Professional Documents

Culture Documents

Gold Eagle Steam Iron Manual

Uploaded by

Sadiqa ZainalOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gold Eagle Steam Iron Manual

Uploaded by

Sadiqa ZainalCopyright:

Available Formats

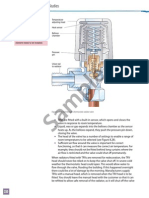

BOILER PARTSNAME

PART NO.

A1

NAME

Host outer shell Liftins handle module Heat insulationcushion Brace Electric outlet module Bracket Steamtube connector Steamvalve module Coil Screw Electromagnetic valveplug

Power cord clip

PART NO.

423

NAME

A2

A3

A4 A5 A6 A7 A8

A8-3

A9 A10 A11 AI2 AI2-I A13 AI4 A15 A16 AI7 A18 A19

Cupreousconjunction 1.24 Cupreousnut complete set p^25 Glasstube A26 Glasstube connector 1.27 Pressure controller L28 Manometer module 429 Sealingring A30 Heatins element A'31 Hexansularscrew A3Z Thermostat 1'33 Six pin the line connector 1'34 Lamp

A35 A36 1'37 A38 A39 Lamp holder Panel

A'20

1.21

A22

Boiler Safety valve connector Safetvvalve base Hexangular nut Safetyvalve Safetyvalve uppercover Keep-warmcotton cover Heat-shieldcotton rins Bottom board Supporting feet module Turn on water the valve Cupreouscover completeset

A40 1.41 p'42

1'43

p'44

p'45 p'46

Indicatorlamp Switch Fusecompleteset Rear cover Powercord clip Powercord Measuring cup Funnel Spring Cable bracket

WiringDiagram the Machine of

9. Diagram a sketchmap

rirlrririir

/--:-\

\7

Instruction Use for

1 . Wi ri ng

Mustconnect witha socketprovided grounding. with Makesurethatthe voltage complies withthatshown themachine. on

2. Water filling

Thismachine equipped a waterboiler with thatneeds water feeding manually. Unload the safety valve(incounterclockwise direction)(drawing 1),filling waterby self-prepared the brew basket cupmeasure. maximum and The capacity thismachine Sl.youcanseethewater of is level through special the indication (drawing Cover safety window. 8). the valvein place after filling out. Makesurethatno waterpoured ontothemachine.

3. Machine operation

1.) Steamtube connection: connectthe end of the steamtube with the valve (drawing A), then fastenthe clip tab (drawing B). 2.) lron connection: Connectthe ironwith 4 pin plug with the waterboiler,insefi it and fix plug. (drawing C) 3.) Plugthe power 4.) Turn on the powerof the water boiler(drawing heatingpilotlight( drawing7), 4), it will take about 10-12 minutesto heatthe waterboiler.lt showsthe water boilerhave alreadyreachedworkingsteampressure when the heatingpilotoff.you can see the pressure the pressure by gauge.The maximumpressure this machineis 0.3gMpa. of 5.) Within2-3 minutesbeforestarting iron,turn on the powerof the iron (drawing to 6), adjustthe temperatureknob (drawing1O)to the mark which cloth materialreadv iron, press the rockerswitch (drawing9), start to steam iron. 6.) Steam volume can be adjustedwith the electromagnetic valve on the water boiler (drawing 3). 7') The waterin the boilerneedsto be checkedthroughthe specialwaterwindow if no steamgenerated the iron duringthe machineoperation. in Waitfor 10-15minutestill boilerif no water,then push the safetyvalve (drawingl in counterclockwise direction, ), add the waterslowly,re-iron accordingly afterheating. 8.) Mustturn off the switchof the boiler(drawing , iron powerswitch(drawing 4) 6), as wellas head powerswitchaftermachineworking.Safetyvalve needsto be loosened(drawing1)to avoidpressure existedin the machine. the boilercooleddown completely afterunplugging powerand closethe the to

4. Maintenance guide

Cut off the powerandconsult witha maintenance workerif machine abnormal work.

