Professional Documents

Culture Documents

Mantech

Uploaded by

Damanjeet SinghOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mantech

Uploaded by

Damanjeet SinghCopyright:

Available Formats

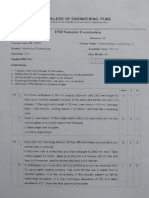

Roll Number: Thapar Univer sity Patiala Department Mechanica.l of Engineering .

Mechanical 3'" Year, I E-MBA 3'o Year ME002: Manufacruring Technology Fall Semester,Mid semesterexam, 22 September,2010 Time: 02 Hours; Maximum marks: 60 Name of Faculty: Dr Rahul Chhibber, Mr, Ankur GoeI

NOTE:All questions are compulsory, Attempt all parts of the attemptedquestions. Missing data if any may suitably be assumed. Support your answers with neat sketches wherever rcquired

I (a) Amongthe typesof sands usedin mouldingsandpreparation which sandhasthe highestmeltingpoint 2 marks andwhich hasthe lowestcoefficientofthermal exnansion? out around1600centipFades whichtvpe ofclay is used? I mark Jb)_ Whencastingis carrield at temperatures Whatis the idealshape riserandwhy? ola 2 marks (d) ln the cupola furnace what are the various zones and in which zone do we find the maximum 3 mark temperatures? fe) is !!ich type of die castingprocess usedto cast copperbasealloysandwhy? 2 marks (0 Which type of Manual Metal Arc Welding eleotrodes also known as generalpurposeelectrodes I mark are ald canbe usedeffectivelyfor bothAC andDC polarities? (e) What is the coating factof in Manual Metal Arc welding electrodes? are electrodesclassified 2 marks How acaording mngeof coatingfactor? to (h) Why thori4ledtungsten electrodgs preferred are over puretungsten electrodes TIG weldins? in I marks (i) When and Why does mode of metal transfer changefrom globular to axial spray mode, for same diameterelectrode. Whatarethe othermodesof metalTransfr? matks Why do we prefer using constantcurrenttype of welding power sourcewhon welding is doneusing I mark Shielded metalarcweldingprocess. (k) Differentiatebetween orthogonal co-ordinate and reference systems usedin tool nomenclature 1 mark (D Differentiatebetween orthogonal obliquecuttingprocess and I mark (m) Enlist the seven basicelements singlepoint cuttingtool nomenclaturc of 2 marks (n) Definetool life? What arethe factorsaffectinstool life? 2 mark (o) How do cutting fluids affect tool life? I mark 2 marks ll/hef is sintering?Why is it requiredto sinterthe powdermetallurgycompact? (q) What is atomization ? What are other methods of powder preparation? 2 mark (r) What is the thicknessrqngeof the shell in shell moulding process? I mark (s) Differentiatebetween Misrun andCold Shut. I mark Whatis friability?Whatis grinding ratio(G-Ratio) ? 2 mark 2(a) The following^equatiol_for life is givenfor a tuming operation tool 4 marks

c)

A 60 minute tool life wasobtained whilecuttingat V= 30 m/mi4 f = 0.3mm/rev. d = 2.5mm and Determinethe changein tool life if the cutting speed,feed and depthof aut are increased by 20% indirriduallyandalsotakentogether. (b)

An aro weld is being made on a steel plate under the fo[owing conditions, Welding Voltage 20 V, 2 marks welding current 200 A, Heat h'ansfer efticiency f1 = 90%, melting efficiency f2= 30%, welding speed = 5 mm/s, The melting point of steel plate is 800 degree centigrades. Calculate the total weld metal cross-section areamelted.

