- Disaster Management Notes and QuestionsDocument15 pagesDisaster Management Notes and QuestionsSid Singh100% (1)

- Bechtel Technology Journal: Major OfficesDocument216 pagesBechtel Technology Journal: Major Officesข้าวเม่า ทอดNo ratings yet

- GE Protimeter MMS ManualDocument28 pagesGE Protimeter MMS ManualconstructermanNo ratings yet

- EN 636 Plywood - SpecificationsDocument2 pagesEN 636 Plywood - Specificationsjasekan.dcNo ratings yet

- Manual Direct Fired 160h Through 800h PN 54000 07-12-13 - 1Document53 pagesManual Direct Fired 160h Through 800h PN 54000 07-12-13 - 1Fer YamashitaNo ratings yet

- Climate Change Forecasting Using Machine Learning AlgorithmsDocument10 pagesClimate Change Forecasting Using Machine Learning AlgorithmsIJRASETPublicationsNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The 16 Commandments - Chateau HeartisteDocument3 pagesThe 16 Commandments - Chateau HeartisteDimitris Tselios100% (2)

- Morphy Richards Fastbake 48280Document20 pagesMorphy Richards Fastbake 48280winosNo ratings yet

- SMART IRRIGATION SYSTEM Using IoT PDFDocument5 pagesSMART IRRIGATION SYSTEM Using IoT PDFpadhmanabanNo ratings yet

- Harvest Moon Back To Nature Prima GuidesDocument127 pagesHarvest Moon Back To Nature Prima GuidesSamuelGreenNo ratings yet

- Preparedness Improvement Action Plan and ReportDocument36 pagesPreparedness Improvement Action Plan and ReportHonolulu Star-AdvertiserNo ratings yet

- AL 3.2 - Selecting and Constructing Test Items and TasksDocument8 pagesAL 3.2 - Selecting and Constructing Test Items and TasksJessa ParedesNo ratings yet

- The Rime of The Ancient Mariner by Samuel Taylor ColeridgeDocument7 pagesThe Rime of The Ancient Mariner by Samuel Taylor ColeridgeSiddhi DasNo ratings yet

- Flexible Pavement DesignDocument21 pagesFlexible Pavement Designnunajihah0% (1)

- FR Apyrol BKWDocument2 pagesFR Apyrol BKWMuhammad Aasim Hassan100% (1)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)