5. Common malfunction solution &

1.) No steam comeout,however, pressure existed theboirer in

GOLD

EAGLE

I NSTRUCT FORUSEAND I NSTALLAT I ONS I ON

MODEL

DL-5

llllllllllllllll

liii;liijlliijlllll;

.',.. .'," a

power if turnon (drawing 6). A. Check the ironswitch valvecloseor not(drawing B. Check thesteam if 3) 11). if cordof theironbreak not(drawing or C. Check thepower if valveburnoutor not(drawing 2). D, Check thecoilof thesteam E. Check the button switch ironbreak not(drawing if & of or 9). generated the boiler power 2.) No steam from afterboiler energized A. Check water if existin theboiler not(drawing or 8) B. Check the boiler if heating element break not(drawing or 12) part valvebreak not(drawing thisis thecritical and if or 1), C. Check thesafety needs be placed changed problems to or if occur.

6. Warning:

o o Safetyvalve openingis forbidden duringnormaluse (drawing1) Unplugthe unit and releasethe steamtill the boilercoolingdown beforefilling the water. a

ll

This machineis not intended otherpurposes. for Don'tmake any flammable material closeto the machineduringuse. Don'tcoverwith clothwhen the boilerenergized. Can use by the authorized adultsonly. Cleanactionduringthe machineoperation forbidden. is To avoidany accidents, make sure provided groundwire. a

l. o a a o

guide thetemperature 7. Scale for dial

1. Nylon 85t 2. Silkfabric 116'C tabric147"C 3. Woolen 4. Cotton fabric178t fabric 5. Linen 210"C

guide 8. Parameter

Voltage Boilerheater lron heater

) 220V-

) 110V-

1500w

900w

4.0Mpa 5L 7-8 HOURS 13 KG 54.29.5*45CM

pressure Steam

Boilercapacity

Autonomy

Weight Packingdimension

B oiler E xplodedVie w

n

\

\-A4o

@-otu

,

\\

tl

\__\

I

FW-A15 @ -n+

l -Fl

A 6-l

t@ t {I

oo

El

@

A5

5

ffi

ffi - ts

@w m

e

@o

@

1" \',

@o@

o@a

I tl

a vo

a@

@o

E>*

m---rTl @ _=\

e

!-*

A23

Y w ^ ^J' ^"-m H 0tr{h x)

#

e

fl"

ren

"il-^4

_^

A.r o - U

4!-A3e

'-ft

A34_a-l

LJ

ryffi-0"

@ - egz

428

<@

,r2eA3o ffi#.e

I

436

DISASSEMBLED OF B3TNIRON VIEW

--l [<r-r-tr | | \[

I

8315

)""

-8310 8309 8308

azrc-fl

8318-1

s I

l -- -- -- -\ t _

lt' ^"Jl

I

|

,nu

tw / td

l-

| I

e=-8307

ffi)-$17

8318_

Fm F e@

FFg FF FF

318-2-

aso+-z-Q

ct0l03

n 8304-1-u

ffi

I I

JS-eszz

F tl

!oL

8318-5

tl

:r

U

a---------------? scm

J-,,0,

8319---------o $$lQ- or-------o $$!l-r-7.5",

bcm 6",

PART NO.

NAME

PART NO. 8309 Thermalbaffle 8310

Aluminum card

NAME

PART NO.

