Professional Documents

Culture Documents

Untitled

Uploaded by

pewenggworksOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Untitled

Uploaded by

pewenggworksCopyright:

Available Formats

Scribd Upload a Document Search Documents Explore Documents Books - Fiction Books - Non-fiction Health & Medicine Brochures/Catalogs

Government Docs How-To Guides/Manuals Magazines/Newspapers Recipes/Menus School Work + all categories Featured Recent People Authors Students Researchers Publishers Government & Nonprofits Businesses Musicians Artists & Designers Teachers + all categories Most Followed Popular Sign Up Log In 1 / 14

View Mode Slideshow Scroll Reading should be social! Post a message on your social networks to let others k now what you're reading. Select the sites below and start sharing. Readcast this Document Login to Add a CommentShare & Embed Download this Document for Free

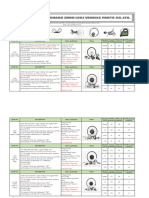

Maintenance Manual for BG coaches of ICF design Bogie Mounted Air Brake System Chapter 6, Page 1 of 14CHAPTER 6 BOGIE MOUNTED AIRBRAKE SYSTEM 601 GENERAL I n order to overcome the problems of slack adjuster failure as well as problemsas sociated with cast iron brake blocks, adesign of brake system incorporating 8"si ze two cylinders on each bogie alongwith K type high friction compositebrake block

s has been introduced. 602DESIGN FEATURES OF THESYSTEM (refer figure 6.1) This t ype of system is exactly similar tothe standard air brake system except forthe f ollowing: a) External slack adjuster is removed/ eliminatedb) Four cylinder of 8" size is providedfor each coach in place of twocylinders of 14"in standard air brake system. These cylinders havebuilt in single acting slack adjusterfor takin g the slack created betweenwheel and brake block on account of wheel / brake blo ck wear. Mountingof cylinders is done on either side of the bogie frame in betwe en centrallongitudinal members connecting thebogie transom to the headstocks.Eac h cylinder controls the brakingon one wheel set. Each cylinder hasa piston take up stroke of 32 mmandadjustment capacity of 305 mm (Ref. Drg. RDSO Sk- 81057)c) High friction composite brake blocksof K type have been used.d) Bogie brake riggin g has beenmodified to incorporate a totalmechanical advantage of 7.644 perbogief or non-AC coaches and8.40per bogie for AC coaches.e) Curved profile pull rods ha ve beenused to interconnect leverscontrolling braking one wheel set.These pull r ods provided with oneadditional hole for the adjustment of slack between wheel a nd block afterspecified amount of wear.f) Since brake cylinders have beenmounted on the bogie frame, 15mm.bore pneumatic pipeline has beenlaid over bogie frame to interconnect the brake cylinders of onebogie. Output pipe line of distributor valve has been connected to bogiepneumatic line through flexiblehoses to provide flexibility toalround dynamic movement.603COMPOSITE BRAKE BLOCK 603aGeneral Lo w friction composite brake blockshave the following benefits: n Reduced braking distance due touniform co-efficient of friction.n Reduced weightn Reduction in the replacement of brake blocks vis a vis cast iron due tohigher wear life in t rain operation.n Reduced wear and tear of brakerigging.n Reduced noise during br aking. 603bCharacteristics of composition brakeblocks i. Composition of materia l The composition of materialconstituting the brake blocks must bechosen to give the best balancebetween : The braking characteristics The wear and service lif e of blocks Wear on the running surface of thewheels The effect on adhesion betwee n therail and wheel ii. Requirement concerning friction The average coefficient of friction is0.25. As far as possible the coefficient of friction must be indepe ndent of theinitial braking speed, the state of bedding-in of the brake block, t hespecific pressure also thetemperature and atmosphericconditions. ContentsHin di Maintenance Manual for BG coaches of ICF design Bogie Mounted Air Brake System Chapter 6, Page 2 of 14*STROKEINITIAL RELEASEPOSITION281117.522STROKE(MUST BEIN A STRAIGHTLINE)4-FIXINGRESETTING LATCHMAX.MAX.25RELEASE POSITION AFTERFULL 305 TAKE-UPLEVERS MUST BETHE CROSSHEAD ISARRANGED SUCH THATHELD WITH IN 1.5mmLEVERS MUST BE ARRANGEDSO THAT THE PATH OF THEMAX.MAX.21BRAKE CYLINDER WITHSKETCH-81057 B.G.203.2 mm x 95.25 mm (8"X 3 3/4")EMU STOCK & SELF GENERATINGR(C)D SO. . . .SU PERSEDED BY:SUPERSEDES:PCDT J.S.SCALEGROUP21-2/99TOLERANCE + 0/-10mm ADDED-CD/35/98 NOTE 1 ADDED & TITLE CHA NGED12/88 FLOPPY No. :-DATEDESCRIPTIONAUTHY.ALT.ITEMASSEMBLY DRAWINGSREFERENCE:SLACK ADJUSTERMAIN LINE COACHESON DIMENSION 685.CD/7/99%%UNOTE:-HOLES %%C21OF TH IS AXIS.CROSSHEAD CENTRE LIESBETWEEN THESE LINES.MAX. WORKING MOVEMENTMOVEMENT T O BE ALLOWED FOR..+ 0-10%%p0.5MAIN LINE COACHES, REFER RDSO SK-81200 AND THE1. T O MANUFACTURE BOGIE MOUNTED BRAKE CYLINDER FORBILL OF MATERIAL FOR DIFFERENT COM PONENTS.INDIAN RAILWAY STANDARDS 3 4 53-CD/21/99 NOTE 2 ADDED.12/994-CD/4/2K1.2.3.%%p0.5FIXING HOLE DIA. CHANGED TO 21mm.DIM. 117.47mm CHANGED TO 117.5 .DIMENSION 101.6mm CHANGED TO 102.5CD/8 /2K-DRAWING REVISED11/2K4/2KHAND BRAKE TRUNNION95 MAX.130127%%p0.5204204%%p0.5== POSITION B FOR EMU MOTOR COACHES==36540047473167968531POSITION A FOR MAIN LINE S ELFGENERATING AND BG EMU TRAILORCOACHESWORKING STROKE,32mm FOR SELFGENERATING MA IN LINE COACHES,60mm FOR BG EMU COACHES.*1271272 Nos.AIR INLET PIPE CONNECTION,O NE CONNECTION IS TO BE MADEDUMMY BY PLUGGING.REWINDING THE ADJUSTING TUBE.ADJUST ER IS TO BE RESET BY305 MAX. SLACK TAKE UP.95 MAX.%%p0.5SK-81200SK.SRIVASTAVAMa i n t e n a n c e Ma n ua l f o r B G I C F C o a c h e s B o g i e Mo un t e d A i r B r a k e S y s t e mC h a t e r 6 , P a e 2 o f 1 4 ABFIGURE 6.1 ContentsHindi Maintenance Manual for BG coaches of ICF design Bogie Mounted Air Brake System