(c)

of ks uptoofthe constituents 1000 andis made composition variousolements of Constituent Proportion Percentage %

o/oc o/oSi o/oMn

o/oP

l )_ | marks

%S

3(a)

(b) (c) (o,

I i

0.4 0.02 J.) 3 20 Pieiron I u.) 0.8 0.01 1.5 20 Pis Lon 2 0.5 0.08 J.) 1.8 0"60 Scrap 30 0.035 0,6s 0.16 3.3 2.5 Retums 30 Phosphorus, Sulfurin the melt assuming a Manganese, of Silicon, Calculate percentage Carbon, the 'a for a a net gainof O.l|y:o Carbon, net lossof 15Yo silicon, net lossof 10%for manganese, ne1 for lossof ohosphorus 60/o, netgainof sulfurof 0.01%, of a grinding wheelof diameter mm,having 4 marks 150 resinoid surface Mr. Odumbe usinga siliconcarbidois of 9 cutting pointsper mm' of its surfaceareaat a surfacespeed 1600m/secfor removinga layer of with a speed of400 m/ sec. workpiece whichis beingmoved 4 metal mm &oma roundbaraluminum chip thicknoss ratio being 16. in The layer is removed form of chipswith chip width to average and it for chip by the Kindly helpMr. Odumbe deriving expression undeformed thickness estimating for this grindins operation. ofdifferentshapes sucl 3 marks times"t"for casting the UsingChvorinov's equationcompare solidification , '. F'ind theirr*iio. havi.ig same volume"V ascuiric. cylindrical spherical, and for Derivethe expression critical radiusofNucleation "r", in termsof surfacefiee energro, volume 2 marks Nucleation. ofhomogeneous freeenergychange for case AF, of CardModel, derivethe expression shearangle"q" in termsof backrake angle 2+4 UsingPispanen's '1" for orthogonal machiningusing singlepoint cutting tool. Also for the same marks "a"and cutting ratio Force(F"), FrictionForce(F), of casederivethe expression ShearForce(F"), Normal to Shear (F6) andVertical Thrustforce (Fv) l.trormal friction lc.c: (\D in iermsof HorizontalCuttingForce to angle(rp)andbackrakeangle(4.)usingMerchantCycle on the singlepoint e';.iing torrl andtle shear

L - --L'9.]39m

You might also like

- Study of PDC Cutter DurabilityDocument17 pagesStudy of PDC Cutter Durabilitysuresh_501No ratings yet

- Load Confirmation 95971Document2 pagesLoad Confirmation 95971Dana LegaciNo ratings yet

- Homework Solution p3Document10 pagesHomework Solution p3Petro ManNo ratings yet

- Question Bank For Machining and MetrologyDocument7 pagesQuestion Bank For Machining and MetrologyAbhisheak DineshNo ratings yet

- Me 014Document2 pagesMe 014Jimmy JindalNo ratings yet

- Assignment 3Document2 pagesAssignment 3M Shahrul IzuanNo ratings yet

- Mech311 Midterm 2009, 2011 and 2012Document9 pagesMech311 Midterm 2009, 2011 and 2012Parvinder SinghNo ratings yet

- 2013Document4 pages2013AmyRapaNo ratings yet

- ME3201Document4 pagesME3201Md. Tariqul Islam MunnaNo ratings yet

- Mantech Tie 6122 Assignment Bouquet Oct 2019 PDFDocument4 pagesMantech Tie 6122 Assignment Bouquet Oct 2019 PDFNativity MabasaNo ratings yet

- Question Bank (PPII)Document7 pagesQuestion Bank (PPII)Udaiyar BarathadhithyaNo ratings yet

- PDF MEC3102 Tutorial No 1-ASSIGMENT 1Document4 pagesPDF MEC3102 Tutorial No 1-ASSIGMENT 1Beckham ChaileNo ratings yet

- EMMU 7244-Machine Tool Vibrations and Cutting Dynamics-Exam July 2016Document4 pagesEMMU 7244-Machine Tool Vibrations and Cutting Dynamics-Exam July 2016Charles OndiekiNo ratings yet

- College Roll No: Total No. of Printed Pages: 2: Semester: 5 Sub: Machining Science & TechnologyDocument2 pagesCollege Roll No: Total No. of Printed Pages: 2: Semester: 5 Sub: Machining Science & TechnologyPrabina PatnaikNo ratings yet

