Professional Documents

Culture Documents

Machine Drawing Worked Examples

Uploaded by

euclidlOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Machine Drawing Worked Examples

Uploaded by

euclidlCopyright:

Available Formats

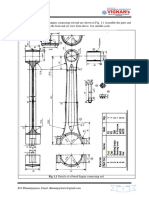

Worked examples in machine drawing

31

139

10

R10 30 R10

15

10

R4

R9 R4

40

75

94

25 48 holes

62 38 1 Clamp base

M10 1.5 15 deep

17

R50

54

106

26

82

12

10

19

R19

10

25 15 31

15 R12 22 25 93

34

19

38

Braze 10 ROD 3 Cam plate

6

89

14

65

19

10

38

25

4 25 5 2 Operating arm 8 38 8 5

Stopscrew

Fig. 18.3

M10 1.5

Braze

25

140

Manual of Engineering Drawing

22 22

Draw your solution in first angle projection and add the title and projection symbol in a suitable title block.

Sphere 19

66

M10 1.5

3 Cam operated clamp

Details of a cam operated clamp are shown in Fig. 18.3 together with a key showing the position of the various components in the assembly. Draw the following views in first angle projection: (a) A front view taken as a section through the vertical centre line of the clamp and generally as outlined in the key. (b) An end view projected on the right-hand side of the front view (c) A plan view drawn beneath the front view Add to your solution a title, scale, projection symbol, parts list and reference balloons.

Plunger

5 Turns of 3 wire ground flat at each end 25 Free length

19

Spring

70

10

19

4 Plug cock

Details of a plug cock are shown in Fig. 18.4. Draw the following two views of the assembled plug cock: (a) A view in half section showing the outside view on the left of the vertical centre line and a section on the right hand side, the position of the valve body being similar to that shown on the given detail. (b) An outside end view Add a title and a parts list. Hidden details are not required in either view. Include on your assembly suitable nuts and bolts and washers where applicable. Between the valve body and cover include a joint ring of thickness 2 mm. The gland should be positioned entering 10 mm into the valve cover. First or third angle projected views will be acceptable.

Arm pivot

45

19

Cam pivot

Note: On assembly, fit a suitable washer over each pivot and drill for 2 mm split pin

10

2 2 M10 / 1.5 Locknuts and washer

5 Air engine

The component parts of an oscillating air engine are detailed in Fig. 18.5. Draw in first angle projection and, at twice full size, the following views; (a) A front view taken as a section through the engine cylinder and flywheel. (b) A plan view in projection with the front view and drawn below the front view. (c) An end view on the right hand side and in projection with the front view. Hidden detail is not required in any view. Add a parts list to your drawing and reference balloons to identify each of the components in the assembly.

8 6 1 7 Key to assembly 3 5

Fig. 18.3 (continued)

You might also like

- Assembly Drawings Part-3Document19 pagesAssembly Drawings Part-3Parameswararao Billa100% (1)

- Drafting ExercisesDocument12 pagesDrafting ExercisesJaime Andres Velez100% (3)

- Machine Drawing Work Sheet On Assembly Drawing@BikiDocument11 pagesMachine Drawing Work Sheet On Assembly Drawing@BikiAgnihothra Sarma OrugantiNo ratings yet

- Roller AssemblyDocument1 pageRoller AssemblySandeep KumarNo ratings yet

- Engineering Drawing: Mechanical Engineering Department L.J. PolytechnicDocument40 pagesEngineering Drawing: Mechanical Engineering Department L.J. PolytechnicTufel NooraniNo ratings yet

- CAMD AssemblyDocument44 pagesCAMD AssemblySameerKulkarni100% (4)

- Assembly Drawing Part 2Document5 pagesAssembly Drawing Part 2Graham MutumaNo ratings yet

- Assembly Drawing ExercisesDocument57 pagesAssembly Drawing ExercisesAli HassanNo ratings yet

- Assembly Drawing AssignmentDocument3 pagesAssembly Drawing AssignmentSagar Dhage100% (1)

