Professional Documents

Culture Documents

MGS Newsletter - JUNE 2011-Final

Uploaded by

tricia_hamblyOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MGS Newsletter - JUNE 2011-Final

Uploaded by

tricia_hamblyCopyright:

Available Formats

TIPS FOR GREEN PRACTICES AT HOME:

Run your dishwasher only when its full Increase the temp on your refrigerator / freezer Insulate your hot water tank Unplug appliances when not in use Use compact fluorescent light bulbs Insulate leaky doors and windows

CORPORATE NEWSLETTER

June 2011

CUSTOMER PROFILE:

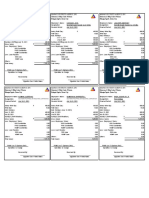

Headquartered in T d Troy, Michigan, Delphi is a leading h l h global supplier of electronics and technologies for automotive, commercial vehicle and other market segments. The company has four different divisions with facilities located in 30 countries. Until 2009, Delphi was a business subsidiary of General Motors. Today, the company supplies products to nearly every major global automotive original equipment manufacturer including G e n e r a l Mo t o r s , Fo r d , C h r y s l e r a n d Hy u n d a i . MGS Mfg. Group has been an essential vendor for Delphi for the past three years. The partnership began in 2008 when Delphi awarded MGS with two large transfer programs: The first was the Ford Canister program which consisted of 55 parts; the second was a 35-part program that was transferred to MGS when Delphis former injection molder went out of business. Since then, Delphi has presented MGS with many other tooling and molding opportunities. One major project was the Chrysler Fuel Handling System. MGS built prototype tools and held a sampling event for part production, and was then awarded the final production tooling and molding which consisted of 11 different tools and 11 different parts. In the beginning of 2011, Delphi created a new platform for the Ford Canister program. Once the redesign was complete, MGS was awarded tooling and production of this next generation component. The program consists of nine tools and seven parts. (Two duplicate tools were built to meet production demands for one of the parts.)

Marcel Alvarez, MGS Business Development Manager for TecStar de Mexico, has worked closely with the Delphi team since the inception of the business relationship. All Delphi manufacturing programs, including the aforementioned Chrysler and Ford programs, currently run at the Chihuahua facility. Delphi is TecStar de Mexicos largest customer to date in terms of annual sales. To put perspective on Delphis growth over the past two years, the companys sales with MGS in the first half of 2011 almost equal its sales for the entire year of 2009. According to MGS Molding Group Estimating Manager Jace Schubert, MGS recently quoted two large new tooling and molding programs for Delphis Packard Division: O n e i s a 1 2 - p a r t p r o g r a m f o r Fo rd , a n d t h e o t h er is a project for General Motors consisting of 32 parts. MGS was verbally awarded the Ford project on May 20th. Eight new presses will be installed at TecStar de Mexico to run production of these parts. Because of the upswing in programs that Delphi has launched and the increase in sales that has occured each year since 2008, it is anticipated that the business relationship between Delphi and MGS Mfg. Group will continue to flourish.

Delphis Ford CD4 Canister program.

DELPHI FAST FACTS:

Delphis sales with MGS Mfg. Group increased 39% in fiscal year 2010 over 2009 Delphi has 111 manufacturing locations Rodney ONeal, CEO and president of Delphi, began his automotive career at General Motors in 1971 Delphi is a sponsor of NASCAR

ENGINEERING FOR OPTIMUM PERFORMANCE

Prototype tools built by PMD for the Chrysler Fuel Handling System.

Please turn to other side...

UW PLATTEVILLE AND MORAINE PARK TOUR MGS FACILITIES

On Wednesday, April 20, MGS Mfg. Group toured students from two Wisconsin colleges. The rst set of visitors included a dozen students focused on careers in the field of tool design and engineering from Moraine Park Technical College in West Bend. The second group traveled to Germantown from the University of Wisconsin Platteville. These undergraduates are studying engineering production. For many years, MGS Mfg. Group has opened its doors to local schools to educate students about the wide range of career opportunities that are available in the plastics industry, particularly the fields in which their curriculums are focused.

MGS ANTIOCH PASSES ISO 13485:2003 SURVEILLANCE AUDIT

On Tuesday, April 26, MGS Antioch received its annual surveillance audit. This audit is required to allow the facility to maintain ISO 13485:2003 Certication. (This certication species requirements for a quality management system where an organization needs to demonstrate its ability to provide medical devices and related services that consistently meet customer requirements and regulatory requirements applicable to medical devices and related services.) According to MGS Antioch Director of Quality Ron Claypool, The auditor who conducted the audit was extremely thorough during the process. He did not nd any noncompliances at our facility and was very impressed with our people and our system. Ron would like to thank everyone for presenting a solid and well prepared operation. MGS Antioch also goes through a complete a u dit every three years. This comprehensive audit typically takes 3-4 days and provides recertification of both ISO 9001:2008 and ISO 13485:2003.

UW Platteville students listen in as tour guide Adam Simons discusses MGSs automation capabilities.