Chapter 6, Page 3 of 14 Under the effect of dampness, theaverage coefficient of friction must notvary, with the other conditionremaining the same, by more than15% in relation to the value obtainedduring braking when dry. After prolonged braking followed bybraking to a stop, particularly hightemperature occur. Even in the c ase of these temperatures (maximum 4000C on the opposing friction surface) theav erage coefficient of friction must notvary with the other conditionsremaining th e same by more than 15%in relation to the value obtainedduring braking in cold and dry state. iii. Geometrical characteristics of thebrake blocks The constructiona l features of thebrake blocks must enable them to weardown to a thickness of 12 mm including the back plate, without thelatter coming into contact with therunni ng surface of the wheel. iv. Mechanical and physicalcharacteristics The various elements making up thebrake blocks must be spread uniformlyin the body of the bl ock. There mustbe no pitting, flaws or other defects.The material must not attac k theopposing friction surface or give riseto the formation of metal inclusions. Composition brake blocks mustnot bring about more serious heatdamage to the whee ls (hot spots,cracks, flaking) than would be causedby cast iron blocks used in t he sameway on the same wheels. The values of specific weight, thermalconductivity , hardness, bendingstrength and the modulus of elasticitymust be given for accep tancepurposes. No method is laid down for fixing thecomposite material part to t he back plate. The back plate must be designedto support the stresses likely to occur. The composition blocks must notaffect to an unacceptable degree theadhesio n values between wheel andrail obtained on vehicles braked withcast iron inserts . 603cNon-asbestos K type compositionbrake block Non-asbestos K type blocks shallgene rally conform to RDSO drawingNo. 98066. The use of asbestos is prohibited. The use of lead or zinc in the metalstate or in the form of compounds isnot advised. Th e same applies to allother compounds, if in the form of powder, particles or gas producedduring the used of the brake blocks,they may constitute a danger to hea lth. 603dAsbestos based K type compositionbrake Asbestos based K type blocks shallge nerally conform to RDSO drawingNo. 98146. 603eMarking Each block must bear the followingmarks:- Name of manufacturer Date of manufacturer (month andyear) Materia l code including KA forasbestos type and KNA for non-asbestos type. Type of service ML. These marks, preferably punched, cut orstamped, must be applied so that the block can be identified, even after being fullyworn in service. 603f Comparison of properties/Usage of composition brake block Vs Cast IronBrake block Type of Brake blocks in use on main linecoachesParam-eters L type CBB K typeCBBCIAppl i-cabilityAll coacheswithunderframemounted airbrake systemAll coacheswith bogiem ountedbrakesystemAllcoacheswithvacuumbrake andunderframemountedbrakesystemSpeed Upto 110KMPHupto 110KMPHUpto 140KMPHCoefficient of friction0.12 to 0.14 0.25 max . 0.12 to0.14Weight Approx. 3kg.Approx. 3kgApprox. 9kg. ContentsHindi