- Assembly DrawingsDocument15 pagesAssembly DrawingsN Dhanunjaya Rao BorraNo ratings yet

- ENGINEERING APPLICATIONS OF SECTIONING AND DEVELOPMENT OF SOLIDSDocument26 pagesENGINEERING APPLICATIONS OF SECTIONING AND DEVELOPMENT OF SOLIDShotnili100% (2)

- Part-B1-Petrol Engine Connecting RodDocument5 pagesPart-B1-Petrol Engine Connecting RodN Dhanunjaya Rao BorraNo ratings yet

- Model Machine DrawingDocument15 pagesModel Machine Drawingசெல்வ குமார்No ratings yet

- Development of Lateral SurfacesDocument8 pagesDevelopment of Lateral SurfacesDeva RajNo ratings yet

- Create and assemble components of Tool Head assemblyDocument42 pagesCreate and assemble components of Tool Head assemblySaif RahmanNo ratings yet

- Student's Project InventorDocument10 pagesStudent's Project InventorSatish BollamNo ratings yet

- CAMD USN 15ME36A/46A Third Semester B.E. Degree ExaminationDocument4 pagesCAMD USN 15ME36A/46A Third Semester B.E. Degree ExaminationVasim MansuriNo ratings yet

- Engineering Drawing Form 4 (Quadrilaterals)Document14 pagesEngineering Drawing Form 4 (Quadrilaterals)farah sakinah100% (1)

- DEMONSTRATION - Const. of A HelixDocument2 pagesDEMONSTRATION - Const. of A HelixNitin B maskeNo ratings yet

- Machine Drawing Through CadDocument91 pagesMachine Drawing Through CadmjdaleneziNo ratings yet

- Chapter 6 - Assembly DrawingsDocument87 pagesChapter 6 - Assembly DrawingsAnonymous ohCM2ktv100% (1)

- Computer Aided Machine DrawingDocument9 pagesComputer Aided Machine DrawingChetan Gowda0% (1)

- CAD LAB - ExercisesDocument63 pagesCAD LAB - Exercisessarath761089% (9)

- AssemblyDocument45 pagesAssemblyKaan Zumrutkaya100% (1)

- Section View ExerciseDocument5 pagesSection View Exerciseprakash silvarajanNo ratings yet

- Lesson 9 Development of Surfaces - IDocument12 pagesLesson 9 Development of Surfaces - IAKSHANSH MATHURNo ratings yet

- Engineering Drawing-II Book for Diploma StudentsDocument9 pagesEngineering Drawing-II Book for Diploma StudentsJithesh.k.sNo ratings yet

- Complete Engineering Graphics SolutionsDocument284 pagesComplete Engineering Graphics SolutionsRebecca PetersNo ratings yet

- Mechanical Engineering Drawings and ProjectsDocument21 pagesMechanical Engineering Drawings and ProjectsRajueswar100% (4)

- Design of Turning FixtureDocument23 pagesDesign of Turning FixtureDIPAK VINAYAK SHIRBHATE100% (1)

- Machine Drawing T-SheetDocument30 pagesMachine Drawing T-SheetIfham Shah100% (3)

- Proiect Catia V5Document5 pagesProiect Catia V5Claudiu ClassNo ratings yet

- Student Project Pro-EDocument10 pagesStudent Project Pro-EAmit GoelNo ratings yet

- MCAD ManualDocument38 pagesMCAD ManualsureshrnalNo ratings yet

- Sample Midterm Problems - Engineering Graphics in DesignDocument5 pagesSample Midterm Problems - Engineering Graphics in Designmaterial manNo ratings yet

- Section of SolidsDocument25 pagesSection of SolidsSuneel Kumar MeenaNo ratings yet

- Engineering Drawing Form 4 (Circles)Document12 pagesEngineering Drawing Form 4 (Circles)farah sakinahNo ratings yet

- Assembly Drawing ExercisesDocument57 pagesAssembly Drawing Exercisesxitta00100% (10)