- Engineering Academy: ESE Conventional Revision TEST - IIIDocument8 pagesEngineering Academy: ESE Conventional Revision TEST - IIIvidya chakitwarNo ratings yet

- Adv - Design of Weldments Seme1 2004Document4 pagesAdv - Design of Weldments Seme1 2004mukesh3021No ratings yet

- Example 2Document5 pagesExample 2girma workuNo ratings yet

- MC&TDDocument4 pagesMC&TDGopal Krishan0% (1)

- Study of The Chips Morphology in Turning by Stratified Sampling MethodDocument9 pagesStudy of The Chips Morphology in Turning by Stratified Sampling MethodAbderrahim BelloufiNo ratings yet

- Grinding and Unconventional MachiningDocument2 pagesGrinding and Unconventional MachiningRadhey KrishnaNo ratings yet

- Assignment Metal CuttingDocument2 pagesAssignment Metal CuttingthakurkalidassNo ratings yet

- 2022-Dec ME-312 53Document2 pages2022-Dec ME-312 53Aakash TiwariNo ratings yet

- EMMU 7244-Machine Tool Vibrations and Cutting Dynamics-Exam July 2016Document4 pagesEMMU 7244-Machine Tool Vibrations and Cutting Dynamics-Exam July 2016Charles OndiekiNo ratings yet

- DOPT AssignmentDocument6 pagesDOPT AssignmentRabindra Kumar LakraNo ratings yet

- Spierings 2011 Influence of The Particle Size Distribution On Surface Quality and Mechanical Properties in ADocument10 pagesSpierings 2011 Influence of The Particle Size Distribution On Surface Quality and Mechanical Properties in ARaj RajeshNo ratings yet

- Assignment 1 AMPDocument2 pagesAssignment 1 AMPAryan SaikiaNo ratings yet

- Btech Degree VIII Semester (Supplementary) ExaminationDocument2 pagesBtech Degree VIII Semester (Supplementary) ExaminationpremquilonNo ratings yet

- 1314sem1-Me3162 Me3162eDocument6 pages1314sem1-Me3162 Me3162eZheng YongjiaNo ratings yet

- 6 Semester Mechanical Engineering: Orissa Engineering College, Bhubaneswar MST Online Class TestDocument4 pages6 Semester Mechanical Engineering: Orissa Engineering College, Bhubaneswar MST Online Class TestDipti Ranjan SahooNo ratings yet

- 53112-MT - Theory of Metal Cutting & Tool DesignDocument2 pages53112-MT - Theory of Metal Cutting & Tool Designhari0118No ratings yet

- Tutorial SheetDocument21 pagesTutorial Sheetankita awasthiNo ratings yet

- Asignment Sheet-4Document1 pageAsignment Sheet-4JohnNo ratings yet

- Compre 15-16 Sem1 With Soln (Charsichoco)Document4 pagesCompre 15-16 Sem1 With Soln (Charsichoco)Jasdeep SinghNo ratings yet

- 2022-May ME-322 109Document2 pages2022-May ME-322 109Sidhant SadyalNo ratings yet

- ME 338 Manufacturing Processes II HW#2Document2 pagesME 338 Manufacturing Processes II HW#2Anonymous 2xjDjAcZNo ratings yet

- Home Work No 3Document2 pagesHome Work No 3HarishNo ratings yet

- Problems Sheet Machine Tools 2015 16Document9 pagesProblems Sheet Machine Tools 2015 16Shafiq AhmadNo ratings yet

- Home Cmplab HTML Bbs Data Pds0085 1Document9 pagesHome Cmplab HTML Bbs Data Pds0085 1呂昕儒No ratings yet

- 1 Computer Aided Flank Wear Measurement in End Milling Cutting PDFDocument14 pages1 Computer Aided Flank Wear Measurement in End Milling Cutting PDFTbk TongbankhamNo ratings yet

- Question Paper For MeDocument4 pagesQuestion Paper For MeVishal JhaNo ratings yet