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- 10-Audi A3 QSB WebDocument135 pages10-Audi A3 QSB Webashielanie100% (2)

- 06 DX-LC Swing DeviceDocument24 pages06 DX-LC Swing DeviceSergey100% (2)

- MAC25-4 Hydraulic General InfoDocument115 pagesMAC25-4 Hydraulic General Infole mefNo ratings yet

- Locomotive Components - Air Brake SystemsDocument82 pagesLocomotive Components - Air Brake SystemsVenkatesh Chintala100% (1)

- LIUGONGDocument6 pagesLIUGONGHerlan GarciaNo ratings yet

- Dornier 328Jet-Landing GearDocument27 pagesDornier 328Jet-Landing GearMariomourajunior100% (1)

- Parts Catalog: 850J TIER 3 Crawler Dozer (SN 130886-)Document567 pagesParts Catalog: 850J TIER 3 Crawler Dozer (SN 130886-)Castro FernandoNo ratings yet

- VW Touareg MaintenanceDocument102 pagesVW Touareg MaintenanceNick PNo ratings yet

- Product Guide: FeaturesDocument20 pagesProduct Guide: Featuresoscar albertoNo ratings yet

- Kalmar DRF 450 BrakeDocument42 pagesKalmar DRF 450 Braketuấn anh nguyễnNo ratings yet

- AtzDocument54 pagesAtzRam Shewale50% (2)

- Porsche - US Cayman - 2012 PDFDocument65 pagesPorsche - US Cayman - 2012 PDFSculatorNo ratings yet

- Cnn17ure0014 - (Jum-0148-Ya)Document4 pagesCnn17ure0014 - (Jum-0148-Ya)MAX ARNOLD LUCAS GOMEZNo ratings yet

- 8 - D9R SLDDocument61 pages8 - D9R SLDmeyega noe sergeNo ratings yet

- HONDA SH125 - SH150 21YM Owners ManualDocument164 pagesHONDA SH125 - SH150 21YM Owners Manualmitros_karamitrosNo ratings yet

- EC-MC-SM 125/200/250/300 PART LISTDocument126 pagesEC-MC-SM 125/200/250/300 PART LISTDavid BrezmesNo ratings yet

- Add: 3B Ming Huang Industry, Wujin District, Changzhou, Jiangsu, China, 213100Document4 pagesAdd: 3B Ming Huang Industry, Wujin District, Changzhou, Jiangsu, China, 213100Vinícius MartinezNo ratings yet

- Brake Technicians Service Guide PDFDocument28 pagesBrake Technicians Service Guide PDFleonardo cardenasNo ratings yet

- p2002 JF Amm - Ed2r4Document1,203 pagesp2002 JF Amm - Ed2r4Andrii KlishchevskyiNo ratings yet

- Intertruck Brand Catalogue - Axle and Brake PartsDocument312 pagesIntertruck Brand Catalogue - Axle and Brake PartsAgus YulfizarNo ratings yet

- EH750-3 Rigid Hauler Hydraulic Training 3 RD PartDocument15 pagesEH750-3 Rigid Hauler Hydraulic Training 3 RD Partthan zaw win100% (1)

- Product Catalog: Cleveland Wheels & BrakesDocument296 pagesProduct Catalog: Cleveland Wheels & BrakesАлександр ГладкийNo ratings yet

- AgustusDocument340 pagesAgustusOneCs 007No ratings yet

- Automobile EngineeringDocument3 pagesAutomobile EngineeringErick ThorpeNo ratings yet

- Supreme Coverage Plan DetailsDocument2 pagesSupreme Coverage Plan DetailsTiffany Dacino100% (1)

- Surface Vehicle StandardDocument8 pagesSurface Vehicle StandardLeonardo Gonçalves GomideNo ratings yet

- SEM636D Wheel Loader CEV Stage IVDocument1 pageSEM636D Wheel Loader CEV Stage IVwihardodoNo ratings yet

- Ae MCQDocument27 pagesAe MCQShantoNo ratings yet

- Calculation of Dynamic Loads On Lifitng Mechanism of Overhead Cranes in Emergency BrakingDocument9 pagesCalculation of Dynamic Loads On Lifitng Mechanism of Overhead Cranes in Emergency BrakinglehuylapNo ratings yet

- Helicoid Hydraulic Motor & Drilling Equipment GuideDocument20 pagesHelicoid Hydraulic Motor & Drilling Equipment GuideCristhian AlvearNo ratings yet