W I S C O N S I N TO O L & D I E A P P R E N T I C ES H I P P RO G R A M

MGS would like to congratulate Bryan Eberle and Bryan Wul for being signed to the State of Wisconsin Tool and Die Apprenticeship Program. They both started the program with MGS Mfg. Group on Wednesday, May 11. Bryan Eberle has been with MGS since August 2007 and was mentored by Scott Conrad. Bryan Wul was hired last October and spends most of his time working with Stuart Nitschke. MGS would also like to commend Jeremy Muellenbach for completing the prescribed number of training hours in the design program on April 23rd. Jeremy, who started as an intern in 2007 and works with the PMD team, is now a full-time Mold Designer. Jeremy worked with Brad Beckmann and Roger Skibinski during his internship. What is an apprenticeship program? Apprenticeship is a structured system of training d e s i g n e d to p re p a re i n d i v i d u a l s fo r s k i l l e d

Upcoming Industry Events

June 7-9: MD&M Plastec East Jacob Javits Center - New York, NY MGS Booth #632 Pack Expo Las Vegas Convention Center MGS Booth #S-5817 MEDTEC Ireland Radisson Blu Hotel - Cork, Ireland MGS Booth #315

Sept. 26-28:

October 5-6:

December 6-7: BIOMEDevice West San Jose McEnery Convention Center MGS Booth #1131

occupations. It combines on-the-job training under the supervision of experienced journey workers with related classroom instruction. Apprentices who successfully complete the prescribed number of hours of training in an apprenticeship program become certified skilled workers. Wisconsin is celebrating its 100th Anniversary of Apprenticeship this year.

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 830a - Crew Application Form - Sea ServiceDocument3 pages830a - Crew Application Form - Sea ServiceJingle PalmaNo ratings yet

- Jobs, Career and WorkDocument2 pagesJobs, Career and WorkLịch PhạmNo ratings yet

- Introductory LetterDocument185 pagesIntroductory Letterarvindranganathan100% (1)

- Problem Answer The Following Questions Using The Information Given by The Accompanying TableDocument4 pagesProblem Answer The Following Questions Using The Information Given by The Accompanying TablePhạm KiênNo ratings yet

- Upstream CAE Test 6Document3 pagesUpstream CAE Test 6adevoicu0% (1)

- McqsDocument22 pagesMcqsChandra Sai KumarNo ratings yet

- Wisdom of Best Teacher+Waiting For Superman ReviewDocument9 pagesWisdom of Best Teacher+Waiting For Superman ReviewTan YLunNo ratings yet

- A Case Study On Organizational Culture of PhcoloDocument22 pagesA Case Study On Organizational Culture of PhcoloNaomiGeronimoNo ratings yet

- Mcroeconomics LecturesDocument59 pagesMcroeconomics LecturesElşən OrucovNo ratings yet

- Trade Reviewer SampleDocument81 pagesTrade Reviewer SampleBie100% (1)

- 2019LLB036 - Labour Law II - Semester 06Document24 pages2019LLB036 - Labour Law II - Semester 06Asish Ansuman MishraNo ratings yet

- ACCA F5 - CH 5 - Make or Buy and Other Short-Term Decisions - Free Flash CardsDocument4 pagesACCA F5 - CH 5 - Make or Buy and Other Short-Term Decisions - Free Flash CardsEkin SapianNo ratings yet

- New Directions in Strategic ManagementDocument22 pagesNew Directions in Strategic ManagementMarina Ţurcan-PuşcaşNo ratings yet

- SMETA Audit Criteria GuideDocument24 pagesSMETA Audit Criteria Guidetony s100% (2)

- CEO Bonus Plan Sample-GenericDocument2 pagesCEO Bonus Plan Sample-Genericexpertceo_productionNo ratings yet

- Week 3-Slm 3 - Safety in The WorkplaceDocument27 pagesWeek 3-Slm 3 - Safety in The WorkplaceRachelle Anne MendozaNo ratings yet

- Workplace Stress Can Kill: Case ApplicationDocument2 pagesWorkplace Stress Can Kill: Case ApplicationRaj DasNo ratings yet

- Motivating Yourself and OthersDocument22 pagesMotivating Yourself and OthersMaritza SotoNo ratings yet

- 2 EdcDocument18 pages2 EdcfrizkaintanNo ratings yet

- Unemployment in PakistanDocument10 pagesUnemployment in Pakistanfaris_baba83% (6)

- 7. Đề Thi Thử TN THPT 2021 - Môn Tiếng Anh - Nhóm GV MGB - Đề 7 - File Word Có Lời Giải Chi TiếtDocument7 pages7. Đề Thi Thử TN THPT 2021 - Môn Tiếng Anh - Nhóm GV MGB - Đề 7 - File Word Có Lời Giải Chi TiếtQuỳnh Liên NguyễnNo ratings yet

- July 16-31, 2021Document1 pageJuly 16-31, 2021Nico CiprianoNo ratings yet

- Assignment 5 - AW Ltd.Document2 pagesAssignment 5 - AW Ltd.Kunal SharmaNo ratings yet

- Dinh Phan Management PhilosophyDocument3 pagesDinh Phan Management PhilosophyWeei Zhee70No ratings yet

- Job Profile - IT Sales Staffing - OLXDocument2 pagesJob Profile - IT Sales Staffing - OLXpriyankaNo ratings yet

- Customer FIRST Training ProposalDocument19 pagesCustomer FIRST Training ProposalMofoluso Aribisala90% (31)

- Which Is Good For You": Mujtaba M. MominDocument7 pagesWhich Is Good For You": Mujtaba M. Momincaesar victorianNo ratings yet

- Job Pack Teacher of Maths Apr21Document11 pagesJob Pack Teacher of Maths Apr21Mansoor Aaqib MalikNo ratings yet

- Case Study 1 - Nidhi RawatDocument17 pagesCase Study 1 - Nidhi Rawatnidhi rawatNo ratings yet

- Leave RulesDocument10 pagesLeave RulesjijinaNo ratings yet