- GRIPPER CLAMP SUB-ASSEMBLY HOUSING GRIPPERDocument1 pageGRIPPER CLAMP SUB-ASSEMBLY HOUSING GRIPPERDudeboy Nautic100% (1)

- Student Project Inv 2008Document16 pagesStudent Project Inv 2008Agus PrijantoNo ratings yet

- Wheel Support Assembly PDFDocument2 pagesWheel Support Assembly PDFManuel Djeredjian100% (1)

- Plantas CNC de Madeira Kit 1-1 PDFDocument15 pagesPlantas CNC de Madeira Kit 1-1 PDFalexandrearume5392No ratings yet

- ME2257-Machine Drawing ManualDocument62 pagesME2257-Machine Drawing ManualVPSureshKumar100% (4)

- Draw Die Design by SivapapachariDocument11 pagesDraw Die Design by SivapapachariSiva ChariNo ratings yet

- Isometric Projections: Hareesha N G Dept of Aeronautical Engg Dayananda Sagar College of Engg Bangalore-78Document39 pagesIsometric Projections: Hareesha N G Dept of Aeronautical Engg Dayananda Sagar College of Engg Bangalore-78Hareesha N G100% (5)

- Engineering Drawing from the Beginning: The Commonwealth and International Library: Mechanical Engineering DivisionFrom EverandEngineering Drawing from the Beginning: The Commonwealth and International Library: Mechanical Engineering DivisionRating: 5 out of 5 stars5/5 (3)

- Coolaire Installation InstructionsDocument15 pagesCoolaire Installation Instructionsgeorgemesfin@gmailNo ratings yet

- 04-11 GM Colorado / Canyon 2WD / 4WD 4" Suspension Lift Installation InstructionsDocument10 pages04-11 GM Colorado / Canyon 2WD / 4WD 4" Suspension Lift Installation Instructionstrimoca_234178616No ratings yet

- 2RZ 3RZ SCDocument21 pages2RZ 3RZ SCDiego Pillco0% (1)

- Cordless Reciprocating Saw Technical SpecsDocument11 pagesCordless Reciprocating Saw Technical SpecsJose Sanchez100% (2)

- F16 AvionDocument26 pagesF16 AvionJuan Carlos AlvaradoNo ratings yet

- Food Processor ŽDocument15 pagesFood Processor ŽAndrei Și Mihaela GeantăNo ratings yet

- Fuel Injection Pump - InstallDocument5 pagesFuel Injection Pump - InstallMaria PazNo ratings yet

- Isc 300Document37 pagesIsc 300AwanNo ratings yet

- Cambio Arbol de LevasDocument12 pagesCambio Arbol de LevasgenaroNo ratings yet

- Visual Inspection of The PistonDocument53 pagesVisual Inspection of The Pistondonsallus100% (3)

- Tech Bulletin 0112 - Creaking Clicking of FrameDocument8 pagesTech Bulletin 0112 - Creaking Clicking of FrameRichard HagleyNo ratings yet

- Removal Refitting Variable Geometry Turbocharger GARETTDocument6 pagesRemoval Refitting Variable Geometry Turbocharger GARETTiliecNo ratings yet

- 1988 Tomos A3 Workshop ManualDocument30 pages1988 Tomos A3 Workshop ManualcerubdzijaNo ratings yet

- 140M Elect Diagram PDFDocument27 pages140M Elect Diagram PDFcriman45No ratings yet

- كارير كونسيلد الجديدDocument45 pagesكارير كونسيلد الجديدEZAY ازايNo ratings yet

- Abdul Bari (Dome)Document83 pagesAbdul Bari (Dome)A.F. MominNo ratings yet

- TURK PLAST (PPRC Green+Blue+PE GAS) 01-02-2021 - OutstationDocument1 pageTURK PLAST (PPRC Green+Blue+PE GAS) 01-02-2021 - OutstationicrcgisNo ratings yet

- PROSIS Part InformationDocument2 pagesPROSIS Part InformationMilorad ZelenovicNo ratings yet

- Partslist Avant500Series 260302Document52 pagesPartslist Avant500Series 260302npNo ratings yet