NAME

8301 Soleplate iron of

8302 Curved adapter 8303 Heater iron of 8304 Thermostat components 8304-1Thermostat 8304-2 Thermostat knob 8305 Hexbolt 8306 Fenous outershell 8307 Rubber Circle 8308 Fenous support

8318-l Fixationturnfor steam tube 8318-2 Steam tube (2.4M) 83I 8-3 Power cable(2.4M) 83I 8-5 Plastics buttons "S" shape of 83 t9

50mmheatwire

8311 Screw components 8312 Vaporswitch 8313

Fixation components vaporswitch seat for

8314 Handle iron of

8 31 5

Handle connectinsscrewrod

8320 60mmheatwire 8321 75mmheatwire 8322 Temperature insurance

CKMO3 Four-core plug

8316 8317 83 18

jacket Power cable Junction components box Power cable, steam tubecomponents

You might also like

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Marvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- I702 ManualDocument36 pagesI702 ManualRachel NguyenNo ratings yet

- Deltamv 3Document15 pagesDeltamv 3José MacedoNo ratings yet

- Instruction Manual: Desoldering StationDocument6 pagesInstruction Manual: Desoldering StationUsuario AnonimoNo ratings yet

- Tiemme Automatika Na Kotlu Na Pelet enDocument16 pagesTiemme Automatika Na Kotlu Na Pelet enDraganNo ratings yet

- Drying Machine ManualDocument8 pagesDrying Machine ManualCretulescu Camelia0% (1)

- 6ALBR5233JQODocument23 pages6ALBR5233JQOpinticaniulian9042No ratings yet

- 1700 Tube FurnaceDocument22 pages1700 Tube FurnaceJosé Antonio FontesNo ratings yet

- Sample: RememberDocument2 pagesSample: RemembermohansafNo ratings yet

- Installation & Servicing Instructions: These Instructions To Be Retained by UserDocument44 pagesInstallation & Servicing Instructions: These Instructions To Be Retained by UserErwin De HeusNo ratings yet

- Saunier Duval Thema C23 Installation ManualDocument20 pagesSaunier Duval Thema C23 Installation ManualZmarandoiu SorinaNo ratings yet

- Heatline Capriz 25Document7 pagesHeatline Capriz 25opel1997No ratings yet

- Cuptor Coven - 6emd UslDocument22 pagesCuptor Coven - 6emd UslPaul MocanuNo ratings yet

- Whirpool - 6LBR5132EQ - Manual Servicio PDFDocument31 pagesWhirpool - 6LBR5132EQ - Manual Servicio PDFAldo TonatoNo ratings yet

- Watts Technical CatalogueDocument77 pagesWatts Technical CatalogueMuhidin KozicaNo ratings yet

- Comfort: GC1121, GC1120, GC1115, GC1111, GC1110, GC1015, GC1011, GC1010Document48 pagesComfort: GC1121, GC1120, GC1115, GC1111, GC1110, GC1015, GC1011, GC1010vamshidsNo ratings yet

- Struers Prestopress3 Embedded PressDocument23 pagesStruers Prestopress3 Embedded PressnarutomovieNo ratings yet

- Autoclaves TC 409 y 459 Gemmy PDFDocument4 pagesAutoclaves TC 409 y 459 Gemmy PDFCarlos Guanipa100% (3)

- Vaporetto 2200 RDocument11 pagesVaporetto 2200 RMedMiloNo ratings yet

- Tilting Bratt Pan Gas Instruction and Maintenance ManualDocument8 pagesTilting Bratt Pan Gas Instruction and Maintenance ManualKHOZA SBUSISIWENo ratings yet

- NUVEOT90LSERVICEMANUALDocument31 pagesNUVEOT90LSERVICEMANUALMUSTAFANo ratings yet

- Riello RG5D Burner ManualDocument11 pagesRiello RG5D Burner ManualjadetorresNo ratings yet

- AFA Alco Series ValveDocument3 pagesAFA Alco Series ValveRay RavelNo ratings yet

- Whirlpool Arc 3030Document5 pagesWhirlpool Arc 3030João FigueiredoNo ratings yet

- GN Boiler RangeDocument16 pagesGN Boiler Range9810482818No ratings yet

- 6ALBR5233JQODocument23 pages6ALBR5233JQOTom CatNo ratings yet

- RowentaDocument82 pagesRowentaEscoffierNo ratings yet

- Steam - Generator Maxi 60 GhidiniDocument12 pagesSteam - Generator Maxi 60 GhidiniEttore FrattoneNo ratings yet