- Study Regarding The Optimal Milling Parameters For Finishing 3D Printed Parts From Abs and Pla MaterialsDocument7 pagesStudy Regarding The Optimal Milling Parameters For Finishing 3D Printed Parts From Abs and Pla MaterialsDaniel BarakNo ratings yet

- Effect of Work Material Hardness and Machining Parameters On Burr-Formation and Surface Finish in Micro-Milling of AISI D2 SteelDocument6 pagesEffect of Work Material Hardness and Machining Parameters On Burr-Formation and Surface Finish in Micro-Milling of AISI D2 SteelVinay PaulNo ratings yet

- Solution To Taylors Tool Life ProblemsDocument1 pageSolution To Taylors Tool Life Problems19G133 VASANTH B100% (1)

- Calculation Manufacturing ProcessDocument18 pagesCalculation Manufacturing ProcessEncik MaaNo ratings yet

- PPCE May-June 2007Document4 pagesPPCE May-June 2007Mohan MKNo ratings yet

- Time: 3 Hours Answer All Questions Maximum: 100 MarksDocument3 pagesTime: 3 Hours Answer All Questions Maximum: 100 MarksAnonymous ZB6qyhD6No ratings yet

- Me-1 Ese 2022-23Document2 pagesMe-1 Ese 2022-23AshwinNo ratings yet

- Final Examination SEMESTER I, SESSION2014/2015Document13 pagesFinal Examination SEMESTER I, SESSION2014/2015Mohamad Yusuf HelmiNo ratings yet

- Study Chip Surface Characteristics During The Machining of SteelDocument6 pagesStudy Chip Surface Characteristics During The Machining of SteelSagar DhageNo ratings yet

- End Sem PyqDocument5 pagesEnd Sem PyqJaspreet veeraNo ratings yet

- MM 361: Advanced Manufacturing: InstructionsDocument3 pagesMM 361: Advanced Manufacturing: InstructionsSimLo Lulumani Ko'osiko Taloanimae'aNo ratings yet

- Deber 4Document8 pagesDeber 4jmgavilanesNo ratings yet

- TA202 AssignmentsDocument1 pageTA202 AssignmentsBrajesh kumarNo ratings yet

- EMG 4102 MATERIAL FORMING PROCESSES EXAM (Revised) - PrintreadyDocument4 pagesEMG 4102 MATERIAL FORMING PROCESSES EXAM (Revised) - PrintreadyDuncoh DunNo ratings yet

- MM 361: Advanced Manufacturing: InstructionsDocument3 pagesMM 361: Advanced Manufacturing: InstructionsSimLo Lulumani Ko'osiko Taloanimae'aNo ratings yet

- Unit Test I. 1920Document2 pagesUnit Test I. 1920Balakrushna ParkaleNo ratings yet

- Part C: Production Techniques (ME C342) Open BookDocument2 pagesPart C: Production Techniques (ME C342) Open BookpankazspamNo ratings yet

- Machine Tools Assignments 1 N 2Document3 pagesMachine Tools Assignments 1 N 2Sunkeswaram Deva PrasadNo ratings yet

- Non-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingFrom EverandNon-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingRaman SinghNo ratings yet

- Overview WafdcDocument13 pagesOverview WafdcDamanjeet SinghNo ratings yet

- BodhidharmaDocument4 pagesBodhidharmamadhumitapanigrahiNo ratings yet

- 10 Knowledge MGMT and Corp UniversitiesDocument42 pages10 Knowledge MGMT and Corp UniversitiesDamanjeet SinghNo ratings yet

- Accounting For ManagersDocument9 pagesAccounting For ManagersDamanjeet SinghNo ratings yet

- 10 Minute WorkoutDocument20 pages10 Minute Workout5BaggersNo ratings yet

- Personality & AttitudeDocument31 pagesPersonality & AttitudeDamanjeet SinghNo ratings yet

- Asme Section II A-2 Sa-487 Sa-487mDocument8 pagesAsme Section II A-2 Sa-487 Sa-487mAnonymous GhPzn1xNo ratings yet