- Rewinder Annexue - 'A'Document12 pagesRewinder Annexue - 'A'RishabhNo ratings yet

- Parking Brake - Test: Testing and AdjustingDocument3 pagesParking Brake - Test: Testing and AdjustingRajan MullappillyNo ratings yet

- ERT Calder PDFDocument8 pagesERT Calder PDFHatem JafouraNo ratings yet

- Valvula EsterlingDocument3 pagesValvula EsterlingSAULNo ratings yet

- Carbureted and Ramjet Auto Transmission Control System PDFDocument12 pagesCarbureted and Ramjet Auto Transmission Control System PDFAmor MansouriNo ratings yet

- View Fusibles y Reles Motor SmaxDocument2 pagesView Fusibles y Reles Motor SmaxruitxoNo ratings yet

- KW1466 PDFDocument279 pagesKW1466 PDFJavierRivasNeira100% (2)

- Catálogo de Peças de Reposição: 6415,6615 TRACTORSDocument752 pagesCatálogo de Peças de Reposição: 6415,6615 TRACTORSMiguel MattiesNo ratings yet

- Turbine Engine StartingDocument4 pagesTurbine Engine Startingmamaadam02No ratings yet

- Spare Parts Catalog: 6 WG 210 Material Number: 4657.056.136 Current Date: 28.01.2019Document80 pagesSpare Parts Catalog: 6 WG 210 Material Number: 4657.056.136 Current Date: 28.01.2019Костя ДолинськийNo ratings yet

- FSAE Design Spec Sheet for University of Wisconsin-Platteville Car No. 18Document2 pagesFSAE Design Spec Sheet for University of Wisconsin-Platteville Car No. 18AlexandrKozlenokNo ratings yet

- Catalogo ServoDocument9 pagesCatalogo ServoOMAR DAVID BERNAL CUASPANo ratings yet

- BAYLX UL16 UL18 UL20 2015 ULTRALITE-SPREADER-v3Document32 pagesBAYLX UL16 UL18 UL20 2015 ULTRALITE-SPREADER-v3Jonah RagleNo ratings yet

- Manual Mounting Type Dvc5010 Digital Valve Controllers On Fisher Type 657 667 Actuat en 141856Document6 pagesManual Mounting Type Dvc5010 Digital Valve Controllers On Fisher Type 657 667 Actuat en 141856hocine1No ratings yet

- SANMOTION K Series DC Servo MotorDocument5 pagesSANMOTION K Series DC Servo MotorNisar AhmedNo ratings yet

- Alko Scythe Mower BM5001R ManualDocument26 pagesAlko Scythe Mower BM5001R ManualBernd Wernicke100% (2)

- Series DeVilbiss Compressor PumpDocument5 pagesSeries DeVilbiss Compressor Pumplstrector2008No ratings yet

- Codigos Emcp Ii BRK PDFDocument30 pagesCodigos Emcp Ii BRK PDFRubenNo ratings yet

- Model - Ylaa: Installation Checklist and Request For Authorized Startup EngineerDocument3 pagesModel - Ylaa: Installation Checklist and Request For Authorized Startup EngineerSergio Ito SunleyNo ratings yet

- ASCO Series 300 Automatic Transfer Switch Operator's ManualDocument20 pagesASCO Series 300 Automatic Transfer Switch Operator's ManualdjibtapzNo ratings yet

- Cummins ISX Engine Harness P92-1262 E 01: Usage NoteDocument5 pagesCummins ISX Engine Harness P92-1262 E 01: Usage NoteJuan Pablo Leon RualesNo ratings yet

- 3 HvacDocument31 pages3 HvacFazli SubhanNo ratings yet

- Dimensions and range of a telescopic boom liftDocument14 pagesDimensions and range of a telescopic boom liftjose jimenezNo ratings yet

- What Are Turbines - Types of Turbines & Their Applications - MechStuffDocument7 pagesWhat Are Turbines - Types of Turbines & Their Applications - MechStuffsyazwanNo ratings yet