- ManualDocument5 pagesManualrpichoNo ratings yet

- E Valupak M Specs InstructionsDocument8 pagesE Valupak M Specs Instructionsmgk80No ratings yet

- GSL 1100X6Document19 pagesGSL 1100X6Adolfo LopezNo ratings yet

- Service Manual: Dishwasher GSF 4761 TW-WSDocument27 pagesService Manual: Dishwasher GSF 4761 TW-WSOfer FolkmarNo ratings yet

- CL160CD&E InstallDocument4 pagesCL160CD&E InstallJosë Rodríguez100% (1)

- TP8 EN Manual 20180822Document4 pagesTP8 EN Manual 20180822Nico SkyNo ratings yet

- Whirlpool AWM 5080 ManualDocument21 pagesWhirlpool AWM 5080 ManualCharles ThompsonNo ratings yet

- Awz 410Document13 pagesAwz 410Drasko MitrovicNo ratings yet

- Manual JT7700Document60 pagesManual JT7700Alecsandru NitaNo ratings yet

- Manual Instrucciones Rs 20 20Document3 pagesManual Instrucciones Rs 20 20Armand BasyNo ratings yet

- Magma 150 and 230 Owner Operator ManualDocument48 pagesMagma 150 and 230 Owner Operator ManualAwatef BahloulNo ratings yet

- Cooler DataDocument23 pagesCooler DataAmit Kumar SinghNo ratings yet

- Olusterm Olejovy Horak NavodDocument19 pagesOlusterm Olejovy Horak NavodozuskacNo ratings yet

- Cooling System (2Az-Fe) : On-Vehicle InspectionDocument27 pagesCooling System (2Az-Fe) : On-Vehicle InspectionTung NguyenNo ratings yet

- Boiler Steam Iron ©Document6 pagesBoiler Steam Iron ©pukymottoNo ratings yet

- Ariston Genus 23 RepairDocument44 pagesAriston Genus 23 RepairDaniel PereiraNo ratings yet

- Riello Burners Gas3-2 RMG PDFDocument16 pagesRiello Burners Gas3-2 RMG PDFchnanduNo ratings yet

- 230 Magma Crack Sealer Operator ManualDocument44 pages230 Magma Crack Sealer Operator Manualdominicparramore100% (2)

- Vapourline Eco 50Document130 pagesVapourline Eco 50Alejandra Carolina Ballon BrañezNo ratings yet

- thermCA en Stand 2013 03 18Document56 pagesthermCA en Stand 2013 03 18mohamed ghareebNo ratings yet

- Manual Vulcan en InglesDocument12 pagesManual Vulcan en InglesingegusNo ratings yet

- Ekco l1n487Document20 pagesEkco l1n487Petre MarianNo ratings yet

- User and Maintenance Manual: EnglishDocument12 pagesUser and Maintenance Manual: EnglishPricopNo ratings yet

- Oil and Water Retort, 50mL ModelsDocument14 pagesOil and Water Retort, 50mL ModelsFirdaus SyafruddinNo ratings yet

- Whirlpool Art 666 GDocument5 pagesWhirlpool Art 666 GÓnodi Szilárd0% (1)

- EOA 61 CMP User ManualDocument21 pagesEOA 61 CMP User ManualEl Anonimo50% (2)

- Sample: RememberDocument4 pagesSample: RemembermohansafNo ratings yet

- Manual Bentone ST108PL enDocument20 pagesManual Bentone ST108PL enChris RobertsNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Autoclaved Aerated ConcreteDocument4 pagesAutoclaved Aerated ConcreteArunima DineshNo ratings yet

- Daylighting IN Underground Buildings: Ashraf Ali Ibrahim NessimDocument365 pagesDaylighting IN Underground Buildings: Ashraf Ali Ibrahim NessimthabisNo ratings yet