- IBR 353-359 FlangesDocument5 pagesIBR 353-359 FlangesRajivharolikarNo ratings yet

- Wire Mesh Steel Reinforcement BarsDocument6 pagesWire Mesh Steel Reinforcement Barssattar12345No ratings yet

- New Haven Union Station TOD PlanDocument45 pagesNew Haven Union Station TOD PlanNHUDLNo ratings yet

- Sae J451Document5 pagesSae J451Douglas RodriguesNo ratings yet

- Europe Road Signs in PDFDocument2 pagesEurope Road Signs in PDFJeremiah0% (1)

- Dry Docking NotesDocument16 pagesDry Docking NotesIshan Vyas100% (1)

- DPWHDocument6 pagesDPWHEdwina EgeraNo ratings yet

- Vendor Managed InventoryDocument8 pagesVendor Managed InventoryPatrick Kok0% (1)

- Ficha Tecnica Gruas TabascoDocument18 pagesFicha Tecnica Gruas TabascoGarrido ChimNo ratings yet

- Sea ProtestDocument5 pagesSea ProtestenglisgoNo ratings yet

- CA55 Series: CA5515 CA5515 CA5525 CA5525 CA5535 CA5535 CA5505 CA5505Document11 pagesCA55 Series: CA5515 CA5515 CA5525 CA5525 CA5535 CA5535 CA5505 CA5505machineCanNo ratings yet

- Product Catalogue 2016Document24 pagesProduct Catalogue 2016sineadNo ratings yet

- Ambuja Cements Ltd. Form: Ops 11 - : Drill & Exercise Log Sheet (As Reqd.)Document2 pagesAmbuja Cements Ltd. Form: Ops 11 - : Drill & Exercise Log Sheet (As Reqd.)Venugopal RajagopalNo ratings yet

- Form Works and ScaffoldingsDocument61 pagesForm Works and ScaffoldingsTahir YousafzaiNo ratings yet

- ESCRS GBH Shipping InstructionsDocument5 pagesESCRS GBH Shipping InstructionsCourtney AhrensNo ratings yet

- KP Traffic LawsDocument11 pagesKP Traffic LawsAbhishek BoseNo ratings yet

- FarmaciiDocument81 pagesFarmaciiAndreea IrinaNo ratings yet

- Ficha Tecnica - Microseal - DSDocument2 pagesFicha Tecnica - Microseal - DSedocducNo ratings yet

- Customerinfo - ADxC DC 39 001Document7 pagesCustomerinfo - ADxC DC 39 001João CorredeiraNo ratings yet

- Outsourcing of The Boeing 787: David Mahmoodi 01/31/2009Document27 pagesOutsourcing of The Boeing 787: David Mahmoodi 01/31/2009Arif PranandaNo ratings yet

- Insurance Service PPT MbaDocument23 pagesInsurance Service PPT MbaBabasab Patil (Karrisatte)100% (3)

- Air Traffic ControllersDocument14 pagesAir Traffic ControllersAviation/Space History Library100% (4)

- AmendmentsDocument1 pageAmendmentsSamarth SethNo ratings yet

- 11 Sakr Etal2010 - Pile Load Testing of Helical Piles and Driven Steel Pipes PDFDocument1 page11 Sakr Etal2010 - Pile Load Testing of Helical Piles and Driven Steel Pipes PDFAAAAAAAAAAAAAAAAAAANo ratings yet

- Marine InsuranceDocument28 pagesMarine InsuranceHarsh RakeshNo ratings yet

- Method Statement: MS-CIQ02/M/032/R3.0 A A R Prepared by (Contractor) Reviewed by (Consultant) Approved by (GP) DateDocument10 pagesMethod Statement: MS-CIQ02/M/032/R3.0 A A R Prepared by (Contractor) Reviewed by (Consultant) Approved by (GP) DateMuhammad AdamNo ratings yet

- Nysdot SCM 2013Document320 pagesNysdot SCM 2013alum_91No ratings yet