- Leonhardt Cable StayDocument29 pagesLeonhardt Cable StayTarun Kant GoyalNo ratings yet

- Geotechnical Investigation Into Causes of Failure of A GabionDocument6 pagesGeotechnical Investigation Into Causes of Failure of A GabionParth ShahNo ratings yet

- Railway EngineeringDocument9 pagesRailway EngineeringVIVEK V SNo ratings yet

- Urban Floods Chennai Report NGT Sep2021Document55 pagesUrban Floods Chennai Report NGT Sep2021Vaishnavi Jayakumar100% (1)

- Virtual Case Study Nift (National Institute of Fashion Technology)Document18 pagesVirtual Case Study Nift (National Institute of Fashion Technology)Shubham JainNo ratings yet

- Design and Analysis of A Ladder FrameDocument14 pagesDesign and Analysis of A Ladder FrameNandan PoojaryNo ratings yet

- Pt. Maxxis International Indonesia New Factory Phase - 1 ProjectDocument17 pagesPt. Maxxis International Indonesia New Factory Phase - 1 ProjectNabil RidwanNo ratings yet

- TDS A183n 750 EngDocument3 pagesTDS A183n 750 EngVigneswaranNo ratings yet

- Pressure Vessel InspectionDocument3 pagesPressure Vessel InspectionSpectex dubaiNo ratings yet

- Document Transmittal To Black Cat - Dn80Document2 pagesDocument Transmittal To Black Cat - Dn80Joseph PerezNo ratings yet

- Grouting ProcedureDocument7 pagesGrouting ProcedureArbiNo ratings yet

- Steel Connection Design ClassDocument32 pagesSteel Connection Design ClassJohn HammerNo ratings yet

- Method Statement For Conduit Installation Including Accessories PVC & GIDocument17 pagesMethod Statement For Conduit Installation Including Accessories PVC & GIgangadharan000100% (1)

- 3-Section 05 10 00 Structural Steel WorkDocument40 pages3-Section 05 10 00 Structural Steel WorkAhmad SaadeldinNo ratings yet

- PSOW2 - MS For Waterproofing Dated 04.11.2023Document5 pagesPSOW2 - MS For Waterproofing Dated 04.11.2023projectsNo ratings yet

- Reinforced Concrete - History, Properties & Durability PDFDocument5 pagesReinforced Concrete - History, Properties & Durability PDFLvisionNo ratings yet

- Hitachi ARG Chiller Cat V2 LResDocument28 pagesHitachi ARG Chiller Cat V2 LResĐinh Công NguyệnNo ratings yet

- Internal CoilDocument2 pagesInternal CoilwhngomjNo ratings yet

- DTC P0299 Chevrolet Sonic 2014Document7 pagesDTC P0299 Chevrolet Sonic 2014miguelNo ratings yet

- Case Study: 11.1. Humayun'S Tomb Garden ComplexDocument3 pagesCase Study: 11.1. Humayun'S Tomb Garden ComplexAr Meena JadounNo ratings yet

- Equipment Layout Unit Plot PlanDocument6 pagesEquipment Layout Unit Plot PlanIgnacio OñateNo ratings yet

- Yakmach KharanDocument3 pagesYakmach KharanMunir HussainNo ratings yet

- PWD Retaining WallDocument6 pagesPWD Retaining WallG.C.PatilNo ratings yet

- LooPUB31 PDFDocument71 pagesLooPUB31 PDFAbdallah AlrifaiNo ratings yet

- Design of Steel JointsDocument42 pagesDesign of Steel JointsMehmed100% (1)

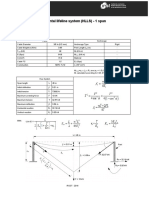

- Horizontal Life Line CalculationDocument1 pageHorizontal Life Line Calculationhasan_676489616100% (1)